Why Your BIM Standards Keep Failing (And How to Build Ones People Actually Follow)

You poured months into crafting the perfect BIM standards manual. It’s comprehensive, detailed, and technically brilliant. And it’s probably sitting on a server, completely ignored.

If your team sidesteps the official standards to meet deadlines, the problem isn’t your people—it’s the system. Most standards are built in a theoretical bubble, disconnected from the daily grind of BIM workflows. They become a rulebook to fight against, not a tool that helps win.

This disconnect creates friction that costs you money. It shows up as inconsistent models, a flood of preventable RFIs, and zero operational consistency from one project to the next. The fix isn't a bigger manual. It's building a framework so ingrained in your production maturity that following it becomes the path of least resistance.

The 5 Reasons Your BIM Standards Are Doomed from the Start

Before you can build a system that works, you have to be honest about why the old one failed. It’s rarely a simple "lack of buy-in." The real problems are baked into how standards are created and managed, turning a strategic asset into a production bottleneck.

1. They’re Too Complicated

The number one reason standards fail: they're too damn complex. A 200-page PDF might feel thorough, but it’s useless on a Tuesday afternoon with a deadline looming. If a team member can't find a naming convention in 30 seconds, they’ll invent one and move on.

Lesson learned: Your standards aren't an encyclopedia; they're a field guide. Clarity trumps exhaustive detail every time. If it feels like a research project to use, it has already failed.

2. They’re Disconnected from Real Project Workflows

When standards are developed by a committee that isn’t in the trenches, they don’t survive first contact with a real project. They become a set of ideal-world rules that clash with the messy reality of deadlines, budgets, and client changes.

Production teams are paid to deliver projects, not to admire a perfect standard. When the official process gets in the way of that, they will find a workaround. Your standards must be built around the actual BIM workflows, not in spite of them.

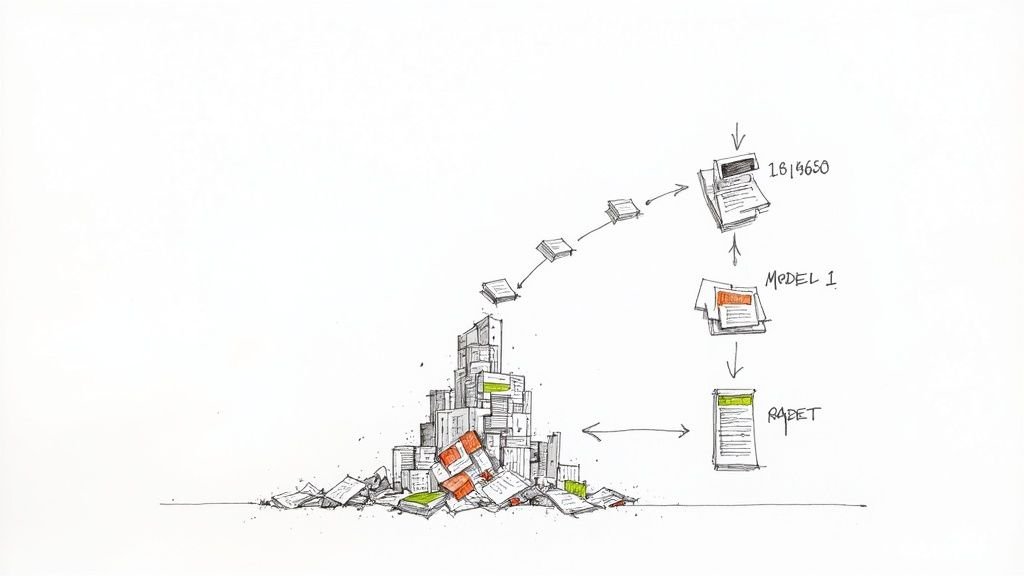

3. There's No Version Control

“Is this the latest version?” If anyone on your team has to ask this question, your system is broken. Standards scattered across Word docs, server folders, and old emails create chaos. It erodes trust.

Without a single source of truth, teams operate on conflicting information. This isn't just disorganized; it's a direct path to rework and margin erosion.

