How Great Shop Drawings Protect Construction Profits

Shop drawings for construction are where design intent meets fabrication reality. For seasoned architects, builders, and design-build leaders, they are far more than a documentation step—they are a critical profit lever and a powerful risk reduction tool. When executed with discipline, they protect schedules, budgets, and the trust you've built with your partners.

But when the process is sloppy or reactive, it becomes the source of endless RFIs, site delays, and remobilization costs. Most construction inefficiencies can be traced back to unclear details, late changes, or disconnected models and sheets.

Why Great Shop Drawings Are a System, Not a Task

It’s time to reframe the conversation around shop drawings. They aren't just a submittal requirement; they are a direct measure of your production maturity. This is the precise point where a project’s success is determined, long before the first boot hits the ground.

Sloppy or reactive shop drawing processes are the root cause of the friction that erodes margins. When details are unclear, tolerances are missing, or section views don't match the plans, the entire project rhythm gets thrown off. That friction leads directly to strained trade relationships and painful budget overruns.

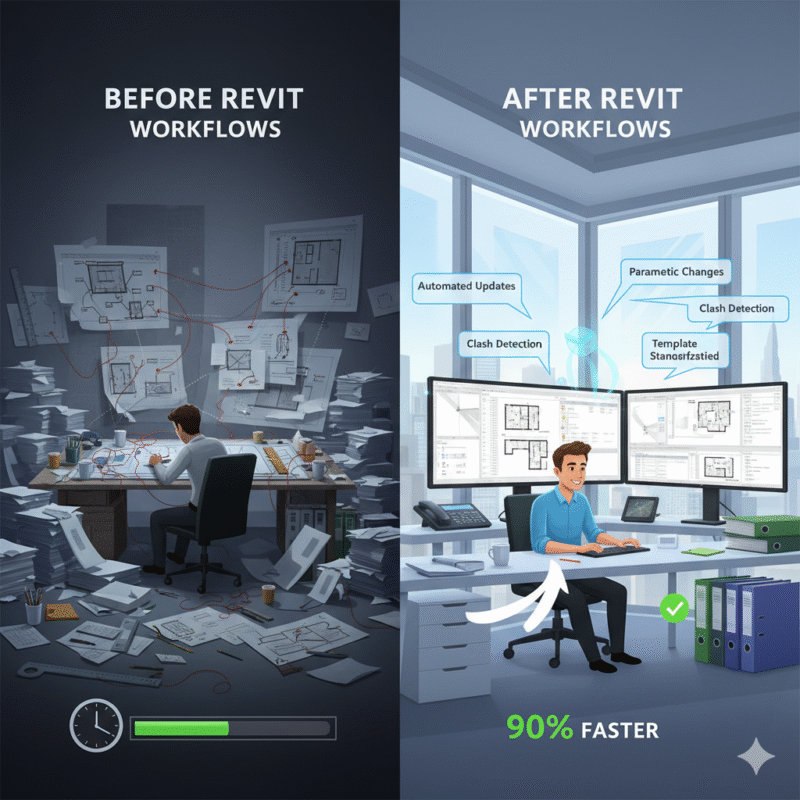

The Shift From Reactive Tasks To a Proactive Engine

The best teams treat submittals as part of a cohesive production engine. This mindset shift is about moving from a chaotic, task-based approach to a system-driven one. We’ve seen trade packages move faster and fabrication cycles tighten up when everyone operates from a shared playbook.

A systems approach to the architectural shop drawing process is built on discipline:

- Template Discipline: Using robust, pre-vetted templates that ensure no critical information is ever missed.

- Rigorous Standards: Enforcing consistent sheet naming, annotation styles, and detailing conventions across every single drawing.

- Clean Model Coordination: Making the coordinated BIM model the single source of truth for all dimensions and assemblies. No exceptions.

- Decision Checkpoints: Implementing structured internal QA before a drawing ever leaves the office to prevent sending errors downstream.

This operational consistency is what delivers predictability. Well-executed BIM shop drawings and collaborative reviews don’t just feel better; they slash rework. Proactive coordination can reduce rework by up to 30%, a massive factor in protecting profitability.

