Shop Drawings, As-Builts, and Record Drawings: Definitions That End the Confusion

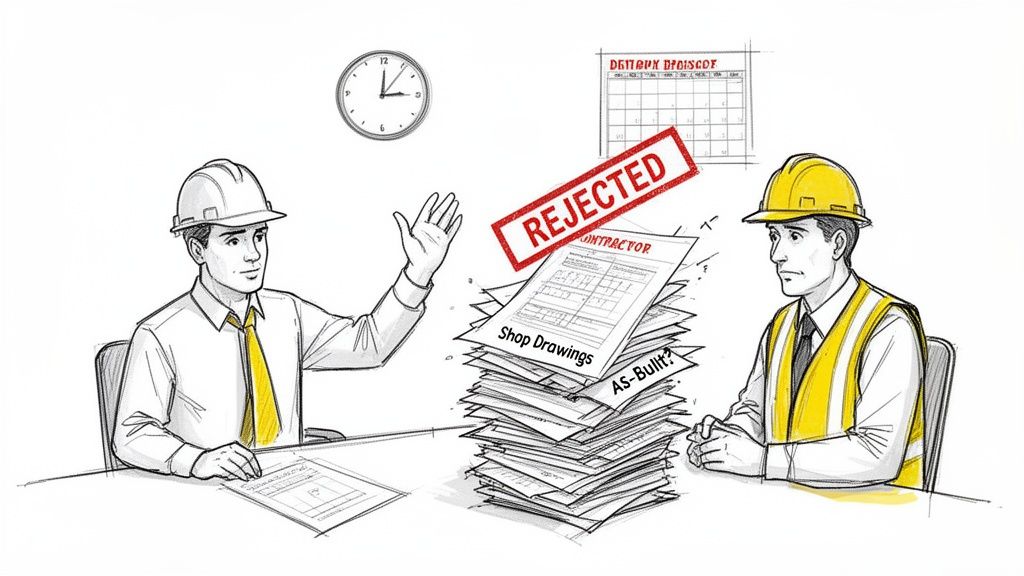

Imagine this: a project manager rejects a contractor's final payment application because their "as-built" submission is actually just a pile of marked-up shop drawings. This isn't a rare mix-up; it's a common source of delays, payment disputes, and coordination failures that erode project margins. When teams use these terms interchangeably, they create predictable friction.

Getting the definition of shop drawings, as-builts, and record drawings right isn’t just about semantics—it’s about operational consistency, margin protection, and predictable project delivery.

Why the Confusion Costs You Real Money

The confusion between shop drawings, as-builts, and record drawings is understandable. They often look similar and their timelines can overlap. But mistaking one for another is a critical error with very real consequences, from preventing RFIs to ensuring a clean handover that protects the owner’s long-term interests.

We've seen project closeout timelines cut by weeks when teams understood the distinct definition and purpose of shop drawings, as-builts, and record drawings from day one. When those lines blur, you get preventable rework, contractual disputes, and warranty issues that hit the budget directly.

Real-World Consequences of Vague Definitions

When your project team—from the architect to the subcontractor—doesn't share a common language for construction documentation, the fallout is predictable and expensive. These aren't just hypotheticals; they are scenarios we see play out in the field.

- Payment Disputes: A contractor submits what they call "as-builts" to trigger their final payment. The architect rightfully rejects the submittal because it's just a stack of uncoordinated, red-lined shop drawings, slamming the brakes on the payment process and kicking off disputes that delay closeout.

- Renovation Coordination Failures: Years later, a facility manager plans a tenant fit-out using the owner's "record drawings." They discover the documents were actually the contractor's unverified as-builts, which completely missed a critical rerouted plumbing line. The result is a costly change order and a major delay during the new construction.

- O&M Manual Gaps: A facility team can't locate a specific valve for emergency shutoff because the handover documents were a jumbled mix of old design drawings and partial as-builts. This documentation gap makes routine maintenance a nightmare and creates serious operational risks.

