How to Reduce Construction Costs Without Compromising Quality

If you want to reduce construction costs, stop looking for cheaper materials. The real savings are found in disciplined pre-construction and crystal-clear information. The biggest budget overruns almost always trace back to rework, delays, and change orders—all symptoms of vague documentation and poor coordination that only surface when it's too late.

This isn’t about surface-level tips. This is about building a mature production system that protects margins by design.

The Real Source of Cost Overruns: Information Gaps

For architects, builders, and design-build firms, the conversation about cost has to shift from materials to maturity. Most "cost overruns" aren't about fluctuating prices; they're information overruns. Ambiguous drawings, inconsistent detailing, late-stage design changes, and reactive coordination create chaos on-site. And chaos is expensive.

True cost control isn't luck—it's the outcome of a mature system. It starts by recognizing that every surprise in the field, from a simple RFI about a door schedule to an emergency MEP reroute, stems from an information gap created months earlier. These gaps force expensive, time-consuming field corrections that obliterate margins and wreck timelines.

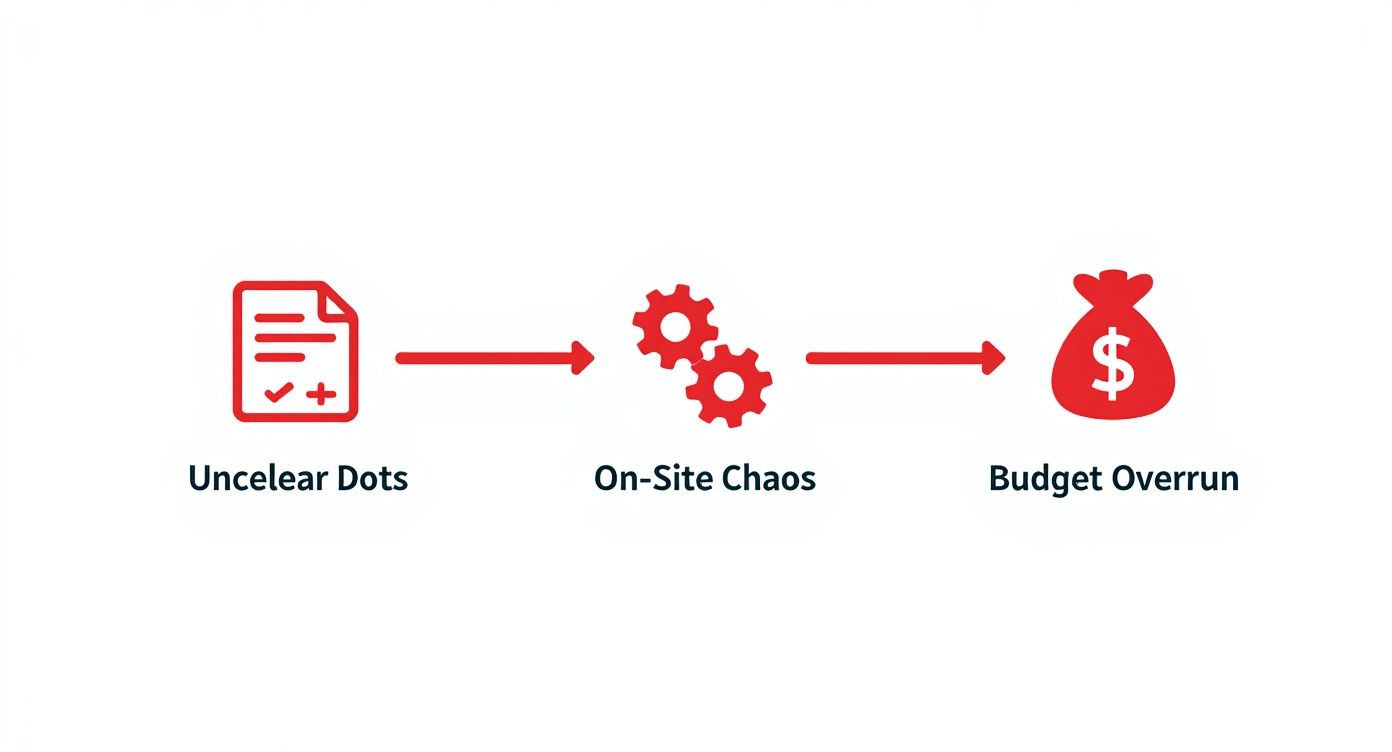

The Domino Effect of Unclear Documentation

When a drawing package is fuzzy or contains conflicting details, a costly chain reaction kicks off. A vague window schedule leads to the wrong order, causing fabrication delays. An uncoordinated structural detail could force last-minute revisions after the permit set is issued, leading to painful rework.

Clarity protects capital. The most expensive problems are born from the cheapest part of the process—the initial planning and documentation phase.

This infographic draws a straight line from unclear documents to budget-busting overruns.

The financial pain is just the final symptom of a problem that started in the information workflow.

How Information Gaps Become On-Site Costs

| Common Pre-Construction Gap (The Cause) | Resulting On-Site Overrun (The Effect) | Mature Process (The Solution) |

|---|---|---|

| Vague or conflicting details in drawings | Frequent RFIs, stop-work delays, incorrect material orders | Disciplined QA/QC checkpoints and standardized detailing |

| Uncoordinated MEP and structural models | On-site clashes requiring costly rework and re-fabrication | Proactive clash detection in a federated BIM model |

| Inconsistent door/window schedules | Incorrect orders, schedule delays, wrong-sized openings | Centralized, model-driven schedules that update automatically |

| Late-stage design changes after CDs | Change orders, premium costs for materials, crew downtime | Frozen design milestones and stakeholder decision checkpoints |

