Revit Model Health: The 15-Minute Daily Ritual Every Team Should Follow

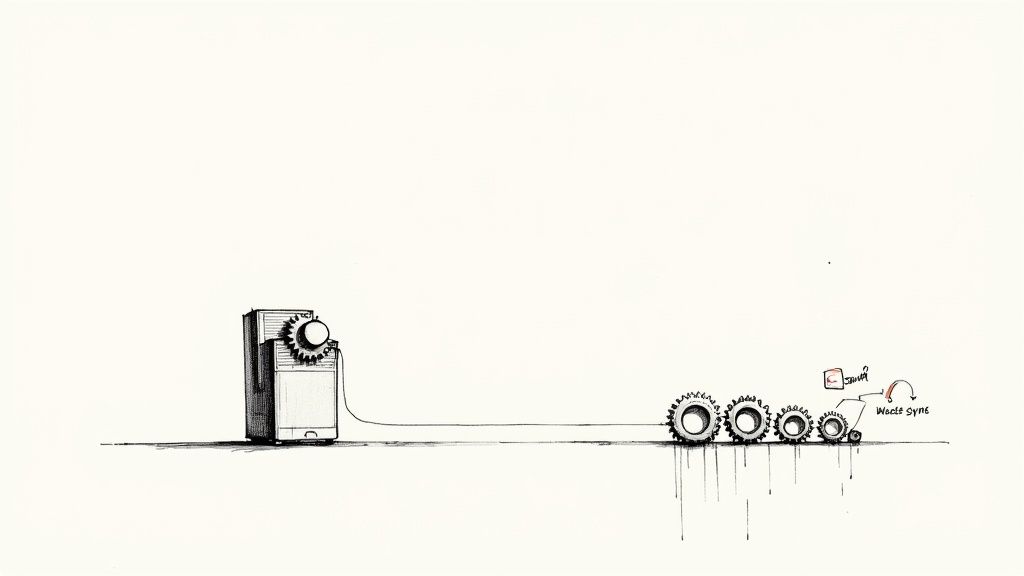

We’ve all been there. The Revit model starts out fast, but by the time you hit permitting prep, it’s crawling. Sync times stretch into agonizing minutes, simple commands lag, and random crashes become part of the workflow. This isn’t just an IT problem; it’s a direct threat to your project’s margins and predictability.

The culprit is rarely the project's complexity. It's the slow, silent decay of model health, caused by tiny, unchecked habits that compound over time. But the fix isn't a weekend-long fire drill. It's a calm, 15-minute daily ritual—a series of small checks that prevent major model failures and protect your operational consistency.

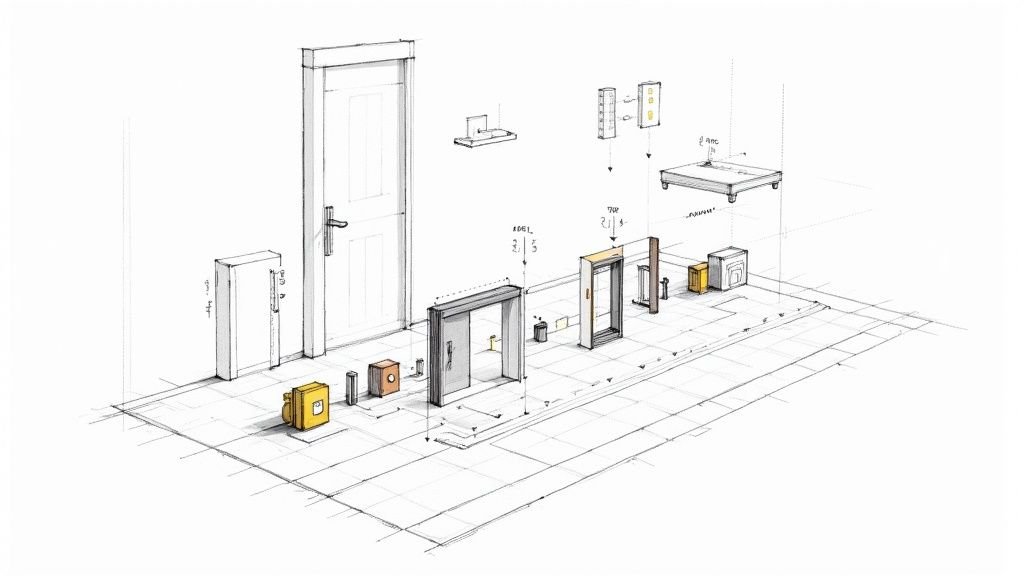

The Daily Ritual: A 15-Minute Model Health Check

Think of this as a pre-flight checklist for your project. Before the day’s production ramps up, one designated team member runs through these quick, tactical steps. This isn't about deep-diving into every nook and cranny; it's about catching the most common sources of corruption and bloat before they take root. This is how you move from a reactive CAD mentality to a proactive BIM workflow.

Making this a non-negotiable part of your daily process is the first step toward building a more predictable, resilient delivery system.

1. Purge Imported CAD Like It's Toxic (2 minutes)

Imported CAD geometry is the number one cause of Revit model corruption. It brings in a storm of unnecessary layers, messy linetypes, and non-native geometry that pollutes your project.

Your first action every morning is to hunt it down and eliminate it.

- Go to

Manage > Manage Links > CAD Formats. - Look for any DWGs, DXFs, or other CAD files.

