What is Constructability Review (And Why It Matters)

Picture this: a multi-story building with a sleek, intricate curtain wall system. The design looks flawless in the BIM model. But once crews are mobilized and materials are on-site, a massive flaw emerges. The specified details make it practically impossible to waterproof correctly under real-world field conditions.

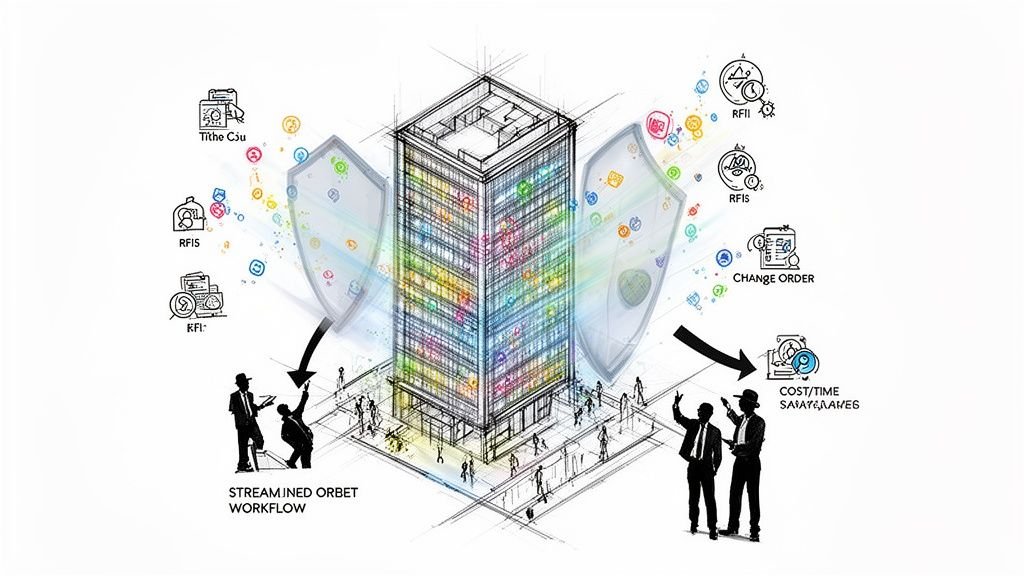

This isn't a bad dream. It’s a classic scenario that triggers a flood of RFIs, work stoppages, and a six-figure redesign. This is the exact kind of “we should have caught this in design” moment that a formal constructability review is built to prevent. It's a proactive risk mitigation process that bridges the gap between design intent and field reality.

This isn't about criticizing design or finding fault. It's about infusing field intelligence into the plans before they become expensive field problems. A constructability review is a systematic evaluation by seasoned builders who ask the tough, practical questions:

- Does this structural detail account for formwork removal?

- Can MEP trades actually access this space in the correct installation sequence?

- Will this material specification create a supply chain delay that derails the schedule?

This deep dive into construction means and methods acts as a critical decision checkpoint, protecting the project’s schedule, budget, and margins. It’s the difference between a predictable project and a chaotic one.

What is Constructability Review: The Definition

A constructability review is a formal process that examines construction documents for “buildability.” It’s a reality check performed by experienced construction professionals who analyze the design from the builder’s perspective, identifying issues that could hinder safe, timely, and cost-effective execution in the field.

This isn't just a meeting. It’s a proactive risk mitigation strategy. It ensures that what looks great on paper is actually buildable without blowing the budget or schedule.

What it Examines and Evaluates

A disciplined constructability analysis scrutinizes the practical aspects of building a design. The review team evaluates:

- Means and Methods Feasibility: Can the proposed design be built using standard construction techniques and equipment?

- Material Availability: Are the specified materials readily available, or do they have long lead times that impact the schedule?

- Installation Sequences: Does the design allow for a logical and efficient sequence of work among trades?

- Access and Logistics: Is there adequate space for material delivery, crane placement, and worker access?

- Tolerances and Fit: Are the specified tolerances realistic for field conditions, and will components fit together as designed?

- Trade Coordination: Are there conflicts between structural, MEP, and architectural systems that need resolution?

