Beyond Clash Detection: What BIM Coordination Services Really Deliver

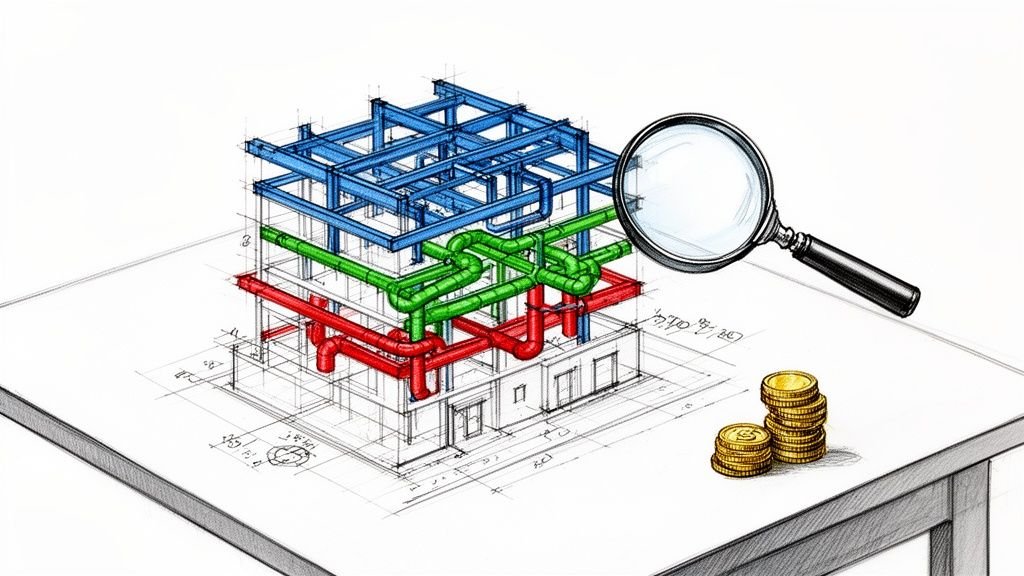

True BIM coordination services aren't about the software you use; they're about production discipline. It’s a structured workflow that governs how information flows between every trade, making sure architects, builders, and MEP contractors are all working from a single, reliable source of truth. Get this right, and you prevent a world of costly surprises on site.

What BIM Coordination Services Really Deliver

Many project teams get this wrong. They think BIM coordination is just about running a federated model through Navisworks and spitting out a clash report. This is a common and incredibly expensive misunderstanding. That reactive approach is like trying to fix traffic jams after they’ve already gridlocked the city.

Real BIM coordination is a proactive system of governance you establish before any significant modeling even starts. It’s the operational framework—the rules of engagement—for every single stakeholder. This isn't some academic exercise; it's a production-level necessity that protects your margins and delivers operational consistency.

We’ve seen coordination cycles shrink dramatically once teams aligned their standards before modeling, not after. The focus shifts from fixing hundreds of trivial clashes to preventing the critical few that cause major delays.

This disciplined approach brings predictability by defining who is responsible for what, and to what level of detail, from day one.

Establishing The Rules of The Road

A proper BIM model coordination workflow gets to the root causes of job site chaos. It tackles the daily headaches that architects, builders, and MEP contractors know all too well:

- Inconsistent Modeling: Different trades modeling “their way” without any shared standards, leading to the same predictable clashes over and over again.

- Ownership Gaps: Endless meetings where no one takes accountability for resolving a conflict, causing critical decisions to stall for weeks.

- Drawing Mismatches: Construction documents that don't actually match the coordinated model, creating a mess of confusion and rework in the field.

- Revision Whiplash: Last-minute design changes that completely derail fabrication schedules because the downstream impacts were never properly managed.

Effective BIM coordination services replace that chaos with a clear, enforceable system. One of the biggest wins from this process is its direct impact on reducing construction costs by catching expensive problems long before they ever reach the field.

A System for Information Management

Think of BIM coordination less as a technology and more as a disciplined form of information management. It’s the system that ensures every trade models within agreed-upon tolerances and according to a shared set of rules.

This includes hammering out the details on:

- Defining LOD Expectations: Clearly outlining the required Level of Development (LOD) for different project phases so everyone knows what "done" looks like.

