Scan to BIM Services: Building Project Certainty from Reality Up

Every renovation project starts with a major liability: the gap between the original drawings and the building that actually exists. Scan to BIM services are the production-grade bridge across that gap. They capture precise laser scans of real-world conditions and translate them into a smart, data-rich digital model. This process isn't about creating a pretty 3D image; it's a disciplined workflow that swaps assumptions for certainty, giving design and construction a reliable foundation to build on.

From On-Site Guesswork to Digital Certainty

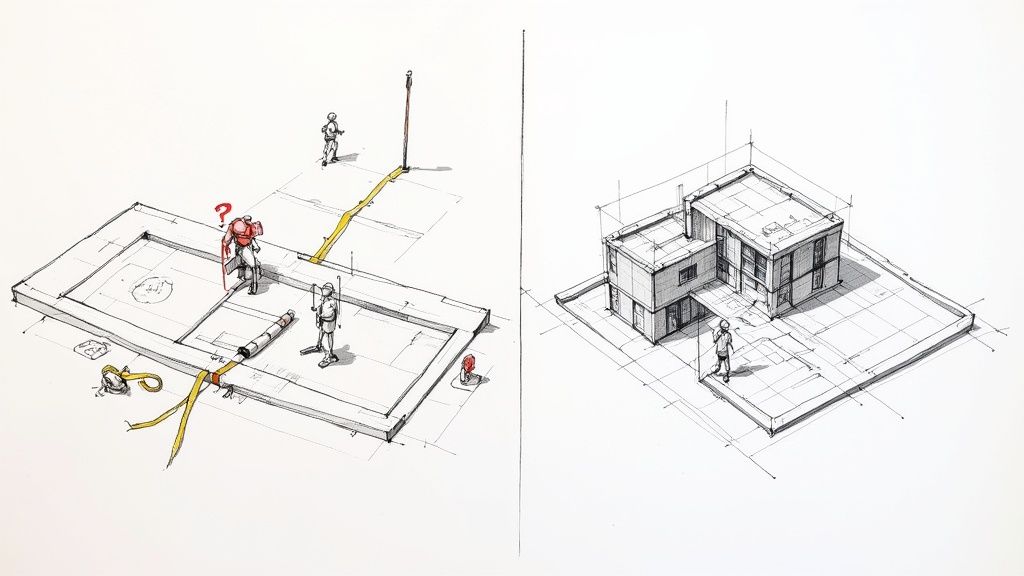

For architects, builders, and construction managers, working off old blueprints is a roll of the dice. Every undocumented change, unrecorded renovation, or subtle structural sag injects a dose of uncertainty that snowballs as the project moves forward. The real cost isn't one bad measurement—it’s the chain reaction of RFIs, change orders, and schedule delays it triggers downstream.

When a steel beam doesn’t fit because a column is a few inches off, or new MEP systems clash with a bulkhead that wasn't on the drawings, everything grinds to a halt. Production stalls, change orders pile up, and profit margins evaporate. This isn't just a simple mistake; it's a failure of data integrity. The information you started with was flawed.

Shifting from Assumptions to As-Built Facts

Scan-to-BIM flips the script by creating a single source of truth grounded in reality, not old paper. It’s a disciplined process that transforms the chaos of an existing site into a clean, workable digital asset. This workflow is built on millions of precise data points captured via laser scanning in construction.

This reality-first approach delivers immediate production benefits:

- Reduced Rework: Spotting an uneven slab condition or a missing ceiling drop in the model—not during framing—prevents the kind of costly demolition and rebuilding that kills budgets.

- Fewer RFIs: When the design team works from an exact digital twin of the site, questions about existing conditions vanish. Project managers can focus on execution, not chasing down answers.

- Tighter Tolerance Control: The precision of as-built BIM modeling means you can confidently prefabricate components off-site, knowing they will fit perfectly upon arrival.

- Faster Permitting Prep: Authorities are more likely to approve plans backed by verifiable, high-accuracy documentation, especially for complex adaptive reuse or heritage projects.

Accuracy isn’t just a technical spec; it’s a strategic investment in predictability. Capturing reality first protects your margins and builds a reputation for reliable delivery.

Ultimately, integrating Scan-to-BIM into your process is a maturity signal. It shows a commitment to data-driven decisions and an understanding that the most expensive problems are the ones you fail to see coming. You build a foundation of certainty from the ground up, ensuring every subsequent decision is based on fact. The result isn't just a better model—it's a more predictable and profitable project.