4. There's No Training Rhythm

The one-and-done "lunch-and-learn" to launch new standards is a classic mistake. Information overload guarantees nothing will stick.

Real adoption comes from a steady rhythm of reinforcement. Think short, regular refreshers during team meetings, task-specific guidance embedded in project templates, and an accessible knowledge base for quick lookups. You need a continuous learning loop, not a forgotten launch event.

5. There's No Enforcement Mechanism

Let's be blunt: standards without accountability are just suggestions. If there are no practical QA processes or decision checkpoints to verify compliance, following the rules is optional.

This isn’t about being punitive. It’s about building checks and balances that catch deviations early, when they're cheap to fix. This is where your standards must connect directly to your BIM Execution Plan (BEP), making quality assurance an active part of the project lifecycle, not an afterthought. You can learn more about structuring this in our guide to effective BIM Execution Plans.

Moving from Theory to Production-Ready

The gap between a theoretical standard and a production-ready one is where most firms stumble. It’s easy to write a perfect document; it’s much harder to build a system that people actually use. The table below contrasts the common failure points with practical, production-focused solutions that get results.

| Common Failure Point | Production-Focused Solution |

|---|---|

| Overly-detailed, static PDF: A massive document that's hard to search and impossible to use under pressure. | A living, searchable knowledge base: A simple, web-based wiki or Notion page that’s easy to update and search in seconds. |

| Top-down creation: Standards are written by managers without input from the production team. | Collaborative workshops: Involve modelers and technicians from day one to identify real-world pain points and build practical solutions. |

| No version control: "Final_v3_final_final.docx" living on a shared drive somewhere. | A single source of truth: A centralized platform with clear version history and change logs so everyone is on the same page. |

| One-and-done training: A single launch meeting where information is dumped on the team, then quickly forgotten. | Continuous reinforcement: Short, frequent check-ins, embedded checklist items, and task-specific video tutorials. |

| No accountability: Standards are published but never checked, leading to inconsistent application. | Integrated QA checkpoints: Build standards checks directly into project milestones and BEP deliverables. |

The key takeaway is simple: your standards must serve production, not the other way around. By shifting your focus from creating a perfect document to building a practical, user-friendly system, you can finally develop BIM standards that stick.

How to Build BIM Standards Your Team Will Actually Use

You know why your current standards are failing. Now, let’s build a framework people want to use. This isn’t about writing a perfect manual; it's about creating a system that makes doing things the right way the easiest, most obvious path for your team.

Successful BIM standards are built on a handful of principles that tie directly to the realities of project delivery.

Start with Margin Protection, Not Technical Purity

Teams adopt standards when they see what’s in it for them. That "why" has to be about more than keeping models tidy. Frame your standards around the outcomes that matter.

Your standards exist to:

- Protect Margins: Every inconsistency is a non-billable hour. Every RFI you prevent is money that stays in your pocket.

- Prevent RFIs: Clear, consistent models don’t leave room for costly interpretation downstream.

- Accelerate Permitting Prep: Clean, predictable documentation packages fly through reviews. No more painful resubmissions.

When your team sees the direct line between a standard and a smoother project, they'll see it as a tool for winning, not a bureaucratic hurdle.

Make Standards Accessible in 30 Seconds or Less

If your standard is a PDF buried on a server, it has already failed. No one has time for a treasure hunt when a deadline is breathing down their neck.

Lesson learned: Friction is the enemy of adoption. A standard that can’t be referenced in under 30 seconds is a standard that won’t be used.

Smart firms use living knowledge bases on platforms like Notion or a simple internal wiki. This is a game-changer.

- Instant Search: Find anything in seconds.

- Embedded Media: Show, don’t just tell, with quick videos or GIFs.

- Easy Updates: One person updates a process, and it's instantly live for everyone. No more version chaos.

This turns your standards from a dusty relic into a tool that fits into the daily BIM workflow.

