How to Build Production Systems That Survive Deadlines, Staff Turnover, and Scaling

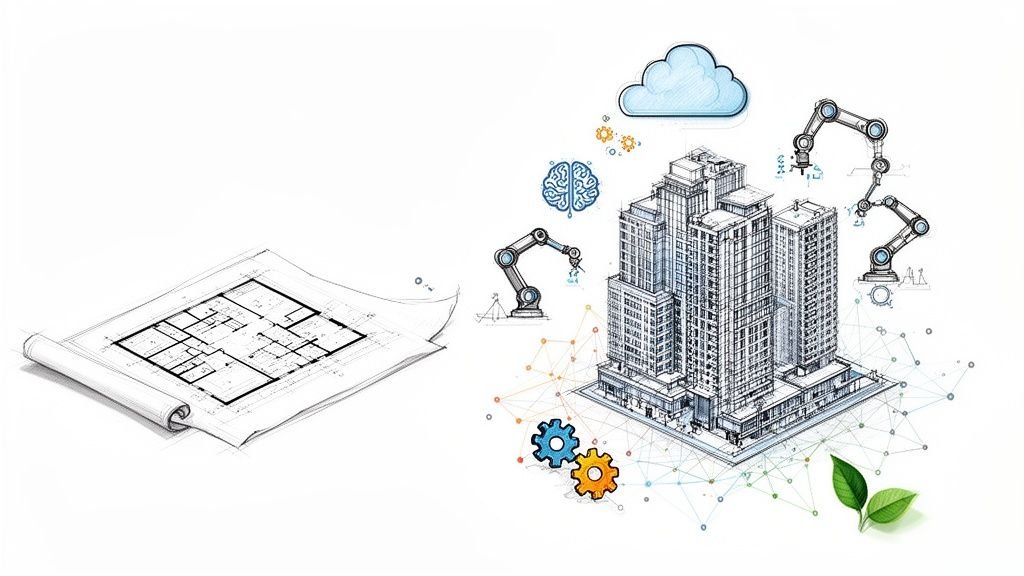

Staring down a deadline, do you rely on individual heroics or proven systems?

For too many growing architecture firms, this question hits a little too close to home. The daily reality is a chaotic scramble of inconsistent drawings, painful onboarding, and workloads that swing from famine to feast. This talent-dependent model is the hidden barrier preventing true, sustainable growth, and it’s a direct threat to your margin protection.

It’s a painful cycle: drawings look different for every project, BIM standards drift, onboarding takes forever, and teams constantly redo the same mistakes. Heroics might save the deadline, but they can’t build a scalable firm. Strong architecture production systems can.

The Hidden Barrier To Scaling Your Architecture Firm

Most firm owners fall into the trap of thinking that hiring more talented people is the silver bullet for scaling. While great people are essential, talent isn't a system.

When you rely solely on individual effort—that one “rockstar” project manager who always saves the day—you’re building a fragile business. What happens when they go on vacation, get sick, or leave the firm? The entire process grinds to a halt, projects stall, and quality takes a nosedive.

This operational chaos shows up as painful symptoms that almost every studio lead recognizes:

- Inconsistent Deliverables: Drawings look different from one project to the next because each team follows its own unwritten rules and personal habits.

- Endless Rework: Redlines explode right before deadlines as unchecked errors bubble to the surface, completely destroying your project margins and predictability.

- Painfully Slow Onboarding: It takes months for new team members to become productive because they’re constantly asking basic questions about standards that should have been documented.

- Constant Reinvention: Your teams are re-drawing the same details and solving the same problems on every project, burning through valuable time and preventing RFI prevention.

These issues aren't a reflection of your team's skill. They're a direct result of not having robust architecture production systems in place. Real scalability comes from engineering a resilient production engine where clarity and operational consistency are baked into the process from day one. To get a better handle on where time is actually going, specialized tools like Time Tracking Software For Architects can also reveal major efficiency gains.

Shifting From People-Dependent to System-Driven

A system-driven firm operates on a different level. It runs on a backbone of repeatable workflows, crystal-clear standards, and shared knowledge. This is where the real magic of scalable AEC operations happens.

The core idea is simple: Firms don’t scale because of talent—they scale because their systems create consistency no matter who’s in the chair or how fast the deadline arrives.

The table below breaks down the key differences between these two operational styles. It’s a snapshot of the chaos many firms experience versus the calm, controlled environment a system-driven approach provides.

Hero-Driven vs. System-Driven Production

| Operational Area | Hero-Driven Approach (The Chaos) | System-Driven Approach (The Solution) |

|---|---|---|

| Workflow | Relies on individual memory and improvisation. | Follows documented, repeatable processes. |

| Quality | Inconsistent; depends on who is working on it. | Standardized and predictable through QA processes. |

| Onboarding | Slow and mentor-dependent; new hires drain resources. | Fast and efficient using checklists and training paths. |

| Knowledge | Hoarded by key individuals; lost when they leave. | Centralized in templates, libraries, and standards. |

| Resilience | Fragile; a key person's absence creates a crisis. | Robust; the system keeps running smoothly. |

Instead of leaning on memory and individual habits, system-driven firms use templates, strict naming conventions, built-in QA/QC cycles, and shared detail libraries. This approach makes the firm far more resilient to staff turnover and compressed deadlines. It shifts the entire focus from heroic, last-minute efforts to reliable, repeatable outcomes.

