ISO 19650 for Architecture Firms

ISO 19650 is the international standard for managing information over the life cycle of a built asset using Building Information Modeling (BIM). For an architecture firm, it’s not just another certificate. Think of it as a practical framework for organizing, producing, and exchanging project data in a way that’s consistent, predictable, and protects your margins. It’s about adopting a disciplined production system.

What ISO 19650 Actually Means for Your Firm

If you’ve heard the term ISO 19650 and dismissed it as another layer of paperwork for mega-projects, it’s time to look at it differently. Forget the dense clauses and the certification process for a minute. At its core, ISO 19650 is a production system—a playbook designed to bring clarity and order to the chaos of architectural projects.

It's a direct solution to the operational headaches that quietly eat away at your profitability and create unnecessary stress.

Think about the daily friction in your office: the chaotic shared folders, the wildly inconsistent file naming, or the constant reinvention of workflows for every single project. These aren’t just minor annoyances; they're symptoms of a broken information flow that leads directly to rework, missed deadlines, and a burned-out team.

Moving Beyond the Badge to Better Habits

The real value of ISO 19650 isn't the certificate—it's the daily habits and discipline the standard helps you build. We’ve seen firms gain more from implementing a few ISO 19650 workflows than from the certification itself. It’s about codifying the best practices you probably already want to follow, like:

- Predictable File Naming: So everyone can find what they need, instantly.

- Clear Version Control: Making sure no one is working from an outdated model.

- Defined Responsibility Matrices: Ending the endless "who owns this task?" debate.

- Structured Approval Workflows: Creating clear decision checkpoints before information is released.

- Consistent Model Governance: Auditing models to keep them clean and performing well.

This is the real heart of BIM information management. It's a shift from ad-hoc processes to a reliable, scalable system that protects your bottom line and delivers operational consistency.

A Framework for Production Maturity

Adopting principles from ISO 19650 is a clear sign of production maturity. It’s how your firm stops relying on individual heroics and starts operating with a dependable system. When your information is managed this way, you reduce RFIs, improve coordination with your consultants, and make preparing for permitting that much smoother.

The biggest challenge in scaling a firm isn't finding more work; it's delivering that work consistently without burning out your team. ISO 19650 provides the operational backbone to make that possible.

This systematic approach lets you train new staff faster because they're plugging into a documented process, not just shadowing someone. It allows you to build out scalable delivery pods that all operate with the same high standards, no matter the project. The ISO 19650 implementation journey is ultimately about building a calmer, more predictable, and more profitable practice. It’s not about adding bureaucracy; it’s about creating clarity.

Unpacking the Core Principles of ISO 19650

Let's cut through the academic jargon. This isn't a textbook to memorize. Think of it as a playbook for running healthier, more predictable projects.

Each core principle is a direct response to a common headache in architectural production. These aren't just abstract ideas; they're proven ways to dial down the chaos, protect your margins, and get everyone on the same page. By understanding the "why" behind them, you can build better habits, whether you're chasing certification or just a better workflow.