How a Point Cloud Becomes a Usable BIM Model

A raw laser scan is an incredibly dense digital photograph made of millions of data points. While surgically precise, it isn't "smart." The real value in scan to BIM services comes from the disciplined process that turns this chaotic point cloud into a structured, usable BIM model—a genuine digital asset for decision-making. This is a systematic workflow that demands serious technical skill and a mature production process.

The entire point is to translate real-world complexity into digital clarity. Each phase builds on the last, ensuring the final model is not just accurate but truly functional for architects, engineers, and builders.

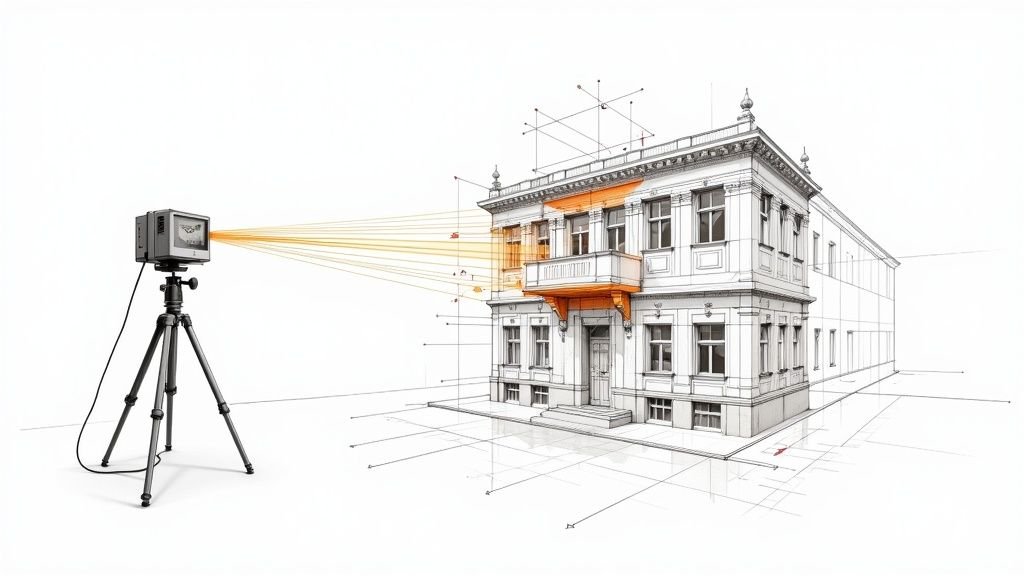

Phase 1: Laser Scanning and Data Capture

It all starts on-site with laser scanning in construction. A terrestrial laser scanner is set up in multiple positions throughout the building. From each spot, it fires millions of laser points, measuring the distance to every surface it hits and recording its exact X, Y, and Z coordinates. The data from one scan is just a single piece of the puzzle.

To capture an entire building, technicians perform dozens, sometimes hundreds, of individual scans from different vantage points. This guarantees total coverage, grabbing data from above, below, and around tricky elements like MEP systems and structural beams. The goal is to eliminate the blind spots that lead to expensive surprises.

Phase 2: Point Cloud Processing and Registration

Once fieldwork is complete, the individual scans are brought into specialized software for registration. This is the critical step where separate scans are digitally "stitched" together into a single, cohesive point cloud. Using common reference points, the software aligns each scan with millimeter-level precision, creating one unified dataset that shows the building exactly as it exists.

This registered point cloud is the raw material for your BIM model. It’s a powerful tool on its own, allowing your team to take measurements and conduct visual inspections without another site visit. But to unlock its full potential, this static data must be converted into an intelligent model. This is where point cloud to BIM modeling truly begins. You can learn more about this process in our comprehensive guide on how to convert point cloud data to BIM models.

A registered point cloud is the undeniable record of as-built conditions. It is the single source of truth that removes ambiguity and prevents the costly arguments that arise from inaccurate legacy drawings.

This phase is also a crucial decision checkpoint. Before modeling begins, the registered cloud is rigorously checked for alignment errors, data gaps, or "noise." A clean, accurately registered cloud is the non-negotiable foundation for high-quality as-built BIM modeling.

Phase 3: As-Built BIM Modeling and QA

The final and most intensive stage is translating the point cloud into a parametric Revit model. This is not an automatic conversion. Skilled BIM technicians manually model every building element—walls, floors, columns, pipes, ducts—using the point cloud as a precise tracing guide. They aren't just creating geometry; they're building an intelligent model with embedded data, families, and relationships, adhering to strict template discipline.

This is where production maturity makes all the difference:

- Correcting Imperfections: A modeler traces an uneven floor slab exactly as the scan captured it, providing actionable data for leveling or design adjustments.

- Revealing the Unseen: Hidden ceiling drops, misaligned columns, or undocumented plumbing runs are modeled with precision, preventing clashes with new design elements.