- Schedule Implications: How do design decisions impact the critical path and overall project timeline?

- Cost Efficiency: Are there alternative details or methods that could achieve the same design intent more cost-effectively?

What It's NOT (Distinguishing From Other Review Types)

It’s crucial to understand how a buildability review differs from other common project reviews. Each has a specific, non-overlapping purpose. Mistaking one for another dilutes their effectiveness and leaves risks unaddressed.

| Review Type | Primary Goal | Focus | Key Questions |

|---|---|---|---|

| Constructability Review | Ensure the design is buildable in the real world | Feasibility & Efficiency | Can we access this area? Is this sequence logical? Are these materials actually available? |

| Design Review | Assess aesthetics, function, and design intent | Program & Aesthetics | Does this meet the program? Is the aesthetic right? Is it functional for the end-user? |

| Code Review | Verify compliance with building codes and regulations | Legal Compliance | Does this meet fire codes? Is it ADA compliant? Does it meet local zoning laws? |

| Value Engineering (VE) | Reduce project costs without sacrificing core function | Cost Optimization | Can we use a different material? Is there a cheaper way to achieve the same function? |

A code review confirms a design is legal. A design review confirms it's what the owner wants. VE asks if it can be built cheaper. Only the constructability review process asks if it can be built as planned without causing massive headaches in the field. This unique focus is what protects margin, predictability, and operational consistency.

