BIM and 3D Modeling: Why Your Workflow is More Important Than Your Software

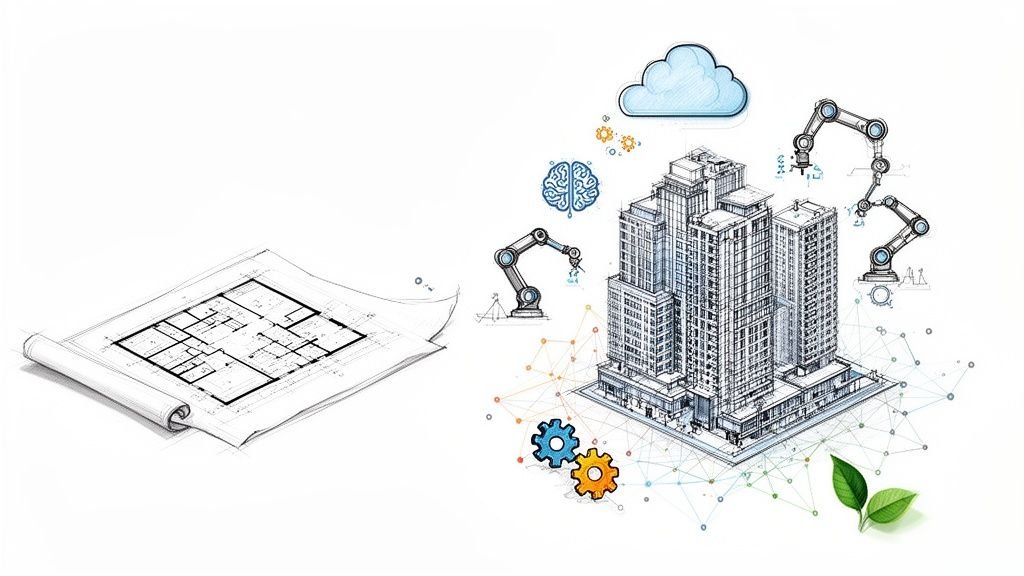

Many firms believe they're doing BIM when, in reality, they're just creating complex 3D models. While BIM and 3D modeling both produce three-dimensional visuals, the operational difference is massive—and it directly impacts your margins, timelines, and field certainty.