- Ensuring Consistency: The modeling team works from strict project templates and standards, ensuring every element is categorized correctly and the final model is clean and organized.

The growing demand for this level of precision is clear. The global Scan to BIM Services market was valued at US$ 471 million in 2024 and is projected to hit US$ 673 million by 2031, growing at a steady clip. This growth reflects the AEC industry's shift toward data-driven methods that protect project predictability.

After modeling, a rigorous quality assurance process begins. The completed BIM model is overlaid directly onto the point cloud to check for deviations. Every element is verified against the scan data to ensure it meets the required tolerance and Level of Detail (LOD). This final QA check confirms that the digital twin you receive is an exact match to the real-world conditions.

High-Impact Applications For Scan To BIM

Knowing the workflow is one thing; knowing where it delivers the biggest return is another. While nearly any renovation can benefit from better as-built data, some project types get a massive ROI from their scan to BIM services investment.

These are the jobs where complexity, risk, and the cost of being wrong are so high that a tape measure isn't just inefficient—it's a direct threat to your project's success. In these situations, Scan-to-BIM becomes a non-negotiable for protecting your margins and operational consistency.

This infographic breaks down the core process from a physical site to a smart, usable model.

This workflow is about turning chaotic site conditions into a digital asset you can use for design and coordination.

Heritage and Adaptive Reuse Projects

Heritage buildings and adaptive reuse projects are notoriously complex. Original plans are often missing or inaccurate, and decades of undocumented changes create a minefield of hidden problems. Ornate facades, non-standard structural elements, and subtle material decay are impossible to capture with manual measurements.

This is where laser scanning in construction excels. It captures every curve of a historic facade or the exact sag in a 100-year-old beam. This level of detail is crucial for both preservation and permitting, ensuring new work fits into the existing structure with surgical precision.

Complex MEP Retrofits

Nowhere is the value of Scan-to-BIM more obvious than inside a cramped plenum space. In hospitals, data centers, or industrial plants, MEP systems are a chaotic maze of pipes, ducts, and wires. Trying to thread new systems through that mess using old drawings is asking for clashes.

A detailed scan captures the precise location of every pipe and piece of equipment. This lets engineers run clash detection in a virtual environment, resolving conflicts long before construction begins. The result is a dramatic reduction in field modifications, faster installations, and fewer RFIs.

For complex retrofits, the point cloud is your x-ray vision. It reveals every potential conflict in the ceiling cavity, turning a high-risk coordination nightmare into a predictable, sequenced installation.

The broader 3D scanning market that supports these services is growing fast. It's projected to top $16 billion by 2030, and North America makes up over 35% of that market. This growth shows a clear industry move toward using data to verify conditions as a standard practice.

Large-Scale Renovations and As-Built Documentation

For large residential or commercial renovations, establishing an accurate baseline is critical. Scan-to-BIM creates a precise as-built model that becomes the single source of truth for the entire project, from design through to facility management.

New components like window systems, curtain walls, or prefabricated interior units can be designed and built knowing they'll fit perfectly. This process changes how teams deal with existing structures. For a deeper look, check out our guide on transforming construction with point cloud to BIM modeling for architectural, structural, and MEP.

Scan to BIM Application Impact Analysis

The table below breaks down how Scan-to-BIM addresses common challenges in these high-impact project types, turning potential disasters into predictable successes.

| Project Type | Challenge Without Scan to BIM | Solution with Scan to BIM | Primary Benefit |

|---|---|---|---|

| Heritage & Adaptive Reuse | Inaccurate or missing drawings, undocumented changes, complex geometry. | Captures every detail of the existing structure, including ornate features and structural sag. | Risk Mitigation: Prevents costly design errors and ensures preservation compliance. |

| Complex MEP Retrofits | Congested spaces with countless clashes, leading to rework and delays. | Creates a detailed 3D model of all existing systems for virtual clash detection. | Efficiency: Drastically reduces field conflicts, speeds up installation, and minimizes RFIs. |

| Large-Scale Renovation | Baseline inaccuracies cause fitment issues with new components like curtain walls. | Provides a precise as-built model for design and prefabrication. | Accuracy: Guarantees new elements fit perfectly, reducing material waste and labor costs. |

| As-Built Documentation | Manual as-builts are time-consuming, prone to error, and quickly become outdated. | Delivers a data-rich, intelligent BIM model for long-term facility management. | Lifecycle Value: Simplifies maintenance, space planning, and future upgrades for building owners. |

As you can see, the impact goes far beyond just creating a 3D model. It's about providing the certainty needed to execute complex projects successfully.

