Drained vs. Pressure-Moderated Rainscreens: A Technical Guide

A rainscreen cladding system is a multi-layered exterior assembly designed for superior moisture control. It consists of an outer cladding panel, an air cavity, a water-resistive barrier (WRB), and the structural wall. Together, these components manage water and air to keep a building dry and durable. But how they perform that function is where the critical details lie.

Drained vs. Pressure-Moderated Rainscreens Explained

The terms "drained rainscreen" and "pressure-moderated rainscreen" describe two distinct performance strategies, not interchangeable marketing labels. The difference is grounded in physics: one manages water that gets in, while the other aims to stop the forces that push it in.

Understanding this functional divide is the first step toward buildable differentiation. The name specified on the drawings matters far less than how the assembly’s components will actually behave under wind and rain. The difference isn’t terminology — it’s how the assembly actually manages air and water in the real world.

Performance Logic Over Definitions

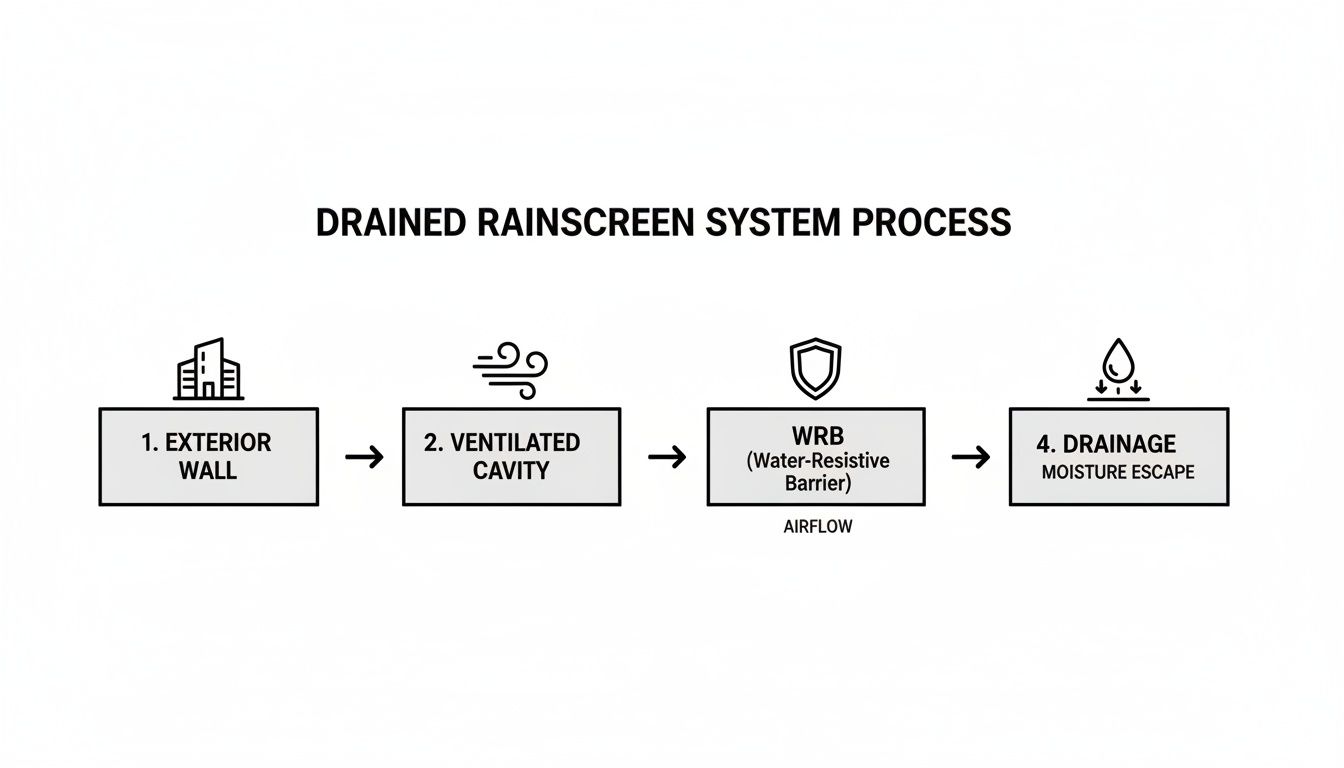

A drained rainscreen accepts that some water will breach the outer cladding. Its primary function is to provide a clear path for that water to drain harmlessly out of the assembly. It is a passive water management system.