- Enforcing Naming Conventions: Using strict template discipline to make sure all model elements are organized, identifiable, and easy to find.

- Establishing Review Cycles: Creating a predictable rhythm for model reviews and clash resolution, complete with structured agendas that keep meetings productive.

- Filtering the Noise: Moving beyond raw clash reports to identify and prioritize the conflicts that genuinely impact construction, not just the ones the software flags.

When coordination is treated as a foundational workflow, it creates operational consistency. The federated model transforms from a source of conflict into a source of clarity—a trustworthy tool for decision-making, permitting, and fabrication. This systematic approach is what delivers true project predictability.

Moving From Reactive Clashes To Proactive Coordination

Too many project teams are stuck in a reactive loop. It’s a story we’ve all seen play out: trades model their systems in isolated silos, the federated model gets updated whenever someone remembers, and coordination meetings dissolve into endless finger-pointing over a clash report with hundreds of meaningless conflicts.

This isn't just frustrating—it's expensive. When teams rely on software to catch problems after the fact, they’re essentially building rework into the project plan from day one. This is the critical difference between simply running clash detection services and implementing a true BIM coordination services workflow.

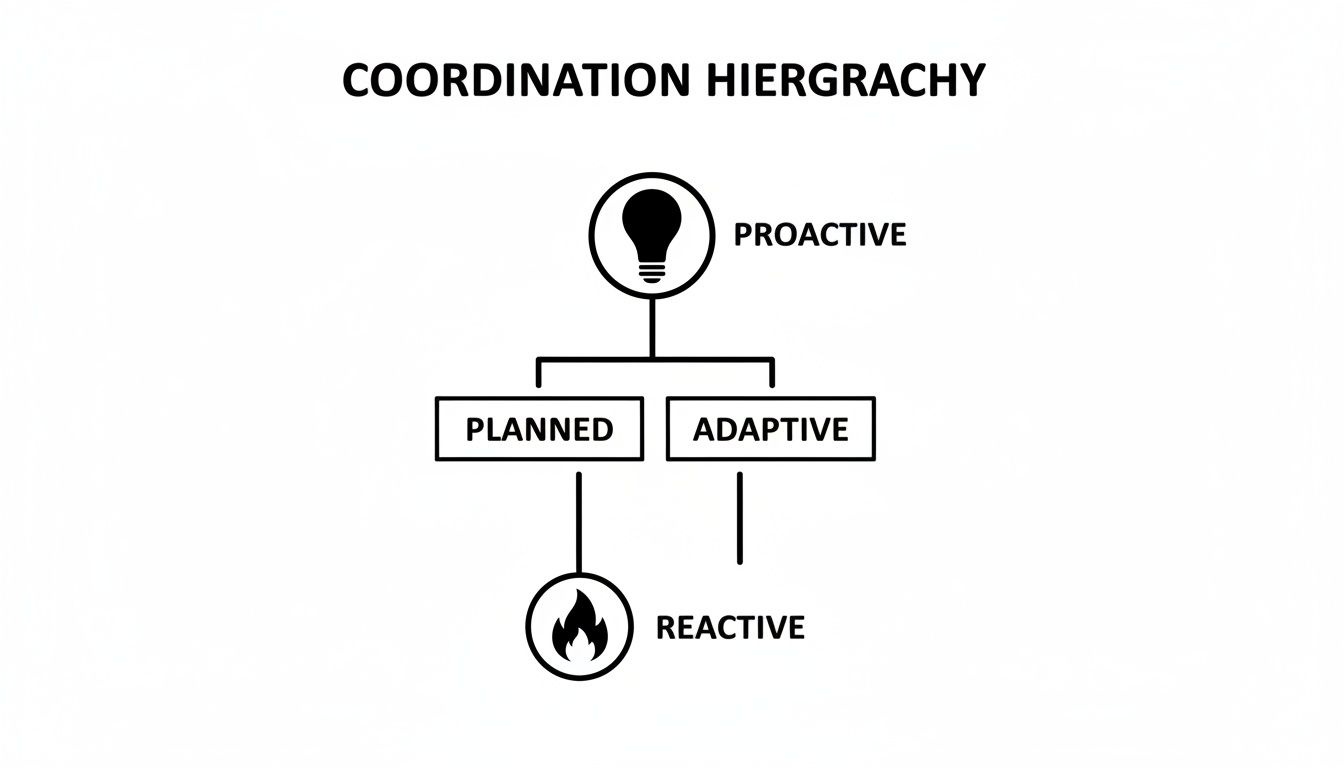

The reactive approach is like waiting for the fire alarm to go off. A proactive approach builds with fire-resistant materials from the start.