- The rule: No live CAD links in the model. If a link is needed for coordination, it should be brought in, checked, and removed immediately. If it's for tracing, that work should happen inside a family, not the project.

This single habit prevents countless downstream problems, from file bloat to printing errors, and is a core tenet of mature template discipline.

2. Clean the Warning List (5 minutes)

The "Warnings" dialog isn't just an annoyance; it's your model's health report. Letting warnings accumulate is like ignoring the check engine light on your car. Sooner or later, you're going to break down.

- Go to

Manage > Inquiry > Warnings. - Sort the list and focus on the high-impact items first.

- Top offenders to fix immediately:

- "Highlighted walls overlap." This can corrupt wall joins and skew takeoffs.

- "Elements have duplicate 'Mark' values." This is a direct threat to your schedules and data integrity.

- "Room separation line is slightly off axis." This can lead to inaccurate area calculations.

Don't try to fix all 500 warnings at once. Just spend five minutes chipping away at the most critical ones. This daily maintenance keeps the list manageable and prevents a single, unresolved issue from snowballing into a major RFI.

3. Manage Worksets and Check Sync Times (3 minutes)

For team-based projects, workset hygiene is critical for performance. A messy workset structure slows down every single "Synchronize with Central" operation, bleeding productivity from the entire team.

- Open the Worksets dialog (

Collaborate > Manage Collaboration > Worksets). - Check for misuse: Are team members modeling on the wrong workset? Are there worksets loaded that aren't needed?

- The "CAD Links" and "Revit Links" worksets should almost always be closed by default unless actively needed for coordination.

- Note the sync time. If it's creeping up day after day, it’s an early indicator of a deeper problem, like a bloated family or a corrupt link. This is a critical decision checkpoint for further investigation.

We once saw a project’s sync time jump from 30 seconds to over 5 minutes. The culprit? A single user had accidentally modeled an entire curtain wall system on the "Shared Levels and Grids" workset. A quick daily check would have caught this in hours, not weeks.

4. Audit Families Loaded Today (3 minutes)

Unvetted 3d models Revit families are the Trojan horses of BIM. A team member, under pressure, downloads a "perfect" chair from the internet, and suddenly the entire project slows to a crawl.

This check isn’t about running a full QA process on every family. It’s a quick scan for new, unauthorized content.

- Use a tool like Project Browser organization or a third-party add-in to see which families have been loaded into the project recently.

- Spot-check any new additions. Is the file size suspiciously large? Open it. Does it contain imported CAD? Delete it from the project immediately and replace it with an approved asset.

This reinforces your firm’s content standards and prevents the "wild west" of random downloads from eroding your margins.

5. Validate Origins and Wall Joins (2 minutes)

Two final, quick checks can prevent major modeling headaches and documentation errors.

- Check the Project Base Point: Make sure it hasn't been accidentally moved. A relocated origin can wreck your coordinates and cause chaos with linked files.

- Spot-Check Wall Joins: Pan around a few complex intersections in the model. Are walls joining cleanly, or are they mitered incorrectly? Use the "Wall Joins" tool to quickly fix any sloppy connections. Bad joins are a common source of graphical errors in construction documents.

This entire ritual—15 minutes of calm, focused effort—is one of the most powerful things you can do to ensure project predictability. It’s a system that transforms production maturity from an abstract goal into a daily, actionable habit.

From Daily Checks to Scalable Delivery

Adopting this 15-minute ritual does more than just keep your models clean. It fundamentally shifts your team's culture from reactive firefighting to proactive quality management. Instead of burning hours troubleshooting a catastrophic failure, you're investing minutes to prevent it from ever happening.

This is the essence of scalable delivery. It’s not about working harder; it’s about having disciplined systems that create operational consistency. When your models are reliable, your timelines become more predictable, RFIs decrease, and your margin protection improves.

The table below outlines the shift. It's the evolution from a fragile, high-stress process to a resilient, systems-driven workflow.

The Impact of a Daily Model Health Ritual

| Metric | Without Daily Checks (Reactive) | With Daily Checks (Proactive) |

|---|---|---|

| Model Performance | Degrades over time, with slow syncs and frequent crashes. | Remains stable and performant throughout the project lifecycle. |

| Problem Solving | Costly "fire drills" to fix major corruption issues. | Minor issues are caught and fixed daily before they can escalate. |

| Team Productivity | Wasted hours staring at loading screens and rebooting. | Maximized billable time focused on design and documentation. |

| Project Predictability | Deadlines are at constant risk due to technical instability. | Timelines are protected, ensuring reliable delivery and client trust. |

| Margin Protection | Non-billable troubleshooting time erodes project profitability. | Margins are protected by minimizing rework and operational drag. |

This isn't an academic exercise. It's a field-tested workflow that acknowledges the realities of production. By treating model health as a daily priority, you are actively defending your budget, your schedule, and your firm’s reputation for clarity and reliable delivery.

This small investment of time pays massive dividends. It prevents the slow accumulation of technical debt that poisons so many projects, ensuring your BIM process is an asset that drives profitability, not a liability that creates risk. The goal is to build a system where the right way to work is also the easiest way.

We believe production maturity is built on simple, repeatable habits, not complex, aspirational theories. If your team is ready to move beyond constant fire drills, a daily checklist is the best place to start.

Download our free Daily Revit Model Health Checklist to build a foundation for more predictable, profitable project delivery: https://www.bimheroes.com