Why Constructability Review Matters

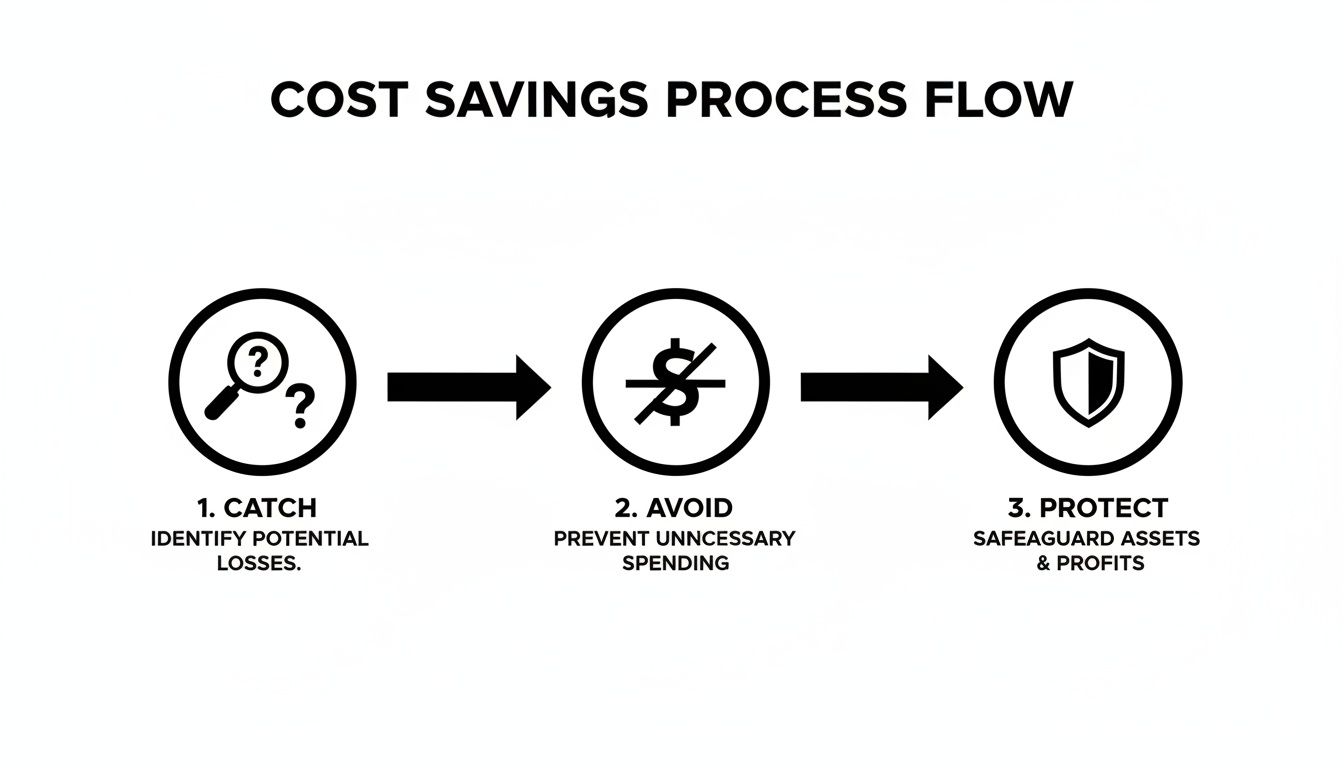

A formal constructability review isn't another layer of bureaucracy—it’s an insurance policy against bleeding profits and derailing schedules. This process turns hindsight into foresight, systematically finding and neutralizing problems when they are just lines on a page and cheap to fix, not thousands in rework, change orders, and wasted materials.

Cost Avoidance (Rework, Delays, Material Waste)

Every project manager knows that sinking feeling when an unexpected issue emerges on site. It’s not just the direct cost of the fix; it's the ripple effect of delays and trade stacking that destroys your margin. A disciplined constructability process is a cost-avoidance machine that heads off major financial headaches like:

- Expensive Rework: Catching a structural-MEP conflict before fabrication prevents costly field modifications.

- Material Waste: Identifying material availability problems before procurement avoids ordering items with crippling lead times.

- Costly RFIs and Change Orders: A proactive review reduces the ambiguity that fuels a constant stream of RFIs and change orders.

This shifts the team from reactive firefighting to proactive risk management, a fundamental step in learning how to reduce construction costs systematically.

Schedule Protection (Sequencing, Logistics, Access)

In construction, time is money. A formal buildability review is one of the most powerful tools for protecting the schedule. It dives deeper than simple clash detection to scrutinize the actual sequence and logistics of the build.

A design that looks perfect on paper can create a logistical nightmare. The review process stress-tests the schedule by asking: Can trades work efficiently in this space? Is there adequate access for material delivery? Does the sequence make sense?

Finding a sequencing issue or access constraint during design is a minor tweak. Finding it after mobilization is a crisis that can bring a project to a halt.

Quality Improvement and Risk Mitigation

Ultimately, a construction review is about achieving predictability and control. It tackles the "unknown unknowns" hiding in the documents. It’s what finds the structural detail that makes stripping formwork impossible or the MEP layout that blocks future maintenance access.

The data backs this up. The Construction Industry Institute (CII) has long documented that formal constructability programs can yield a 10:1 return on investment in cost savings. Research from organizations like the AASHTO Subcommittee on Construction reinforces this, showing that early reviews reduce delays, claims, and cost overruns. A formal review process isn't a cost center; it’s a direct investment in margin protection.

When and Who: Timing and the Review Team

A constructability review isn’t a single meeting. It's a continuous process that injects field intelligence into the design at critical stages. A review done too late is just a report on problems you can no longer afford to fix. The goal is to catch issues when changes are cheapest—when they're just lines on a screen.

When Constructability Review Should Happen

The review process should be woven into project milestones, with each phase having a distinct focus. This phased approach is non-negotiable for achieving operational consistency.

- Schematic Design (SD): This is where you have maximum leverage. The review focuses on major systems, site logistics, structural approach, and material strategies.

- Design Development (DD): As the design gets more detailed, so does the review. The team examines coordination between major trades, vets specific material selections for availability, and scrutinizes key details.

- Construction Documents (CD): This is the final, fine-toothed-comb review before procurement. It’s about sniffing out conflicts, confirming specs are clear, and ensuring the document set is coordinated for the field.