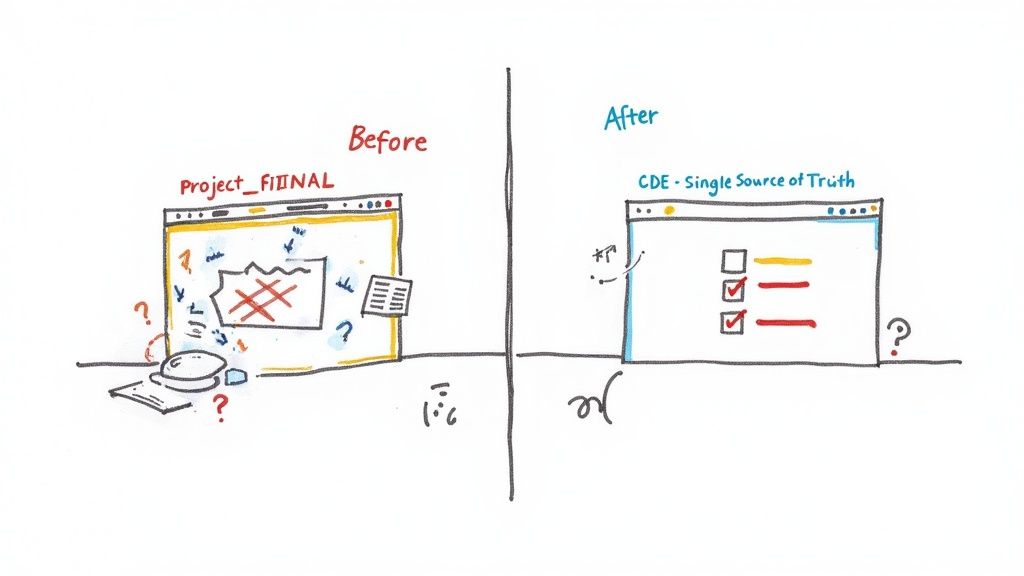

The Common Data Environment as Your Single Source of Truth

The most fundamental concept is the Common Data Environment (CDE). Don't let the acronym scare you. A CDE is just a single, controlled space for all project information. It’s the final answer to the question, "Where is the latest version of…?"

A solid CDE workflow kills the nightmare of digging through chaotic shared drives, endless email attachments, or—worst of all—finding out a team member has been working from an outdated model for a week. It creates a strict process for how information moves from "Work in Progress," to "Shared," and finally to "Published," building clear decision points into the project timeline.

We’ve seen firms gain more from implementing a few ISO 19650 workflows than from the certification itself. The discipline of a CDE alone can dramatically reduce rework and prevent costly RFIs.

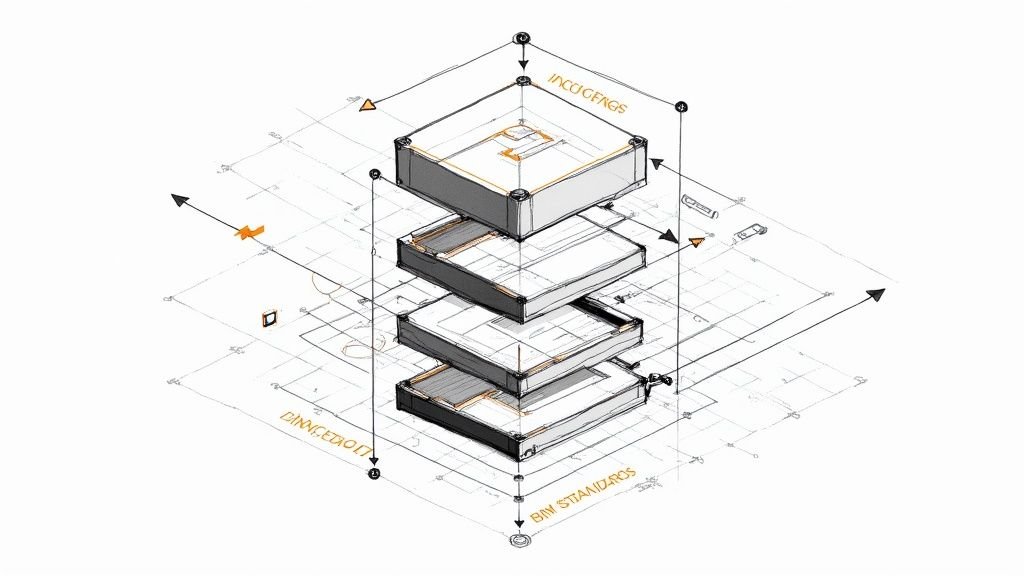

Naming Conventions and Version Control: The Bedrock of Clarity

File names like "Floor_Plan_FINAL_v2_Johns_Comments.rvt" are a recipe for disaster. ISO 19650 gets rid of that guesswork with a strict, standardized naming convention. Every file name contains consistent, machine-readable information about the project, originator, volume, level, type, and revision.

This isn't about being rigid for the sake of it. It's about making information instantly findable and understandable for everyone—from your internal team to your external consultants and the GC. This discipline, combined with rigorous version control, is your best defense against expensive mistakes and wasted hours. This approach is a cornerstone of many effective BIM standards that demand clarity and interoperability.

