Prefab-Friendly BIM: Modeling for Off-Site Construction

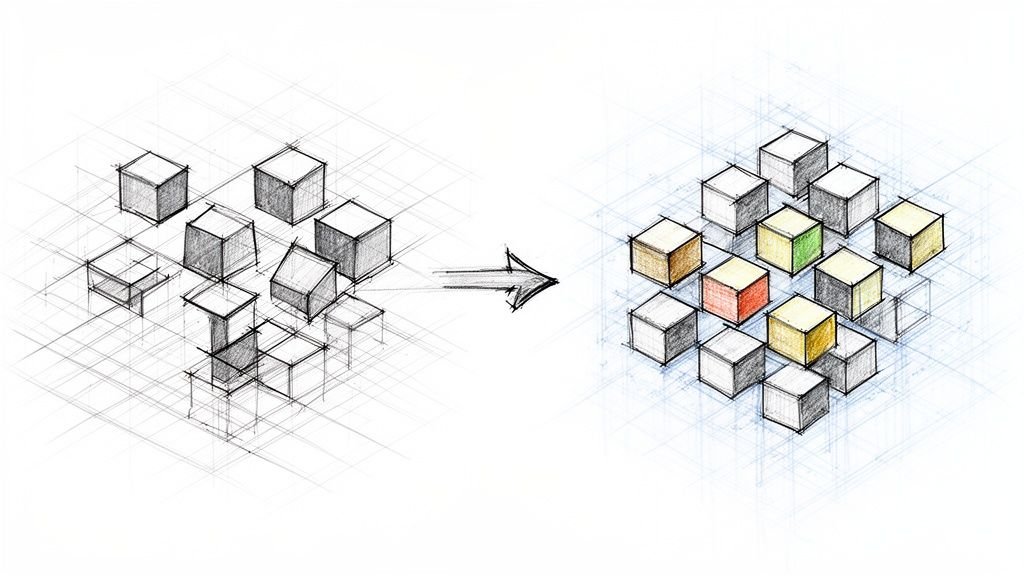

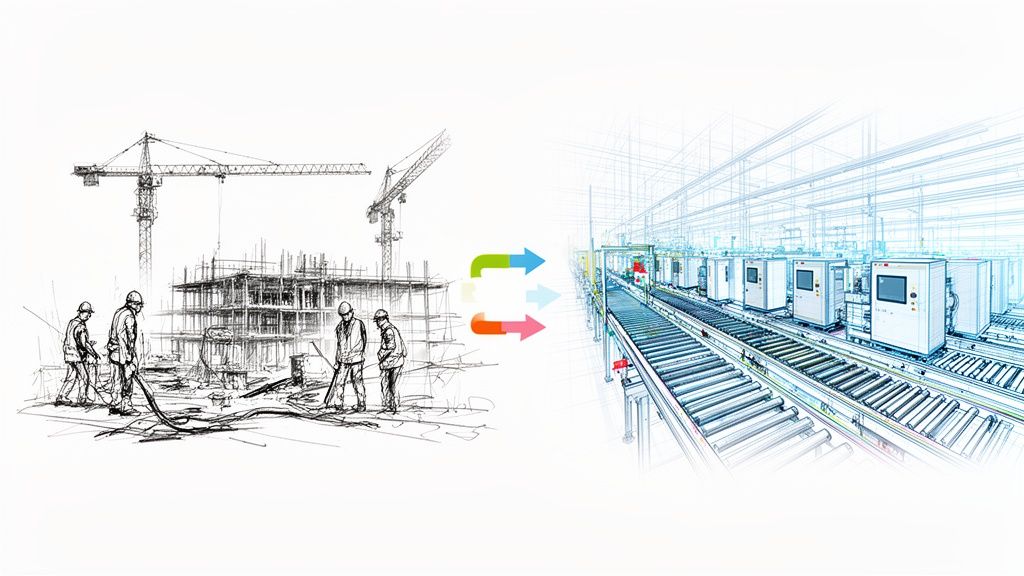

Off-site construction is a fundamental swap from construction logic to manufacturing discipline. Instead of building stick-by-stick on location, components like walls, rooms, or even entire building modules are fabricated under a roof before being shipped for final assembly. But many prefab failures happen because the BIM model is treated like a site-built project until it’s too late.