This table isn't theoretical. It's the daily reality for projects that haven't invested in robust, front-loaded processes.

From Reactive Fixes to Proactive Systems

Shifting from a reactive "fix-it-in-the-field" mentality to a proactive "get-it-right-on-screen" approach is the cornerstone of any real construction cost-saving strategy. This means front-loading the effort to achieve absolute clarity before a shovel hits the ground.

We’ve seen even small firms reap immediate benefits by implementing structured design checkpoints, disciplined QA frameworks, and repeatable BIM standards. This systematic approach pays off in tangible ways:

- Fewer RFIs: Clean, coordinated drawings answer questions before they’re asked.

- Faster Decision Cycles: With a clear model, stakeholder approvals happen faster.

- Smoother Permitting: Consistent drawing sets sail through municipal approvals.

- Predictable Fabrication: Trades build from reliable information, reducing errors.

Achieving pre-construction efficiency is the most reliable path to protecting project margins. We’ve seen teams shave months off pre-con when drawings speak the same language. For a deeper dive into this, the Associated General Contractors of America offers excellent resources on improving project delivery.

Using BIM Workflows to Protect Your Capital

If you think of Building Information Modeling (BIM) as just a 3D visualization tool, you're leaving money on the table. In reality, it is the most powerful engine for true BIM cost reduction and margin protection available to modern firms.

Adopting a BIM-first mindset isn't about prettier renderings. It’s about systematically de-risking a project by solving expensive problems on a screen instead of on-site. The entire value proposition hinges on creating a single source of truth—when architectural, structural, and MEP models live in one coordinated digital space, you kill the ambiguity that fuels budget overruns.

From Clashes to Clarity Before Groundbreaking

One of the most immediate returns from a mature BIM workflow is early clash detection. We’ve all been there: a plumber discovers a conflict with a steel beam during installation. That single moment triggers costly delays, hasty field modifications, and a flurry of change orders.

A disciplined BIM process finds that same clash months earlier. An automated report flags the issue, allowing designers to reroute a pipe run digitally, at virtually no cost. This simple act of digital coordination prevents what could have easily become a multi-thousand-dollar field fix.

A change made during design costs a fraction of a change made in the field. BIM is the system that forces those critical conversations to happen early.