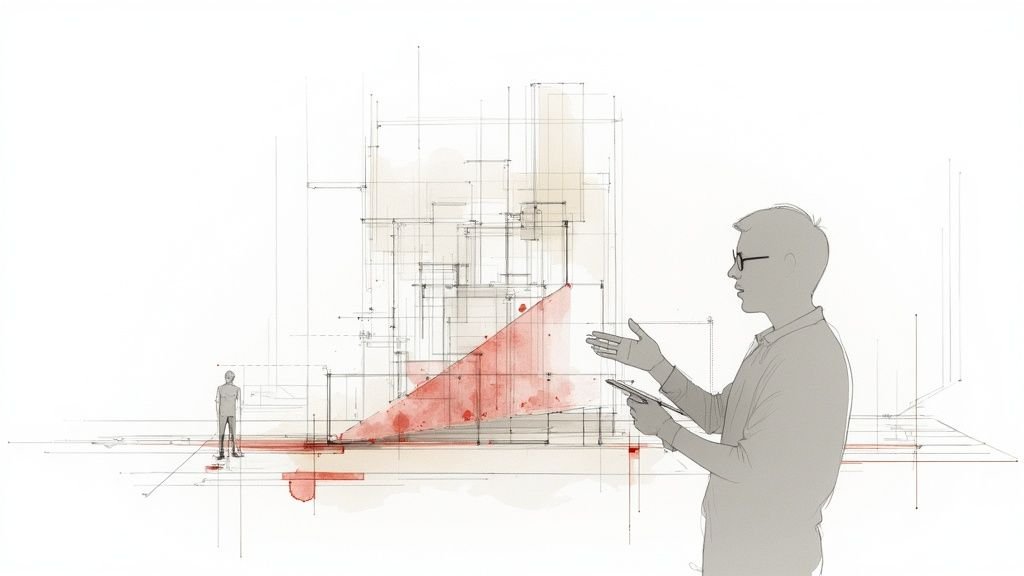

Who Performs Constructability Review

The value of a constructability analysis comes directly from the experience of the people in the room. The best feedback comes from those with dirt on their boots—the builders who understand the real-world consequences of a design decision.

The best review team is a mix of seasoned GCs, key trade contractors, and specialty consultants. Their job isn't to critique aesthetics but to pressure-test practicality from the perspective of the people who will actually build it.

Whether you use an in-house preconstruction team, a third-party expert, or scalable delivery pods, the mission is the same: get unfiltered, practical feedback.

Involving trade partners is especially powerful. The mechanical contractor will spot HVAC clearance issues an architect might miss. The concrete foreman will see formwork challenges invisible in a 3D model. This is where you get a raw look at how builders evaluate your construction drawings and what makes them lose trust. Their insights are key to a truly buildable design.

What a Constructability Review Actually Catches

A disciplined review goes beyond the lines on a page. It’s a systematic gut check that digs into the practical realities of putting work in place. We've seen constructability reviews catch issues that would have added weeks to schedules and hundreds of thousands to budgets—problems invisible on drawings but obvious to experienced builders.

Here are 5-7 common issues a design constructability review identifies:

- Unrealistic Tolerances: A design specifies a tolerance that is impossible to achieve with standard field methods, leading to fit-up issues and rework.

- Structural-MEP Conflicts: A structural beam placement is perfectly sound but directly obstructs a critical duct run that was routed later in the design process.

- Impossible Sequencing: A concrete pour sequence is detailed in a way that blocks access for subsequent pours, requiring costly pumping or re-sequencing.

- Material Availability Problems: A specified facade panel has a nine-month lead time from a single-source supplier, creating a massive risk to the critical path.

- Access Constraints: The planned location for the tower crane is situated over a buried utility that cannot support the load, forcing a last-minute logistical crisis.

- Unmaintainable Systems: MEP equipment is placed in a ceiling with no access panels, meaning a simple filter change would require demolishing a hard lid.

- Flawed Weatherproofing Details: A curtain wall detail looks elegant on paper but is physically impossible for a worker to seal effectively in field conditions, guaranteeing future leaks.

The Constructability Review Process

A successful review is more than just identifying problems; it's about systematically documenting them, recommending solutions, and ensuring those solutions are incorporated back into the design.