The Shift to a Production-Oriented Workflow

Disciplined coordination flips the script. Instead of using meetings to discover problems, it treats them as scheduled decision checkpoints. A professional coordination process sets the rules of the game before anyone starts modeling, turning a chaotic process into a predictable system.

This proactive model is built on consistency and accountability. We’ve seen coordination cycles shrink from weeks to days once teams agree on standards before they model, not after. The conversation immediately shifts from "Whose fault is this?" to "Are we all following the plan?"

A truly coordinated project doesn't just have fewer clashes; it has a shared understanding of how information is created, managed, and trusted. It’s about building a reliable digital asset, not just a pretty 3D model.

A structured environment puts a few key elements in place that are almost always missing in reactive workflows:

- Federated Model Governance: Clear rules on when and how models are submitted, what information they must contain, and who owns their accuracy.

- Structured Meeting Agendas: No more free-for-alls. Meetings follow a strict agenda focused on resolving pre-identified, high-priority issues with the right decision-makers in the room.

- Accountability Matrices: A simple RACI chart clarifies who is Responsible, Accountable, Consulted, and Informed for key tasks. No more guessing games.

- Pre-coordination Checklists: Teams check their own work against project standards before submitting to the federated model, catching most issues before they become someone else’s problem.

To better illustrate the difference, let's look at how these two approaches play out in the real world. The table below breaks down the process, tools, and outcomes when comparing undisciplined clash checking to a structured BIM coordination workflow.

A Comparison Of Reactive Vs Proactive BIM Coordination

| Phase | Reactive Approach (The Problem) | Proactive Approach (The Solution) |

|---|---|---|

| Process | Trades model in silos with minimal communication. Models are combined for the first time during a coordination meeting. | A BIM Execution Plan (BEP) establishes modeling standards, zones, and submission schedules from the outset. |

| Tools | Clash detection software is the primary tool, used to generate massive reports of all conflicts, big and small. | Clash detection is used for final verification. The primary tools are checklists, model checkers, and clear communication protocols. |

| Meetings | Long, argumentative meetings spent identifying problems and assigning blame. Often devolves into redesign sessions. | Short, focused meetings dedicated to resolving pre-vetted, high-priority issues with assigned owners. |

| Outcomes | Constant RFIs, schedule delays, blame games, and costly rework on-site. The project is always behind. | Fewer clashes, predictable schedules, clear accountability, and minimal on-site changes. The project runs smoothly. |

As you can see, the proactive approach isn’t about better software—it’s about a better, more disciplined process that turns coordination into a predictable manufacturing system rather than an unpredictable fire drill.