We've seen firms cut rework dramatically once their production systems replaced guesswork. This structure is a foundational concept for any effective architecture firm business plan, protecting your margins, guaranteeing quality, and making growth something to look forward to—not something to dread.

Why Your Best People Are Not A Scalable System

Every firm has them. The project manager who pulls all-nighters to rescue a deadline. The BIM lead who knows every arcane workaround. The senior architect whose gut feelings are almost always right. We call them heroes, and for good reason.

But leaning on these individuals as your primary production strategy is one of the biggest—and most common—risks a growing firm can take.

The hard truth is that a business built on individual heroics isn’t scalable. It’s fragile. Your most valuable asset, your institutional knowledge, walks out the door every evening. When that key person goes on vacation, gets sick, or moves on, a massive void is left behind. Projects stall, quality dips, and junior staff are left scrambling for direction.

This isn't a people problem. It's a systems problem.

The Hidden Costs of a Talent-Dependent Model

Relying on a few key players creates friction that quietly eats away at your margins and team morale. These aren’t abstract concepts; they are the daily headaches that studio leads and production directors know all too well.

How many times has a project kicked off with someone asking, "Which title block are we using for this one?" or "What are our current layering standards again?" These seemingly small questions are symptoms of a much deeper issue: the lack of a single source of truth.

The consequences ripple outward, creating a kind of predictable chaos:

- Wildly Varying Quality: The final drawing set looks completely different depending on which team lead ran the project, creating confusion for contractors and clients alike.

- Painfully Slow Onboarding: A new hire can take three, six, or even twelve months to get up to speed because they have to learn workflows through trial and error—and constant shoulder-tapping.

- The Panic of Turnover: When a single experienced team member leaves, they can jeopardize an entire project, taking their unique methods and unwritten rules with them.

When you multiply these small moments of friction across dozens of projects and team members, the cumulative cost is staggering. You aren't just losing time; you're losing predictability, consistency, and the ability to confidently grow your operations.

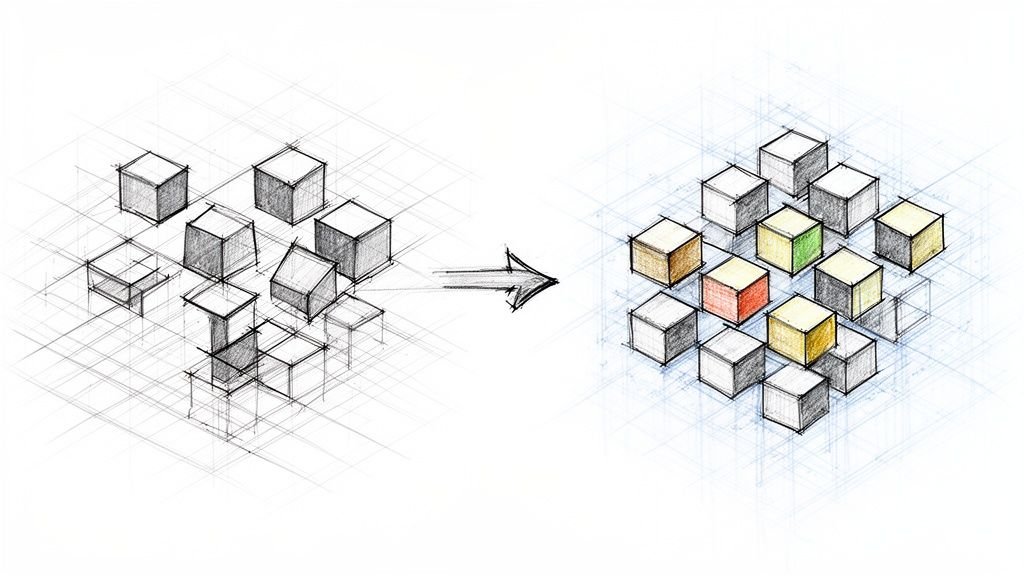

Capturing Expertise and Making It Repeatable

The solution isn't to devalue your experts. It's to build architecture production systems that capture their know-how and make it the standard for everyone. Strong systems codify the best practices of your top performers into repeatable workflows, templates, and checklists that anyone can follow.

We’ve seen firms cut rework dramatically once their production systems replaced individual habits. It’s about making excellence the default, not an occasional act of heroism.

Think of it this way: your best project manager has an internal checklist they run through before issuing a set for permitting. A system takes that personal checklist, refines it with the team, documents it, and makes it a mandatory QA/QC checkpoint for every single project.

This simple shift transforms your firm's operational model. It moves the foundation from "who is doing the work" to "how the work gets done." This is the critical pivot for scaling architectural teams effectively.

Building Resilience Against Chaos

A well-designed system makes your firm resilient. Deadlines can get squeezed, key people can take leave, and new team members can join mid-project, but the operational backbone holds steady. Information flows where it needs to because the pathways are clearly defined.