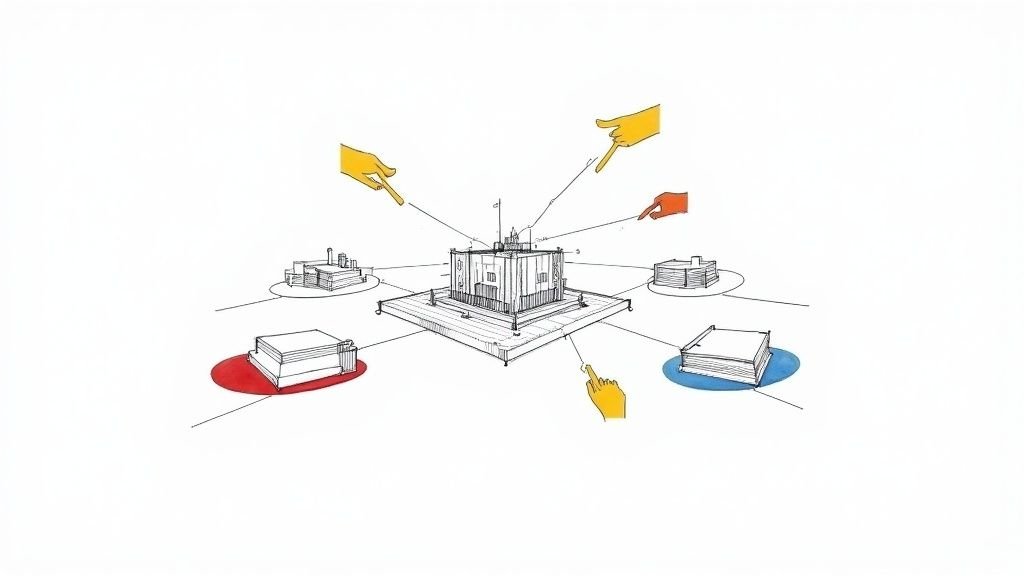

Responsibility Matrices: Ending the Ownership Ambiguity

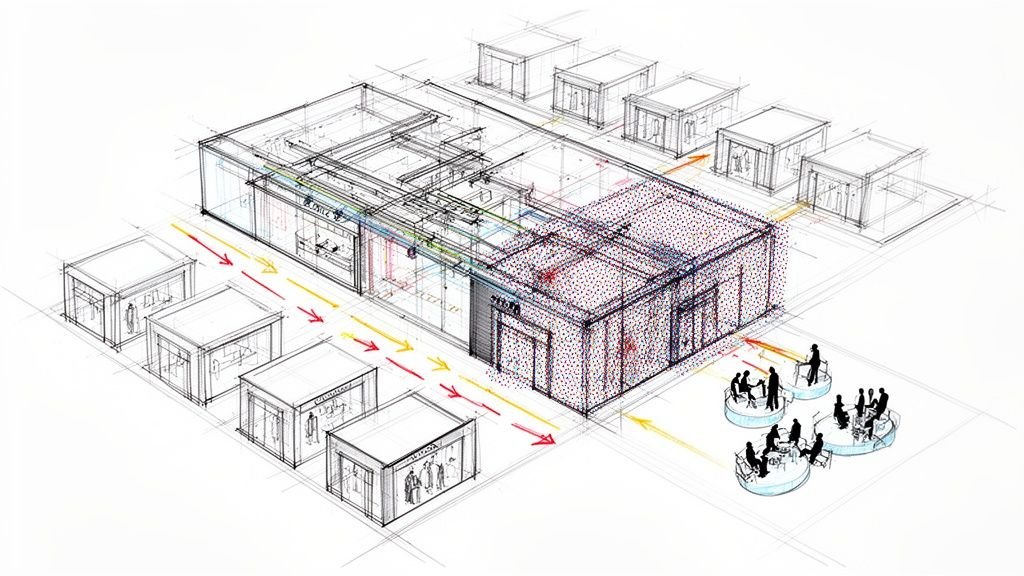

Another huge piece of the puzzle is clarifying who owns what. A responsibility matrix—often part of the Master Information Delivery Plan (MIDP)—explicitly defines who is responsible for producing what information, and by when.