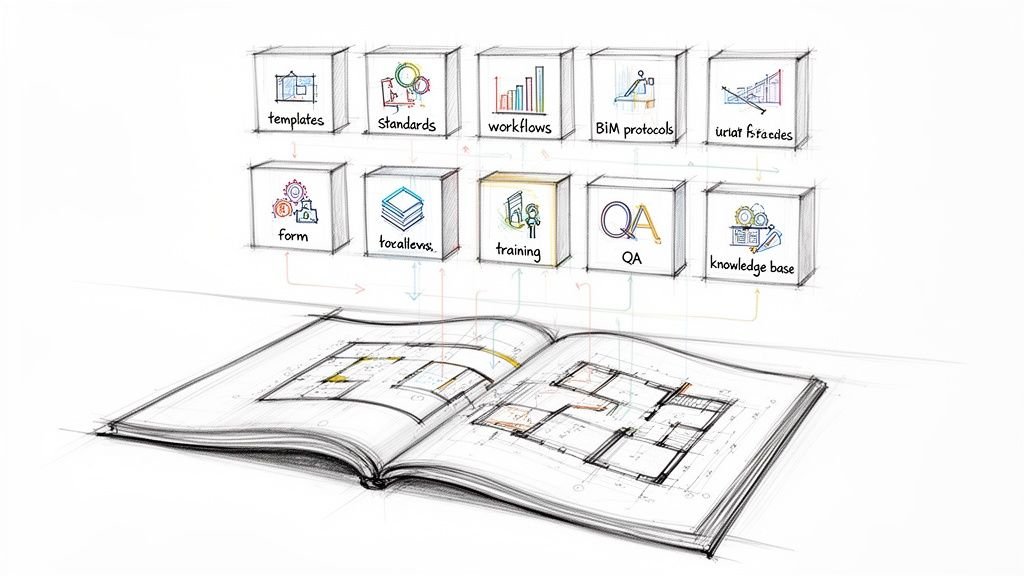

Build Standards into Your Templates

The most effective way to ensure adoption is to embed your standards directly into the tools your team uses every day. This is where template discipline becomes non-negotiable.

Your custom Revit templates should be pre-configured with the correct line styles, view templates, schedules, and naming conventions. When the right way is the default setting, you make compliance the path of least resistance. This proactive approach is infinitely more effective than trying to police standards after the fact.

Design Modular Systems for Scalable Delivery Pods

A one-size-fits-all standard rarely fits anyone well. Your framework must be modular, allowing you to apply specific requirements based on project type or client demands.

This is critical for firms running scalable delivery pods. Each team can build on the same foundation of quality while tweaking protocols for their specific needs—whether it's a high-rise tower or a portfolio of retail builds. This flexibility keeps your standards relevant across your entire project lineup, driving operational consistency without creating pointless rigidity.