Instead of re-explaining CAD standards for the tenth time, your team consults a living document. Instead of guessing at file structures, they follow a clear naming convention. This engineered clarity prevents common errors, reduces the need for constant supervision, and frees up your senior staff to focus on high-value design challenges instead of administrative firefighting.

This is the core of effective AEC operations—creating an environment where quality is an outcome of the process, not just the effort of a few dedicated people.

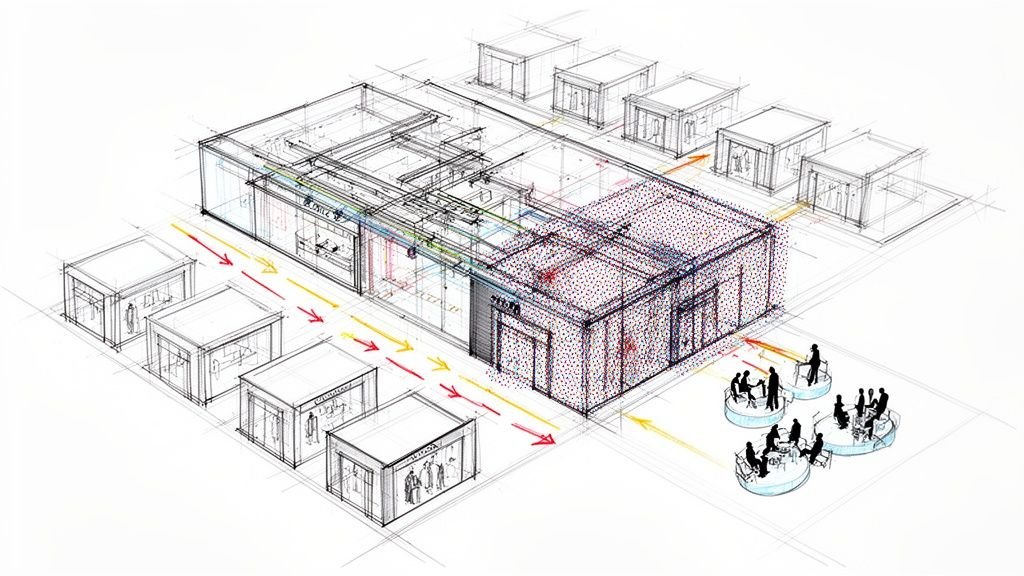

The Building Blocks Of A Resilient Production Engine

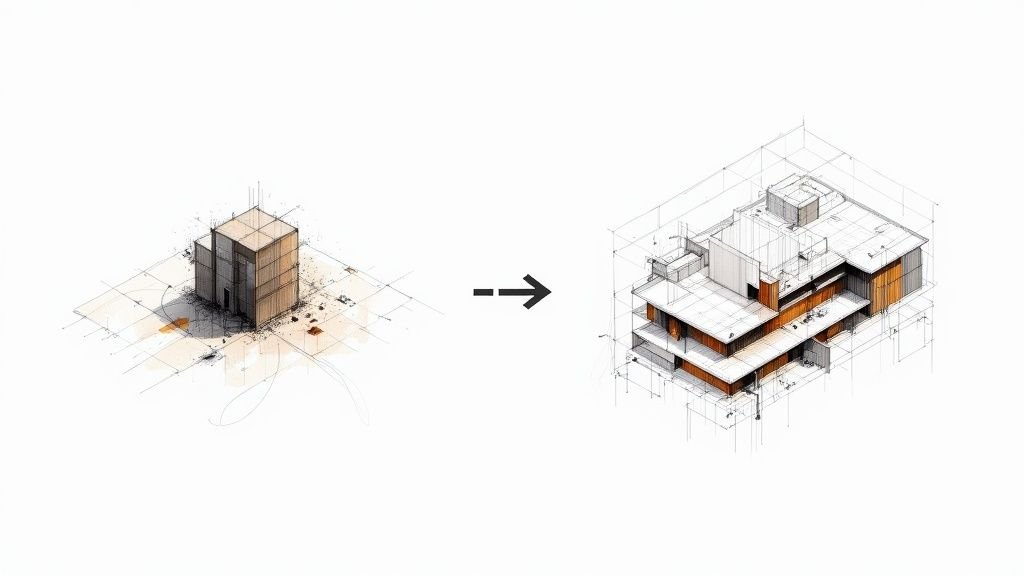

A reliable production engine isn't an abstract goal; it's a tangible system built from specific, interlocking components. Each piece—from templates to QA processes—works to eliminate ambiguity, replacing guesswork with a predictable, repeatable process. When firms complain about drawings looking different on every project, it’s because one or more of these foundational blocks are missing.