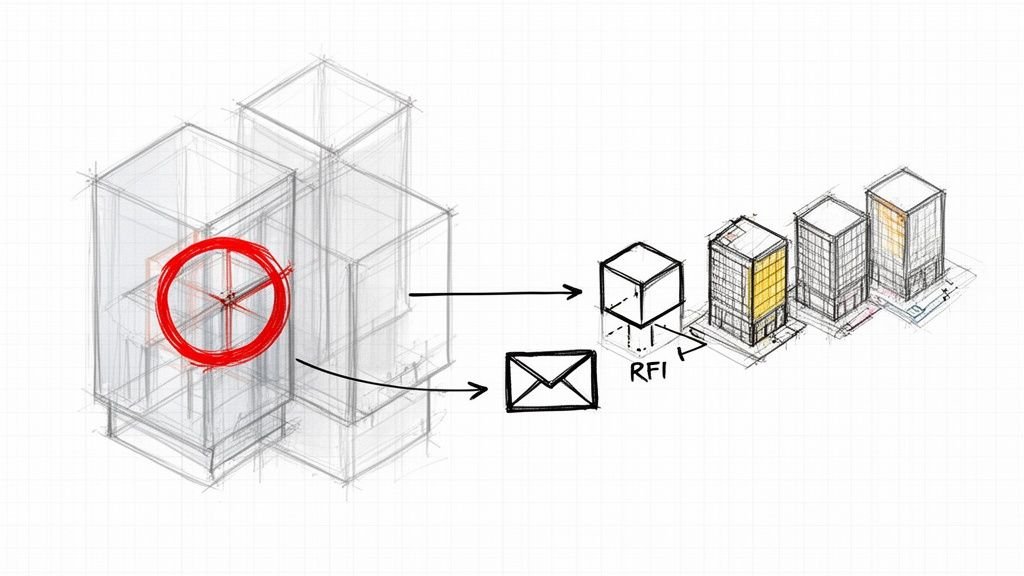

A Tale of Two Projects

Let's make this even more concrete. In a reactive world, an MEP contractor models their ductwork based on their own internal standards. Weeks later, a clash report shows it runs right through structural steel that was also modeled in isolation. The meeting is a mess of arguing over who has to move their system, derailing the schedule and triggering a costly redesign.

Now, imagine the proactive alternative. A BIM model coordination plan was established on day one. The MEP coordination workflow required all trades to use shared origin points and model within designated zones defined in the project's BEP. The contractor’s software, guided by pre-set rules, would have flagged the potential conflict in real-time.

The issue gets resolved in hours, not weeks. No angry meetings, no blame games, no cascading delays. This is what happens when you move from a software-centric view of clashes to a process-driven one. You can learn more about this in our guide to effective clash detection in BIM.

Ultimately, this shift protects the schedule, preserves the budget, and delivers the one thing every project stakeholder values most: predictability.

The Pillars Of An Effective BIM Coordination Workflow

A proactive approach to coordination isn't some fuzzy, abstract idea; it's a structured system built on clear, enforceable rules. Think of it less as a philosophy and more as a production line for reliable project data. When BIM coordination services are set up the right way, they create a predictable rhythm that stops chaos before it even gets started.

This whole system rests on a few key pillars—non-negotiable parts that turn coordination from a reactive scramble into a disciplined workflow. These aren't just "best practices"; they're the foundations that protect your project margins, lock in schedule predictability, and deliver consistency across the board.

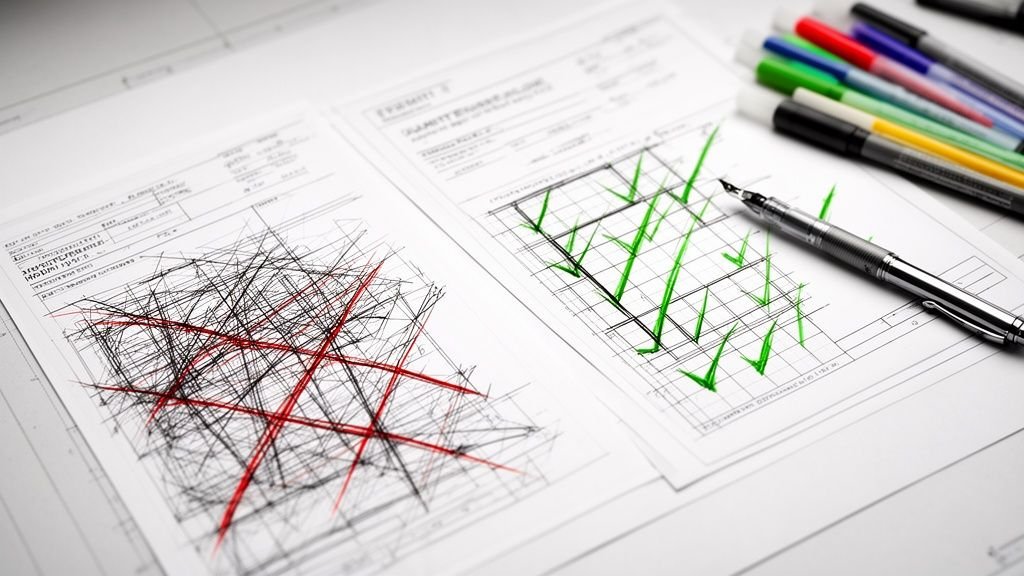

The diagram below shows the fundamental difference between a proactive mindset and a reactive one.

As you can see, truly effective coordination happens at the top level. You’re proactively setting standards to prevent issues, not just putting out fires after they’ve already started.