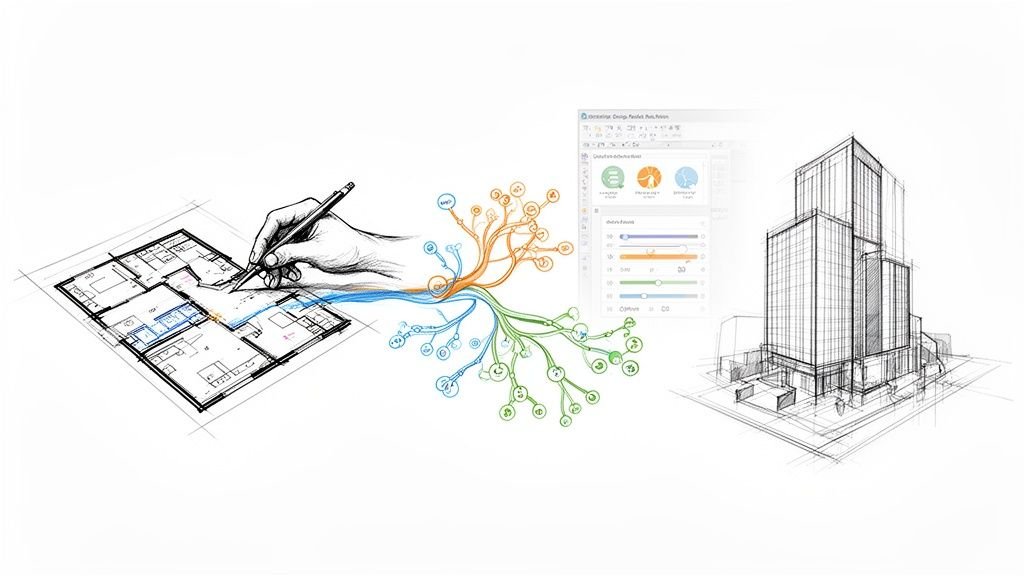

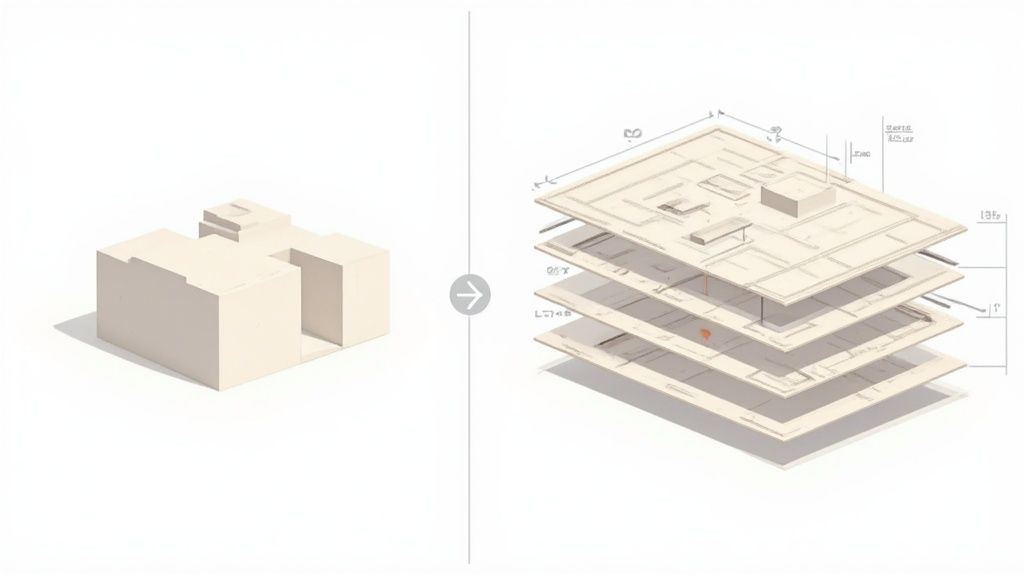

At its core, 3D modeling produces geometry—a digital shape. Building Information Modeling (BIM), on the other hand, is a production system that embeds intelligence into that geometry. It doesn't just show what a building looks like; it provides a data-driven playbook for how it gets built, coordinated, and delivered.

For architects, builders, and design-build firms, understanding this distinction is the first step toward real production maturity.

Beyond Geometry: The Real Difference Between BIM and 3D Modeling

The conversation has been stuck on software features for too long. Let’s reframe it where it matters: on operational consistency, margin protection, and predictable delivery.

Think of a 3D model as a high-resolution photograph. It captures form and aesthetics beautifully, but it’s static. You can’t click on a wall to see its fire rating, manufacturer, or installation sequence.

A true BIM environment is the opposite. It’s a dynamic, digital prototype where every element is an intelligent component. The value isn't just in seeing the building; it’s in the web of connected data that makes construction predictable and prevents costly surprises.

From Visuals to Verifiable Data

Treating BIM as a fancy rendering tool is a recipe for coordination chaos, weak documentation, and a flood of RFIs from the field. We’ve seen teams accelerate pre-con dramatically when they shift their mindset from "making a model" to "building an information system."

A simple 3D model shows you a wall. A BIM element is the wall—it knows its material layers, structural properties, cost code, and required clearances. This embedded data transforms the model from a picture into a database you can build from.

The leap from 3D modeling to BIM is a shift from representation to simulation. One shows you the design; the other lets you build it virtually, catching errors and optimizing logistics long before you break ground.

In well-run BIM environments, the model becomes the single source of truth that drives clarity and prevents expensive rework. To truly grasp how BIM moves beyond mere visual representations, understanding the nuances between a Digital Twin vs. Simulation is essential, as BIM is the foundation for these advanced applications.

Here’s how these two approaches stack up in a production environment.

3D Modeling vs. BIM: A Production-Focused Comparison

This table breaks down the operational differences between a geometry-focused 3D model and a data-driven BIM system.

| Aspect | 3D Modeling (Geometry-Focused) | BIM (Data-Driven System) |

|---|---|---|

| Primary Goal | Create a visual representation of a design's shape and form. | Build an intelligent, data-rich digital prototype of the asset. |

| Core Components | Surfaces, polygons, and textures that create a visual shape. | Parametric objects with embedded data (cost, material, specs). |

| Coordination | Manual or visual checks; relies on human interpretation. | Automated clash detection and rule-based system validation. |

| Documentation | 2D drawings are created separately and must be manually updated. | Drawings, schedules, and details are live views of the model. |

| Data Output | Primarily static images, renderings, and geometric files. | Quantity takeoffs, fabrication models, 4D schedules, cost reports. |

| Lifecycle Use | Mostly limited to design visualization and marketing. | Spans the entire lifecycle: design, construction, and operations. |

One is a picture; the other is a production engine. What they do for your project’s predictability and profitability are worlds apart.

The Foundation of Predictable Construction

Ultimately, the benefits of BIM for architects and builders are rooted in process, not pixels. Great BIM isn’t about fancy visuals; it’s about repeatable workflows, disciplined templates, logical naming conventions, and a culture of rigorous quality assurance.