The completed model isn't just a construction tool—it becomes a living document. For facility managers, this as-built BIM model is the definitive record of the building's assets, making maintenance and future upgrades easier. To see how these services lead to real project success, explore some of Bridge Global's engineering and construction client cases.

The Real ROI of Scan to BIM Services

Let's connect the dots. The real value of scan to BIM services isn’t just a perfect 3D model. It’s about protecting your margins, achieving project predictability, and safeguarding your firm’s reputation. Every dollar spent capturing reality upfront is an investment against much larger, unrecoverable costs down the road.

When your digital model is built from verified site conditions, the project dynamic flips from reactive to proactive. You’re no longer waiting for problems to emerge during construction. Instead, you're finding and fixing them in pre-construction, where the cost of a change is a fraction of what it would be in the field.

Drastic Reduction in Rework and Change Orders

The most immediate return from a Scan-to-BIM workflow is the dramatic drop in rework. A high-fidelity model created from a point cloud captures every inconvenient truth about a site—the uneven slab, the misaligned column, the undocumented MEP run—long before construction begins.

Spotting these conflicts in a digital environment lets teams adjust plans with surgical precision. This breaks the expensive cycle of on-site demolition, re-engineering, and rebuilding. It’s not just about saving money on materials and labor; it’s about protecting the project schedule and preventing the cascading delays that destroy profitability.

This proactive approach is gaining serious ground. The global building information modeling market, valued at USD 8.53 billion in 2024, is projected to hit USD 15.42 billion by 2030. The services side of the industry is a huge part of that growth, signaling a clear shift toward data-driven risk management. You can dig deeper into the trends shaping the global BIM market on Grand View Research.

Elimination of Ambiguity and Fewer RFIs

Ambiguity is the enemy of an efficient job site. When your model is an exact digital twin of as-built conditions, the flood of Requests for Information (RFIs) about existing structures slows to a trickle. The design team has answers baked into their model, and the field team can execute with confidence.

A model built from a point cloud doesn't have opinions or assumptions—it only has facts. This foundation of certainty empowers faster decisions, reduces coordination meetings, and keeps the project moving.

This clarity directly impacts your bottom line. Fewer RFIs mean less administrative overhead, fewer delays, and a more focused team. It's about shifting resources from firefighting to building. To see how this investment pays off, it helps to understand the cost factors of 3D laser scanning services that lay the groundwork for the model.

Tighter Tolerance Control and Prefabrication Confidence

One of the most powerful benefits of Scan-to-BIM is the confidence it enables for prefabrication. When you can trust your as-built model down to the millimeter, you can manufacture components like curtain walls, MEP racks, and modular assemblies off-site, knowing they will fit perfectly.

This unlocks massive production efficiencies:

- Accelerated Schedules: On-site construction and off-site fabrication can happen in parallel.

- Improved Quality: Components are built in a controlled factory setting, ensuring higher quality and consistency.

- Enhanced Safety: Less on-site fabrication work makes for a safer, less congested construction site.

Ultimately, scan to BIM services turn a high-risk renovation into a controlled, predictable manufacturing process. This isn’t just another line item; it's a strategic investment in operational excellence and a powerful signal of your firm's commitment to delivering projects on time and on budget.

How to Choose the Right Scan to BIM Partner

Let’s be clear: not all scan to bim services are created equal. While laser scanning technology is more accessible than ever, the quality of the final, usable BIM model has everything to do with the experience and discipline of the team managing the production workflow.

Treating this service as a commodity is the fastest way to get an inaccurate model that creates more problems than it solves. Choosing the right partner means looking past the sales pitch and digging into their production systems. A great provider doesn't just sell hours; they deliver clarity, systems, and a reliable digital asset your team can trust.

Evaluate Their QA/QC Processes

The most important question to ask is: "Show me your QA/QC process." A mature Scan-to-BIM partner will have a documented, non-negotiable workflow for checking model accuracy against the original point cloud. This isn't a quick visual check; it's a systematic review with defined decision checkpoints.

They should be able to walk you through their tolerance checking methods and explain how they flag and resolve deviations. This process is the only real safeguard against human error, ensuring the as-built BIM modeling you receive is a true digital twin. If a provider can’t clearly articulate this process, consider it a major red flag.

Scrutinize Their Template Discipline and Standards

Consistency is the bedrock of a usable BIM model. A top-tier partner operates with unshakable template discipline. This means they use standardized Revit templates, strict naming conventions, and well-organized family libraries that ensure every model they deliver is clean, predictable, and ready for your team to use.