This one simple document stops critical tasks from falling through the cracks. It puts an end to the back-and-forth arguments over who owns a specific model element or drawing set, creating clear accountability at every project milestone. For an operations lead, this is a powerful tool for making sure your project deliverables line up perfectly with what's in the contract.

By embracing these core concepts, you start to shift from reactive, fire-fighting mode to proactive, systematic delivery. The table below really drives home how ISO 19650 brings order to common project chaos.

From Chaotic Workflows to Structured Production

Moving to an ISO 19650 framework is about trading daily project frustrations for a more predictable and disciplined process. Here's a look at how it directly addresses the pain points we all know too well.

| Common Pain Point | The ISO 19650 Approach |

|---|---|

| "Where is the latest file?" | A Common Data Environment (CDE) serves as the single source of truth. |

| Vague, inconsistent file names | Standardized naming conventions make information instantly discoverable. |

| Using outdated model versions | Strict version control and approval gates ensure only current data is used. |

| Unclear task ownership | A Responsibility Matrix assigns clear accountability for every deliverable. |

| Inconsistent project setups | Template discipline and defined workflows ensure operational consistency. |

Ultimately, these principles work together to create a system where information flows predictably, ownership is clear, and costly errors are caught before they happen. It’s less about bureaucracy and more about building a smarter, more resilient production engine for your firm.

How to Implement ISO 19650 Workflows in Your Practice

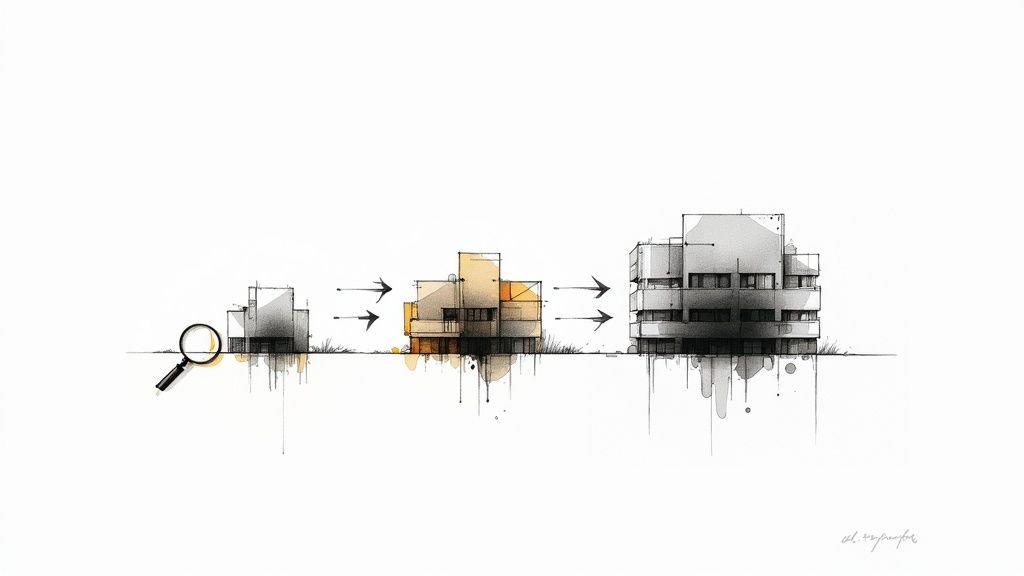

Moving from theory to practice is where you see the real value of ISO 19650. Let's be clear: this isn't a one-day event. It’s a gradual adoption of better habits, building a solid production system piece by piece, starting with the workflows that fix your most immediate headaches.

The goal isn't to flip a switch and become perfectly compliant overnight. You want to create practical, repeatable systems that make your firm more predictable and your projects less stressful.

Start with Your Common Data Environment Workflow

Before you do anything else, map out your information flow. Your Common Data Environment (CDE) is the heart of BIM information management, but it only works if the workflow is clear and everyone respects it. Don't overcomplicate this.