Consider these practical differences:

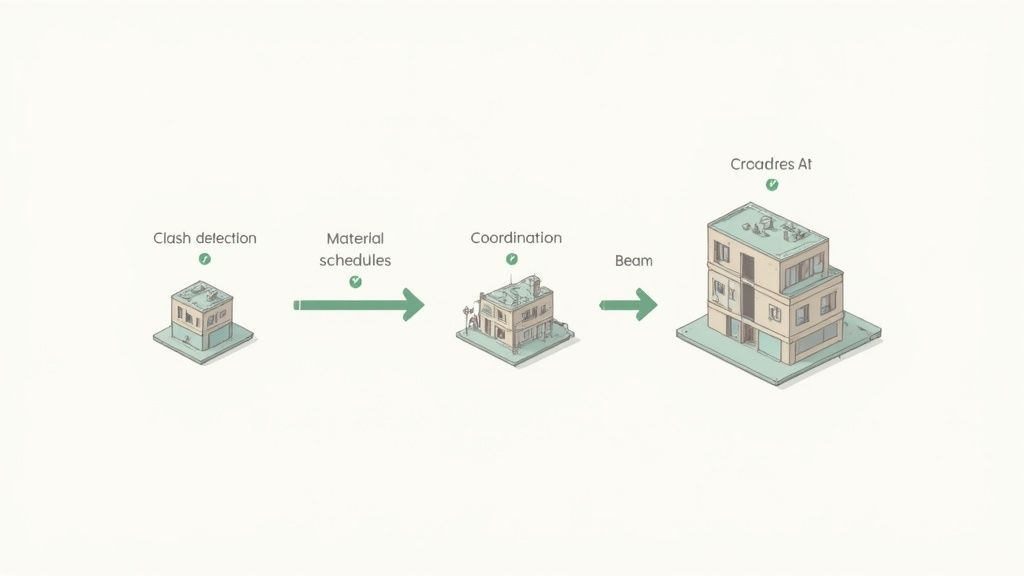

- Clash Detection: A 3D model might look fine, but a BIM workflow runs automated checks that find a pipe running through a beam before fabrication—not after it arrives on site.

- Schedules & Takeoffs: Instead of manually counting fixtures in Excel, a BIM system generates accurate schedules directly from the model. Change a door type, and the schedule updates automatically.

- Documentation: Detail views are dynamically linked to the model. If a window moves, all associated drawings update, eliminating disconnected sheets and outdated information in the field.

This operational discipline is what protects your margins. It’s not about buying better software; it’s about building a smarter, more reliable delivery system. And while the tools are important, mastering 3D modeling software within a structured framework is what truly separates top-performing firms.