The Foundation of Predictable Delivery

Ultimately, great shop drawings for construction are the outcome of a mature system. They are the evidence of discipline, clear communication, and detailing that’s truly aware of what happens in the field. Mastering the document control process is fundamental to making this happen.

When you focus on building this production engine, you deliver the one thing clients and partners value most: predictability. It’s how modern teams protect schedules, budgets, and trust.

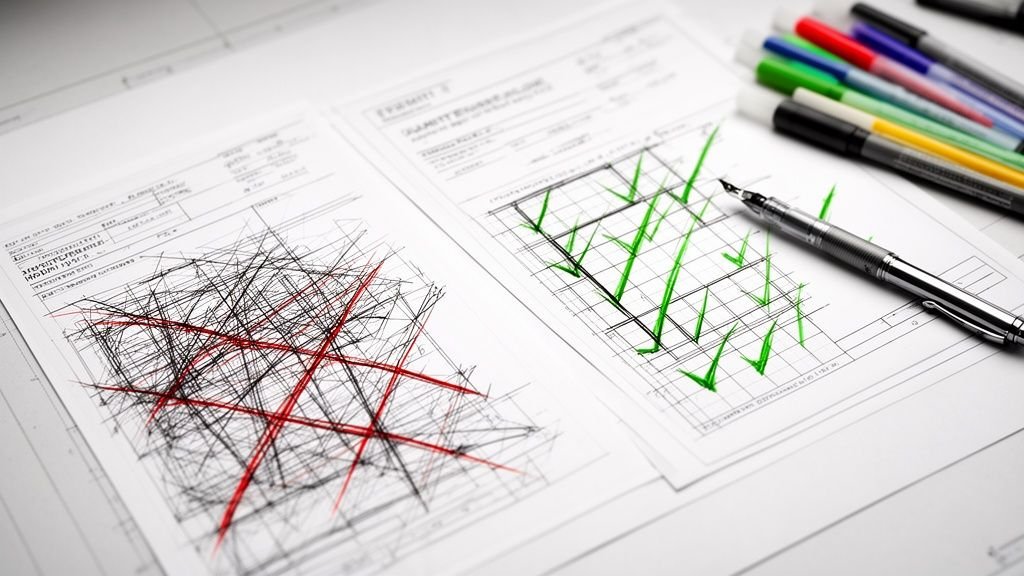

Reactive vs. Proactive Shop Drawing Process Outcomes

| Metric | Reactive Process (The Default) | Proactive System (The Goal) |

|---|---|---|

| RFIs & Change Orders | High volume, constant clarification needed. | Minimal, focused on genuine unforeseen issues. |

| Approval Cycles | Long and unpredictable, with multiple revisions. | Short and predictable, often approved on first pass. |

| Field Rework | Common, leading to budget overruns and delays. | Rare, with up to a 30% reduction in rework costs. |

| Schedule Impact | Frequent delays and stop-and-start work. | Smooth, continuous workflow with fewer interruptions. |

| Team Morale | Frustration and blame between office and field. | High trust and seamless collaboration. |

| Profit Margins | Eroded by unexpected costs and inefficiencies. | Protected and often improved through predictability. |

The table makes it clear: a proactive system isn't a "nice-to-have." It's a strategic advantage that translates directly to smoother projects and healthier financials.

The Anatomy of a High-Impact Shop Drawing

What separates an adequate shop drawing from one that accelerates fabrication and prevents expensive mistakes? A relentless focus on clarity, precision, and field-aware detailing.