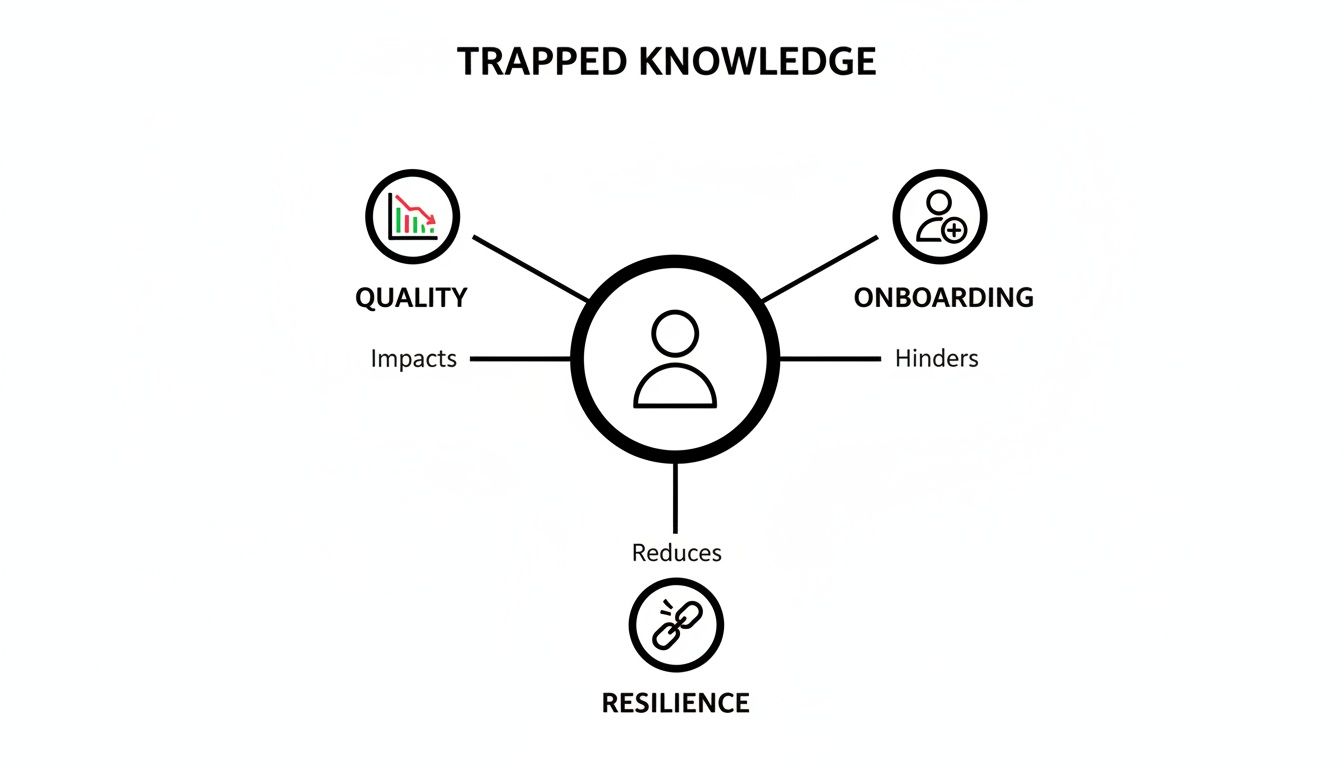

The real problem is that expertise gets stuck in people's heads instead of being built into the system. This "trapped knowledge" is a huge risk.

This diagram drives home a hard-won lesson: without systems to capture and distribute expertise, your firm’s stability is constantly on the line. Let's break down the essential components that form the backbone of a high-performing studio.

Project Templates For A Perfect Start

A project template is far more than a title block. It’s a pre-configured project environment—your firm’s DNA, codified—that ensures every job starts from a position of strength, complete with standard file structures and model governance rules.

A mature template package should include:

- Standardized File Structures: Pre-built folders for documentation, models, exports, and consultant files. No one should ever have to guess where to save or find information.

- Pre-loaded View Templates and Sheets: All the essential drawings and schedules are set up from the jump, ensuring graphic consistency from day one.

- Configured Project Parameters: Key data fields are already embedded in the model, ready for teams to populate.

We've seen firms cut project setup time from a full day to under an hour just by enforcing disciplined template use. It's the single highest-impact change you can make to improve consistency. For more on this, check out our deep dive into creating powerful architecture firm knowledge systems.