When Treating BIM Like a 3D Model Creates Chaos

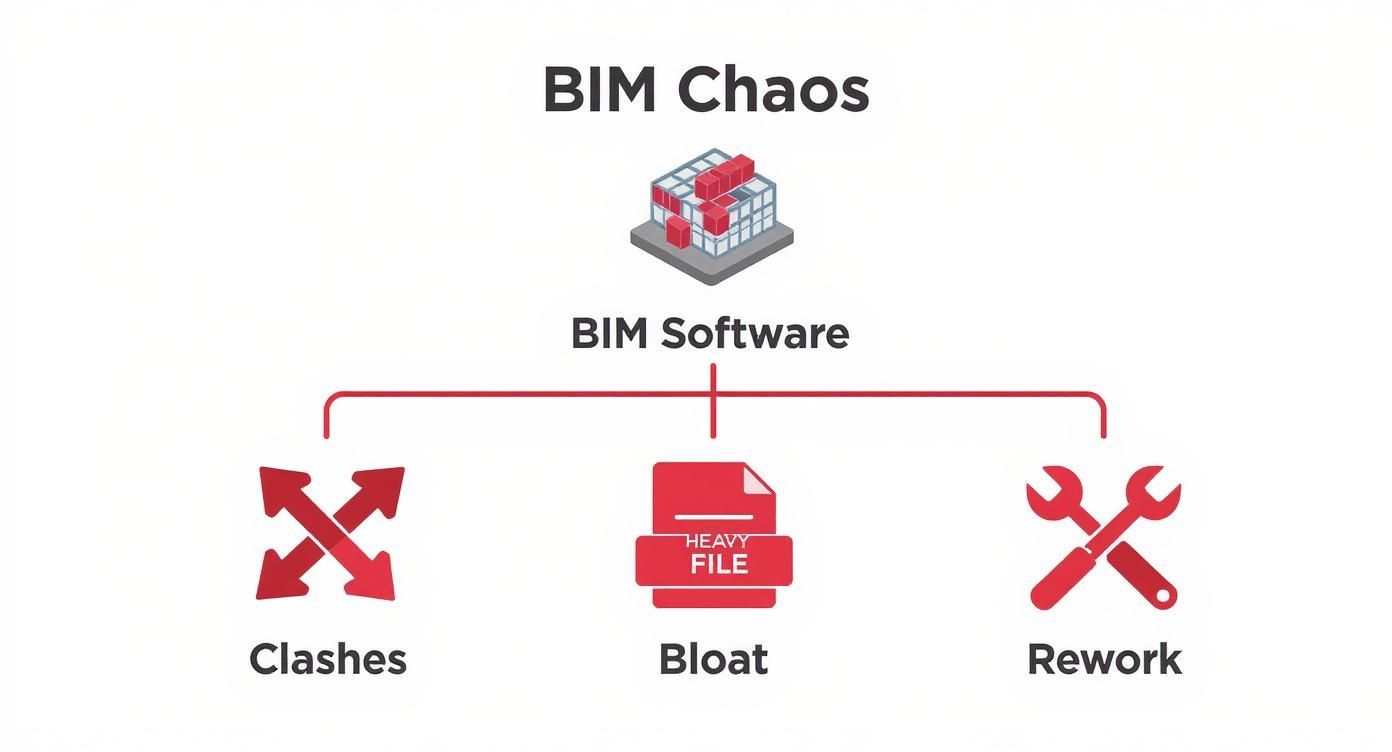

This is where projects go off the rails. Many firms invest in powerful BIM software but fail to establish the workflows to support it. Without discipline, they’re just creating complicated 3D models plagued by the same old problems.

The symptoms hit the budget hard: rampant coordination clashes, bloated model files that slow everyone down, and a constant flood of RFIs from a confused team in the field.

When BIM is treated as just a geometric exercise, its greatest strength—the data—is ignored. You end up with a model that looks right but is functionally useless for coordination and construction. This isn't a software problem; it's a process failure that threatens your margins and project predictability.

The True Cost of a "Dumb" Model

We've seen this story play out time and again. A plumbing model might be visually perfect, but if it lacks embedded data for clearances or insulation thickness, it offers zero value for clash detection.

The chaos that follows is painfully predictable:

- On-Site Clashes: That "correct" plumbing model leads to a collision with HVAC ductwork discovered during installation. Now you’re stuck with expensive rework and cascading delays.

- Manual Takeoffs: Because components are just shapes, the estimating team can't trust the model. They revert to manually counting from 2D sheets, reintroducing the human error BIM was meant to eliminate.

- Disconnected Documentation: Someone changes a window, but the window schedule doesn't update because the intelligent link was never set up. The field team builds from outdated information.

In well-run BIM environments, the model is the engine of production, not just a picture of the final product. Every element is built with fabrication, installation, and coordination in mind from day one.

This operational gap is the real difference between BIM and 3D modeling in practice. One is a static picture; the other is a dynamic system designed to head off problems before they happen. For teams looking to improve, a guide on common BIM modeling errors and how to avoid them can offer a clear roadmap for building better production habits.

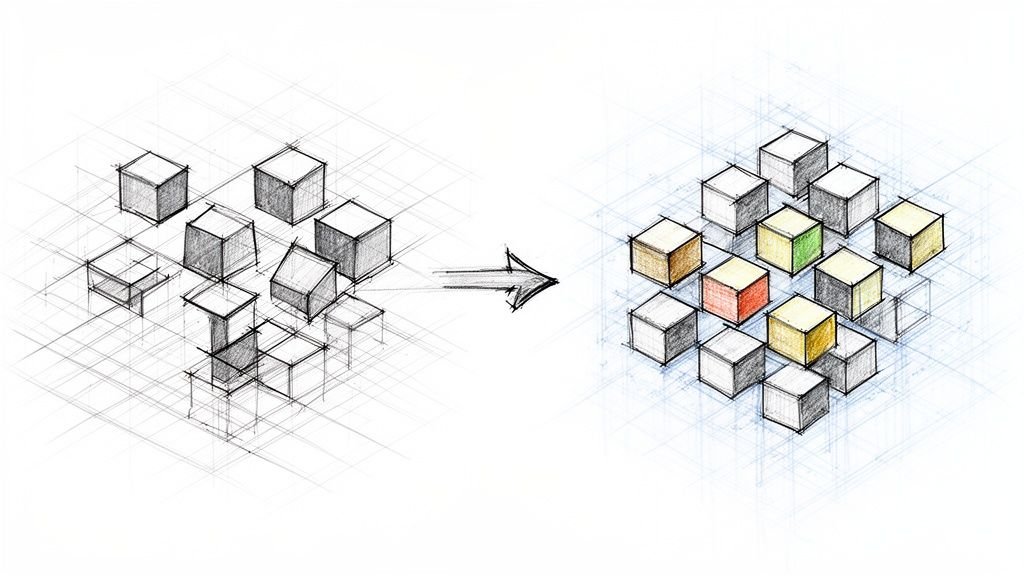

Why Process Trumps Software

The most advanced software on the planet can't fix a broken process. Without solid templates, clear naming conventions, and rigorous QA checkpoints, a BIM model quickly becomes a digital junk drawer—a source of confusion instead of a single source of truth.

We’ve watched teams accelerate their pre-construction timelines dramatically when they shift their focus from modeling speed to workflow discipline. It’s about creating a system where every action has a purpose tied to a downstream outcome—from permitting to fabrication.