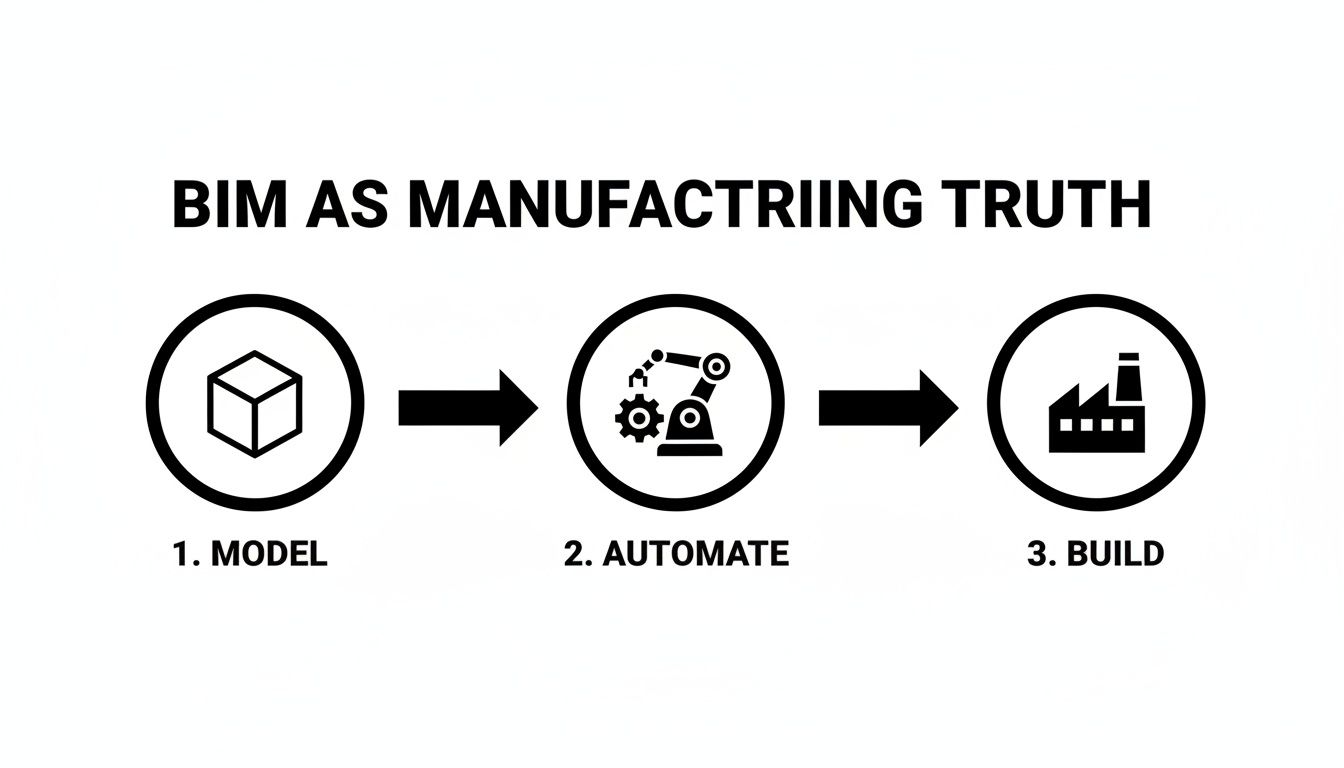

Success in off-site construction requires treating BIM as a manufacturing coordination problem, not just a modeling preference. The model must become a precise set of instructions for the factory, demanding higher discipline much earlier in the process: locked geometry, defined tolerances, clear interfaces, and zero ambiguity.

The Critical Shift to a Manufacturing Mindset

Adopting off-site construction isn't just about changing location; it’s a complete overhaul of operational thinking. It requires leaving behind the fluid, reactive nature of site-built projects for the disciplined, process-driven world of manufacturing. The biggest hurdle isn’t technology—it’s culture.

The phrase “we’ll figure it out on-site” is a direct threat to your margins in a factory. Ambiguity is the enemy of the production line. A successful prefab-ready BIM model isn't just for visualization; it’s the manufacturing engine—a true digital twin you can build from with total precision. This is what protects your margins and ensures operational consistency.

Why Early Certainty is Non-Negotiable

In traditional construction, design evolution is part of the game. The BIM model often serves as a guide that field crews interpret and adjust. With off-site, that flexibility vanishes.

Once a component hits the production queue, the design must be 100% locked. Any change introduced after fabrication kicks off means costly rework, a busted production schedule, and a cascade of delays that erase your profits.

This reality forces a major shift in project timelines:

- Decision Checkpoints: Major design decisions—material choices, connection details, MEP routing—must be finalized much earlier, before a single part is cut.

- Zero Ambiguity: Every element must be modeled with absolute clarity—tolerances, interfaces, and assembly logic. There is no room for interpretation.

- Upfront Coordination: All disciplines must reach a higher level of coordination far sooner than in a typical project lifecycle, preventing downstream RFIs.