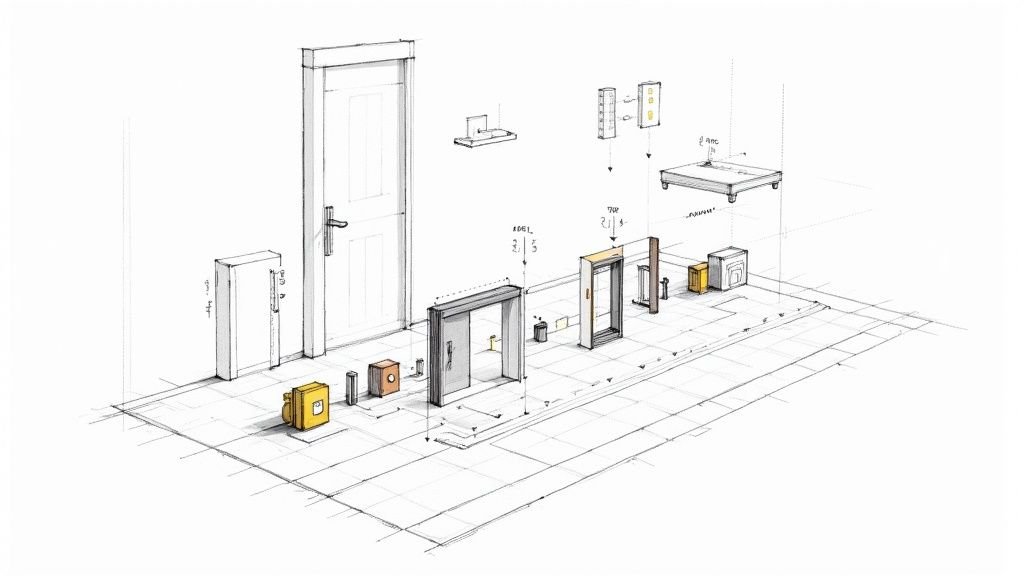

Naming Standards As A Common Language

Inconsistent naming is the silent killer of efficiency. When one person names a detail "WD-01" and another calls it "Wall Detail – Window Head," you create digital chaos that makes finding information nearly impossible.

Robust naming conventions are the common language for your entire production operation. They must cover everything—project files, model elements, sheet numbers, and detail families. This isn't about being rigid; it's about engineering clarity into your AEC operations. A clear standard means less time searching and more time designing.

Model Governance and Detail Libraries

A BIM model is a living database. Without rules, it quickly becomes bloated, slow, and unreliable. Model governance is the set of rules that maintains a healthy digital environment, defining things like model ownership, workset discipline, and when to purge unused elements.

Your detail library is your firm's collected wisdom. It’s a curated repository of proven, pre-vetted solutions that prevents your team from reinventing the wheel on every project.

By establishing clear governance, you ensure your BIM production workflows remain efficient. This is especially critical as projects get more complex. The global architectural services market is valued at $249.2 billion in 2025, with construction output projected to rise 42% by 2030. That growth will demand greater efficiency from firms hoping to capture a share of increasingly complex projects. You can find more insights in the global architectural services market report on IBISWorld.

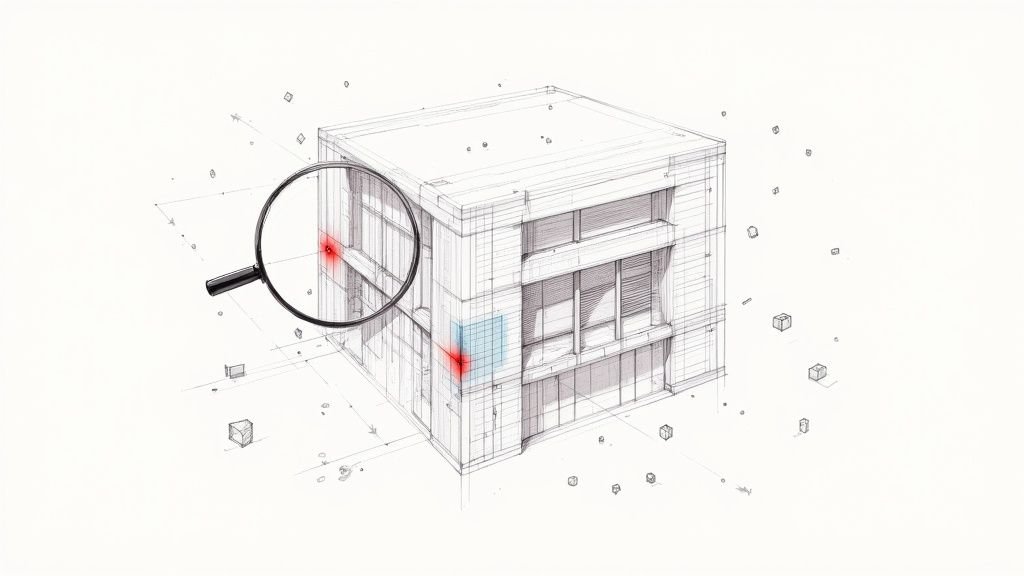

QA/QC Checkpoints and Kickoff Frameworks

Finally, your system needs decision checkpoints. QA/QC checkpoints are non-negotiable review stages—not just at the end, but throughout the project lifecycle. They act as quality gates, catching issues before they move downstream. This replaces the last-minute redline scramble with a proactive, structured review process for permitting prep.

A kickoff framework is the perfect partner to this. It’s a structured meeting that aligns the entire team before a single line is drawn. Standards are reviewed, goals are set, and roles are clarified. This simple act prevents countless downstream errors by ensuring everyone starts on the same page, with the same playbook.

Together, these building blocks form a resilient system that supports scaling architectural teams by making quality a feature of the process itself, not an accident of individual talent.

Implementing BIM Production Workflows That Actually Work

Having documented standards is one thing. Getting your team to actually follow them is another challenge entirely.

Many firms have a dusty binder of BIM standards that looks nothing like their day-to-day architecture production process. The real work isn’t in writing the standards—it’s in building the discipline and systems to make them stick, moving from a CAD-to-BIM evolution in mindset.