Consider the hallmarks of a failing, model-only approach versus a successful, system-driven BIM production workflow:

- Failing Approach: Model elements are named randomly ("Wall-Final-v2"). There’s no standard for how families are built or what data they must contain.

- Successful Approach: A strict naming convention is enforced (e.g., "A-WALL-EXT-CMU-INS-12"). Every model element must pass a QA check to ensure it contains required parameters for scheduling and coordination.

This isn’t about bureaucracy. It’s about building a production engine that delivers predictable, reliable outcomes. The real benefits of BIM for architects and builders are only unlocked when the "Information" is valued just as much as the "Modeling."

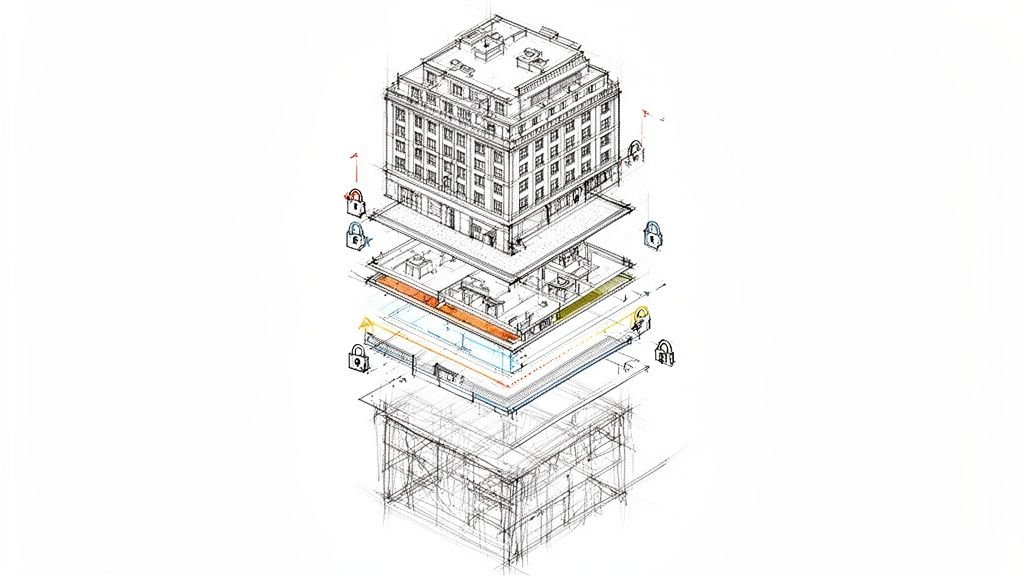

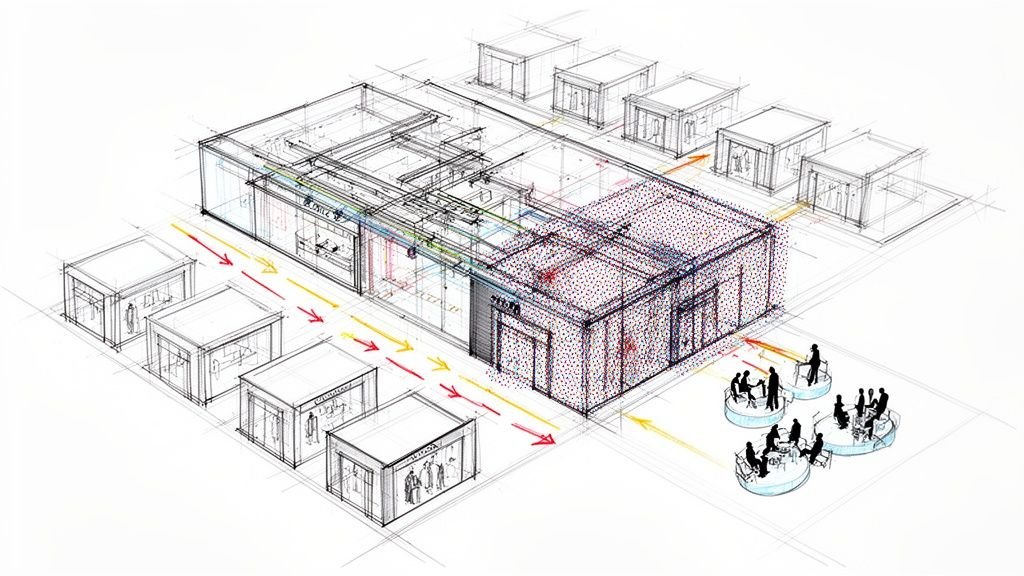

The Anatomy of a High-Performing BIM System

A high-performing Building Information Modeling system isn’t defined by its software but by the discipline and structure governing its use. It’s a production engine, and its power comes from well-designed, repeatable components working in unison.