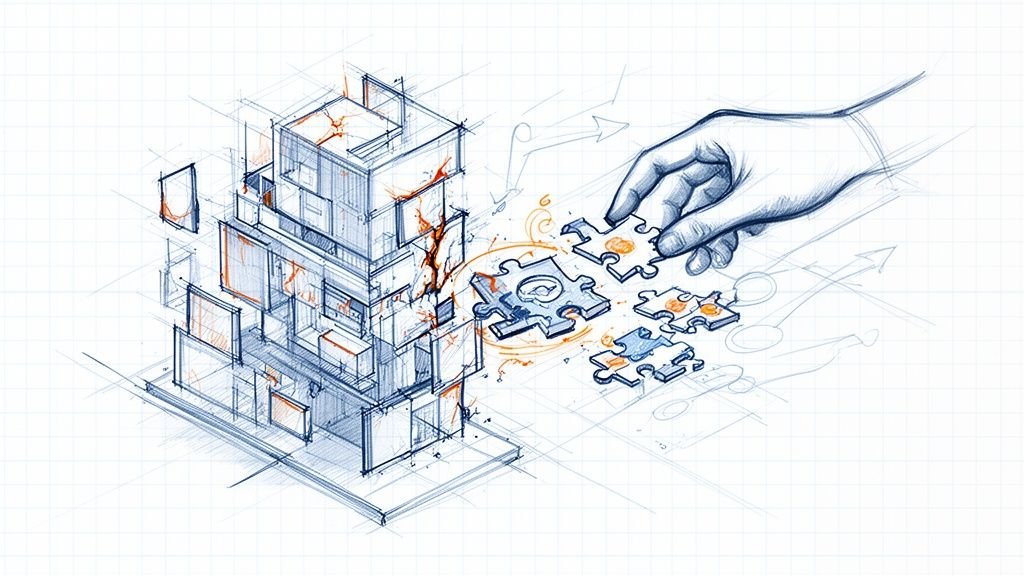

How to Make Global Standards Work for Your Firm

Global BIM standards like ISO 19650 can feel intimidating. They’re dense, exhaustive, and seem built for mega-projects, not for a firm trying to deliver on time and on budget. Many firms try to adopt them whole and end up with a rulebook no one follows.

The secret isn’t to ignore them, but to treat them like a library of good ideas. Your goal isn’t 100% compliance. It’s to cherry-pick the practical wisdom that solves your firm's real-world production problems.

From Theory to Action

Flip the question from, "How do we comply with ISO 19650?" to "How can ISO principles help us prevent RFIs and protect our margins?"

That one shift changes everything. You stop chasing a certification and start building a smarter, more predictable delivery system.

Picking the Right Tools for the Job

Think of global standards as a menu, not a mandate. You don't have to order everything. For example, the full IFC schema is overwhelmingly complex. But you can use its core idea to solve a common headache: coordinating with a structural engineer who uses different software. Set up a simple IFC exchange protocol, and you’ve just used a global standard to fix a local problem.

Another example is COBie data. Instead of seeing it as an annoying contract requirement, see it as a process that forces discipline in how you name and classify assets. That discipline makes your own models easier to audit and manage long before handover.

Lesson learned: Find the 20% of the standard that solves 80% of your firm’s coordination and data headaches.

This pragmatic approach shows you understand the reality of production. It’s about using proven concepts to improve your own CAD-to-BIM evolution, not just ticking a box.

Learning from Mandates Without Being Ruled by Them

Many standards got their start from government mandates, like the UK’s BIM Level 2 requirement. This push was a huge driver for adoption worldwide, a trend explored in VDCI.edu’s insights on global BIM software trends.

The takeaway isn’t that you need a government mandate. It's that standards-driven workflows deliver measurable improvements. Your firm can get the same benefits by adopting the spirit of the mandates—focusing on consistency and structured data—without getting buried in bureaucracy.

Your Blueprint for a Practical BIM Governance Framework

Theory is great, but execution is where the money is. A practical governance framework turns high-level ideas into a system that drives consistency and protects your margins. It’s the operating system for your firm’s production engine.