In the old CAD world, a drawing was just lines on a page. In BIM, the model is a living database, and every change has ripple effects. Without solid enforcement, standards crumble, models get corrupted, and all those promised BIM efficiencies vanish.

We’ve seen firms slash rework once they replaced individual habits with production systems. This doesn’t happen by accident. It’s the result of building a culture of consistency, backed by practical training, clear documentation, and a firm-but-fair approach to enforcement.

From Document to Discipline

The difference between a successful BIM implementation and a failed one rarely comes down to the quality of the standards document. It's all about the operational discipline you build around it. The goal is to make following the standard the path of least resistance.

You're essentially turning abstract rules into concrete, daily habits for your team. It’s about making the "right way" the "easy way."

This cultural shift is more important than ever. The global Architecture, Engineering, and Construction (AEC) market is expected to hit a massive $16.3 trillion in 2025. To keep up, 53% of architecture firms are already using AI, and advanced BIM is the norm for complex projects. You can find more on these AEC industry trends at OpenAsset.com.

A standard nobody follows is just a suggestion. A system that guides, checks, and reinforces the standard is a production engine. This distinction makes all the difference in protecting your margins and delivering predictable results.

Core Pillars of a Sustainable BIM Workflow

To make your standards a living, breathing part of your operations, focus on three key areas. These pillars ensure your workflows are not only adopted but stick around for the long haul, surviving everything from staff turnover to last-minute deadline pressure.

- Systematic Onboarding and Training: Don’t just hand a new hire a 100-page manual. Create a structured training path with checklists, hands-on exercises, and clear milestones. Onboarding should be a system, not a casual mentorship that changes with every new employee.

- Embedded QA/QC Checkpoints: Quality control can’t be an afterthought. Build automated and manual checks directly into your workflow at key project stages—like before issuing drawings for consultant coordination or submitting for a permit. Think of them as quality gates that stop errors from moving downstream.

- Proactive Model Governance: Your BIM Manager or Production Director needs to perform regular, proactive health checks on project models. This isn't micromanaging. It's about catching and correcting bad habits before they corrupt the model and throw the project off track.

Making Standards Stick

Discipline without the right tools is just wishful thinking. Your standards need to be baked into the project environment your team uses every single day. This is where a well-structured BIM Execution Plan (BEP) becomes non-negotiable.

A BEP translates high-level company standards into project-specific rules of the road, defining roles, responsibilities, and key deliverables. If you want to dive deeper, check out our guide on creating an effective BIM Execution Plan. It's the playbook for that specific project, making sure everyone knows the rules of the game from day one.

Ultimately, implementing effective BIM production workflows is about engineering accountability directly into your process. When templates are locked, checklists are mandatory, and model reviews are scheduled events, you create an environment where consistency becomes the default. This systematic approach is the only way to ensure your firm’s standards can survive the chaos of real-world project delivery.

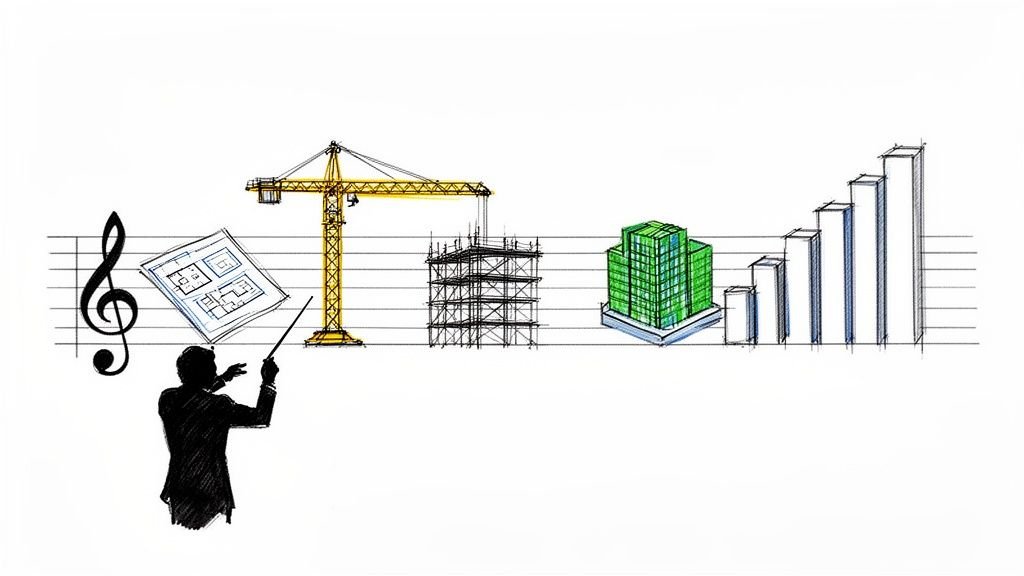

From Endless Redlines To Predictable Project Delivery

For many architecture firm owners, the final stretch of a project is a familiar nightmare. It’s a chaotic storm of last-minute redlines, late-night heroics, and that sinking feeling as profit margins evaporate. Contractors flood your inbox with RFIs born from unclear drawings, and the churn of rework becomes the default tempo.