Off-site construction succeeds when design freedom is intentionally reduced as production certainty increases. The model must become the single source of truth, not a starting point for field adjustments.

This disciplined approach transforms BIM for modular construction from a design sketch into a precise set of manufacturing instructions. To cultivate this mindset, teams need rock-solid communication systems. Specialized tools, like communication software for manufacturing companies, are critical for ensuring perfect alignment with the locked-down model.

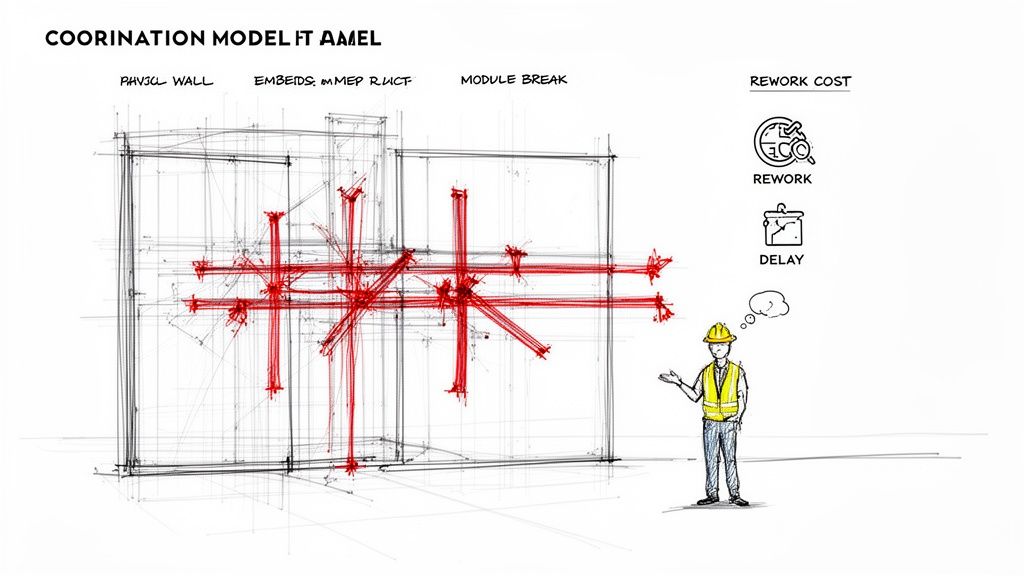

Why Coordinated Models Fail on the Factory Floor

We’ve all seen it: a BIM model that sails through clash detection gets the green light, only to fall apart when it hits the reality of production. This is where project margins go to die. The disconnect happens because teams treat the model like it’s for a site-built project until it's far too late.

The failures are frustratingly predictable. We see MEP routed without module logic, framing that ignores transport constraints, and drawings that look coordinated but can’t be assembled in sequence. These issues cause factory rework, site delays, and crippling cost overruns.

Teams nail geometric coordination—making sure pipes don’t hit beams—but completely miss manufacturing coordination. That’s a different game about build sequence, tolerances, and assembly logic. A clash-free model doesn’t guarantee a buildable component.

From Digital Clashes to Physical Rework

In a factory, there are no rough openings to adjust with a sledgehammer. Here are a few all-too-familiar scenarios where a “good” model leads to expensive rework:

- Undefined Connection Details: A steel beam touches a column, but the bolt-hole patterns and plate thickness are missing. The fabrication line stops cold while the team fires off an RFI.

- Ignored Tolerances: A precast panel is designed with zero room for error. The real-world component arrives off by a fraction of an inch and won’t fit, forcing costly on-site modifications.

- Lack of Assembly Logic: Wall panels look perfect in the model, but embeds for MEP hangers make it physically impossible to install them in sequence. Workers are forced to cut into finished panels, creating waste.

These issues are a direct result of failing to treat the prefabrication BIM model as a set of precise manufacturing instructions from day one.

The goal isn't just to design a building; it's to design the components and the process for assembling them. The model must answer how it will be built, not just what it will look like.

The Growing Cost of Getting It Wrong

As the industry doubles down on prefabricated methods, the financial stakes of these modeling failures are skyrocketing. The global offsite construction market is on track to hit USD 226.7 billion by 2034, driven by a need for efficiency. You can read more about the offsite construction market growth and see why this precision is so critical.

In off-site construction BIM, the model isn’t a sketch; it’s the direct blueprint for fabrication. The only way to stop the bleeding from RFIs and rework is to adopt a disciplined, fabrication-first approach to BIM. The specifics matter, especially in different modular construction workflows.