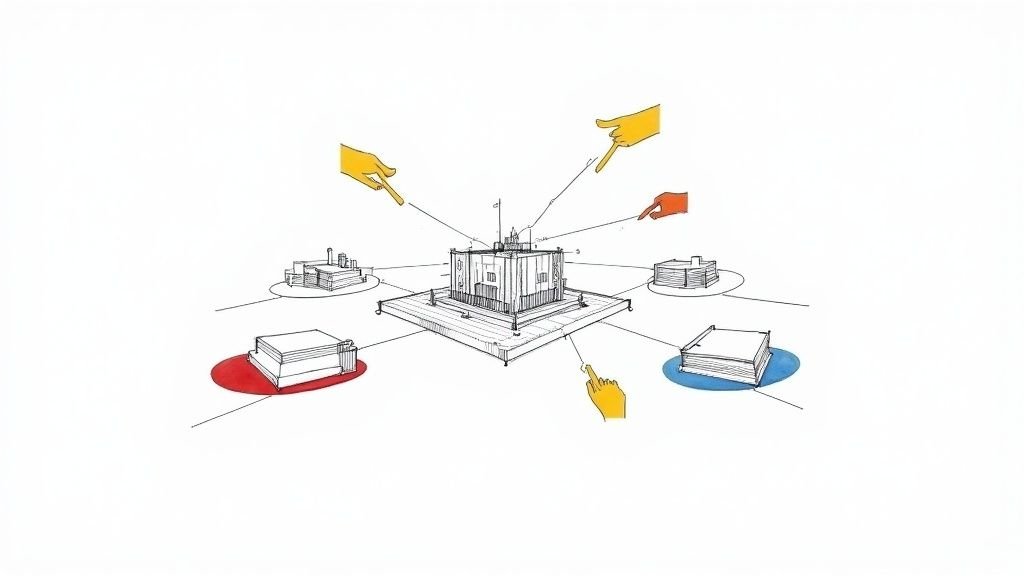

1. Assemble a Cross-Functional Standards Committee

Your standards can't be created in an echo chamber. Get the right people around the table—not just for buy-in, but to build a system that works on the ground.

Keep the committee small and agile:

- A seasoned Project Manager who understands client pressure.

- A technical lead who lives in the model every day.

- A BIM Manager to handle the technical backend.

- Representation from different delivery pods to ensure it scales.

This group becomes the permanent owner of the standards, responsible for keeping them alive.

2. Establish a Simple Feedback Loop

Standards that don’t evolve, die. Your framework needs a dead-simple way for team members to suggest improvements. A dedicated Slack channel or a basic Microsoft Form works wonders.

Lesson learned: Make providing feedback feel like a contribution, not a complaint. When your team sees their suggestions implemented, they take ownership.

This loop is your early warning system, telling you where the friction is in your BIM workflow before it costs you.

3. Develop a Rhythm for Training and Reinforcement

Good governance relies on a steady rhythm of reinforcement, not a one-and-done info dump.

Try smaller, frequent touchpoints:

- Monthly "5-Minute Fixes": A quick email highlighting one specific standard.

- Project Kickoff Refreshers: A mandatory 10-minute review before a new project starts.

- Just-in-Time Resources: Embed links to your standards wiki inside your Revit project templates.

This approach weaves learning into the flow of getting work done.

4. Build QA Directly into Your Checkpoints

Standards without accountability are just suggestions. Integrate QA processes directly into your project milestones. These aren’t punitive audits; they are essential decision checkpoints designed to catch mistakes early.

This can be a mix of automated and manual reviews at key phases, like 50% DD and 75% CD. This systematic approach ensures your standards are actively protecting project quality and preventing RFIs. Just as a BIM governance framework manages project information, establishing strong key data governance best practices is crucial for enhancing the security and quality of all valuable data.