Start by defining the four states of information:

- Work in Progress (WIP): The sandbox where individual teams create and iterate. Nothing here is visible to other teams until it's ready.

- Shared: Once a model or drawing set has been checked, it moves here. This is where other disciplines can reference it for their own work.

- Published: After a formal sign-off, information is moved here. This is the official, authorized data used for construction, permitting, or other formal deliverables.

- Archived: The final resting place for all project information, creating a perfect audit trail.

The single most important step here is defining clear gates and approval checkpoints between these states. Nothing should ever move from WIP to Shared without a proper QA check, and nothing should hit Published without a formal sign-off. This discipline is what stops the costly rework that happens when people use unverified information.

Establish and Enforce Template Discipline

Your firm’s templates are the bedrock of consistency. "Template drift"—where every project manager tweaks standards to their own liking—is a recipe for production chaos. ISO 19650 implementation requires a firm hand here.

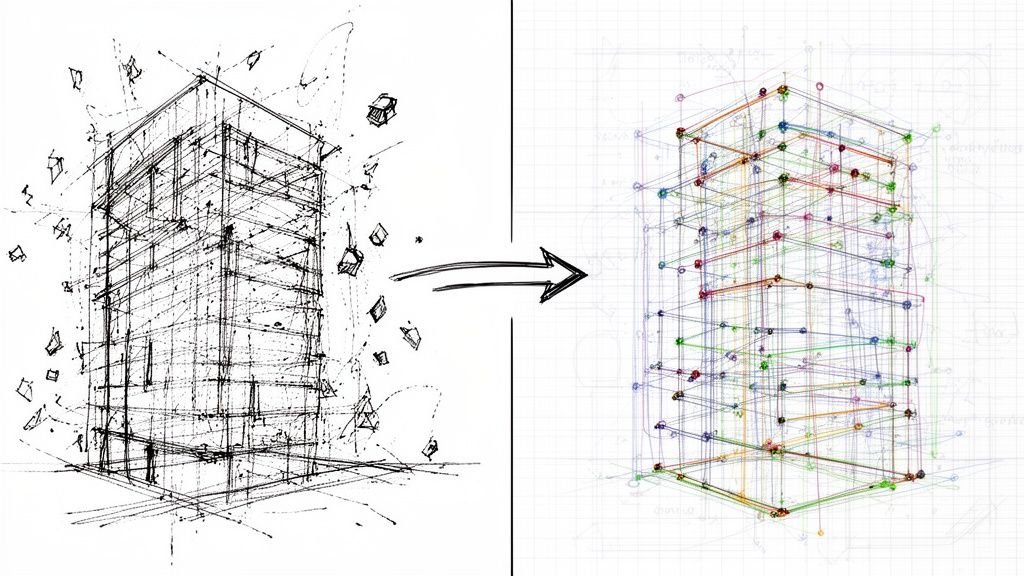

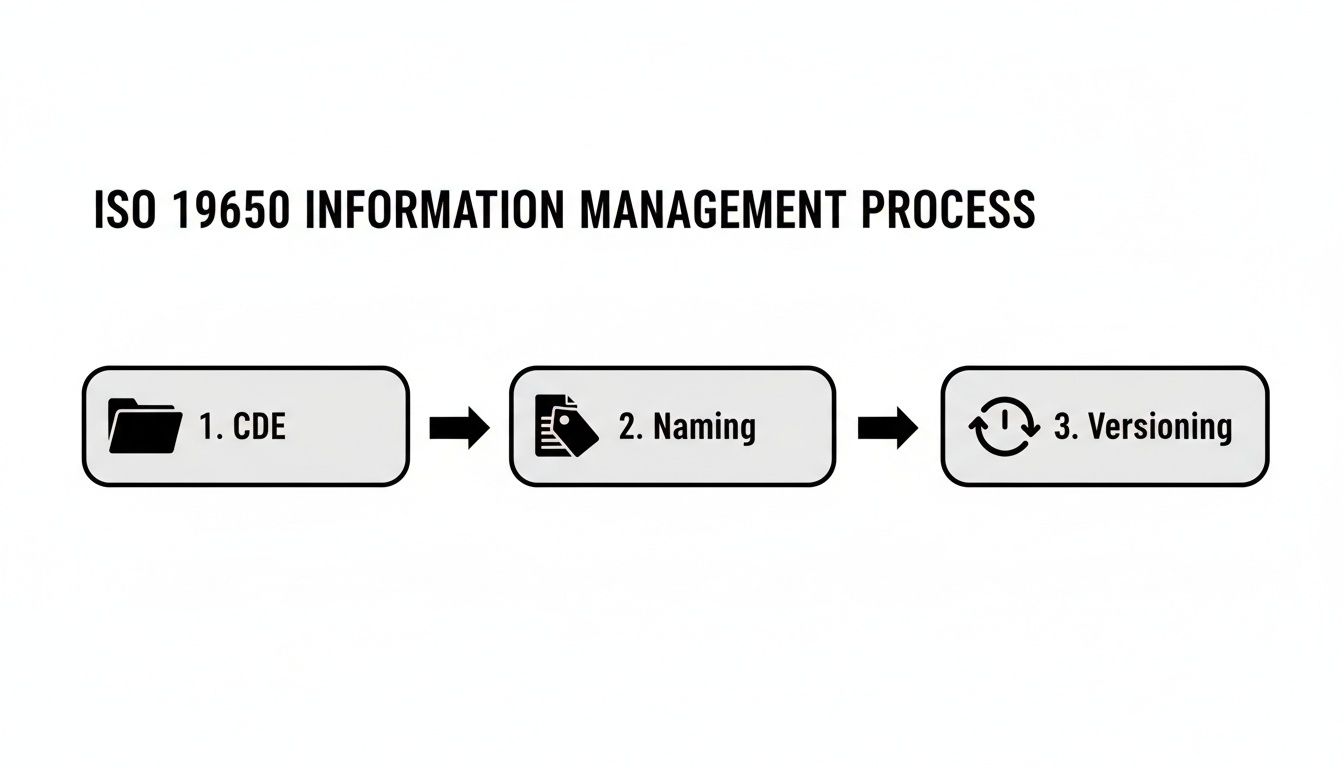

This process lays out the essential steps for getting information under control: first, you establish a single source of truth (the CDE), then you enforce consistency (Naming), and finally, you manage change (Versioning).

This structured flow guarantees that every piece of data is created, identified, and tracked in a predictable way from beginning to end.

Lock down your project templates for file structures, title blocks, and model setup. Document your naming conventions so they're crystal clear, and build them directly into your project startup checklist. A non-negotiable, standardized naming convention is the calling card of mature AEC production systems. It makes information instantly findable and kills ambiguity.