Modeling Practices That Actually Work for Off-Site

Knowing the difference between a model that looks coordinated and a component that can be built is the first hurdle. The next is embedding specific, non-negotiable modeling practices into your workflow. This isn’t about creative flair; it's about applying manufacturing discipline directly to your BIM process.

Establish a Fixed Datum Strategy

Before anyone models a single component, the project must be locked to a fixed datum—a universal grid of control points. This is the absolute frame of reference for every panel, module, and assembly. It ensures that parts made in different locations align perfectly on site, eliminating the geometric drift common in traditional projects.

Define Repeatable Units and Parametric Assemblies

The power of off-site construction BIM comes from repetition. Instead of modeling every bathroom pod as a one-off, successful teams create detailed, repeatable unit types. These are smart, parametric assemblies with built-in rules that enforce standards, allow for controlled variation, and enable rapid deployment across the project. This approach treats building components like manufactured products, a foundational principle for any successful prefab modeling workflow.

Model to Clear Interface Zones

One of the most common failure points is at the seams—the connections between modules or panels. An interface zone is the clear, unambiguous boundary where separate fabricated components meet. These zones must be defined early, and every trade must model their scope with absolute respect for them, leaving no detail to chance. Modeling an MEP line that crosses an interface without a defined coupling detail is a surefire way to halt the production line.

Align LOD with Fabrication Milestones

For off-site, Level of Development (LOD) must be tied directly to real-world fabrication and procurement milestones, not abstract design phases. The model doesn't just need to reach "LOD 350"; it needs to contain enough detail to generate accurate shop drawings for the wall panel fabricator by a specific date. This ensures a model’s maturity is directly linked to its readiness for production, which is critical when producing high-quality shop drawing examples.

Enforce Strict Change Control

Finally, once a component is released for fabrication, the model for that component is locked. This is the point of no return. Any proposed change must go through a formal control process to evaluate its impact on cost, schedule, and already-built parts. The discipline to say "no" to late-stage changes is the hallmark of a mature off-site delivery team.

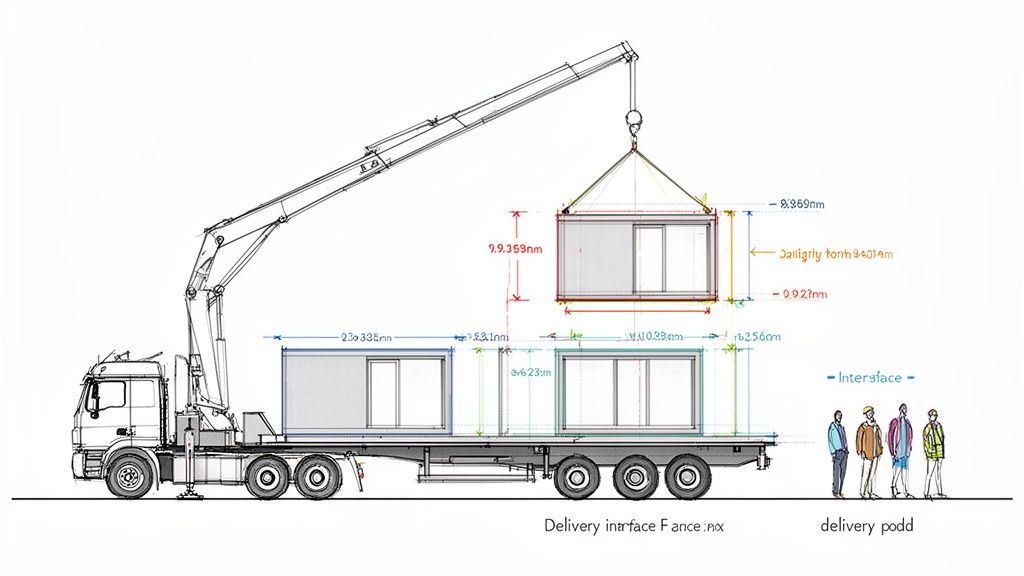

Structuring Your BIM for Assembly and Logistics

A perfectly fabricated module that can't be delivered or installed is just a monument to wasted effort. True success in off-site construction hinges as much on logistics as on manufacturing precision. The model must be a detailed plan for getting that module from the factory to the job site and lifted into place.

This means embedding logistical data directly into your BIM workflow, treating transportation limits and crane capacities with the same respect as structural loads.

Modeling for Transportability and Site Constraints

Every component built in a factory must travel on public roads and be hoisted by a crane. Factoring these physical limits into the model early is a non-negotiable part of any mature prefabrication BIM strategy.

Your model should answer critical questions long before the first truck is loaded:

- Weight and Center of Gravity: Is the module’s weight accurately calculated and balanced for a safe lift?