A pressure-moderated rainscreen is an active defense system. It is engineered to neutralize the air pressure differential between the exterior and the cavity—the primary force that drives water into a wall. This requires a much higher degree of design discipline and detailing precision.

This core distinction shifts the focus from industry jargon to the real-world physics of the building envelope. One drains what gets in; the other works to prevent it from being forced in at all.

Why This Distinction Protects Margins

When design clarity is missing, the failures are predictable: moisture intrusion, staining, corrosion, and degraded thermal performance. These issues trigger a cascade of RFIs, expensive rework, and damage to your firm’s reputation. Margin protection starts with design clarity.

By grounding your project in the right performance principles, you build in predictability and operational consistency. This guide provides a technical breakdown to ensure your design intent survives contact with reality. Mastering these concepts aligns with the precision demanded by robust architectural drawing standards. First, let's look at the force that makes these systems necessary.

The Unseen Force: How Air Pressure Drives Water Intrusion

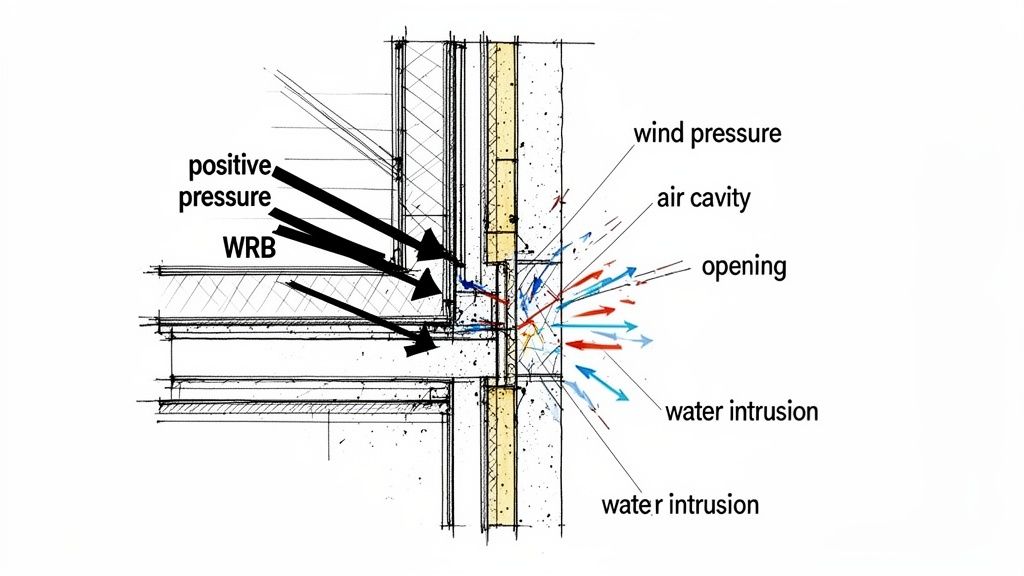

Water doesn't just passively run down a façade; it's actively forced into gaps and joints. While gravity and surface tension play a role, the most relentless force a rainscreen cladding system must overcome is the air pressure differential. This is the culprit behind most bulk water intrusion.

When wind strikes a building, it creates positive pressure on the exterior surface. The air within the wall cavity and inside the building remains at a lower, more neutral pressure. This imbalance creates a powerful force, pushing rainwater on the cladding surface through any available opening, no matter how small.

The Physics of Façade Moisture Control

For water to penetrate a wall assembly, three conditions must exist simultaneously:

- Water is present on the surface.

- An opening exists for water to enter.

- A force is present to drive the water through the opening.

A drained rainscreen concedes the first two points, accepting that water will get past the cladding and find openings. It focuses solely on managing the water once it’s inside. A pressure-moderated rainscreen attacks the third condition: it is designed to eliminate the force by neutralizing the air pressure differential. This is the core of high-performance façade moisture control.

Why Detailing Quality Matters More Than Terminology

Think of wind pressure like a syringe. Pushing the plunger forces liquid out; the wind hitting a building acts like a thumb on that plunger, forcing water into the lower-pressure cavity behind the cladding. This is why a system with minimal gaps can still leak significantly during a wind-driven rain event.