Forget the fancy visuals. Operational excellence in BIM and 3D modeling is built on a foundation of simple, robust standards. This is the shift from reactive modeling to proactive project management—it’s where firms protect their margins and deliver consistency.

In well-run BIM environments, the system itself prevents common errors, accelerates documentation, and ensures every team member is building from the same playbook.

This diagram shows what happens when you use powerful BIM software without a disciplined system: you get the most common sources of project chaos.

The lesson is critical: the software is just a tool. Without a guiding system, it can amplify inefficiency just as easily as it can create clarity.

The Power of a Bulletproof Project Template

The single most impactful element of a mature BIM workflow is the project template. A weak template forces your team to reinvent the wheel on every project, wasting hours on setup and introducing massive inconsistencies.

A well-built template is a force multiplier for efficiency. It's a pre-built project environment where the foundational work is already done, including:

- Pre-loaded View Settings: Standard plan, section, and elevation views are configured with the correct visibility graphics, scales, and detail levels.

- Organized Sheet Structures: The entire drawing set is pre-populated with title blocks, sheet numbers, and a logical hierarchy, ready for views.

- Standardized Schedules: Key schedules for doors, windows, and rooms are created and formatted, set to automatically populate as the model develops.

- Defined Line Weights and Object Styles: All graphical standards are locked in, ensuring every drawing is consistent and professional.

By starting with a robust template, you ensure every project kicks off with the same high standard of organization, directly contributing to faster permit prep and more predictable outcomes.

Logical Naming Standards for Total Clarity

As a BIM model grows, its usability depends entirely on how well it's organized. This is where logical naming standards become non-negotiable. Without them, your model becomes a digital junk drawer, impossible for anyone but its original creator to navigate.

A disciplined naming convention is the central nervous system of a healthy BIM model. It ensures anyone on the team can find what they need, understand what it is, and trust that it's the correct component.

This discipline applies to everything. A random view name like "Section-2-Final" is useless. A standardized name like "A-SECT-BLDG-NS-L1" (Architecture-Section-Building-NorthSouth-Level1) provides immediate context. The same logic applies to families, ensuring designers use approved, data-rich components. Optimizing a BIM system involves efficiently managing digital content libraries, which is crucial for consistency.

Disciplined QA Processes and Decision Checkpoints

Finally, a high-performing system relies on a culture of quality assurance. This isn't a final-hour review; it's a series of disciplined checks and balances integrated throughout the entire BIM production workflow. Great teams build QA into their process with defined decision checkpoints.

These checkpoints are formal moments to review the model against established standards, including:

- Model Audits: Regularly running checks for warnings, file size bloat, and adherence to naming conventions.

- Coordination Reviews: Holding weekly clash detection meetings where issues are assigned and tracked to resolution.

- Version Control: Implementing a clear process for how models are shared, updated, and archived. Managing this effectively is a core competency; learn more with these best practices for version control for BIM projects.

We’ve seen teams accelerate pre-con dramatically when these QA steps are treated as essential production tasks. They catch clashes early, prevent RFIs before they’re written, and ensure the model remains a reliable single source of truth. This isn't bureaucracy; it’s building a system that delivers operational consistency and protects your margins.

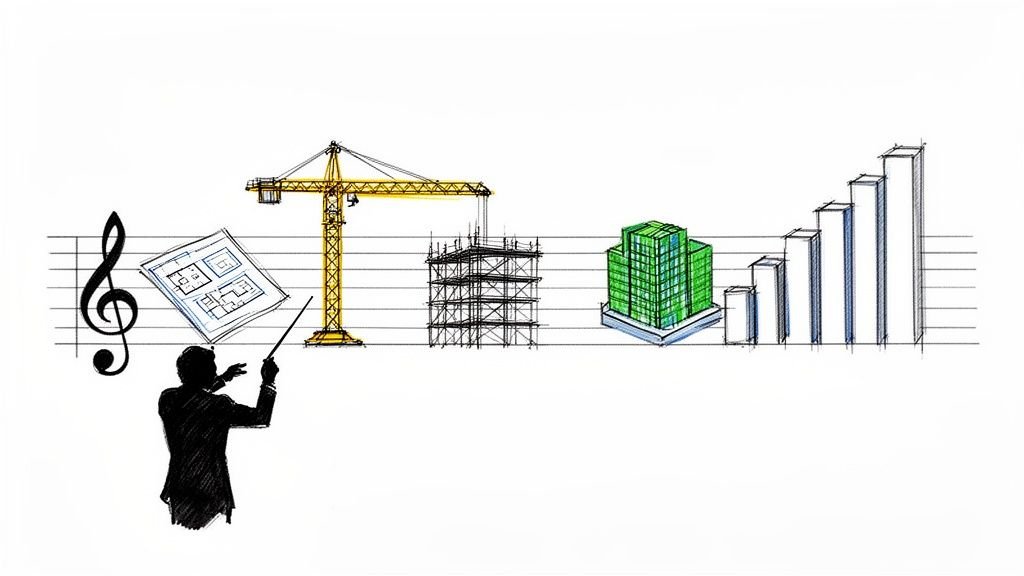

Driving Predictable Outcomes with BIM Workflows

A disciplined BIM process isn't an academic exercise—it's a direct line to tangible business results. It’s about protecting your margins and bringing certainty to the field. When you get it right, construction becomes less reactive and far more predictable.