Pillar 1: The BIM Execution Plan as The Project Constitution

The single most important document in any coordinated project is the BIM Execution Plan (BEP). This isn't just another piece of paper to sign and file away; it's the project's constitution. The BEP is where the rules of engagement for every single trade are spelled out in clear, unambiguous terms.

A solid BEP governs every part of the information flow. It outlines things like:

- Roles and Responsibilities: Who is on the hook for modeling which elements? Who’s in charge of resolving clashes?

- Modeling Standards: What coordinate systems, origin points, and file naming conventions are we all using?

- LOD Requirements: What Level of Development is needed from each discipline at every project milestone?

- Submission Schedules: When are models due for integration into the main federated model?

Without a BEP, every team just falls back on its own internal standards. That’s a guaranteed recipe for misaligned models and the same clashes popping up over and over. A well-written BEP ensures everyone is playing the same game by the same rules.

Pillar 2: Strict Model Discipline and Template Governance

Consistency is the engine that drives an effective MEP coordination workflow. You get there with strict model discipline, enforced by standardized templates and naming conventions. When a mechanical contractor models a duct run, it has to be named and categorized the exact same way, every single time.

This isn't about micromanaging; it's about turning the model into a searchable, reliable database. When every element—from structural beams to plumbing fixtures—follows a consistent protocol, it becomes dead simple to isolate systems, filter clash reports, and run quality checks.

A project that lacks template discipline will inevitably produce a "noisy" federated model. We've seen teams waste hundreds of hours sifting through clash reports that were 90% noise, all because basic modeling standards were never enforced.

This pillar is all about establishing a common language. It ensures that when you look at the model, you're not just seeing geometry; you're seeing organized, intelligible data that you can actually use to make decisions.

Pillar 3: Structured Review Cycles and Noise Filtering

Coordination meetings in a reactive environment are often long, unproductive, and focused on digging up problems. In a disciplined workflow, meetings are short, structured checkpoints for making decisions. The secret is systematic review cycles and intelligent clash filtering.

A mature BIM model coordination process doesn't just run Navisworks and dump a 500-item PDF report on the team. Instead, it’s a multi-stage review:

- Rule-Based Model Checking: Before anything gets federated, individual models are automatically checked against the BEP for compliance. This catches the simple mistakes before they pollute the federated model.

- Initial Clash Detection: The coordinator runs the clash detection services to identify every geometric conflict.

- Intelligent Filtering and Grouping: This is the most important step. The coordinator filters out the insignificant "noise" (like minor tolerance issues) and groups related clashes into a single, actionable problem.

- Prioritization and Assignment: The cleaned-up clash report is then prioritized by severity and assigned to specific trade partners for resolution before the meeting even starts.

This process ensures that meeting time is spent resolving high-priority issues that have already been vetted and assigned. The agenda is built around solutions, not problem discovery.

Pillar 4: Defining Tolerances and Modeling Boundaries

Finally, a proactive workflow establishes clear modeling tolerances and ownership boundaries right from the get-go. A lot of clashes aren't major design flaws; they’re the result of different trades modeling with slightly different assumptions.

For instance, does a pipe need a 2-inch clearance from a steel beam, or is 1 inch okay? Who’s responsible for modeling the block-outs for MEP penetrations through a concrete wall—the structural engineer or the MEP trade?

These questions seem minor, but if you don't answer them upfront, they lead to countless clashes down the road. A disciplined coordination process defines these tolerances and ownership lines in the BEP. It creates a shared understanding of spatial requirements, making sure every trade models with the same set of ground rules. This simple act of pre-defining boundaries prevents a huge percentage of common clashes, freeing up the team to solve real design challenges instead of arguing over inches.

