Beyond the Checkbox: Why Your BIM Execution Plan is a Profit Machine

If your project’s BIM Execution Plan is just a file collecting digital dust, you aren't just disorganized—you're actively leaking profit. Too many firms treat the BEP as a contractual formality, a checkbox to tick before the real work begins. This is a critical, and incredibly costly, mistake.

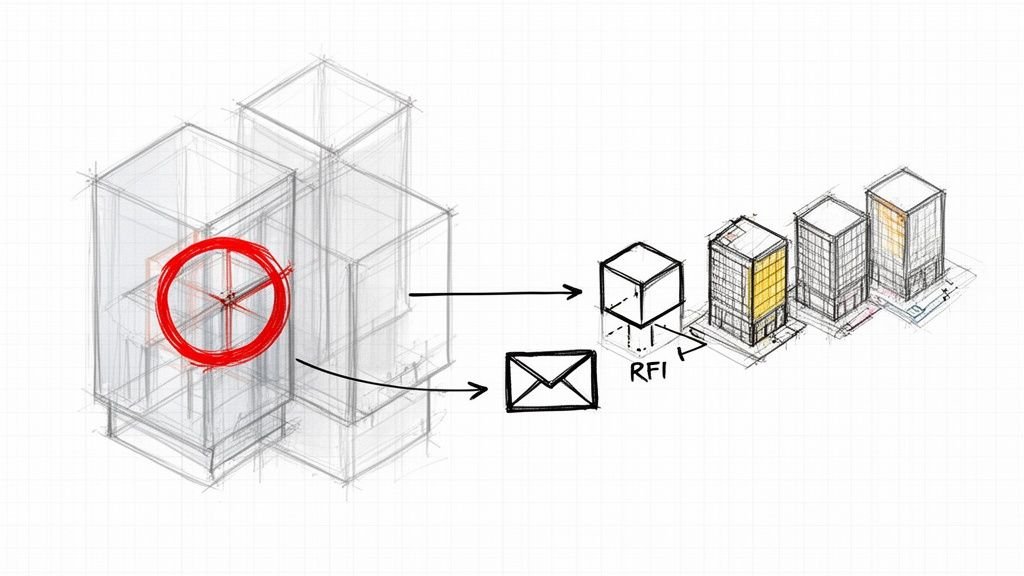

A weak, copy-paste BEP is a direct cause of the most common project headaches: scope creep, endless RFIs, clashing models, and expensive rework. It creates late surprises, unclear ownership, and model inconsistency.

Mature firms get it. They know a well-structured BIM Execution Plan (BEP) is the project's central control system. It’s the blueprint for how projects really run, acting as a safeguard for profit, clarity, and coordination. A BEP done right means fewer RFIs, faster approvals, and calmer teams.

Your BEP is Profit Protection, Not Paperwork

A strong BEP moves beyond theory and enforces real clarity on the ground. We’ve seen teams accelerate pre-con dramatically when the BIM Execution Plan is treated as a living operational playbook, not a static PDF. It preemptively answers the very questions that cause chaos down the road:

- Model Responsibilities: Who models the structural steel versus the MEP hangers?

- LOD Clarity: What Level of Development is required for the 30%, 60%, and 90% deliverable milestones?

- Handoff Logic: How are files named, versioned, and shared between trades to avoid version control nightmares?

- Clash Strategy: When will clash detection be run, and who is responsible for resolving the issues?

Without these rules of engagement, you’re inviting friction and budget overruns. A well-defined BEP in construction translates directly to predictable production and operational consistency. It's the foundation for margin protection.