How It’s Conducted

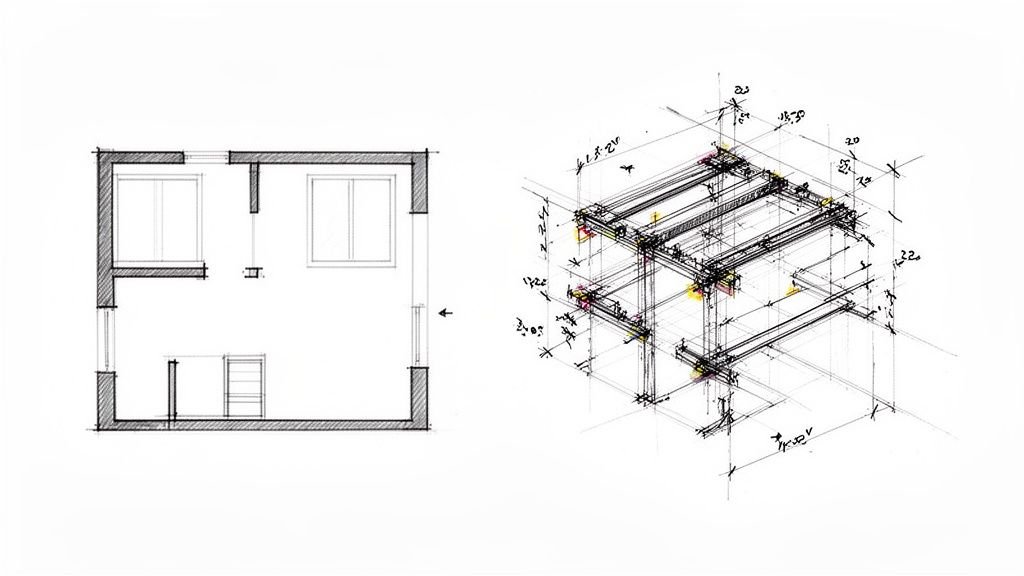

The process typically involves a dedicated review team examining documents at each design milestone (e.g., 30%, 60%, 90% CDs). Using checklists and their own experience, they redline drawings, generate questions, and meet with the design team to resolve issues collaboratively.

Deliverables and Documentation

The output isn't a vague list of complaints. The deliverables are professional, actionable tools that drive decisions:

- Marked-Up Drawings: Visual comments directly on the plans showing the location and nature of each issue.

- Written Reports: A formal summary of findings, categorized by discipline and prioritized by severity.

- Issue Log/Matrix: A spreadsheet tracking each issue, its potential impact, the recommended solution, and its final resolution status.

- Alternative Approaches: Where applicable, suggestions for more buildable details or sequences that still meet the design intent.

This rigorous documentation transforms the review from an informal chat into a disciplined quality assurance (QA) process and a valuable permitting prep tool.

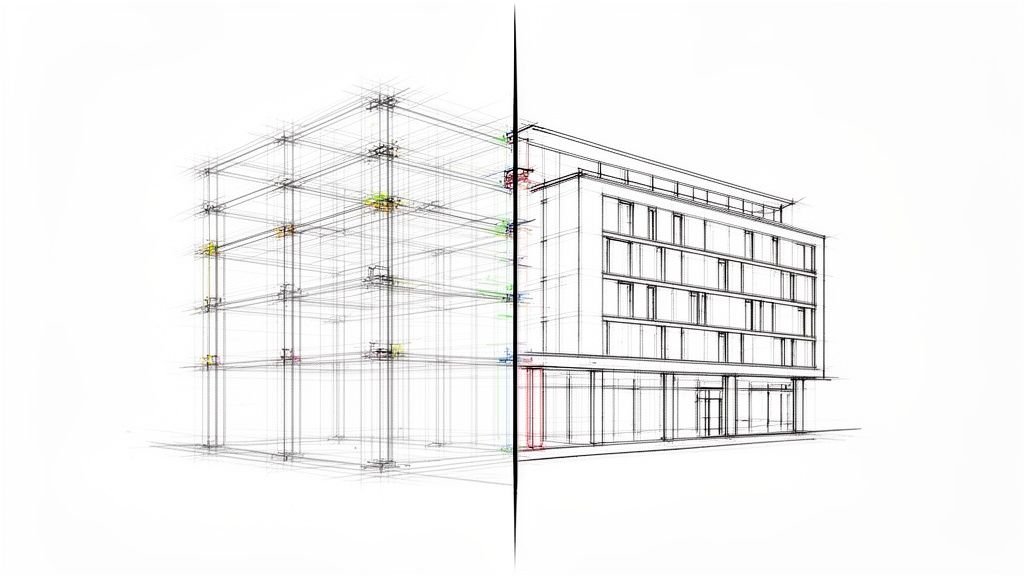

How BIM Enhances Constructability Review

Building Information Modeling (BIM) doesn't replace field wisdom; it supercharges it. BIM workflows transform a static, manual check into a dynamic, data-rich simulation, making the abstract tangible and the invisible obvious.