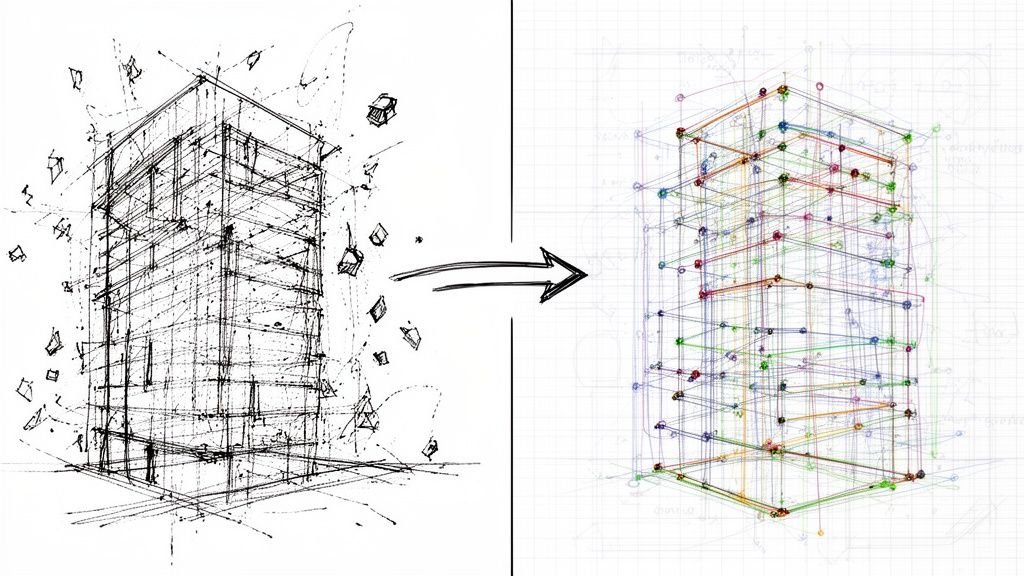

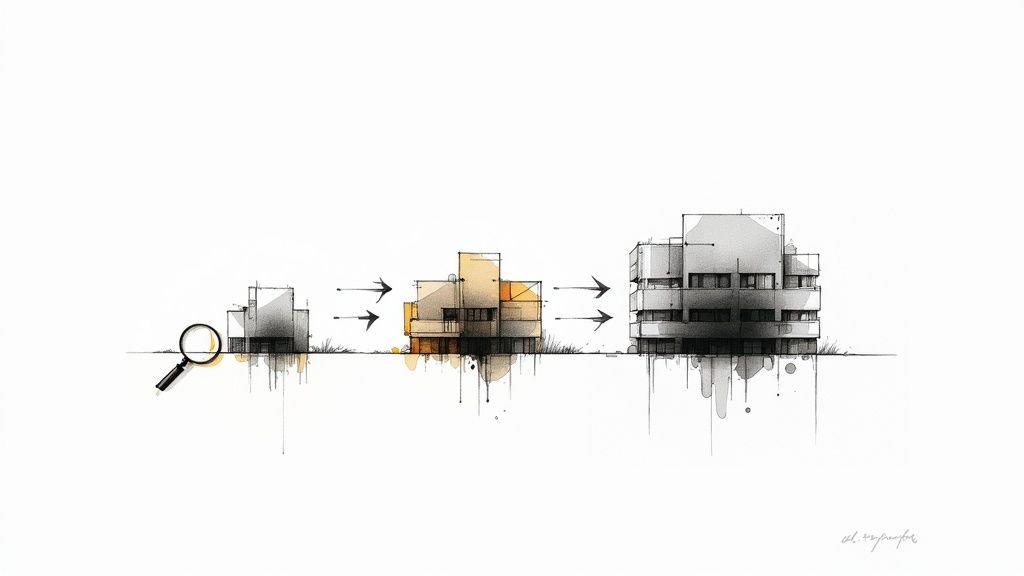

From Standards on Paper to Predictable Delivery

At the end of the day, BIM standards are a strategic tool for one purpose: delivering predictable, profitable projects. When adopted, they become the engine for operational consistency, directly protecting your margins by killing the endless cycle of rework.

This moves you from being a standards enforcer to a leader improving the firm's production maturity. The goal is a system where doing things the right way is also the easiest way.

