Architectural Drafting Services for Pre-Engineered Buildings: A Growing Niche

Pre-engineered metal buildings (PEMBs) are supposed to be fast, but too many projects grind to a halt at the permit office. Why? There's a critical documentation gap between what the manufacturer provides and what local jurisdictions require. The supplier's fabrication drawings are not the architectural plans your building official needs to see. This is where specialized architectural drafting services for pre-engineered buildings become essential, translating factory specs into a permit-ready package that protects your timeline and margin.

Why Pre-Engineered Buildings Are Surging

It’s no secret PEMBs are booming. Driven by demands for speed-to-market and cost efficiency, sectors like warehousing, manufacturing, aviation, and self-storage are turning to these systems. They aren't just "metal boxes" anymore; they are sophisticated building solutions offering supply chain advantages and architectural flexibility.

But this speed creates a unique bottleneck. PEMBs have a documentation workflow most general architectural drafting services are not equipped to handle. The drawings from a PEMB manufacturer are brilliant for one thing: guiding efficient factory fabrication and on-site assembly. They were never intended to satisfy a local building official checking for site-specific code compliance.

The Documentation Gap: What Manufacturers Provide vs. What Permits Need

The single biggest point of failure in a PEMB project is the assumption that manufacturer drawings are sufficient for a permit. Submitting the manufacturer's package alone is a near-guaranteed rejection, sending you back to square one while the clock ticks.

A manufacturer’s goal is to fabricate and deliver a steel building system. Their drawings reflect that: detailed shop drawings, erection diagrams, and an anchor bolt plan showing foundation connection points. That’s where their scope typically ends.

A building official, however, needs to see the whole picture: how the building integrates with the site, meets local codes, and ensures public safety. This is the gap that triggers delays and busts budgets.

What PEMB Manufacturers DO and DON'T Provide

Understanding this scope distinction is critical for project planning. Here’s a clear breakdown:

What Manufacturers Typically Provide:

- Erection Drawings: Assembly instructions for the steel framing.

- Shop Drawings: Fabrication details for individual steel components.

- Anchor Bolt Plan: Shows the locations and reactions for foundation connection points.

- Structural Calculations: For the pre-engineered building system itself.

What They DON'T Provide (But Permits Require):

- Site Plan: Showing property lines, setbacks, utilities, and grading.

- Architectural Floor Plans & Elevations: Showing interior layouts and exterior finishes.

- Stamped Foundation Plans: Designed by a local engineer for site-specific conditions.

- Code Compliance Plans: For life safety, accessibility (ADA), and energy codes.

- Architectural Details: For elements like storefronts, canopies, and wall transitions.

Unique Architectural Drafting Requirements for PEMBs

Specialized architectural drafting services for pre-engineered buildings bridge the gap by creating the documents the manufacturer doesn't. They act as the integrator, ensuring the factory-produced system becomes a fully compliant, site-specific asset. Their work is about delivering clarity and preventing RFIs.

This is more than just drawing lines; it’s about production maturity. An expert drafting partner adds architectural details the manufacturer’s package omits.

Scenario 1: The Storefront Integration. A retail PEMB needs a glass storefront entry. The manufacturer provides the steel opening, but not the details for weatherproofing, flashing, and attaching the aluminum storefront system to the steel girts. A specialized drafting service provides these critical section details, preventing leaks and costly field fixes.

Scenario 2: The Roof Penetration. An industrial facility requires rooftop HVAC units. The manufacturer doesn't detail the structural curbs, flashing, and roofing tie-ins needed to maintain the roof's integrity and warranty. This must be documented by the architectural drafting team to ensure a watertight installation.

These common scenarios highlight the need for expertise in metal building drafting for elements like:

- Entries, canopies, and facade elements

- Transitions between metal walls and other materials (like masonry)

- Interior partition layouts and mezzanine integration

- Coordination with site utilities and overhead doors

Foundation Coordination: The Most Critical Interface

Nothing stops a PEMB project faster than a foundation mistake. The manufacturer's anchor bolt plan is not a foundation design. It is a data sheet showing the loads the steel structure will exert. Turning that data into a buildable, code-compliant foundation is the job of a local structural engineer.

Your architectural drafting services team is the crucial link in this process. They ensure the engineer receives the correct anchor bolt plan and architectural context to design a foundation that matches both the building's loads and the site's geotechnical report.

Without this disciplined coordination, projects suffer from foundation plans that don't match building loads, anchor bolts that clash with rebar, and slab edges that don't align with wall panels. This is where predictability is won or lost.