The real ROI of BIM isn't found in a flashy rendering. It’s measured in the problems that never happen.

Imagine a clash detection run flags a ductwork collision with a structural beam. The fix? A few hours of coordination time. Now, picture that same clash being discovered on-site. The cost instantly balloons to include field modifications, project delays, and the ripple effect on every trade that follows.

This is the core value of a mature BIM workflow.

It's about shifting problem-solving from the expensive construction phase back to the low-cost digital design phase. When you move from simple 3D modeling to a true BIM production workflow, you fundamentally de-risk the entire project.

From Manual Guesswork to Model-Driven Certainty

The difference between traditional methods and a BIM-driven system is night and day. It’s the difference between proactive control and reactive chaos.

Just look at a few common production tasks:

- Material Schedules: Instead of an estimator counting doors from 2D drawings in an error-prone spreadsheet, a BIM system generates precise schedules straight from the model. A design change happens, and the schedule updates automatically.

- Permitting Prep: A well-organized model with clean, standardized sheets makes pulling together permit sets significantly faster, shaving weeks off the permitting cycle.

- RFI Prevention: We’ve seen teams slash their RFIs by over 50% by resolving coordination issues in the model first. A clear, coordinated BIM gives the field crew unambiguous instructions, killing the back-and-forth that grinds productivity to a halt.

This is what field certainty really means: knowing the plan has been virtually built, tested, and validated long before the first shovel hits the ground.

BIM as a Margin Protection System

Every RFI, change order, and on-site fix is a direct hit to your project's profitability. A disciplined BIM and 3D modeling process acts as a powerful margin protection system by systematically stamping out the root causes of these costly mistakes.

The goal isn't just to deliver a building; it's to deliver the project with the planned margin intact. A robust BIM workflow is one of the most effective risk mitigation tools available to architects and builders today.

In well-run BIM environments, the model drives not just the drawings but also procurement, fabrication, and installation sequencing. You simply can't achieve that level of integration with static 3D models.

The True Impact on Project Delivery

Here’s a side-by-side comparison of how a critical task—MEP coordination—plays out in a traditional versus a BIM-driven workflow.

| Task Stage | Traditional 2D/3D Modeling Workflow | Disciplined BIM Workflow |

|---|---|---|

| Coordination | MEP routes are drawn on 2D plans. Clashes are found by eye or, worse, during installation on-site. | Automated clash detection runs identify hundreds of conflicts between systems inside the model. |

| Resolution | The field team flags a clash. An RFI is sent. The project stalls while a solution is designed and approved. | Coordination meetings are held to resolve the digital clashes. The model is updated to reflect new routes. |

| Outcome | Costly rework, schedule delays, and finger-pointing between trades. The margin takes a serious hit. | The coordinated model is issued to the field. Installation proceeds smoothly with minimal on-site issues. |

This shows that the benefits of BIM for architects and builders are unlocked through process discipline. It requires a real commitment to using the model as the single source of truth. Firms that master this can dramatically improve their delivery speed and accuracy. Explore specific techniques like the top Revit workflows to speed up your CD sets to see how.

Ultimately, a mature BIM system gives you control. It allows you to build with a level of predictability that was not possible before, ensuring what you design is actually what gets built—on time and on budget.

How to Scale Your BIM Production Workflows

Keeping quality high as your firm grows is one of the toughest challenges in the AEC industry. The secret to scaling successfully isn’t just hiring more modelers; it’s about building repeatable BIM production workflows that keep projects consistent and margins intact.

This is where you shift from relying on individual heroics to building dependable “delivery pods”—small, focused teams that pull from the same playbook of standards and processes. It’s about setting a solid foundation so that excellence becomes your default, not an accident.

Documenting Your Workflows for Consistency

You can't scale what you haven't written down. The first step is getting hard-won knowledge out of your senior team's heads and into a practical guide. This document becomes the single source of truth for how your firm gets things done.

It needs to clearly outline:

- Project Kick-off Procedures: What are the exact steps for starting a new project, from selecting the right template to running initial model audits?

- Modeling Standards: How do we model core systems? What Level of Development (LOD) is expected at each project stage?

- QA/QC Checkpoints: At what milestones do we stop and review a model? Who is responsible, and what are they looking for?

When you systemize your process, you create an operational playbook that lets you onboard new team members faster and juggle more projects without a drop in quality.