The demand for enclosures that withstand these forces is growing. Stricter energy codes and the need for resilient materials are driving innovation. You can discover more insights about the North American market growth and its drivers.

The lesson learned in the field: you cannot ignore air pressure. A drainage gap is a passive defense; controlling the pressure differential is an active strategy.

This physics explains why detailing quality is paramount. A discontinuity in the air barrier, a poorly sealed penetration, or a flawed flashing detail isn't just a potential drip. It's an invitation for pressure to drive moisture deep into the assembly, compromising long-term performance. This is where BIM for façade systems becomes non-negotiable for modeling and verifying these critical details before they become problems.

Functional Deep Dive: The Drained Rainscreen System

A drained rainscreen is the industry's default, but its function is often misunderstood. It is not designed to be an impenetrable barrier. Instead, it is built to manage the inevitable moisture that gets past the cladding by providing a clear, controlled path for it to exit safely.

Think of it as a controlled management plan, not a prevention strategy. The system accepts that water will enter the air cavity and focuses on drainage and drying.

The Drainage Path and Drying Mechanism

When wind-driven rain hits the façade, some water is forced through panel joints and openings into the air cavity. From there, the system takes over:

- Entry: Water enters the air cavity behind the outer screen.

- Drainage: Gravity pulls the water down the back of the cladding or, more critically, down the face of the continuous water-resistive barrier (WRB). The air cavity acts as a capillary break, preventing water from clinging and bridging to the WRB.

- Exit: Water collects on through-wall flashings and exits the assembly through weep holes or open joints at the base of the wall and above openings.

Beyond drainage, the air cavity facilitates drying. Ventilation allows air to circulate and evaporate residual moisture, preventing the slow degradation caused by trapped dampness. This is a core part of what rainscreen systems explained means in practice.

A lesson learned in the field: a drained rainscreen is only as good as its drainage and drying capability. If either function is compromised, performance degrades rapidly.

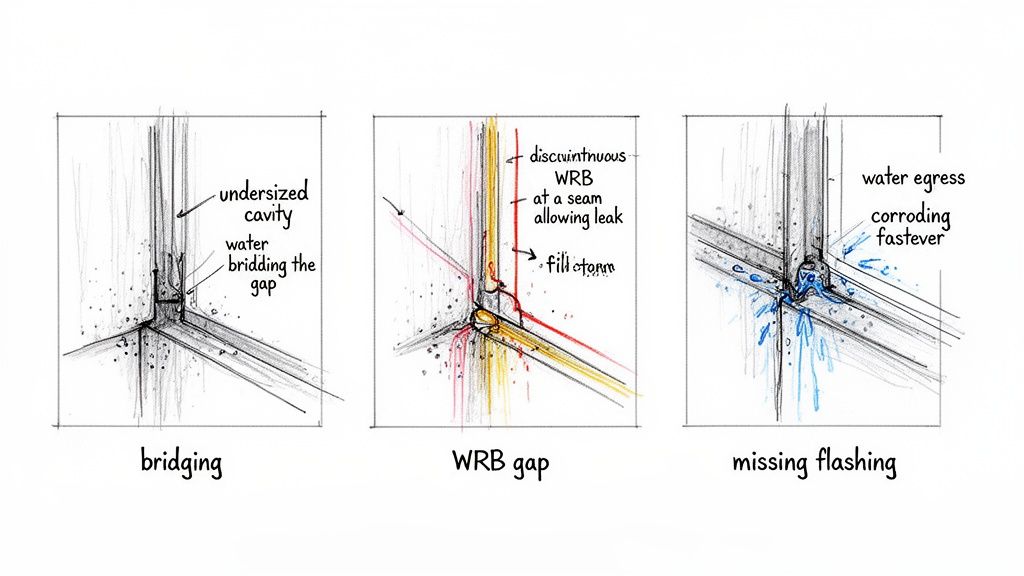

Where Drained Systems Typically Fail

The simplicity of a drained rainscreen is also its vulnerability. Failures almost always occur where the drainage path is interrupted or the WRB is compromised. These are not material failures; they are design and execution failures.

Common field and design mistakes include:

- Undersized Cavities: An air gap narrower than 3/8" allows water to bridge from the cladding to the WRB via surface tension, defeating the cavity's purpose.

- Discontinuous WRB: Improperly lapped WRB, unsealed penetrations, or gaps create direct water pathways into the structural wall. The WRB must be detailed with the continuity of a roofing membrane.