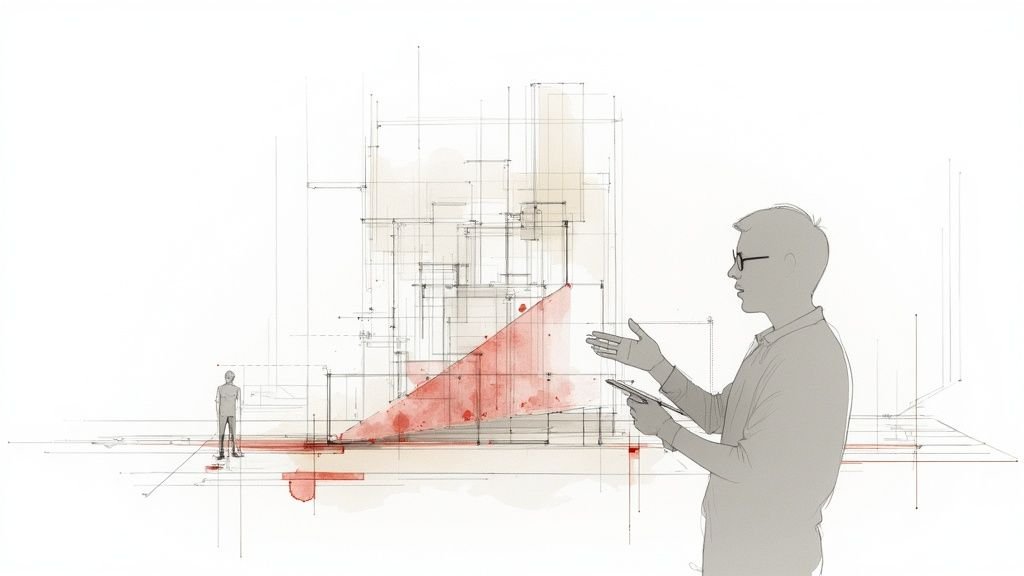

A high-impact drawing anticipates the installer’s questions and answers them before they’re asked. The best shop drawings for construction are created from the viewpoint of the person who will build, assemble, and install the component. They go beyond basic geometry to provide a complete, foolproof set of instructions.

We’ve seen it time and again: trade packages sail through approvals when the drawings are clean, the data is consistent, and the instructions are crystal clear. This is where you start protecting your margins.

Beyond Dimensions to Fabrication Intent

A great shop drawing tells a story. It communicates not just what to build, but how it plugs into the bigger puzzle.

The most common friction points—the ones that generate endless RFIs and bring work to a grinding halt—are almost always buried in the details. These are the real-world friction scenarios we've seen inside production rooms:

- Missing Tolerances: Failing to specify acceptable fabrication and installation tolerances is a recipe for disaster, especially with prefabricated parts that need to fit perfectly.

- Unclear Annotations: Vague notes like "match existing" or "verify in field" create ambiguity and shift responsibility, which always leads to delays.

- Mismatched Views: When a plan view doesn’t line up perfectly with its section or elevation, work stops. It creates immediate confusion and kills trust in the drawings.

- Sheet Naming Chaos: An inconsistent naming system turns a submittal package into a nightmare to navigate, wasting valuable time for every reviewer.

These aren’t just minor slip-ups; they are systemic failures that lead directly to busted budgets and broken schedules.

Key Elements of a Field-Ready Drawing

To create a drawing that prevents problems, every element must be executed with discipline. Teams that get this right have rigorous internal review cycles that catch these issues long before they get to the field.

A truly effective shop drawing must contain:

- Unambiguous Dimensions and Annotations: Every dimension needs to be clear, purposeful, and easy to read. Clean and consistent annotation isn't optional. For a deep dive, see these 10 rules for accurate CAD dimensioning.

- Comprehensive Material Specifications: Clearly identify all materials, including grades, finishes, and relevant performance standards (like ASTM or ACI).

- Fabrication and Assembly Details: Include step-by-step assembly sequences, weld symbols, and connection details so the fabrication team has a complete roadmap.

- Clear Coordination References: The drawing must reference specific architectural and structural drawings, grid lines, and elevations so everyone understands where it fits.

A shop drawing is the last line of defense against on-site errors. Every unclear detail is a potential change order waiting to happen. The goal is to create a document so clear that it stops RFIs before they are ever written.

This level of detail is the direct result of a mature production system. It requires strong shop drawing coordination workflows, solid templates, and a QA process that asks one simple question: "If I were building this, would I have any questions?"

Integrating BIM for Smarter Coordination Workflows

The evolution from CAD to BIM is the single biggest leap forward for modern construction teams. Leading firms now use Building Information Modeling not just for visualization, but as the single source of truth for generating precise, fully coordinated shop drawings for construction.

