The Benefits of BIM for High-Rise Projects: Coordination at Scale

Traditional 2D workflows and coordination meetings are effective for standard construction, but they break down under the immense complexity of high-rise projects. A 40-story building isn't just twice as complex as a 20-story one; its coordination challenges grow exponentially. The sheer volume of interconnected systems, the critical importance of vertical distribution through congested cores, and the management of repetition with slight variations across dozens of floors create a coordination problem of a different magnitude. Above a certain threshold—often around 20 stories—the risk of cascading errors, schedule overruns, and catastrophic rework costs becomes unmanageable with conventional methods. This is precisely where the benefits of BIM modeling transition from a competitive advantage to an operational necessity for high-rise coordination.

In high-rise construction, coordination chaos across 30+ identical floors, core congestion where every trade needs vertical shaft space, and structural-MEP conflicts that cascade through dozens of levels are not edge cases; they are the norm. This article moves beyond generic discussions to focus on the specific, scale-dependent benefits of BIM that are crucial for the successful delivery of tall buildings. We will explore how a mature BIM workflow provides the clarity, systems, and reliable delivery needed to conquer vertical complexity, ensuring predictability and margin protection from foundation to rooftop.

Core Coordination Benefits of BIM for High-Rise Projects

The fundamental challenge of a tall building is managing three-dimensional complexity at a scale that overwhelms manual oversight. BIM addresses this by creating a single, federated environment where coordination happens proactively, not reactively.

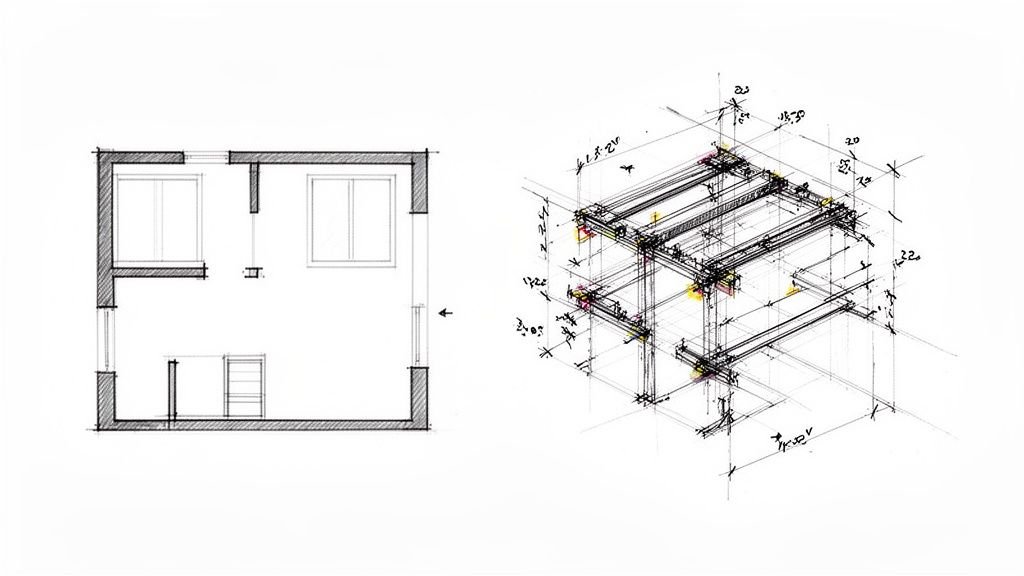

Managing Repetition Across Typical Floors

A high-rise might have 30 to 40 identical residential or office floors. In 2D, a change on one floor requires manually updating dozens of sheets, a recipe for error. With BIM, teams create a highly-coordinated "typical floor" template. Once approved, this template is propagated vertically. Any change made to the template automatically updates all instances, ensuring consistency and saving thousands of hours in drafting and checking.

Vertical Distribution and Core Coordination

The building core is the logistical heart of a high-rise, a congested space where all MEPF risers, structural elements, and elevator shafts must coexist. Manually coordinating this vertical puzzle with 2D sections is nearly impossible. A BIM model allows for precise, 3D coordination of all vertical systems, ensuring that a conflict between a 12" chilled water riser and a primary structural column is identified and resolved digitally, not discovered after 20 floors of concrete have been poured.