This isn’t a sign of a bad team; it’s the predictable outcome of a broken system.

Now, imagine the alternative: a state of operational calm where delivery is predictable. Where information flows cleanly from the design model to the job site. Where your team isn’t fighting fires but executing a well-defined plan. This isn’t a fantasy—it’s the direct result of having robust architecture production systems in place.

This shift from chaotic to calm isn't about working harder. It’s about working smarter by embedding clarity and control directly into your workflows.

Protecting Margins By Preventing Rework

Rework is the silent killer of profitability in architecture. Every time a detail is redrawn, a dimension is corrected, or a clash is resolved late in the game, you are giving away free work. Strong production systems attack this problem at its source.

- Disciplined Templates: When every project starts with a rigorously developed template, you eliminate hundreds of small decisions that lead to inconsistencies. We’ve seen firms achieve incredible consistency just by improving their foundational project setups, a topic we dive into in our guide to crafting powerful Revit templates.

- Built-in QA Checkpoints: Instead of one massive, high-stress review right before a deadline, the system introduces smaller, mandatory checks at key milestones. This catches errors when they are small and cheap to fix, not large and catastrophic.

- Standardized Detail Libraries: Your team pulls from a library of pre-approved, proven details instead of reinventing the wheel on every project. This dramatically reduces both drafting time and the risk of errors.

These elements work together to build a defensive wall around your project margins. They transform quality control from a last-minute scramble into a continuous, proactive process.

From Ambiguity to Clarity for Contractors

Let's be honest: contractors don’t send RFIs for fun. They send them when construction documents are ambiguous, contradictory, or incomplete. Every single RFI represents a breakdown in communication and a potential delay on site.

A firm with mature architecture production systems produces documents that are exceptionally clear. The system demands it.

Predictable delivery is the ultimate competitive advantage. Clients and contractors don't just value great design; they value reliability. A firm that consistently delivers clear, coordinated documents on time becomes the go-to partner.

When every sheet looks the same, when naming conventions are clear, and when details are drawn from a single source of truth, contractors can build with confidence. This cuts down on friction, prevents costly change orders, and builds a reputation for professionalism that wins repeat business. The whole dynamic shifts from reactive problem-solving to proactive, predictable execution.

This operational consistency is the bedrock for scaling architectural teams. You're no longer dependent on the individual habits of a few key players. Instead, you're running a delivery engine that produces reliable results, project after project. This isn't about being rigid; it’s about being dependable—and in this industry, dependability is currency.

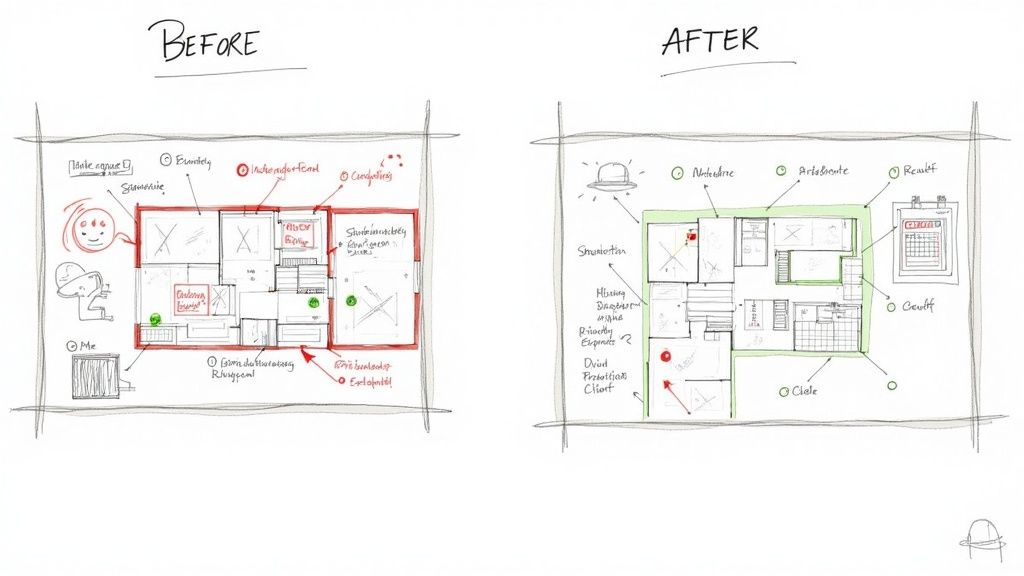

Your First Steps To A Scalable Production System

Overhauling your firm’s entire operation is a massive undertaking, and honestly, it’s not the right way to start. Building a resilient, scalable production system isn't about a disruptive teardown. It’s about securing small, deliberate wins that create real momentum.

Instead of trying to boil the ocean, focus on a single, high-impact area. Pick one spot where you can bring immediate clarity and see a tangible return. This incremental approach is far more sustainable. The firms that pull this off don’t wait for the perfect moment—they start where the pain is sharpest, whether that's a chaotic project kickoff or a messy server.