A project that kicks off with a clean, standardized folder structure and naming convention is already on the path to a smoother delivery. It sets a tone of discipline from day one.

Define Practical Model Governance and QA Processes

"Model governance" might sound intimidating, but it's really just about setting simple rules to keep your BIM data clean and efficient. This is a critical QA step that stops your models from becoming slow, bloated, and riddled with errors. For any firm wanting to get a better handle on information flow, exploring these essential document management best practices provides a solid foundation.

Start with a basic checklist for model audits at key project milestones:

- Run Interference Checks: Find and fix clashes between disciplines before they become RFIs.

- Purge Unused Elements: Regularly clean out unused families and materials that bog down performance.

- Check Naming Convention Compliance: Do a spot audit to ensure files stick to the project standard.

- Validate Model Health: Use tools to check for warnings, file sizes, and other performance metrics.

When you bake these steps into your project timeline, you create built-in decision checkpoints. They ensure your information quality is being actively managed, not just something you scramble to fix before a deadline. It's a system of accountability that protects the quality of your deliverables.

This entire process is often a key component documented within well-structured BIM Execution Plans, which lay out the rules of engagement for every project. By building these workflows, you're not just chasing a standard; you're building a more reliable, scalable, and profitable firm.

The Tangible Payoffs of a Streamlined System

Adopting a new standard can feel academic, but aligning your production system with ISO 19650 is a direct investment in your firm's operational health. Structured BIM information management isn't just about better BIM; it's about building a more resilient and profitable practice.