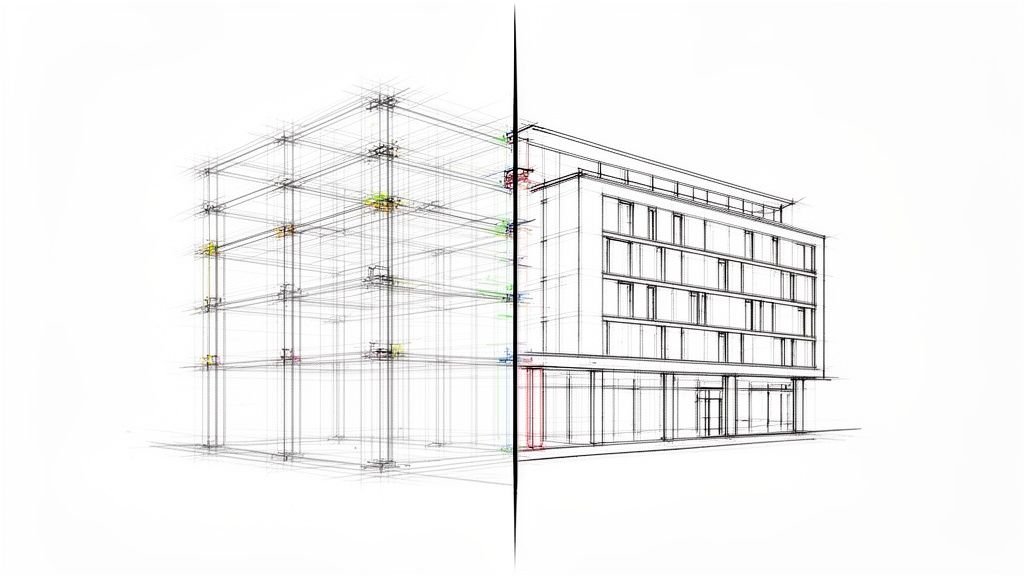

Façade and Structural Interface Coordination

The connection between the curtain wall system and the slab edge, repeated thousands of times, is a common source of RFIs and field conflicts. BIM enables precise coordination of anchor points, thermal breaks, and fire safing across every floor. This digital alignment ensures prefabricated façade panels fit perfectly on-site, accelerating enclosure and preventing costly rework. We've seen the benefits of BIM modeling become exponentially more valuable above 20 stories—the coordination complexity that breaks traditional methods is exactly where BIM excels.

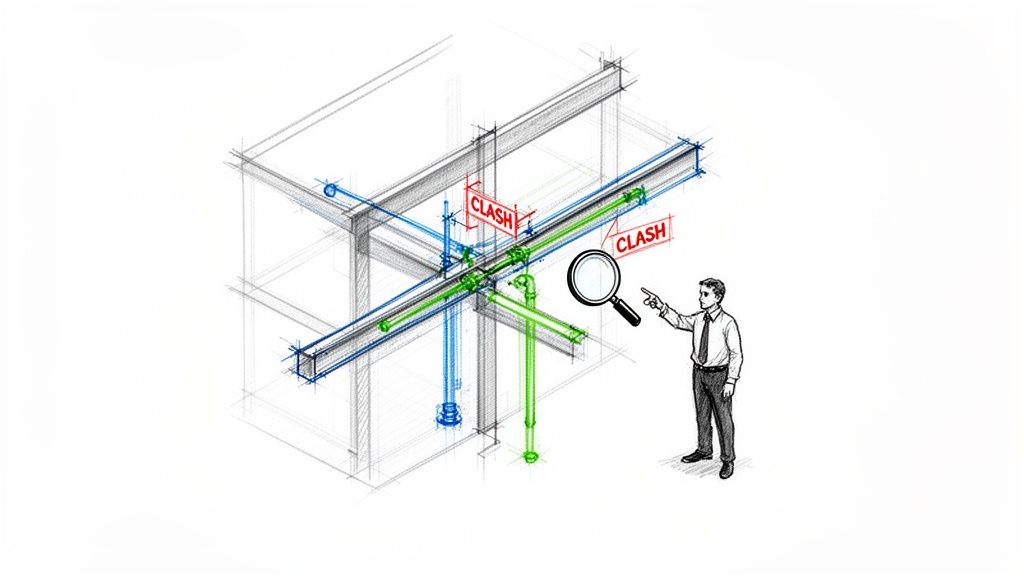

Clash Detection at Scale: Preventing Compounding Errors

In a low-rise building, a clash between a duct and a beam is a localized problem. In a high-rise, that same clash on a typical floor can repeat 40 times, compounding into a catastrophic cost and schedule impact.