- Poor Flashing Continuity: Missing end dams or flashings that don't integrate into a continuous drainage plane trap water inside the wall, leading to corrosion and damage.

- Blocked Weep Holes: Mortar droppings or misplaced sealant can clog exit paths, turning the bottom of the cavity into a reservoir.

These issues underscore why robust façade detailing and shop drawings are non-negotiable. The drawings must clearly communicate the continuity of the drainage plane to prevent RFIs and costly field corrections.

Functional Deep Dive: The Pressure-Moderated Rainscreen

While a drained system manages water, a pressure-moderated rainscreen system manages air. This represents a significant leap in performance, shifting the strategy from passive drainage to actively neutralizing the force that drives water into a building. Achieving this, however, demands exceptional design discipline.

The core principle is simple: if the air pressure within the cavity behind the cladding is equal to the exterior air pressure, wind has no force to push rain through the joints. The system achieves this balance through an airtight barrier and compartmentalization of the air cavity.

The Role of Compartmentalization and Air Seals

A true pressure-moderated rainscreen requires two elements working in perfect unison: a continuous, robust air barrier and a compartmentalized air cavity. The air barrier is the true sealed plane of the assembly; the cladding is merely a screen.

To achieve pressure equalization, the cavity must be divided into small, sealed compartments, both horizontally and vertically. These chambers are formed by baffles and seals that connect the cladding back to the air barrier. Each compartment is vented to the exterior. When wind hits the façade, air enters the vents, and because the compartment is small and airtight, the pressure inside it rises almost instantly to match the exterior pressure.

The lesson from the field is stark: without meticulous compartmentalization, you do not have a pressure-moderated rainscreen. You have a well-intentioned drained system that will not perform as designed under dynamic wind loads.

This commitment to advanced building science is driving market growth. You can dive into research about these market trends and their drivers.

Common Field and Design Mistakes

The physics is sound, but execution is everything. Failures happen when the detailing doesn't reflect the system's true operational needs.

Critical errors that undermine performance include:

- Treating a Drained System as Pressure-Moderated: Specifying a pressure-moderated system without detailing the necessary airtight compartments is the most common failure. Without seals, wind-washing occurs, pressurizing the entire cavity and stressing the WRB.

- Missing or Poorly Detailed Air Seals: A discontinuous air barrier or leaky compartment seals make pressure equalization impossible. Drawings must specify not just the seal, but how it integrates with the continuous air barrier.

- Oversized Cavities/Compartments: If compartments are too large, they cannot equalize pressure fast enough during wind gusts, allowing water intrusion to occur during the pressure lag.

- Lack of Coordination: Failure to model the air barrier, compartment seals, and cladding attachments in a federated model leads to clashes and gaps on site. This is where enclosure coordination in BIM becomes an essential QA process.

A pressure-moderated rainscreen offers superior performance but has a lower tolerance for error. It demands a production-minded approach where every detail is designed to control air, not just drain water.

Design Clarity and Detailing Discipline

The performance gap between a rainscreen system on paper and its real-world behavior is almost always a failure of detailing. This is where design intent breaks down, leading to RFIs, rework, and long-term enclosure failures.

The most damaging mistake is a conceptual one: assuming a drained system will perform like a pressure-moderated one without the requisite detailing for compartmentalization and air barrier continuity. This fundamental error translates directly into moisture intrusion, staining, and corrosion.

Why Drawings Must Reflect Actual Pressure Behavior

A note on a drawing calling a system "pressure-moderated" means nothing if the assembly isn't detailed to manage air pressure. Without airtight compartments, wind pressure rushes laterally behind the cladding, searching for any vulnerability in the WRB.

The lesson from the field: You can't achieve pressure-moderated performance without pressure-moderated details. The system’s name is irrelevant if the physics of air control are ignored.

Design clarity prevents these failures. Effective enclosure coordination in your BIM workflows allows you to model and verify these critical seals before they become a real-world problem, preventing costly RFIs.

The Non-Negotiable Continuity of Barriers and Flashings

Even in a simple drained system, the continuity of the WRB and flashings is absolute. Drawings often fail to clearly show how the WRB integrates with flashings at windows, floor lines, and material transitions.