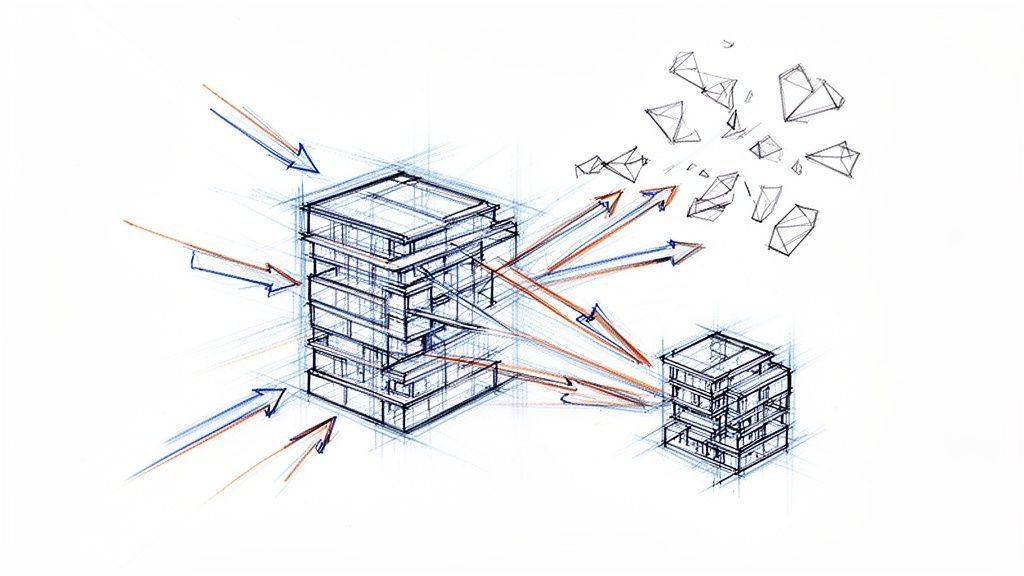

Why Modern Construction Demands Specialized Coordination

The days of sorting things out on-site with informal handshakes are long gone. Modern construction projects, especially in the commercial and public sectors, have become far too complex, fast-paced, and financially risky to leave coordination to chance. The sheer density of systems we now squeeze into buildings makes the old way of doing things completely unsustainable.

This is precisely why specialized BIM coordination services have shifted from a nice-to-have luxury to a core strategic need. An architect, a structural engineer, and an MEP contractor can all be brilliant in their own fields, but someone has to own the disciplined process of weaving their work together into a single, reliable digital truth. Without that specialized oversight, projects are left wide open to preventable risks that kill profit margins and send schedules flying off the rails.

This is especially true in North America, a clear leader in BIM adoption. Market analysis shows that commercial projects are a major driver of this demand—some reports estimate they make up around 38% of the market. It makes sense, given they involve more stakeholders and intricate systems that absolutely require rigorous model coordination. To get a better sense of these trends, you can explore detailed insights on the building information modeling market here.

The Rise of BIM Mandates and Compliance Burdens

Another huge factor is the growing wave of BIM mandates from government agencies and large private owners. These clients aren't just asking for a 3D model anymore. They're demanding structured data, strict adherence to digital standards, and a verifiable coordination process just to get in the door.

For firms without a mature, in-house BIM department, these mandates create a heavy compliance burden. You can't just "wing it" when the contract requires you to deliver a model that meets specific BEP, LOD, and data exchange protocols. This is where specialized BIM coordination services offer immediate value. They bring the systems, templates, and proven workflows needed to check all the boxes without forcing a company to build an entire department from the ground up.

Outsourced coordination isn't about replacing your team's expertise. It's about augmenting it with a production-level workflow that ensures everyone's expert contributions fit together correctly, predictably, and in line with what the owner demands.

Where Coordination Failures Hurt Most

While coordination problems can pop up anywhere, they are most common—and most costly—at the intersection of Mechanical, Electrical, Plumbing (MEP), and structural systems. The tight tolerances and complex routing involved in an MEP coordination workflow create a natural hotspot for clashes that can bring site work to a screeching halt for weeks.

- Ductwork vs. Steel: The classic conflict. A massive HVAC duct runs smack into a primary structural beam, often forcing expensive and time-consuming rerouting.

- Plumbing vs. Electrical: Think of those densely packed ceiling plenums and utility rooms where conduit and piping are fighting for the exact same limited space.

- Fire Protection vs. Everything: Sprinkler systems have to navigate a maze of every other trade, where even a tiny misalignment can cause major installation headaches down the line.

These aren't just minor annoyances; they're direct threats to your budget and schedule. A single unresolved clash in a critical area can trigger a painful cascade of RFIs, change orders, and finger-pointing. Professional BIM model coordination is the strategic defense that shields your project from these costly failures, delivering predictability from design all the way through fabrication and installation.