Code Compliance: Translating a System for Local Review

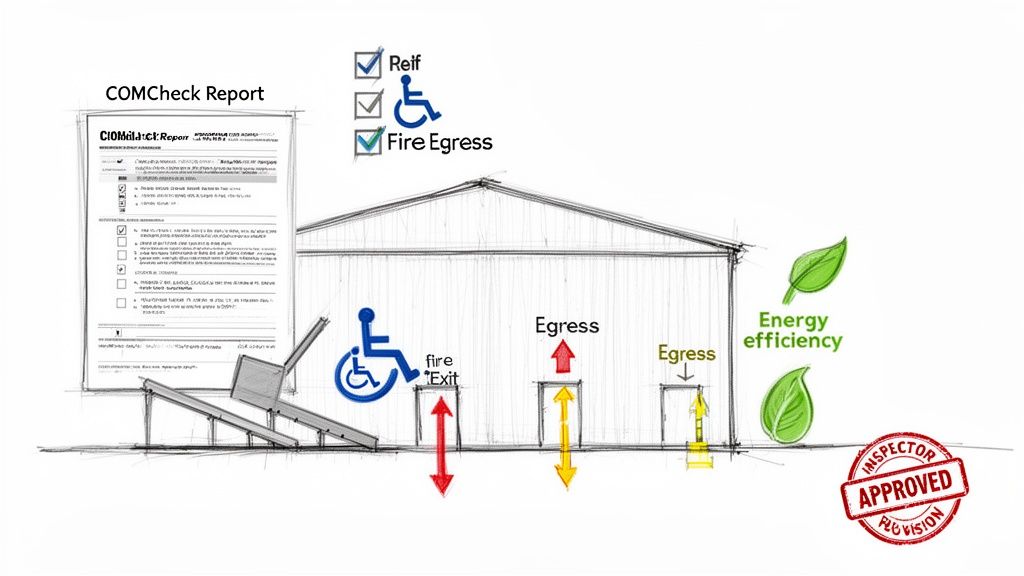

A pre-engineered building is structurally sound, but it doesn't automatically comply with local energy, accessibility, or life safety codes. This compliance gap is a major source of permit rejection. A knowledgeable drafting partner anticipates these requirements.

We've seen PEMB projects move from purchase order to permit approval in weeks when architectural drafting services understand the unique workflow these buildings require.

Specialized metal building drafting services produce the specific documentation inspectors need to see:

- Energy Code Compliance: COMcheck reports and detailed wall/roof assembly sections proving thermal performance.

- Fire & Life Safety Plans: Egress paths, occupant loads, exit signage, and fire-rated wall details.

- Accessibility (ADA) Details: Compliant ramps, door clearances, restroom layouts, and accessible parking.

A permit rejection is rarely about the quality of the PEMB. It's about the quality and completeness of the documentation submitted. For more information on industry standards, the Metal Building Manufacturers Association (MBMA) is an excellent resource.

Best Practices for Working with Drafting Services on PEMB Projects

To ensure operational consistency and protect your margins, follow these actionable best practices:

- Engage Early: Bring your drafting partner in as soon as the PEMB is ordered to align schedules.

- Verify PEMB Experience: Ask for examples of past PEMB projects, not just general commercial work.

- Establish a Single Point of Contact: Designate one person to manage information flow between the manufacturer, engineer, and drafting team.

- Confirm the Geotechnical Report is Complete: The foundation design depends on accurate soil data.

- Review the Draft Permit Set Together: Hold a coordination meeting to review drawings before submittal to catch any final disconnects.

- Use a Disciplined QA Process: Ensure your partner has a clear quality assurance workflow to prevent RFIs.

Quick Reference: PEMB Project Documentation Checklist

A complete permit submittal for a pre-engineered metal building should include far more than the manufacturer's package. Use this checklist as a guide.

| Document Category | Key Item | Purpose |

|---|---|---|

| Architectural & Site | Site Plan | Shows building location, setbacks, utilities, and site features. |

| Architectural & Site | Architectural Floor Plans | Details the interior layout, rooms, doors, and dimensions. |

| Architectural & Site | Building Elevations & Sections | Shows exterior finishes and critical construction assemblies. |

| Structural | Stamped Foundation Plan | Provides the site-specific design from a local structural engineer. |

| Structural | Manufacturer's Drawings | Included for reference (anchor bolt plan, erection drawings). |

| Compliance | Life Safety & Egress Plan | Demonstrates code-compliant exit routes and safety features. |

| Compliance | Accessibility (ADA) Details | Confirms the building meets all accessibility standards. |

| Compliance | Energy Code Report (e.g., COMcheck) | Proves compliance with local energy efficiency requirements. |

The answer isn't avoiding PEMBs—it's partnering with architectural drafting services that know how to make them permit-ready. These teams don’t sell hours; they sell clarity, systems, and reliable delivery that keeps your project on track.

If you're planning a pre-engineered building project, understanding these documentation requirements is the first step to a successful outcome.

Download our Pre-Engineered Building Permit Checklist to ensure your next submittal is complete and ready for approval.