These detailing flaws become liabilities under pressure. They don’t just drip; they funnel water deep into the wall assembly. A successful rainscreen cladding system isn’t just specified; it’s designed with an obsessive focus on how water and air will behave at every transition. Clear, unambiguous drawings that reflect physical reality are your best defense.

Achieving Performance Through Production Discipline

A high-performance rainscreen cladding system is the direct result of production discipline. It’s a mindset that protects design intent from concept to installation, ensuring that verifiable performance, grounded in physics, matters more than terminology.

This operational consistency separates a successful enclosure from a future liability. It requires a commitment to systematic, repeatable processes—from BIM workflows and template discipline to QA checkpoints—that ensure every detail is built as designed. This is how firms protect margins and deliver predictable outcomes. We don't sell hours; we sell clarity, systems, and reliable delivery.

From CAD-to-BIM Evolution to Buildable Reality

The value of a sophisticated façade design can be lost in the handoff from digital model to physical assembly. A rock-solid BIM workflow for enclosure coordination is essential. A federated model serves as the single source of truth, allowing teams to vet the continuity of critical layers like the air barrier and prevent clashes before they reach the field.

Disciplined detailing templates are another non-negotiable. They institutionalize lessons learned, preventing teams from reinventing the wheel and ensuring high-performance standards are applied consistently across every project. This is about building a scalable production system for quality.

Decision Checkpoints, Permitting Prep, and RFI Prevention

Getting rainscreen systems right relies on robust construction quality control checklists and rigorous production discipline. Clear decision checkpoints throughout the design and pre-construction phases validate performance assumptions and ensure buildability, preventing RFIs and preparing a clear path for permitting.

This structured approach transforms complex enclosures from a source of risk into a predictable, scalable product. This level of organization is precisely what clients value when we prepare shop drawings for construction—the final, critical step in translating design into reality.

The core outcome here is reliability. When you operate with production discipline, you deliver clarity, consistency, and a building enclosure that performs exactly as intended.

This focus on systems protects project margins by reducing rework and eliminating the guesswork that plagues complex façade installations. To help your team standardize its approach and reinforce detailing discipline, we've developed a technical resource that breaks down the critical differences between these systems.

Download our Rainscreen System Comparison Checklist to ensure your projects achieve their intended performance goals.

Frequently Asked Questions About Rainscreen Cladding Systems

Even for seasoned architects and enclosure specialists, a few common questions always seem to pop up when you move from theory to the nitty-gritty of buildable details. Let's tackle the practical differences and critical requirements for a high-performance rainscreen cladding system.

What Is the Minimum Cavity Depth for a Drained Rainscreen?

The absolute, rock-bottom minimum is 3/8 inch (about 10mm). This is just enough to create an effective capillary break.

Anything less, and you risk water bridging the gap through surface tension, which completely defeats the purpose of having a cavity in the first place. That said, the optimal depth really depends on your cladding type and expected wind loads—larger, more irregular panels might need a deeper cavity to ensure water drains and the wall can properly dry out.

Can a WRB Also Function as the Air Barrier?

It can, but it doesn't happen automatically. While a water-resistive barrier (WRB) is essential for moisture control, it only pulls double duty as an air barrier if it's detailed to be completely continuous and airtight.

This means meticulously sealing every single lap, penetration, and transition back to the main structure. If you're designing a pressure-moderated system and just assume your WRB is an air barrier without this level of detailing discipline, you're setting the stage for system failure. It's one of the most common mistakes we see.

Do All Rainscreen Systems Need Compartmentalization?

Nope, only pressure-moderated (or pressure-equalized) systems require it. Compartmentalization is the key physical feature that allows the cavity's air pressure to match the exterior wind pressure.

Why does that matter? Because it neutralizes the main force driving water into the building. A standard drained rainscreen, on the other hand, doesn't need compartments. Its job is much simpler: just drain away any water that gets past the cladding, not actively manage air pressure.

If you're curious about the different materials that can serve as the outer leaf of a rainscreen, exploring various product categories like timber cladding options can offer some great insight into both aesthetics and performance. Just remember, no matter how beautiful the material is, the system's true performance always comes down to the quality of the detailing behind it.

At BIM Heroes, we help firms achieve predictable outcomes by establishing rigorous production discipline for complex enclosures. If your team needs to move beyond theory to create reliable, buildable façade systems, we can help.

Explore how we deliver clarity and operational consistency through our architectural BIM services.