Automated clash detection in a federated model is the only viable QA process for managing this risk. Instead of relying on human review of 2D overlays, software like Navisworks can analyze the entire building—all 500,000 square feet—and identify every single conflict simultaneously. This allows teams to:

- Run Zone-Based Clash Tests: Focus coordination efforts on the most critical areas, such as the building core, mechanical floors, and typical floor layouts.

- Resolve Conflicts Systemically: Fix a clash once in the typical floor model and have the solution propagate to all other levels.

- Prevent Critical Path Delays: Identify and resolve conflicts involving long-lead items or critical path systems months before they would have been discovered on-site.

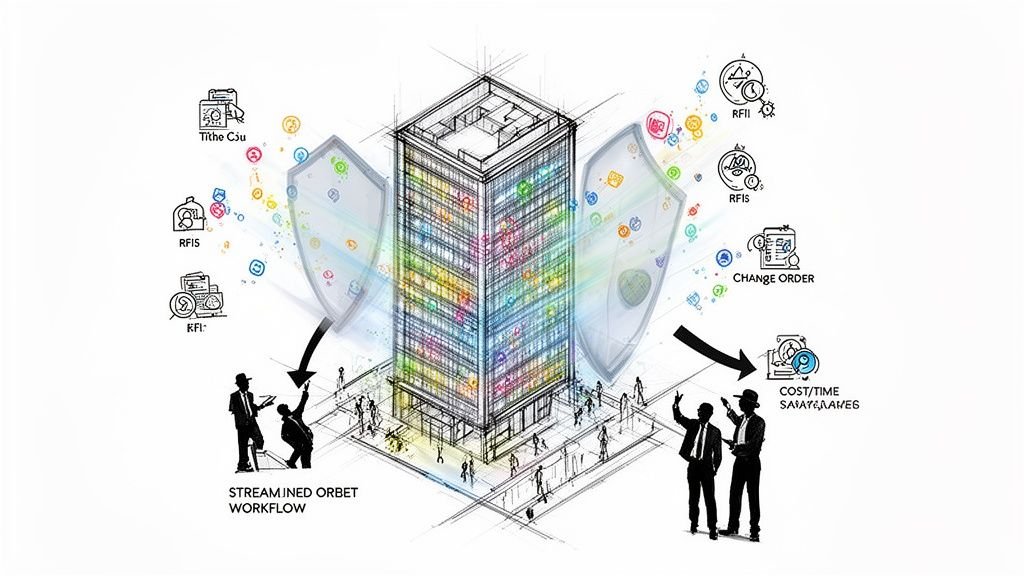

This systematic process transforms conflict resolution from a source of field delays into a managed, pre-construction task. Rigorous BIM coordination services can reduce RFIs related to system conflicts by over 80% on complex tall building BIM projects.

Schedule and Cost Benefits: Predictability in Vertical Construction

The financial stakes in high-rise construction are immense. Margin protection depends on schedule predictability, which is impossible without robust coordination.

Rework Avoidance on Upper Floors

The cost of rework multiplies with height. Fixing a mistake on the 35th floor involves significant logistical costs for moving labor, materials, and equipment vertically. By resolving conflicts in the model, BIM directly prevents this high-cost, high-risk rework, preserving both the schedule and the budget. This is a core component of optimizing project budgets on large-scale builds.