This isn't just about swapping software. The CAD-to-BIM evolution is a fundamental change in how project information is managed. A well-built, data-rich model sidesteps the risky manual cross-checking that plagues 2D workflows. When you change the model, it ripples across every related drawing, ensuring plans, sections, and details always match.

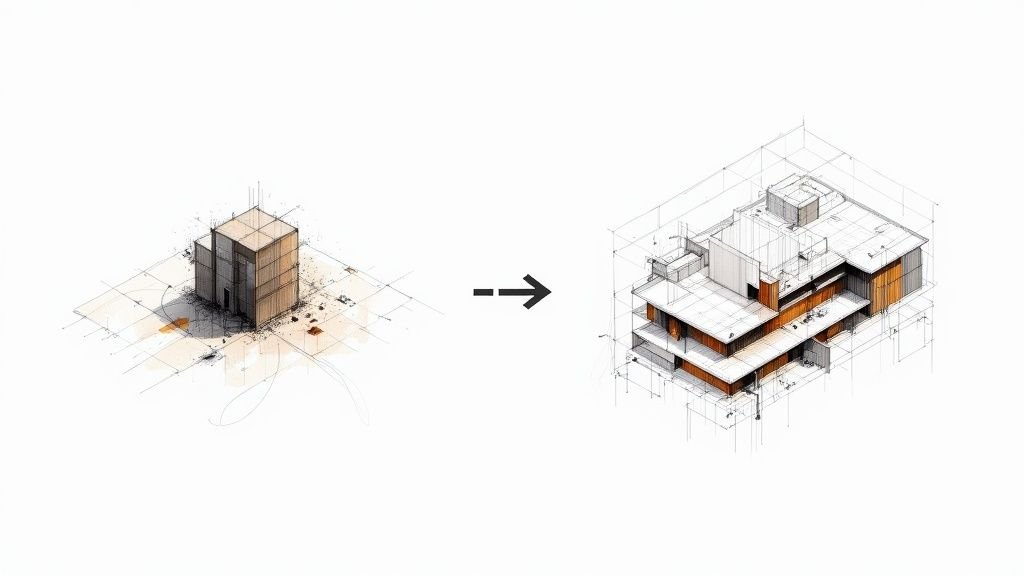

From Disconnected Sheets to a Centralized Model

In a traditional 2D process, every drawing is an island. Change a dimension on a floor plan, and you have to hope someone remembers to update every related elevation and section. It’s a recipe for mistakes.

BIM shop drawings eliminate this problem. By generating every sheet directly from a coordinated 3D model, you guarantee consistency.

The model becomes the central nervous system of the project. This shift from manual drafting to model-based generation is where teams reclaim lost hours, slash human error, and build a more predictable delivery pipeline.

This disciplined approach ensures the entire architectural shop drawing process is rooted in validated data. The model’s inherent data richness produces intelligent, error-resistant drawings that protect project margins from costly rework.

Leveraging the Model for Operational Excellence

A solid BIM Execution Plan (BEP) is the playbook for this modern workflow. To build smarter coordination workflows, it's critical to understand the best practices for implementing Building Information Modeling (BIM). This document sets standards, defines the required Level of Development (LOD), and establishes clear rules for trade coordination.

When the BEP is followed, the benefits go far beyond cleaner drawings:

- Fewer Coordination Issues: The model becomes a digital sandbox for pre-construction. We’ve seen teams resolve complex MEP and structural conflicts in the model months before they would have become expensive field problems. Learn more about formalizing these shop drawing coordination workflows in our guide on the BIM clash detection process and standards.

- Faster Approval Cycles: Reviewers gain confidence when they know the entire submittal package comes from a single, coordinated source. That trust translates into faster approvals.

- Tighter Fabrication Schedules: Fabricators can work with certainty, knowing dimensions are accurate and checked against all other trades.

This systematic approach transforms BIM from a design tool into a powerful production engine.