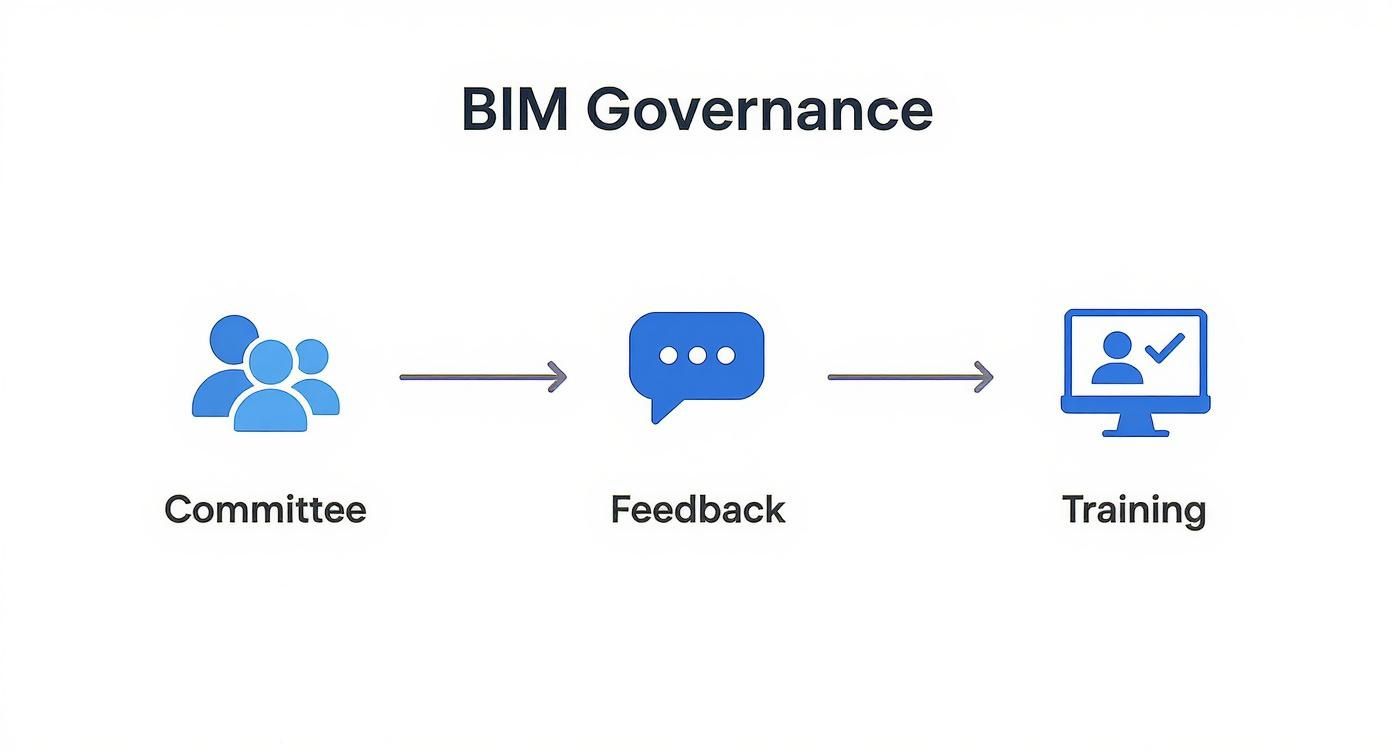

This process flow shows how a simple governance structure keeps your standards alive.

It’s a continuous loop—committee oversight, user feedback, and ongoing training—that keeps your standards grounded in real-world BIM workflows.

Getting this right is critical. The global BIM market is projected to shoot up from USD 9.7 billion in 2025 to USD 29.6 billion by 2035, a surge driven by standardization. You can read more about this market expansion and its drivers. This growth highlights the massive competitive advantage a solid internal framework provides.

Lesson learned: Well-adopted standards are your best defense against scope creep and unpredictable delivery. They transform chaos into clarity.

Frequently Asked Questions About BIM Standards

Here are real-world answers to common hurdles BIM managers face when rolling out BIM standards.

How Do We Get Our Team to Adopt New BIM Standards Without Causing Disruption?

Start small with a pilot project or a single delivery pod. This gives you a safe space to test the standards and get honest feedback. When you involve team members in building the standards, they feel a sense of ownership. Frame the standards as a tool to make their jobs easier, not another hoop to jump through.

Lesson learned: Think evolution, not revolution. Small, incremental changes are far easier to absorb than a massive overhaul.

What Is the Single Biggest Mistake to Avoid When Creating BIM Standards?

Creating them in a vacuum. When standards are developed without input from the production teams who have to live with them, they are guaranteed to be ignored. Your modelers and project architects know the real-world pain points. Ignoring their expertise is the fastest way to create a theoretically perfect but practically useless document.

Should Our BIM Standards Be a Single, Large Document?

Absolutely not. A monolithic PDF is a recipe for failure. Build a searchable, easy-to-navigate resource—like an internal wiki using a tool like Notion. This approach, championed by experts at BIM Pure, lets your team find what they need in seconds. It also means you can update specific sections as things change, keeping your BIM standards a living asset people actually use.

Effective BIM standards are the backbone of predictable, profitable project delivery. They create the clarity and systems you need to scale your operations without quality taking a nosedive. We help build and execute these frameworks, ensuring your production engine runs smoothly.