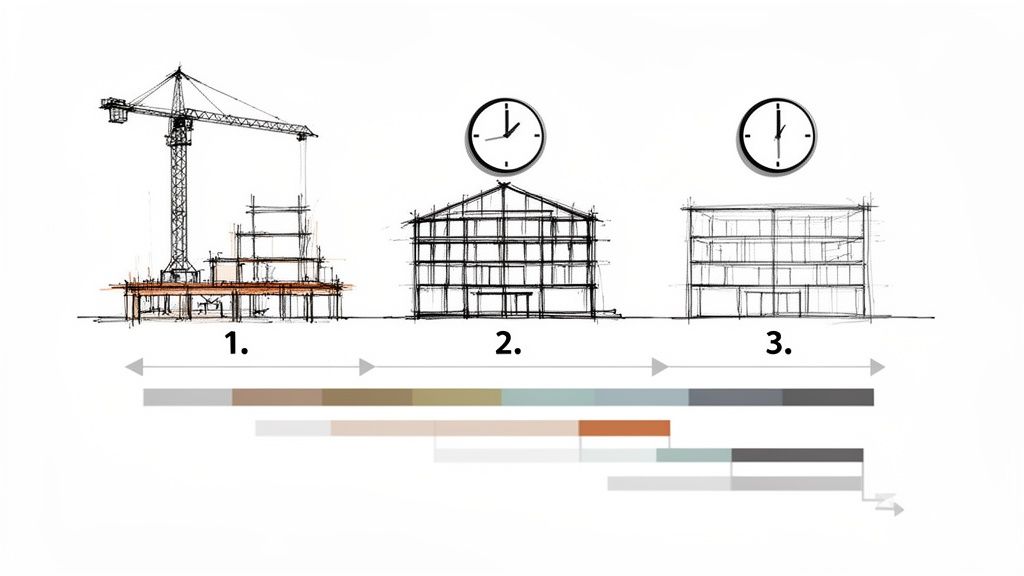

4D Sequencing for Construction Logistics

One of the most powerful benefits of BIM modeling is the ability to link the 3D model with the construction schedule, creating a 4D simulation. For a high-rise, this is essential for planning crane placement, material hoisting, and just-in-time deliveries to a congested urban site. Teams can virtually rehearse the entire construction sequence, identifying logistical bottlenecks and safety hazards before they impact field operations, a key part of modern project schedule management.

Enabling Prefabrication

High-rise projects rely heavily on prefabricated components like bathroom pods, MEP racks, and façade panels to accelerate the schedule. This is only possible with the high degree of dimensional accuracy that BIM provides. The model serves as the single source of truth for fabrication, ensuring components built off-site fit perfectly when they arrive.

Information Management: A Single Source of Truth for the Entire Team

Managing thousands of drawings and documents for a tall building is a recipe for version control chaos. BIM solves this by creating a centralized, data-rich model that serves as the undisputed single source of truth for all stakeholders.

This unified digital environment ensures that every architect, engineer, and contractor is working from the same coordinated information. When a change is made, it is reflected in the model instantly, eliminating the risk of teams building from outdated drawings. This clarity is crucial for:

- Change Tracking and Version Control: A clear digital record of every design decision.

- Automated Documentation: Generating coordinated drawings, sections, and schedules directly from the model.

- Field Access to Current Information: Foremen and site staff can access the 3D model on tablets, resolving field queries in minutes instead of days.

This approach also de-risks the permitting phase. A coordinated model provides clear documentation for building code compliance, reducing comments from review authorities and accelerating approvals.

Essential BIM Practices for High-Rise Coordination Success

Harnessing these benefits requires more than just software; it demands production maturity and disciplined workflows.

- Establish a High-Rise Specific BIM Execution Plan (BEP): Define roles, Level of Development (LOD) requirements, and protocols for managing typical floors and vertical zones.

- Implement Federated Model Coordination: Mandate regular model sharing and establish a clash detection matrix targeting high-risk interfaces.

- Enforce Template Discipline: Create and lock down coordinated typical floor models to ensure consistent propagation.

- Conduct Vertical Alignment Checks: Run specific checks to ensure MEPF risers and structural elements are perfectly aligned from the foundation to the roof.

- Utilize a Common Data Environment (CDE): Use a cloud platform like ACC or Trimble Connect to ensure everyone is working from the same live data.

- Manage Model Size and Performance: High-rise models become massive. Implement strategies for model splitting and hardware optimization to ensure performance.

- Integrate 4D/5D Workflows Early: Link the model to schedule and cost data from the outset to maximize planning benefits.

From Advantage to Necessity: Adopting BIM for High-Rise Success

For projects that extend beyond 20 stories, the question is no longer whether to use BIM, but how to implement it effectively. The sheer scale of a tall building’s coordination challenges—core congestion, vertical system alignment, and managing repetition—creates a complexity threshold that traditional 2D methods simply cannot cross without exposing the project to unacceptable levels of risk.

The benefits of BIM for high-rise projects aren't just incremental improvements; they represent a fundamental shift in how complexity is managed. By providing a single source of truth, enabling proactive clash detection, and ensuring consistency across repetitive floors, BIM transforms high-rise construction from a high-risk endeavor into a predictable, manageable process. The answer isn't working harder to coordinate tall buildings traditionally—it's recognizing that at this scale, only a mature BIM workflow can deliver the clarity, consistency, and margin protection required for success.

Developing a robust BIM workflow for high-rise projects requires a deep understanding of production systems and coordination discipline. Download our High-Rise BIM Coordination Framework to see the templates and processes that leading firms use to deliver complex buildings with predictability and control.