These aren't isolated incidents; they're symptoms of a systemic communication breakdown. Establishing a clear, shared understanding of these document types is the first move toward preventing RFIs, securing timely payments, and ensuring a clean project handover.

Shop Drawings: The Complete Definition

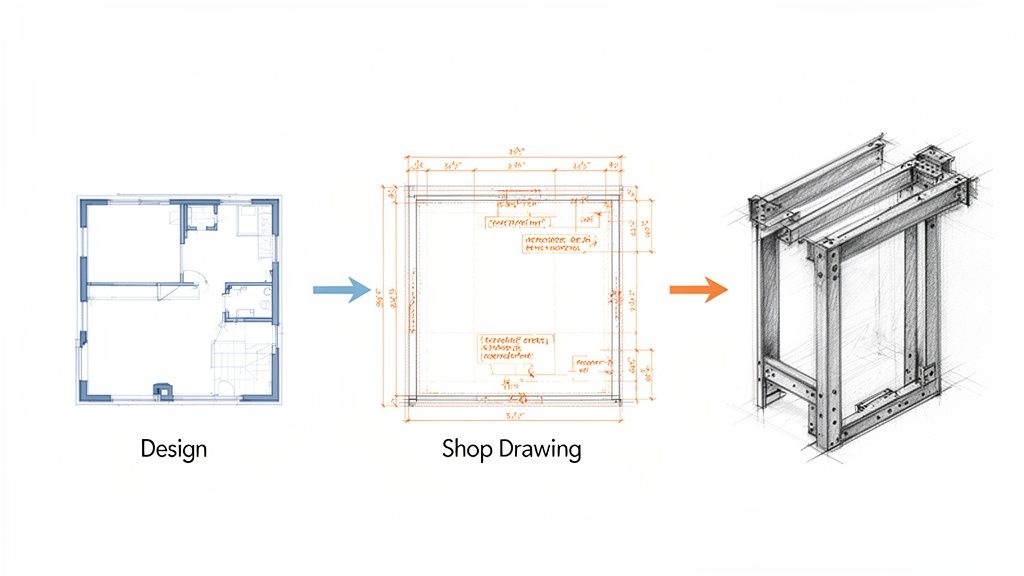

If you’ve ever wondered how an architect’s design intent becomes a physical, buildable reality, the answer lies in shop drawings. They are the crucial bridge connecting the design concept in contract drawings to the tangible components fabricated in a workshop. They are a core part of a mature production workflow.

Think of it this way: the architect’s drawings show the "what" and "where"—the overall design, dimensions, and placement. Shop drawings define the "how." They are hyper-detailed instructions created not by the design team, but by the fabricators, suppliers, and subcontractors who will actually build the pieces. They provide answers before fabrication begins, preventing costly guesswork.

When They're Created & Who Creates Them

Shop drawings are created during pre-construction, before fabrication or installation begins. The responsibility falls to the subcontractor, supplier, or fabricator responsible for manufacturing the component—like the steel fabricator, millwork shop, or curtain wall manufacturer. Their deep product and manufacturing knowledge is essential.

What They Contain & Their Purpose

A good shop drawing leaves nothing to interpretation. It translates design intent into a precise manufacturing guide. When a subcontractor submits a shop drawing, they are certifying they have field-verified conditions and understand how to produce the component to fit perfectly within the coordinated project model. This makes the review process a critical decision checkpoint.

Key contents include:

- Precise fabrication dimensions, tolerances, and connection details.

- Specific material specifications, product models, finishes, and part numbers.

- Assembly instructions and manufacturing standards.

- Coordination details showing how the component interfaces with adjacent trades.

Their purpose is to gain approval from the architect and engineer that the fabricator's interpretation aligns with the design intent before material is cut. This proactive QA process is fundamental to margin protection, especially with the rise of prefabrication.

Legal & Contractual Status

A shop drawing is the fabricator's proposed method for executing the work. The architect's review is for conformance with the design concept and contract documents. However, as noted by legal experts, the responsibility for the means, methods, and accuracy of the drawing remains with the fabricator. You can read more about construction drawing risk on jimersonfirm.com.