The global market for construction design software, valued at USD 10.96 billion in 2024, is projected to reach USD 19.12 billion by 2030. This growth is heavily driven by BIM adoption and the demand for systems that deliver predictability. You can find more details on this trend from Grand View Research.

Integrating BIM lets teams build the project virtually first—ironing out wrinkles before a single boot hits the ground. This digital rehearsal is how modern teams deliver smoother builds.

Establishing a Bulletproof Review and Approval Process

Even the most perfect shop drawings for construction are useless until approved. Approval bottlenecks are a classic source of project delays, creating a domino effect that kills margins. A reactive review process isn't just inefficient—it's a direct threat to your budget.

The key is a structured, transparent, and predictable approval workflow. Teams with structured review cycles avoid late surprises because they treat the process as a series of deliberate decision checkpoints, not just another hurdle.

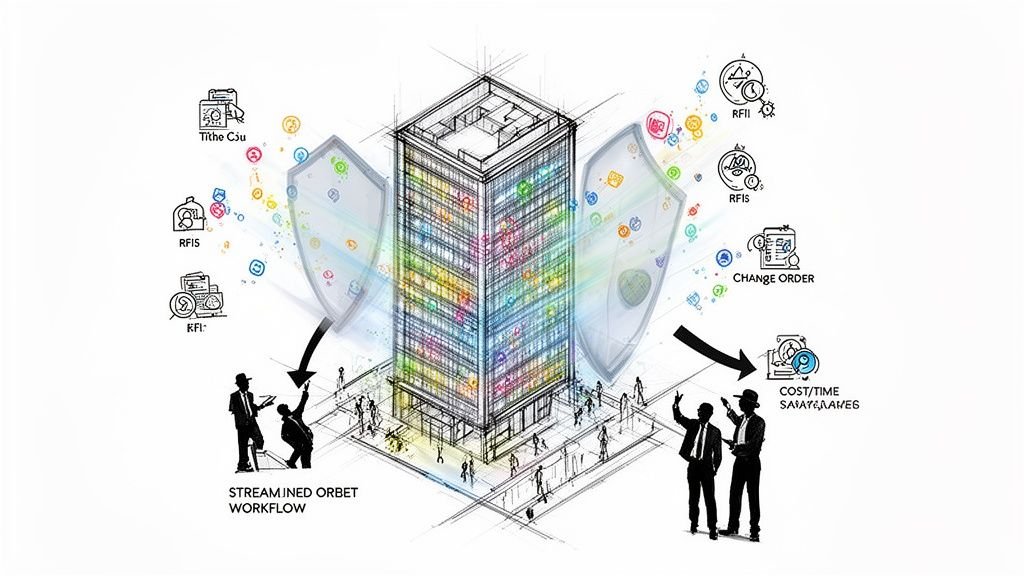

This infographic shows the evolution from old-school 2D drafting to modern BIM-driven workflows.

A central BIM model becomes the single source of truth, making the shop drawing a reliable output of a coordinated system rather than a standalone document.

From Submittal to Approval: A Disciplined Framework

A bulletproof architectural shop drawing process comes down to clarity and accountability. We've seen trade packages get signed off much faster when everyone knows the rules before the first PDF is sent.

A solid system always includes:

- Internal QA Checkpoint: A drawing should never be submitted without a tough internal review. This is your first line of defense against simple mistakes that waste reviewers' time.

- Defined Reviewer Roles: Make it crystal clear who is responsible for what. The structural engineer checks connections; the architect reviews for design intent. Vague responsibilities lead to conflicting comments.

- Standardized Comment Formats: Insist all reviewers use a consistent method for feedback, like a platform that creates a clean, actionable list of revisions.

The review and approval stage is where trust is either built or broken. A messy, unpredictable process signals a lack of control, while a smooth workflow proves your team has its act together.

Taming Revisions and Ensuring Version Control

The back-and-forth of revisions is where schedules go off the rails. A sloppy approach can lead to multiple versions of a drawing floating around, creating a huge risk that the wrong one gets sent to the shop. Meticulous version control is non-negotiable.

Every revision needs to be clearly labeled, and any resubmittal should include a summary of changes. This respects the reviewer’s time and focuses their attention. To get a handle on this, explore the best practices for version control for BIM projects, which provides a solid framework for maintaining a single source of truth.