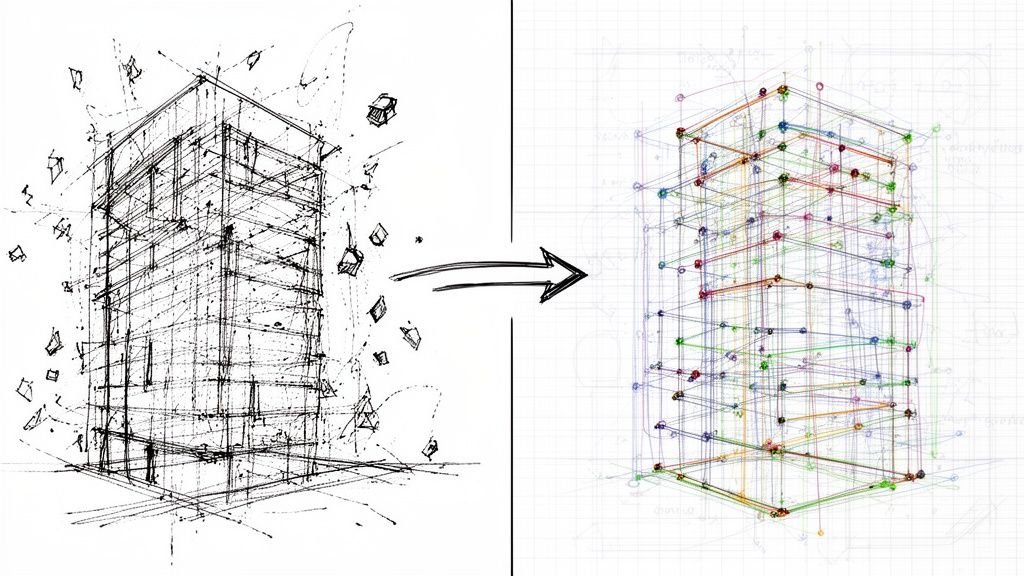

From Document to Governance System

Ultimately, the power of a BEP is in its ability to standardize success. When teams adopt structured BIM standards and workflows, the results are measurable. This shift—from seeing the BEP as just another document to using it as a true governance framework—is what separates high-performing projects from the chaotic ones. As you dig deeper into the benefits of strategic foresight, it becomes clear how effective early planning strategies in construction directly impact project timelines and budgets.

A BEP isn’t a document. It’s governance for predictable, high-quality delivery.

The Anatomy of a BEP That Actually Works

A powerful BEP is a lean, clear set of rules—a playbook built to solve real-world production problems before they blow up your budget and timeline. It’s less about enforcing bureaucracy and more about creating operational consistency.

Model Responsibilities and LOD Clarity

This is ground zero for preventing coordination disasters. Without clear rules, you get the structural engineer modeling to a fabrication-ready LOD 400 while the MEP team is still at LOD 200. The result is always the same: clashes, confusion, and wasted modeling effort.

A strong BEP gets specific. It defines exactly who models what, and to what Level of Development (LOD), at each project milestone. This simple clarity ensures everyone is building their part of the digital twin with the same precision at the same time.

File Naming Standards and Handoff Logic

"Is this the latest version?" If you hear that question, your workflow is broken. Inconsistent file naming across trades—like STRUCT_FINAL_v3.rvt versus S-Model-2024-10-28.rvt—creates chaos.

An effective BEP enforces a single, logical naming convention and spells out the handoff logic: the precise schedule and method for sharing models. This template discipline is the only way to maintain a single source of truth. For a solid framework, review these best practices for BIM version control.

We’ve seen teams accelerate pre-con dramatically when the BEP is treated as a living operational playbook, not a static PDF. It turns ambiguity into action by setting clear expectations from the start.

Clash Detection and QA Cycles

A BEP shifts clash detection from a reactive fire drill to a proactive, scheduled process. It creates decision checkpoints by answering the critical questions up front:

- Frequency: Are we running clash reports weekly or just before major submissions?

- Responsibility: Who runs the clash tests in Navisworks?

- Resolution: What’s the deadline for a trade to resolve their assigned clashes?

- Tolerance: What’s an acceptable clash tolerance for different systems?

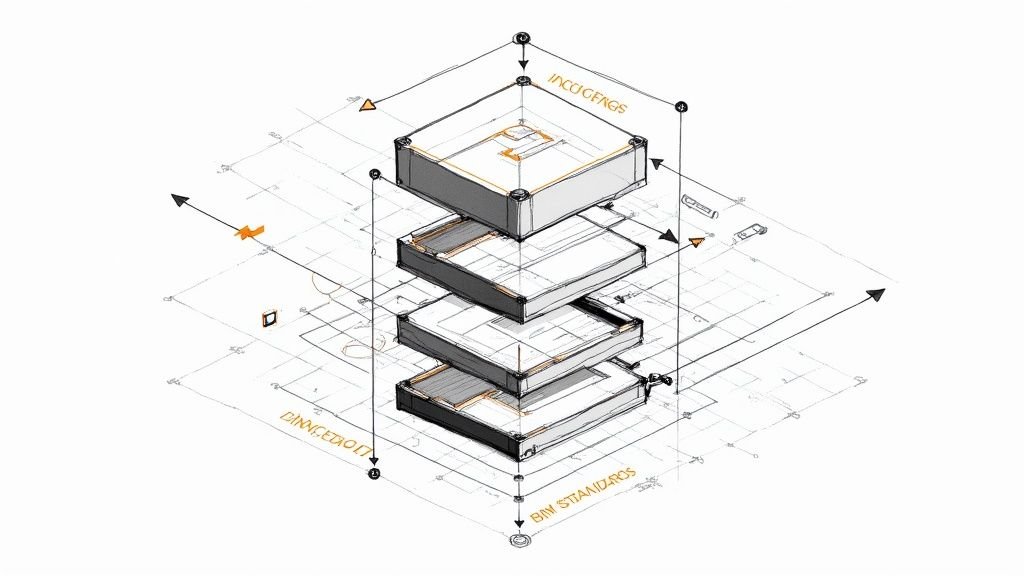

Defining these QA processes creates a predictable rhythm. Issues are found and fixed early when the cost of change is practically zero. The infographic below shows how a solid BEP creates a chain reaction leading from predictability right to profit protection.