As-Built Drawings: The Complete Definition

If shop drawings are the pre-game plan, as-built drawings are the live field record of what actually happened during construction. They are the contractor's on-the-ground documentation of every deviation, adjustment, and change from the original contract drawings. Their entire purpose is to capture the finished reality, which rarely matches the initial plans perfectly.

When They're Created & Who Creates Them

As-builts are created concurrently with construction, not before or after. The responsibility for creating them lands squarely on the General Contractor and their subcontractors. They are in the field witnessing the changes as they happen. Submitting accurate as-builts isn't just good practice; it's a standard contractual deliverable required for final payment.

What They Contain & Their Purpose

As-builts are essentially a red-lined, annotated diary of the project. They are often marked up by hand in the field, but they are packed with essential information that forms the basis for the final project archive. Their value lies in their immediacy and authenticity—a truthful record of what was installed and where.

A solid set of as-builts will include markups showing:

- Final, field-verified locations of hidden elements like in-wall plumbing and electrical conduits.

- Dimensional changes that differ from the original design.

- Material substitutions that were approved during construction.

- Details of any significant deviations, often referencing the associated RFI or change order.

The purpose is to create a factual record of the constructed work. Without this running log, the project’s institutional knowledge evaporates the moment the construction team leaves the site.

Legal & Contractual Status

As-built drawings are the contractor's certification of the final constructed conditions. They are a critical deliverable, and their accuracy is the contractor's responsibility. The owner and architect rely on this information to be a truthful representation of the work performed, and it is a prerequisite for project closeout and final payment release.

Record Drawings: The Complete Definition

After the contractor’s work is done and as-builts are submitted, one final step remains: creating the record drawings. This is the official project archive, the definitive "as-is" set of documents the owner will rely on for decades of facility management, maintenance, and future renovations.

If as-builts are the raw field notes, record drawings are the polished, verified final edition. They represent a formal handover of information from the construction team to the owner, synthesized by the design professional. This deliverable is a cornerstone of a successful project closeout.

When They're Created & Who Creates Them

Record drawings are prepared after construction is substantially complete, during the project closeout phase. The responsibility for creating them almost always falls to the Architect or Engineer of Record. They take the contractor's as-built markups and meticulously incorporate that information into the original BIM model or CAD files.

What They Contain & Their Purpose

Record drawings are far more than just tidied-up as-builts. The architect integrates all relevant information into one coherent set of documents, creating a single source of truth for the owner.

Key contents include:

- Incorporated as-built markups: All field-verified changes are professionally drafted into the drawings.

- Official change orders: All approved changes are formally incorporated, ensuring the drawings reflect the final contractual scope.

- Key RFI clarifications: Information from critical RFIs is added to provide complete context.

The purpose is to give the building owner a clean, reliable set of documents for the building's entire lifecycle, which is essential for any future work or facility management task.

Legal & Contractual Status

Record drawings carry professional liability for the architect or engineer. While they rely on the accuracy of the contractor's as-built notes, they are professionally responsible for accurately transcribing that information into a final, cohesive set of documents. This distinction is critical from a risk management perspective. The architect is not field-verifying the conditions, but providing a professional service to compile all known changes into the official project archive.

Side-by-Side Comparison: Shop Drawings vs. As-Builts vs. Record Drawings

To cut through the noise, here’s a simple table breaking down the key differences. Use this as a cheat sheet on your next project to clarify responsibilities and ensure everyone is speaking the same language. It's a foundational tool for establishing predictable project documentation workflows.