A mature shop drawing coordination workflow transforms the approval phase from a point of friction into a value-added step. It builds trust, protects the schedule, and turns the approval process into a competitive advantage.

Common Pitfalls That Erode Project Margins

Even with a mature process, small oversights in shop drawings for construction become expensive, real-world problems. These common pitfalls aren’t just minor errors; they're insidious margin killers that introduce risk and trigger delays. We’ve been inside production rooms long enough to see these issues firsthand.

Understanding these friction points is the first step toward building a system that actively prevents them.

Ignoring Fabrication Tolerances and Clearances

One of the most frequent mistakes is detailing a perfect component without accounting for how it will be made and installed. A steel beam dimensioned perfectly on paper is useless if the drawing doesn’t specify the acceptable tolerance for its length or bolt hole placement.

The same goes for installation clearances. Teams that detail without thinking about how a component will be lifted into place create impossible-to-install conditions. This forces field crews to make costly on-the-fly modifications, generating RFIs and derailing the schedule.

Detailing Without Shipping Constraints in Mind

We’ve seen it happen: a beautifully detailed assembly is fabricated exactly to the shop drawing, only to be found too large to transport to the site. This is a five-figure mistake that could have been avoided with a single question.

A mature architectural shop drawing process always considers the entire lifecycle of a component. Great detailers ask, "What’s the largest piece we can ship?" This field-aware thinking prevents huge logistical headaches.

The Chaos of Inconsistent Sheet Naming

This may seem like a minor task, but a chaotic sheet naming convention is a major source of confusion and risk. When drawings use different naming logic, it becomes nearly impossible to track versions and ensure everyone is working from the latest information.

Sheet naming isn’t just about organization; it’s a core element of risk management. A disciplined, predictable naming system is a hallmark of a professional production engine.

Disconnected Models and Uncoordinated Penetrations

Even with BIM, problems pop up when the model isn't the single source of truth. When an MEP engineer models a duct run but the precast detailer isn’t working from the latest file, you get clashes. A penetration off by a few inches can mean hours of core drilling on-site.

A truly integrated shop drawing coordination workflow mandates that all trades work from a federated model. Teams with structured, cross-disciplinary review cycles avoid these expensive surprises.

Mistakes are inevitable, but costly rework doesn’t have to be. Most errors stem from a lack of clear, repeatable processes. By anticipating common failure points and building systems to prevent them, you can protect your margins.

Common Shop Drawing Errors and Their System-Based Solutions

| Common Pitfall | Resulting Project Impact | System-Based Prevention Strategy |

|---|---|---|

| Ambiguous Dimensions | Fabricator makes incorrect assumptions, leading to components that don't fit and require on-site modification. | Implement a multi-stage QA/QC checklist that includes a specific check for dimensional clarity and tolerance callouts. |

| Outdated Model Information | A trade details their scope based on an old model, creating clashes with other systems (e.g., ductwork running through a beam). | Mandate the use of a federated model in a common data environment (CDE) with scheduled model updates and version tracking. |

| No Shipping/Logistics Review | A large, prefabricated assembly is built but cannot be legally transported to the site, causing massive delays and cost overruns. | Add a "Logistics & Transport Review" milestone to the shop drawing production schedule before issuing drawings for fabrication. |

| Unclear Naming Conventions | Installers work from an outdated drawing version because they can't easily identify the latest revision, leading to incorrect installation. | Establish and enforce a project-wide sheet naming convention (e.g., Project-Discipline-Level-Sheet#-Rev#) in the BIM Execution Plan. |

| Ignoring Installation Clearances | A component is fabricated perfectly but cannot be maneuvered into place on-site due to lack of space for equipment and personnel. | Require detailers to model "installation zones" or clearance boxes around key components to verify access during constructability reviews. |

By turning these common pain points into structured checklist items and process milestones, you shift from reacting to problems to proactively preventing them.

Ultimately, avoiding these pitfalls isn't about being perfect; it's about having a system robust enough to catch human error before it costs money.