This proactive approach completely transforms the dynamic between the design team and the builder. You're no longer dealing with costly surprises; you're executing planned solutions. This is foundational to any serious strategy for how to reduce construction costs.

The Power of Data-Rich Models

A well-built model is more than geometry; it’s a database. This is where truly transformative construction cost-saving strategies emerge.

- Laser-Accurate Quantity Takeoffs: A detailed BIM model can generate precise material quantities in minutes. This leads to more accurate bids, less waste, and smarter procurement.

- Automated Schedules: In a BIM workflow, door, window, and finish schedules are generated directly from the model. Change a door type, and the schedule updates automatically, eliminating a massive source of error.

- 4D and 5D Simulations: Connecting the model to schedule (4D) and cost (5D) data lets you visualize the construction sequence and cash flow, optimizing logistics and spotting bottlenecks early.

These capabilities are the direct result of pre-construction efficiency driven by template discipline and scalable delivery pods. Mature firms build libraries of smart components and have rigorous QA checks to ensure model integrity. For many, achieving this means leaning on specialized partners. Exploring how BIM outsourcing reduces project costs is a practical step for firms looking to scale their capabilities.

Leveraging Modular and Off-Site Prefabrication

Beyond digital workflows, one of the most powerful ways to reduce construction costs is to change where the work gets done. Shifting construction from an unpredictable job site to a controlled factory environment is a sign of a mature, efficient operation. Off-site prefabrication and modular construction directly tackle waste, schedules, and quality control.

This isn't about designing cookie-cutter boxes. It's about designing for manufacturing from the start. When you treat building components—from bathroom pods and wall panels to entire structural modules—as products assembled in a controlled setting, you systematically stamp out the variables that inflate on-site costs.

From On-Site Chaos to Factory Precision

The traditional construction site is vulnerable to weather delays, trade stacking, and inconsistent skill levels. A factory is a controlled ecosystem built for efficiency. That shift delivers immediate, tangible benefits.

- Slashed Timelines: While foundations are underway, modules are being built in parallel, compressing the overall schedule dramatically.

- Lower Labor Costs: Factory labor is often more stable and productive, with streamlined workflows and less downtime.

- Unbeatable Quality Control: Repetitive tasks in a controlled setting with constant QA checks mean a higher-quality product and less rework.

- Drastically Reduced Waste: Materials are ordered precisely, and offcuts can be reused, cutting down on waste.

This operational consistency is a direct line to protecting your margins. The controlled environment also boosts worker safety, which can lead to lower insurance premiums. For a deeper dive into off-site solutions, check out this ultimate guide to prefabricated metal building kits.

The Financial Case for Building Off-Site

The numbers don't lie. Modular and off-site methods are proving to be some of the most effective ways to drive down construction costs globally. Projects that fully embrace these techniques consistently report significant savings.

Studies show modular construction can shrink project timelines by 30-50%. That translates directly into lower costs for labor, financing, and site management. Material waste can be cut by up to 30%, further shielding the budget.

Designing for prefabrication isn’t just a construction method; it’s a production philosophy. It forces clarity and decision-making discipline early in the design phase, where true cost control is established.

That discipline is everything. The entire team—architect, engineer, and builder—has to be aligned from day one. For a detailed walkthrough of this integrated approach, our guide on the complete prefabrication workflow explained lays out a practical roadmap.

By building off-site, firms are building smarter. They’re swapping the unpredictability of the field for the reliability of the factory, turning cost control into a repeatable system.

Driving Efficiency with Digital Project Management

Process discipline is essential, but without the right technology, it doesn’t scale. Modern digital tools are the central nervous system for any construction project, managing the complex flow of information from the office to the field.

Adopting this tech is a direct investment in predictability and margin protection. It’s how you shift from reactive problem-solving to proactive, data-driven management. The smart firms know it’s a strategic lever for pre-construction efficiency. These tools aren’t about moving faster; they’re about moving smarter by creating clarity and closing the information gaps that lead to expensive mistakes.

From Guesswork to Data-Driven Decisions

The days of running complex jobs with spreadsheets and email chains are over. Today’s digital project management platforms create a single source of truth that connects everyone in real time.