When information flows predictably, the gains are real, measurable, and protect what matters most: your margins, your timelines, and your team's sanity.

Dramatic Reduction in Costly Rework

The most immediate benefit you'll see is a sharp drop in rework. Think about the last time someone on your team accidentally worked from an outdated structural model or an old client redline. Every hour spent fixing that mistake is a direct hit to your bottom line.

An ISO 19650 implementation nips this in the bud by establishing a single source of truth with clear approval gates. It's a system designed to ensure your teams are always building on verified, current information. The result? Fewer late-game coordination blow-ups and less of the frustrating rework that kills both budgets and morale.

We've seen it time and again: firms with disciplined information workflows spend far less time on non-billable rework. That saved time goes straight back into project profitability.

Faster Onboarding and Improved Scalability

How long does it take for a new hire to become productive at your firm? When faced with inconsistent workflows and chaotic project folders, that timeline can stretch into months.

In a firm running on clear AEC production systems, a new architect or technician can plug into a documented, repeatable process from day one. They aren't left guessing about file naming or how to navigate a messy server—the system guides them. This produces two huge advantages:

- Faster Onboarding: New staff start contributing meaningfully in weeks, not months.

- Scalable Delivery Pods: You can build out new project teams with confidence, knowing they will all operate under the same high standards.

Smoother Coordination and Fewer RFIs

Clear, well-structured information is your best defense against a flood of RFIs. When consultants, contractors, and other partners can easily find and trust the data you provide, ambiguity vanishes.

A shared understanding of naming conventions, version control, and model status simply means fewer questions and less time wasted clarifying things that should have been obvious. This is especially true during permitting. A clean, organized submission package built on ISO 19650 principles is far less likely to get bogged down in delays or rejections.

The predictability you build into your internal system extends outward, creating smoother relationships with every project partner. It’s not just about managing files; it’s about managing risk and protecting your firm’s credibility.

Overcoming Common Implementation Hurdles

Adopting a standard like ISO 19650 is a change management challenge. It requires patience, a solid strategy, and a real understanding of the human side of the equation. Acknowledging where you're likely to hit friction is the first step to a smooth transition.

We’ve seen firms stumble, not because the principles of ISO 19650 are flawed, but because they underestimated the effort needed to shift ingrained habits. The goal is to introduce these better workflows as a natural evolution, not a forced revolution.

Securing Leadership Buy-In with Early Wins

One of the biggest hurdles is getting firm leadership to see ISO 19650 implementation as more than an overhead cost. The key is to reframe the conversation around protecting margins and cutting down on risk.

Instead of pitching a massive overhaul, propose a pilot project. Pick a small project and implement just a few core workflows: a strict naming convention, a basic CDE folder structure, and a simple responsibility matrix.

Then, track the time saved hunting for files or the reduction in coordination mistakes. Presenting tangible data—"we saved 20 hours this phase because no one used the wrong model"—is infinitely more powerful than any theoretical argument. These small, provable wins build a rock-solid business case for a wider rollout.

Overcoming Team Resistance to Change

Your team is the engine of your firm, and if they're resistant, any new initiative is dead in the water. That resistance usually comes from a place of fear—fear of a slower process or losing autonomy.

The answer is education and empowerment, not top-down mandates. You have to show them how a standardized system makes their jobs less stressful. Frame it as a way to kill the frustrating, time-wasting tasks they already hate, like digging through servers for the right file or staying late to fix someone else's mistake.

The most effective way to get team buy-in is to focus on the pain you're removing. ISO 19650 isn't about adding rules; it's about eliminating the chaos that leads to late nights and project fire drills.

A great way to start is by getting your team leads involved in creating the new standards. When they have a hand in building the system, they become its biggest champions.

Avoiding the "All or Nothing" Trap

Many firms get stuck because they think they need to implement every clause of the standard perfectly from day one. That's an impossible task that often leads to analysis paralysis.

In reality, the principles are completely scalable. A five-person firm can get just as much value from a simple CDE and naming convention as a 500-person firm can from a full-blown information management system. The key is to start small and be consistent.