The Strategic Value Of Outsourcing BIM Services

Given the complexity of modern construction, many AEC firms are at a crossroads: do they build a mature BIM coordination department from the ground up, or do they partner with a specialist? While building an in-house team sounds good on paper, the reality is often a slow, expensive, and distracting process that pulls focus from your core business. It’s a huge investment in talent, training, software, and workflow development.

This is why a growing number of architects, builders, and MEP contractors are choosing to outsource their BIM coordination services. They see it for what it is—not just offloading tasks, but a strategic move to get immediate access to production-ready systems and seasoned experts without the punishing overhead and learning curve. It’s about getting clarity, systems, and reliable delivery from day one.

The numbers back this up. The global BIM market was recently valued between USD 8.5–9.7 billion, with the services segment projected to see the fastest growth—a compound annual growth rate of over 13% through 2033. This shift is driven by project complexity and the non-negotiable need for operational consistency. You can read the full research on BIM market projections to see how this trend is reshaping the industry.

Buying Maturity Instead Of Building It

When you bring on a specialized coordination firm, you’re not just hiring extra hands or renting software licenses. You are plugging your project directly into a mature, battle-tested production engine. This model gives you key advantages that are nearly impossible to replicate quickly in-house.

- Proven Workflows and Templates: A specialist firm arrives with a library of refined templates, checklists, and BEP standards that have been perfected across hundreds of projects.

- Scalable Delivery Pods: They can assign a dedicated, multi-disciplinary “delivery pod” to your project almost instantly, giving you scalable capacity that flexes with your needs.

- Technology Mastery: Their teams are masters of tools like Navisworks and Revit, squeezing every ounce of efficiency and accuracy out of the software.

- Objective Oversight: As a third party, an external coordinator can enforce the rules of the BEP impartially, cutting through internal politics and keeping all trades accountable.

Choosing to outsource is a decision to prioritize your core business. It lets architects focus on design, builders on construction, and engineers on performance, while a dedicated partner manages the critical information flow that connects them all.

Protecting Margins and Ensuring Predictability

Ultimately, the decision to outsource comes down to protecting project margins and achieving operational consistency. An external partner focused solely on BIM model coordination delivers a clear ROI by preventing the very issues that eat into profitability—costly rework, schedule delays, and endless RFIs. Their entire business is built on delivering predictability.

By offloading the complex and time-consuming process of managing multi-trade models, firms can focus on what they do best. This approach gives you a clear path to leveraging expert-level coordination without the risk and cost of building it yourself. You can learn more about how outsourcing BIM helps reduce overall project costs in our detailed guide. It’s a powerful strategy for any firm looking to compete more effectively.

How To Implement A Disciplined Coordination Process

Knowing you need a disciplined workflow is one thing, but actually putting one in place is a whole different ballgame. Making the leap from reactive firefighting to proactive coordination isn't about buying the fanciest new software—it's about committing to a process. Success comes from establishing a new set of rules and, critically, getting every single stakeholder to play by them.

To implement effective BIM coordination services, you have to start treating the project model like a manufactured product, not some artistic sketch. Just like any manufacturing line, it needs standards, quality control checkpoints, and crystal-clear accountability. This is how you ensure the final output—a fully coordinated, reliable digital asset—is built right the first time around.

The guiding principle is simple: define the rules before you play the game. This foundational step is what separates the predictable, profitable projects from the chaotic, money-losing ones.

Establish Your Single Source of Truth

The first, most critical step is to hammer out a comprehensive BIM Execution Plan (BEP). Think of this document as the constitution for your entire project. It's not a formality you check off a list; it’s the central rulebook that kills ambiguity and stops teams from defaulting to their own siloed, incompatible standards. Our guide on crafting effective BIM Execution Plans offers a much deeper dive into this essential document.

A rock-solid BEP has to clearly define:

- Project Goals: What are we actually using this model for? Is it just for clash detection, or will it be used for quantity takeoffs, fabrication, and eventually facility management?

- Roles and Responsibilities: Who owns what? A simple matrix that assigns ownership for every model element is non-negotiable. Who models the sleeves for pipe penetrations? Who has the final say on a structural vs. MEP clash?

- Modeling and Naming Standards: Mandate the basics. Everyone must use the same shared coordinates, project templates, and strict naming conventions for all files and families. This simple discipline keeps the model organized and searchable.