- Lifting and Rigging Points: Are the engineered lifting points clearly defined and modeled to guide the assembly sequence?

- Transportation Envelopes: Does the module’s size comply with shipping regulations and the delivery route?

- Site Access and Laydown: Has the delivery path on the job site been simulated to ensure trucks can reach the crane?

Failing to embed this information pushes critical decisions to the field, where mistakes are exponentially more expensive. As experts from Harvard's Joint Center for Housing Studies note, mastering logistics is essential to realizing the full savings of off-site methods.

Simulating the Assembly Sequence

A well-structured BIM for modular construction allows teams to rehearse the entire assembly process digitally, catching clashes and optimizing the workflow. This is far more than a simple 4D simulation; it's a rigorous operational plan that de-risks the most critical phase of the project.

The assembly simulation isn't just a visualization—it's a QA process for your site logistics. It proves that the physical components can be put together safely and efficiently in the real world.

This digital rehearsal validates every step, from the moment a module is lifted off the truck to its final placement. It provides clear, unambiguous instructions, preventing the on-the-fly problem-solving that leads to errors and safety incidents.

Making BIM Your Single Source of Manufacturing Truth

When you shift to off-site construction, the BIM model becomes the single source of manufacturing truth—the digital DNA from which every component is born. It feeds instructions directly to automated machines and generates shop drawings for the assembly line. Its data has to be perfect.

This role demands a new level of discipline. Rigorous templates, systematic QA checks, and firm decision deadlines are the guardrails that keep your budget and schedule from flying off a cliff.

From Template Discipline to Production Readiness

Predictability on the factory floor begins with consistency in the model. This is where template discipline and robust QA processes become invaluable. Instead of starting with a blank file, seasoned teams build from templates with standards, fabrication logic, and data parameters already baked in.

From there, rigorous Quality Assurance (QA) processes must be layered on top, going beyond simple clash detection:

- Data Integrity Checks: Confirm every component has the correct data for fabrication—material codes, part numbers, and finish specs.

- Manufacturability Audits: Review models not just for clashes but for assembly logic. Can this panel actually be built and installed as designed?

- Tolerance Validation: Confirm all components are modeled to the tight tolerances required for factory production.

In off-site construction, the BIM model is the master instruction set. If the instructions are flawed, the product will be flawed. There is no "fix it in the field" safety net.

This discipline is essential as the market grows. Research shows that BIM is shaping the growing off-site market by enabling the precision needed to deliver projects 30-50% faster. By treating the BIM model with the seriousness of a manufacturing model, teams finally achieve the predictability that off-site construction has always promised.

Adopting a Production-Focused Workflow

Making the leap to off-site construction isn't about new software; it's a fundamental shift in how you work. Success comes from adopting the discipline of a manufacturer. The technology just enables a more predictable, consistent, and profitable process.

The entire approach boils down to one core message: off-site construction only works when BIM is treated as a manufacturing model, not a design sketch that keeps evolving.

The True Business Outcomes: Margin Protection and Consistency

Ultimately, a production-focused BIM workflow is about locking in two things: margin protection and operational consistency. Every modeling standard, every QA check, and every decision gate is there to stamp out the ambiguity that leads to rework, delays, and budget overruns.

Predictability becomes your most valuable asset. This systemized approach creates a repeatable, scalable delivery model, moving your firm from selling hours to delivering reliable outcomes. It’s how you build a reputation for clarity and systems that work.

From Theory to Actionable Systems

Making this shift demands practical tools. Architects, BIM managers, and VDC teams need clear guidelines to turn traditional modeling habits into factory-ready information. Implementing a structured approach means getting specific about:

- Early Module Definition: Locking down the modular grid and unit types before detailed design.

- A Fixed Datum Strategy: Aligning every trade and component to a single, unchangeable set of control points.

- Clear Interface Zones: Modeling the precise boundaries where modules connect, leaving zero ambiguity.

- Fabrication-Tied LOD: Escalating model detail based on factory milestones, not generic design phases.

These practices aren't about limiting design; they’re about channeling creativity through a production-aware framework. The lesson learned in the field is simple: firms that master this discipline will lead the industry. You can see how these pieces fit together in our guide on the complete prefabrication workflow.

By embracing this production-first mindset, you can move from wishing for better outcomes to reliably delivering them.

At BIM Heroes, we know that success in off-site construction comes from clarity and systems. To help your team make this critical shift, we’ve developed a practical resource based on lessons learned from the field.

Download our Prefab-Ready BIM Checklist, an actionable framework for aligning your modeling workflows with manufacturing requirements. https://www.bimheroes.com