Implementing the standard is a journey. This methodical, step-by-step approach ensures your AEC production systems mature in a sustainable way, embedding quality right into your firm's DNA.

Your First Steps Toward a Better Production System

Looking at a new standard like ISO 19650 can feel overwhelming. The good news: you don't need a massive, firm-wide overhaul to start seeing real improvements.

The goal isn’t immediate, perfect compliance—it's about making a gradual shift toward a more predictable, scalable, and less stressful way of working.

Frankly, we’ve seen firms get more value from implementing just a few core workflows than from the certification itself. It all starts with the decision to stop reinventing the wheel on every project and begin building a consistent operational backbone. This is how you move from constantly putting out fires to systematically delivering quality work.

Three Simple Actions You Can Take This Week

Instead of getting bogged down in theory, pick one area of friction and apply a small dose of discipline. Here are three simple, high-impact actions you can take right now to begin your journey toward better BIM information management:

- Audit a Single Project’s Naming Convention: Grab a recently completed project folder. How consistent are the file names? How long would it take a new hire to find a specific drawing? Document the chaos and draft a simple, one-page naming standard based on what you find.

- Map One Project’s Information Flow: On a whiteboard, trace the journey of a key deliverable. Who creates it? Who needs to review it before it’s shared? Who gives the final sign-off? This exercise will instantly reveal the gaps in your current approval process.

- Define a Simple Responsibility Matrix: On your next project, create a basic spreadsheet listing the primary deliverables. Next to each item, assign a single person responsible for it. This small act of clarifying ownership eliminates ambiguity from day one.

These initial steps aren't about creating more paperwork; they're about building better habits. Consistent file naming and clear version control for BIM projects are foundational disciplines that slash rework and save countless hours. Each small improvement reinforces the value of a structured approach, making it easier to tackle the next challenge.

Your ISO 19650 Questions, Answered

Even when you grasp the big picture, practical questions always surface. Let’s tackle the most common ones we hear from architecture firms about bringing ISO 19650 into their practice.

Do We Really Have to Get ISO 19650 Certified?

Short answer: no. While some public sector work might require it, ISO 19650 compliance is not a universal mandate.

That said, more and more sophisticated clients are asking for ISO 19650-aligned workflows. Why? Because they know it lowers project risk and makes delivery more predictable. For most firms, the real prize isn't the certificate—it's the operational discipline you build. Think of it less as a requirement and more as a competitive edge.

What's This Going to Cost Us?

The investment can vary wildly. If you're chasing full, audited certification, you'll spend on consultants, training, and software. But if your goal is simply to adopt the core principles to clean up your AEC production systems, the cost can be surprisingly low.

Your biggest initial investment is time to audit your workflows, document new standards, and get your team on board. The real ROI, however, comes from the massive reduction in rework, faster onboarding, and fewer costly errors. Those benefits almost always outweigh the upfront time commitment.

Does This Mean We Need a Full-Time BIM Manager?

A dedicated BIM Manager is a huge asset, but it’s not a deal-breaker. A smaller firm can succeed if a motivated operations lead or a senior project architect takes the reins.

The critical piece is clear ownership. Someone has to be responsible for defining the standards, creating the templates, and—most importantly—making sure the team sticks to the plan. You don't need a specific job title, but you absolutely need a champion.

Can We Use This for Our CAD Projects?

Absolutely. While ISO 19650 grew up in the world of BIM, its core ideas about information management apply to any kind of project.

Structured folder systems, standardized file naming, clear version control, and defined approval gates bring clarity to any production environment, including traditional 2D CAD workflows. In fact, applying this discipline to your CAD projects is a fantastic first step toward improving your firm's overall BIM information management maturity.

At BIM Heroes, we help firms build these exact systems. We don’t just deliver production work; we help you install the operational discipline needed for scalable, predictable delivery.

If you're ready to move toward a more structured production system, our ISO 19650 Implementation Checklist is a practical resource to help you start. It offers a step-by-step framework to bring order to your projects, one workflow at a time. Download your copy and take the first step toward a calmer, more profitable practice. Learn more about how we can help at https://www.bimheroes.com.