| Attribute | Shop Drawings | As-Built Drawings | Record Drawings |

|---|---|---|---|

| Timing | Pre-Construction (Before Fabrication) | During Construction | Post-Construction (At Closeout) |

| Creator | Subcontractor, Fabricator, Supplier | General Contractor & Subcontractors | Architect or Engineer of Record |

| Purpose | To detail fabrication & installation methods | To document in-field changes & deviations | To create a final, official archive for the owner |

| Content | Hyper-detailed specs for a single component (dimensions, materials, assembly) | Red-lined markups on contract drawings showing final locations & changes | Clean, consolidated drawings incorporating all as-built data, RFIs, & change orders |

| Recipients | General Contractor, Architect, Engineer (for review) | Architect, Engineer (for creating Record Drawings) | Owner, Facility Manager |

| Legal Status | A submittal certifying buildability; reviewed for design intent | Contractor's factual record of work performed; a contractual deliverable | The official project record; carries professional liability for the designer |

A visual timeline can also help clarify the sequence:

Project Lifecycle Timeline:

Pre-Construction -> Construction -> Closeout

(Shop Drawing Submittals) -> (As-Built Documentation) -> (Record Drawing Creation)

How to Prevent Confusion on Your Projects

Knowing the definitions is the first step. Implementing a system to enforce them is what protects your margins and ensures operational consistency. It's about moving from theory to practice with a proactive approach that establishes clear decision checkpoints.

Here are four practical tips to prevent confusion on active projects:

- Define Terms in the Kickoff Meeting: Don't assume everyone knows the difference. Dedicate 15 minutes in your project kickoff meeting to review the definition, purpose, and responsibility for each drawing type.

- Use a Detailed Submittal Log: Your submittal log should clearly specify the required drawing type for each deliverable (e.g., "Shop Drawing – Steel," "As-Built Drawings – Final"). This prevents a contractor from submitting the wrong document type at a critical milestone.

- Standardize the As-Built Process: Provide clear instructions for as-builts. Specify that they must be marked on a clean set of contract drawings and updated regularly (e.g., weekly or bi-weekly).

- Create a Closeout Documentation Checklist: Your project closeout checklist must explicitly list "Contractor's Final As-Built Drawings" and "Architect's Final Record Drawings" as separate line items with distinct due dates.

Contract Language That Clarifies Responsibilities

Ultimately, your most powerful tool is the contract itself. Vague language is an invitation for conflict. Your agreements must spell out each drawing type and pin down responsibilities.

Contract Language Recommendations:

- For Shop Drawings: "The Contractor shall submit Shop Drawings prepared by subcontractors, manufacturers, or suppliers, illustrating the precise method of fabrication and installation for project components. Review by the Architect is for conformance with the design concept only."

- For As-Built Drawings: "Throughout construction, the Contractor shall maintain a complete set of As-Built Drawings, consisting of red-lined markups on the Contract Drawings, documenting the actual in-place locations, dimensions, and routing of all work. Submission of complete and accurate As-Built Drawings is a condition precedent to final payment."

- For Record Drawings: "Upon receipt and acceptance of the Contractor's As-Built Drawings, the Architect shall prepare a final set of Record Drawings incorporating all documented field changes. These drawings will represent the final constructed condition and will be delivered to the Owner as a condition of final project closeout."

Quick Reference Summary

Let's distill this down to its core. This isn't just about different names for drawings; it's about a logical, sequential process that ensures quality and clarity from start to finish.

- Shop Drawings are created before work begins to show how something will be built.

- As-Built Drawings are created during the work to show what was actually built.

- Record Drawings are created after the work is done to provide a clean, final archive for the owner.

Adopting these precise definitions is a direct reflection of your firm’s commitment to reliable delivery. It demonstrates production maturity and shows clients you run a tight ship, where every detail is managed with intent. When a facility manager receives a clean set of record drawings on day one, it's the final proof that the project was executed flawlessly.

To help your team put these practices into action, download our Shop Drawings vs. As-Builts vs. Record Drawings Quick Reference Guide. It’s a simple, one-page resource to share with your project teams to ensure everyone is aligned from day one.

At BIM Heroes, we believe clear documentation is the bedrock of any predictable, profitable project. Our production support and BIM consulting services help firms build the systems and discipline needed for flawless execution, from the first design sketch to the final handover.

Learn how we can bring operational consistency to your projects.