3D Visualization of Complex Conditions

The most obvious win is seeing the project in three dimensions. Complex geometries and tight clearances that are difficult to decipher on 2D plans become immediately clear in a 3D model, allowing builders to virtually "walk" the site and spot spatial conflicts.

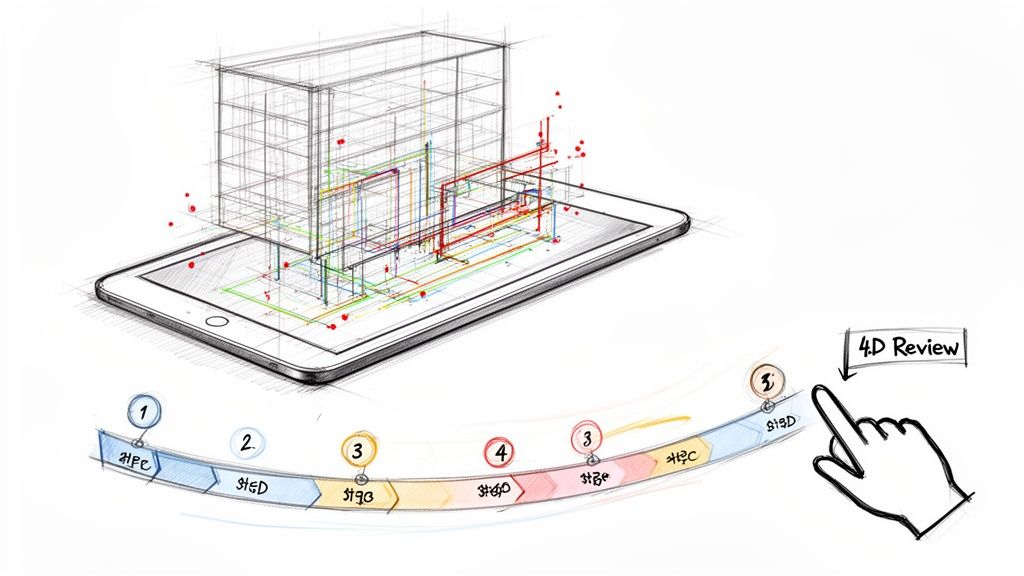

Sequence Simulation (4D)

Adding the fourth dimension—time—to the model allows the team to simulate the entire construction timeline. This 4D sequencing flushes out logistical flaws, out-of-sequence work, and site congestion before they can cause chaos in the field.

Clash Detection Integration

While a traditional review relies on sharp human eyes, BIM automates the grunt work of finding interferences. Automated clash detection in BIM can identify thousands of conflicts between MEP, structural, and architectural systems when they cost nothing to fix. This evolution from basic CAD-to-BIM workflows into mature, integrated processes can even lead to advanced applications like digital twin examples, which allow for continuous analysis throughout a project's life.

The Bottom Line: From Paper to Predictable Reality

A constructability review isn't an optional luxury or a bureaucratic checkbox. It’s a systematic process for stress-testing a design against the realities of the field—catching buildability issues when they're cheapest and easiest to fix.

The goal isn't simply to build what's designed and deal with problems as they arise. The goal is to review constructability throughout the design process so that what's designed is actually buildable. This commitment to production maturity and template discipline is what protects margins, ensures predictability, and provides the operational consistency that separates the best firms from the rest.

A disciplined constructability review process is one of the most effective ways to ensure project success. To help you implement this on your own projects, we've developed a framework based on best practices. Get our Constructability Analysis Framework to start building with more clarity and confidence.