Start With A Single, High-Impact Win

Pick one area to systematize first. The goal here is to solve a real, nagging problem and get your team's buy-in by showing them a better way is possible.

Here are a couple of practical starting points:

- Standardize Your File Structure: Create a non-negotiable folder template for every new project. It’s a simple act of discipline, but it wipes out confusion and saves countless hours that your team would otherwise waste hunting for files.

- Develop a Project Kickoff Checklist: Document the essential steps and talking points for every single project launch. This makes sure every team member starts on the same page, with the same information, preventing a ton of downstream errors.

Build Incrementally and Iterate

Once you've nailed down one piece of the system, move to the next. After standardizing your file structures, maybe you tackle the naming conventions for your BIM elements. After mastering the kickoff checklist, you could create your first QA/QC checkpoint for the Schematic Design phase.

This iterative process creates a positive feedback loop. Each small improvement makes life easier for your team, which builds enthusiasm for the next change. To really get this moving, the next step is to understand how to automate business processes—a fundamental skill for any modern architecture firm.

The core idea is to replace individual habits with a shared playbook, one page at a time. Consistency isn't achieved overnight; it's built through a series of small, intentional steps.

This systematic approach also future-proofs your firm. Consider this: the construction sector was responsible for 32% of global energy demand in 2023. As sustainability becomes non-negotiable, having strong architecture production systems will be essential for weaving in new efficiency standards without causing operational chaos. You can read more about this trend in the 2024 Global Status Report for Buildings and Construction.

Firms don't scale on talent alone. They scale because their systems create consistency, no matter who is doing the work or how tight the deadline is. You now have a practical path forward.

For a head start, grab our Production System Starter Blueprint. It’s a practical framework to help you pinpoint your first, highest-impact area for improvement.

Common Questions About Architecture Production Systems

Switching to a more systematic way of working always brings up good questions. Firm leaders, understandably, want to know if the effort is going to pay off and how it might change their studio's culture. Here are a few of the most common questions we hear from firms navigating this shift.

Will Systems Stifle Our Creativity?

This is a big one. There's a real fear that putting rigorous architecture production systems in place will turn designers into robots and snuff out the creative spark. But the reality is actually the complete opposite.

Think about it. When your team isn't constantly reinventing file structures, digging for the right detail, or fixing drawings that don't match, they get a ton of mental energy back. Good systems take care of the repetitive, low-value stuff, freeing up your sharpest minds to focus on what really moves the needle: design innovation and solving tough client problems. Predictability in production actually creates more room for creativity, not less.

Systems don't limit great designers; they liberate them from the administrative churn that bogs down the design process.

How Do We Get Senior Staff On Board?

Getting buy-in from your most experienced people can definitely be a hurdle. They often have personal habits and workflows that have served them well for decades. The key is to frame the change not as a critique of their methods, but as a way to scale their expertise for the entire firm.

Show them how a central detail library can capture their best solutions for everyone to use. Better yet, involve them in defining the new standards, making them the architects of the new system. When senior staff see the goal is to make their hard-won knowledge the firm-wide standard, they often become the biggest champions of the change.

What Is The First Step We Should Take?

The most common roadblock is just not knowing where to start. My advice? Don't try to boil the ocean. The best way forward is to pinpoint the single biggest point of friction in your current BIM production workflows and tackle that first.

- Is project setup a chaotic mess every single time? Focus on creating a rock-solid project template.

- Are you drowning in RFIs from the contractor? Start by building a simple QA/QC checklist for every drawing set that goes out the door.

- Is onboarding new hires painfully slow? Just start by documenting your file structure and naming conventions.

Pick one area, get a win, and use that momentum to roll into the next improvement.

We get it—these are tough questions with a lot of nuance. To help you navigate the process, we've put together a table answering some more frequently asked questions about implementing new production systems.

Frequently Asked Questions

| Question | Answer |

|---|---|

| How long does it take to see a return on investment (ROI)? | You can see small wins almost immediately in reduced errors and faster setup times. A more significant ROI, like a 15-20% reduction in production hours, typically becomes clear within 6-12 months as the systems become second nature. |

| Do we need a dedicated "BIM Manager" to make this work? | Not necessarily, especially for smaller firms. You do, however, need a "champion"—someone who owns the system, keeps it updated, and helps train the team. This role can often be filled by a senior project architect. |

| Will this require expensive new software? | Often, no. The biggest gains come from standardizing how you use the tools you already have, like Revit or AutoCAD. The investment is more in time and strategic thinking than in new licenses. |

| What happens if our team doesn't follow the new standards? | Adoption is key. That's why involving the team in creating the standards is so important. Start with clear documentation, provide training, and make the "right way" the easiest way. Gentle, consistent enforcement from leadership helps, too. |

Building resilient systems is a journey, not a destination. But with a clear strategy and a focus on solving one problem at a time, any firm can make the transition from reactive chaos to proactive clarity.

At BIM Heroes, we help firms build these kinds of resilient systems every single day. If you're ready to move from chaos to clarity, our production system blueprint can give you a clear roadmap.