Establishing Clear Decision Checkpoints

In a growing firm, ambiguity is the enemy. Scalable BIM and 3D modeling operations run on clear decision checkpoints where the team formally reviews progress. These aren’t casual check-ins; they are structured reviews designed to spot problems early.

A scalable BIM system runs on rhythm and routine. Scheduled checkpoints for model health, coordination, and documentation turn quality control from a reactive afterthought into a proactive part of the production cycle.

Think of these as quality gates. For example, a "Design Development Hand-off" checkpoint ensures the architectural model passes a series of checks before it’s released to engineers. This simple step prevents a mountain of downstream rework.

Creating a Centralized Content Library

Few things kill productivity faster than your team constantly hunting for—or recreating—model components. A centralized, firm-approved content library is non-negotiable for both speed and standardization.

Your curated library should be stocked with:

- Standard Families: Go-to components (doors, windows, fixtures) built to firm standards with correct data parameters already baked in.

- Detail Components: A full library of standard 2D detail components ready to drop in, speeding up construction documents.

- Approved Materials: A defined set of materials with accurate graphical representations and data properties.

We've seen teams speed up their pre-con phase dramatically once they commit to this discipline. It takes the guesswork out of the equation and guarantees consistency. This systemization is becoming more critical as the global BIM market is expected to jump from $9.88 billion in 2025 to $25.77 billion by 2034. You can read the full research on this explosive market growth to see where the industry is headed.

By building these systems—documented workflows, clear checkpoints, and a central library—you’re building a production engine that can scale reliably.

Building a Smarter Future, Not Just a Fancier Model

The path from 3D modeling to a true Building Information Modeling system isn’t about buying new software—it’s about committing to a new way of working. A stunning model can still lead to chaos on-site if it isn’t built on a foundation of operational discipline. The real goal isn't a fancier rendering; it's a smarter, more predictable construction process that protects your margins and delivers certainty.

When you shift from a "modeling" mindset to a "BIM system" mindset, you move from creating static geometry to building a dynamic production engine. This engine—driven by smart templates, rigid standards, and critical QA checkpoints—is what stops costly rework, speeds up permit cycles, and slashes the RFIs that bring projects to a halt.

Beyond the Model: A System for Predictable Delivery

This transition is quickly becoming a global standard. Adopting BIM and 3D modeling is a matter of both regulation and strategy. By 2025, several European nations will mandate Level 3 BIM for public projects, and Japan’s i-Construction initiative aims to boost productivity by 20% using these principles. You can dig deeper into these global BIM mandates and their impact on the AEC industry.

The real value of BIM isn’t in the model itself, but in the clarity, consistency, and control it brings to the project lifecycle. It’s about building smarter, not just drawing better.

This disciplined approach ensures every workflow serves one purpose: to deliver projects on time and on budget. It’s about building a reliable system that empowers your team to execute with confidence, turning the model into your single source of truth.

The question isn’t if your firm uses BIM, but how deeply you’ve embedded its principles into your daily operations.

To help you build a more robust production system, we’ve put together a BIM Standards & QA Checklist. It’s a practical tool designed to help you implement the workflows and decision checkpoints that create true operational consistency. Download it to start building a smarter, more predictable future for your projects.

Frequently Asked Questions

Here are some of the most common questions we hear from firms making the jump from 3D modeling to a full BIM production workflow.

Can We Use Our Existing 3D Modeling Staff for BIM?

Yes, but it requires a fundamental mindset shift. Your team needs to evolve from digital artists who create geometry to production managers who build intelligent, data-rich assets. The skills are less about software clicks and more about grasping data management, QA processes, and how the model directly impacts what happens on site. This means getting them comfortable with BIM production workflows, template discipline, and consistent data entry.

What Is the Biggest Mistake Firms Make in This Transition?

The most common mistake is treating powerful BIM software like an upgraded 3D modeling tool. Teams build a model that looks fantastic but is hollow on the inside, neglecting the underlying data, standards, and QA checkpoints. This approach leads straight to coordination chaos. The model lacks the "I" in BIM—the intelligence—to prevent clashes or automate schedules. Success in both BIM and 3D modeling comes from process discipline, not just software proficiency.

Does Great BIM Require Expensive, High-End Software?

Not always. While powerful software helps, the real engine driving value is the system you build around it. I've seen firms with modest software but bulletproof templates, strict naming conventions, and a rigorous QA culture run circles around firms with the latest tech but no process. Operational consistency and predictable outcomes are born from disciplined workflows, not expensive licenses. The real benefits of BIM for architects and builders are unlocked through systems thinking.

How Long Does It Take to See a Return on Investment?

You'll see an impact on the very first project that uses a well-defined BIM workflow. The reduction in RFIs, faster permit prep, and elimination of on-site clashes provide a clear and rapid return. Your margin protection begins the moment your team catches the first major coordination error in the digital model instead of discovering it in the field. That's ROI you can take to the bank.