Ask to see a sample deliverable. Is the project browser a chaotic mess? Are the element categories logical? This discipline is a dead giveaway that they understand production maturity, not just basic modeling. It means the model will slide right into your existing BIM workflows without hours of cleanup.

A partner’s commitment to standards reflects their respect for your project’s efficiency. A clean, well-organized model saves your team time and prevents downstream confusion, directly protecting your margins.

Understand Their Delivery Structure

How a provider staffs projects says a lot about their ability to handle complexity and scale. Look for firms that use a scalable delivery pod structure. This model typically pairs a dedicated project manager with a consistent team of modelers who work together repeatedly.

This operational structure offers huge advantages over a generic pool of technicians:

- Deep Project Knowledge: The same core team stays with your project, building institutional knowledge and understanding its unique challenges.

- Consistent Communication: You get a single point of contact who is deeply involved in the day-to-day work, preventing details from getting lost in translation.

- Scalable Output: The pod structure allows the firm to add resources predictably without sacrificing the quality or communication flow you rely on.

This operational maturity separates a true production partner from a staffing vendor. They aren’t just selling hours; they’re delivering a systemized, reliable service that reduces your risk.

Building Your Foundation on Reality

In construction, accuracy isn't just a goal—it's the foundation. It must be built on real-world data. Scan to BIM services are more than a technology; they’re a signal of production maturity. Adopting this approach demonstrates a serious commitment to mitigating risk, ensuring predictability, and protecting margins from surprises buried in old drawings.

By closing the gap between the physical job site and the digital model, you systematically eliminate the root causes of rework, RFIs, and coordination busts. Accuracy becomes the starting point for every decision, not something you hope for when crews arrive. It’s the difference between reacting to problems on-site and solving them months ahead in pre-construction.

From Data to Dependable Delivery

This shift gives your team the confidence for tight coordination and enables the tolerance control required for prefabrication. By capturing existing conditions with laser precision, Scan-to-BIM helps you build a rock-solid digital foundation. This is essential for good planning and for conducting a thorough asset survey that facility managers can rely on for years. It turns a chaotic existing building into an orderly, intelligent asset.

The core idea is simple: accuracy isn't optional—it has to be built from reality up. Investing in a precise as-built model is the single best way to make a project predictable and deliver it on time and on budget.

This commitment to data-driven construction protects your firm’s reputation for getting the job done right. It proves you have the systems in place to handle complex projects without sacrificing quality or schedule.

At BIM Heroes, we specialize in turning real-world data into dependable digital precision. To see how a mature production process locks in accuracy, download our Scan to BIM Workflow Checklist. It’s a no-nonsense framework for turning site data into a reliable foundation for your next project.

A Few Common Scan to BIM Questions

When architects and project managers start looking into scan to BIM services, the same practical questions always come up. Let's get right to them.

What Level of Detail Do I Really Need?

It all comes down to the model's end use. For early-stage design or checking major spatial conflicts, an LOD 200 or 300 model is usually sufficient. It provides the main structural and architectural elements, which is plenty for basic clash detection without unnecessary detail.

But if you're preparing detailed construction documents, prefabrication, or a handover model for facility management, you'll need LOD 350 or 400. This level captures specific assemblies, connections, and critical MEP components.

The key is to define the end use of the model first. This simple step prevents you from paying for detail you’ll never use. A good partner will walk you through this to define the most cost-effective LOD for your goals.

How Long Does the Scan to BIM Process Take?

The timeline varies depending on the project's size, complexity, and the required LOD.

For a small commercial interior of around 5,000 sq ft, you might expect a day or two for scanning and another one to two weeks for modeling. On the other hand, a large, complex facility like a hospital (100,000+ sq ft) with dense MEP systems could take several weeks to scan and a month or more for the as-built BIM modeling.

Site access and weather can also play a role. Any experienced provider will give you a clear, broken-down schedule after reviewing the scope so you know what to expect for data capture, registration, and modeling.

Can I Use the Point Cloud Data Directly?

Absolutely, and you should. The registered point cloud is a valuable asset from day one. You can pull it directly into software like Navisworks to run clash detection against your new design models. It’s a fast, brutally honest way to spot coordination problems early.

The point cloud also serves as a permanent, hyper-accurate as-built record for facility managers. It can be used for floor flatness analysis, pulling precise 2D drawings, or for virtual site walk-throughs. According to Autodesk, using reality capture data this way is a cornerstone of modern construction. It’s an excellent way to visually verify conditions as you move through design and construction.

At BIM Heroes, we believe accuracy isn't optional—it’s built from reality up. We specialize in translating complex real-world data into dependable digital precision. To see how we ensure accuracy from data capture to final model delivery, download our Scan-to-BIM Workflow Checklist.