Structure Your Coordination Rhythm

With a BEP in place, the next move is to create a predictable rhythm for communication and review. This means ditching the ad-hoc meetings that spiral into arguments and embracing structured, decision-making checkpoints instead. Any well-run MEP coordination workflow absolutely depends on this steady cadence.

Start by implementing a formal model submission schedule. Each trade uploads their updated model at a regular, agreed-upon interval—say, every Tuesday by 5 PM. This simple act creates a consistent dataset for the coordination lead to work with, turning a messy process into a predictable, manageable cycle.

A disciplined process filters the noise before the meeting even begins. When teams show up to review a concise list of pre-vetted, high-priority issues, meetings become short, productive sessions focused on solutions, not on discovering problems.

Focus on Prevention Over Detection

Here's the secret: true BIM model coordination is less about finding clashes and more about preventing them from ever happening. This requires a mental shift, moving the focus from just running clash reports to rigorously enforcing modeling standards from day one.

A great way to do this is with pre-submission checklists for all trades. Before a model can even be uploaded to the federated environment, the designer must confirm they’ve followed key BEP requirements.

This simple QA step catches a huge percentage of common errors—things like incorrect origin points or non-standard element naming—before they ever get a chance to pollute the central model. This proactive quality control shrinks the pool of potential conflicts, freeing up the entire team to focus their brainpower on resolving the complex, high-value coordination challenges that truly matter. It’s this approach that protects your margins and keeps operations running smoothly.

Ready to Build Your System?

Successful clash detection services are the result of a great system, not the system itself. By establishing a clear plan, a predictable rhythm, and a focus on proactive QA, you build a production workflow that delivers clarity, reliability, and profitability.

For teams looking to put these principles into action, having the right tools can make all the difference. We’ve developed a BIM Coordination Responsibility Matrix Template to help you define roles and streamline accountability right from the start. Download it to begin building a more predictable and profitable coordination process on your next project.

Your Questions About BIM Coordination, Answered

When teams start digging into a structured BIM workflow, a lot of questions pop up. The good news? The answers almost always point back to the same thing: success comes from a solid process and team discipline, not just fancy software.

What's The Difference Between Clash Detection And BIM Coordination?

Think of it this way: clash detection is just one play in the game, while BIM coordination is the entire playbook.

Clash detection services are reactive. They use software to run a check and spit out a report of all the places where models are geometrically bumping into each other. It’s a necessary task, but it happens after the modeling work is done.

True BIM coordination services are the whole process. It’s a proactive strategy that includes setting up the BIM Execution Plan, defining Level of Development (LOD) requirements for everyone, and running structured review cycles. The goal is to prevent clashes from ever showing up in the first place.

When you only rely on clash detection, you're constantly putting out fires. A proper coordination service stops those fires from starting.

When Should BIM Coordination Start In A Project?

As early as humanly possible. The ideal time is during the design development phase, long before serious modeling work kicks off.

The real value of coordination is in setting the "rules of the road" upfront. When you establish standards, clarify responsibilities, and define how everyone will communicate before they start building their models, you avoid the expensive and time-consuming rework that happens when teams are off modeling in their own silos.

Getting coordination started early means every trade builds their model on a shared, agreed-upon foundation. That’s how you protect your project's margins and keep the schedule from going off the rails.

Do We Still Need Coordination If Our Team Uses The Same Software?

Yes. One hundred percent, yes.

Just because everyone is using Revit, it doesn't mean you’re coordinated. It’s a common misconception. Without a disciplined process, you can still have one team using a different template, another using inconsistent modeling techniques, and a third using wonky naming conventions. The result? A federated model that’s a disorganized, unreliable mess.

A disciplined BIM model coordination process is the secret sauce. It ensures that every single person—from the architect to the MEP engineer to the contractor—is using the software according to a single, shared project standard. That discipline is what makes the combined model accurate, reliable, and truly useful.

At BIM Heroes, we know that predictable outcomes are a direct result of a disciplined process. We don't just sell hours; we deliver clarity, systems, and reliable delivery.

Ready to move from reactive problem-solving to proactive control? Download our complimentary BIM Coordination Responsibility Matrix Template to start defining clear roles and building accountability into your next project.