Here’s what effective digital management delivers:

- Real-time progress tracking: See where every phase stands against the schedule and budget, allowing you to pivot before a small hiccup becomes a major overrun.

- Streamlined communication: Centralized platforms for RFIs, submittals, and change orders end communication breakdowns and create a clear, auditable record.

- Improved resource allocation: AI-powered scheduling can optimize labor and equipment, cutting down costly downtime.

This systematic approach to information flow is a powerful construction cost-saving strategy. It turns project management from an art into a science.

Leveraging Advanced Tech for Proactive Problem-Solving

Beyond basic management software, a new wave of tools is giving forward-thinking firms a serious competitive edge. These are practical solutions delivering a measurable ROI right now.

The digital twin—a virtual, data-rich replica of the physical construction site—is a game-changer. It allows teams to simulate construction sequences, monitor progress in real time, and solve problems before they happen on-site.

Drones are another key piece. They slash surveying times from days to hours, providing highly accurate topographical data for better planning. To see how this improves efficiency, check out the benefits of drone use in construction.

The Measurable Impact of a Digital-First Approach

Adopting these tools has a direct, positive impact on your bottom line. The data backs it up: a digital-first strategy is one of the most reliable ways to protect your margins.

Firms that adopt technologies like digital twins, drones, and data analytics have reported up to a 15% reduction in project costs and a 25% decrease in delays. Digital twins, for example, have reduced unplanned downtime by up to 30%.

This shift fundamentally changes the risk profile of a project. Instead of reacting to costly surprises, teams are equipped to anticipate challenges and make smarter, faster decisions. Getting the right tools and processes in place is critical, which is why we created The Architect’s Comprehensive Guide to Project Management.

A mature digital strategy transforms cost control from a project-by-project battle into a core operational strength.

Implementing Strategic Procurement and Supply Chains

Sophisticated cost control goes beyond the job site. The most mature firms understand that what you buy and how you buy it are strategic decisions that protect margins long before the first delivery arrives. This isn't about chasing the lowest bid. It’s about building a procurement process that values predictability, quality, and supplier partnerships.

Thinking strategically about procurement means you're no longer just reacting to market volatility—you're insulating your projects from it. This is a core pillar of any effective approach to reducing construction costs without compromising the final product.

Moving Beyond a Price-Tag Mentality

True cost savings in procurement come from early, informed decisions. It starts during the design phase with value engineering—a disciplined process of evaluating materials and systems to find cost-effective alternatives that maintain or improve performance and design intent.

This proactive approach allows teams to lock in material choices early and build long-term relationships with key suppliers. These partnerships yield more than better pricing; they secure availability, guarantee quality, and provide technical expertise that prevents costly on-site issues.

Procurement isn't a transaction; it's a strategic capability. The goal isn't just to buy materials, but to buy certainty—in price, delivery, and performance.

The Power of Centralized and Just-in-Time Systems

Another powerful strategy is shifting from project-by-project purchasing to a more centralized system. By consolidating purchasing, firms can leverage their total volume to negotiate better rates and establish master agreements with preferred vendors. This operational consistency streamlines workflows and cuts down administrative overhead.

Pair that with a just-in-time (JIT) delivery model, and you also minimize on-site storage costs, reduce the risk of theft or damage, and prevent material waste. It requires tight coordination, but it pays off in efficiency.

The financial impact is well-documented. Firms that implement centralized procurement systems and long-term supplier contracts have seen material cost savings of 10-15%. Using e-procurement platforms has also cut procurement cycle times by 20% and administrative costs by 10%.

Integrating Procurement with Project Delivery

Ultimately, your procurement strategy must align with your overall project plan. The choice of materials, suppliers, and delivery timing directly impacts scheduling, labor allocation, and cash flow. Making these decisions in a silo is a recipe for friction.

This is where your chosen delivery method becomes critical. A design-build approach, for example, allows for much earlier collaboration between the designer, builder, and key suppliers. To better understand how different approaches impact collaboration, take a look at our comprehensive guide to project delivery methods in construction.