Building a Scalable Shop Drawing Delivery System

The goal isn't to fight fires on a project-by-project basis. It's to build a repeatable, scalable system for producing high-quality shop drawings for construction. This isn't about checking off tasks; it's about creating a production engine that delivers clarity and consistency every time. We don’t sell hours; we sell clarity, systems, and reliable delivery.

Getting that consistency is the result of a deliberate, system-driven approach that turns shop drawing production into a core operational strength.

From Ad-Hoc to Systemized Production

A scalable system is built on three pillars: enforced standards, solid templates, and a non-negotiable QA process. When these are locked in, your team can handle more volume without a drop in quality. It’s how you grow your capacity for excellence.

Teams with structured review cycles sidestep the late surprises and costly rework that plague reactive firms. Their delivery pods work from the same playbook, ensuring every drawing meets a consistent quality bar.

This is the foundation of a true production engine:

- Enforced Standards: Don't just have standards—enforce them. This covers everything from sheet naming and layer discipline to annotation styles and dimensioning protocols.

- Leveraging Robust Templates: Kick off every project with pre-vetted, intelligent templates that include standard details, title blocks, and checklists. Template discipline is the easiest way to squash common errors.

- Implementing Rigorous QA: Your internal QA checkpoint is the single most important step in the architectural shop drawing process. This review must be tough and systematic, focused on catching subtle mistakes that mushroom into big problems.

Precision in shop drawings is how modern teams protect their margins. A well-oiled delivery system catches errors before they leave the office, stops RFIs before they are written, and gives fabricators the clarity they need to work with confidence.

The Profitability of Predictable Delivery

Building this system is a direct investment in your margins. Every dimension conflict caught internally is a potential change order you just dodged. As your team grows, this systematic approach lets you scale up without sacrificing quality or profitability.

It can also highlight strategic opportunities, like recognizing when the benefits of outsourcing drafting services could boost your delivery capabilities, freeing up your core team for higher-value work.

Ultimately, a scalable shop drawing system is a sign of operational maturity. It’s the engine that drives smoother builds, faster approvals, and tighter fabrication cycles. If you're looking for a practical first step, our shop drawing review checklist can help build this discipline into your daily workflow.

Frequently Asked Questions About Shop Drawings

Even with a solid system, tricky situations will arise. Here are a few common friction points and how experienced teams handle them.

How Do You Handle Conflicting Comments From the Architect and Engineer?

This is a classic project bottleneck. The best way to get ahead of it is to establish a clear review hierarchy and a single point of contact before sending the first submittal.

When you do get conflicting feedback, don’t guess. Consolidate every comment into one document and issue a formal RFI to the design lead. This forces their team to give you a single, official direction. Never proceed with fabrication based on ambiguous feedback. A disciplined RFI process creates the paper trail needed to protect everyone from back-charges down the road.

What Is the Best Way to Integrate Field Measurements Into BIM Drawings?

When dealing with a renovation or complex tie-in, there’s no room for error. The most reliable method is to laser scan the site to capture as-built conditions. That point cloud data can be dropped directly into your BIM software, giving you a perfectly accurate underlay to model against.

For simpler situations, manually verify critical dimensions. The key is that those verified dimensions must be used to update the model before you generate new shop drawings for construction. The golden rule: build a dedicated "field verification" checkpoint into your workflow. Always model from reality, not assumptions.

When Does Outsourcing Shop Drawing Production Become Cost-Effective?

Outsourcing becomes a strategic move when your in-house team lacks niche expertise or your project pipeline is too unpredictable to justify full-time staff. It’s also a smart play when your project managers’ time is better spent managing the project, not buried in drafting tasks.

A great partner doesn't just sell drafting hours; they bring a proven system and the ability to scale up or down as needed. The real calculation isn’t about comparing hourly rates. It’s about total project value—reducing risk, hitting your schedule, and freeing up your team to win more work.

Building a mature production system for shop drawings takes discipline and experience. If your team is looking to improve predictability and protect margins, the experts at BIM Heroes can help you implement the systems that drive reliable delivery. Learn more about our approach at https://www.bimheroes.com.