Smart procurement is a system. It’s about making informed, strategic decisions early on, backed by solid data and strong industry relationships.

Your Framework for Predictable Project Budgets

We've moved past surface-level tips to focus on what drives budget predictability. This is a framework for achieving production maturity. Sustainable cost reduction comes from discipline, not luck.

The most powerful cost-saving strategies are rooted in clarity, solid systems, and smart decisions made early. The core takeaway is simple: clarity protects capital. By front-loading efforts in pre-construction, you systematically stamp out the information gaps that lead to expensive surprises on site.

The Pillars of a Cost-Control System

Protecting your margins is about building a repeatable capability. Let’s recap the key pillars that turn cost control into an operational reality:

- Embracing BIM Workflows: This is your engine for BIM cost reduction. Using clash detection and data-rich models de-risks projects before you break ground.

- Leveraging Modern Methods: Off-site prefabrication shifts work into a controlled environment, slashing timelines and material waste.

- Implementing Digital Management: Using technology to create a single source of truth turns reactive fire-fighting into proactive management.

- Adopting Strategic Procurement: Building supplier partnerships and making smart material choices early insulates your budgets from market swings.

Most "cost overruns" are failures in communication and coordination. A mature pre-construction process solves for information first, knowing that the money will follow.

You now have the insights to build a system for predictable project delivery, where clean drawings, faster decisions, and fewer RFIs are just the way you do business.

To help put these ideas into practice, we've created a tool to translate concepts into action. Download our Free Pre-Construction Workflow Template and apply this framework to your next project.

Common Questions About Reducing Construction Costs

We get practical questions from architects and builders trying to get a better handle on their project costs. Let's dive into a few of the most common ones.

How Can Small Firms Implement BIM Without Huge Overhead?

The barrier to entry for BIM cost reduction has fallen dramatically. You don't need a massive budget to get started.

For smaller firms, the key is to be strategic:

- Start with one discipline. Don't try to model the entire project at once. Focus on getting the architectural or structural scope right first. This lets you build skills without overwhelming your team.

- Use scalable "delivery pods." Instead of hiring full-time specialists, partner with an outsourcing firm. This gives you access to deep expertise on a project-by-project basis, so you're not on the hook for salaries and expensive software.

- Lean on templates. Never start from a blank slate. A disciplined system of templates for families, view settings, and sheet layouts is a massive accelerator. It ensures consistency, a cornerstone of pre-construction efficiency.

The goal is to adopt workflows that solve your most pressing coordination issues now, then scale from there.

What’s the Best Way to Handle Change Orders?

The best way to manage a change order is to prevent it from happening. This loops back to the central theme: clarity protects capital. The vast majority of change orders are born from gaps or ambiguities in the original drawing set.

A change order isn't just a document; it's a record of a coordination failure. The cost isn't just the change itself, but the ripple effect of delays and rework it causes.

When changes are unavoidable, the process has to be ironclad.

- Formalize everything. Every request must go through a clear, auditable system. No exceptions.

- Assess the full impact. Analyze the schedule and cost implications for every trade touched by the change.

- Get approval before you act. No work should proceed until the owner has formally signed off on all impacts.

How Early Should We Start Value Engineering?

Value engineering delivers the most bang for the buck when it's baked into the schematic design phase—long before drawings are locked in. When you wait, you’re usually just talking about superficial changes, like swapping finishes for cheaper alternatives, which can gut the design intent.

Real value engineering is about questioning the project's core systems. Can we use a different structural grid to slash foundation costs? Could a prefabricated facade system speed up the schedule? These are the high-impact conversations that truly shape a project's financial outcome.

All these strategies point to the same conclusion: the most effective way for how to reduce construction costs is through mature processes, disciplined checkpoints, and a relentless focus on pre-construction clarity.

At BIM Heroes, we help firms build these exact systems. We don’t just deliver drawings; we provide the production maturity and BIM workflows that lead to predictable, profitable projects. Learn more at https://www.bimheroes.com.