This hierarchy makes it clear: the operational rules you set in the BEP are the launchpad for hitting financial targets.

Weak BEP vs. Strong BEP: A Comparison of Outcomes

The difference between a vague BEP and a specific one isn't academic—it directly impacts your bottom line.

| BEP Component | Weak BEP (Causes Chaos) | Strong BEP (Drives Clarity) | Project Outcome |

|---|---|---|---|

| LOD Definition | "Model elements as needed." | "Structural steel to be LOD 350 at 90% CD milestone." | Weak: Rework, inaccurate takeoffs. Strong: Coordinated models, reliable estimates. |

| File Naming | "Use logical file names." | "File Naming: [Project#]-[Discipline]-[ModelName]-v[##].rvt" | Weak: Confusion, lost data. Strong: Clear version control, single source of truth. |

| Clash Detection | "Clashes will be reviewed." | "Clash detection report due every Friday. Critical clashes resolved within 48 hours." | Weak: Last-minute fire drills. Strong: Proactive issue resolution, lower rework costs. |

| Model Handoff | "Share models when ready." | "MEP models to be uploaded to CDE every Tuesday and Friday by EOD." | Weak: Delays, outdated information. Strong: Predictable coordination cycles. |

Specificity is everything. A strong BEP replaces vague suggestions with direct, measurable instructions. It helps to ground your plan in the principles of effective process documentation, turning your BEP into a system for reliable delivery.

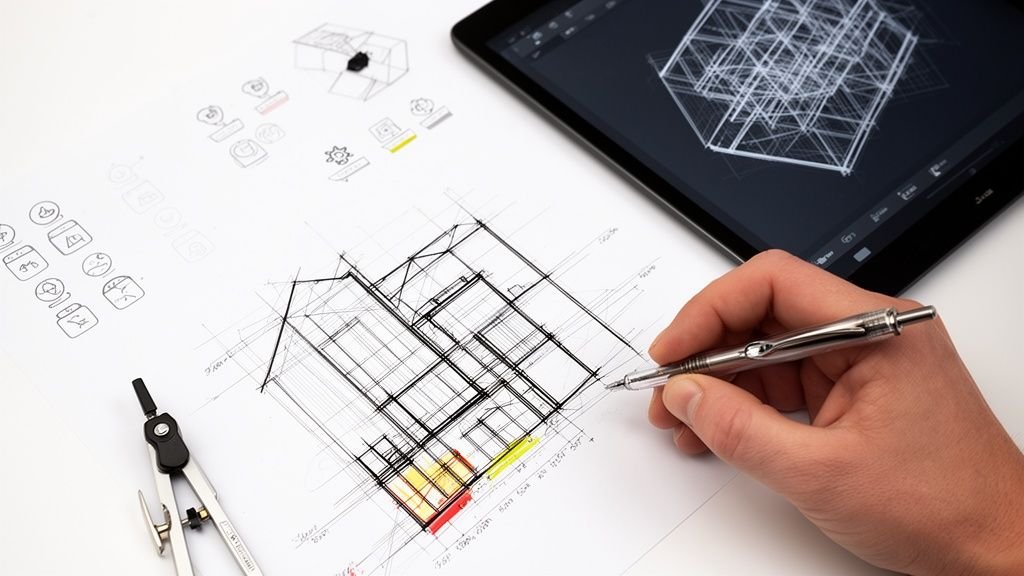

Turn Your BEP Into a Living Project Playbook

Here’s the biggest mistake we see: treating the BEP like a one-time setup document. It gets crafted, signed off, and then filed away, never to be seen again. This approach misses the point and is a fast track to the very coordination chaos the BEP was designed to prevent.

An effective BEP isn’t a static PDF. It's a living, breathing operational playbook that evolves with the project. It needs to be referenced constantly.

Launch with a BEP Kickoff Meeting

Success starts with alignment. The first step is a mandatory kickoff meeting with every key stakeholder. This isn't a formality; it's where you establish the rules of engagement.

Walk everyone through the core components, confirm handoff logic, and lock down the clash resolution workflow. When everyone can look each other in the eye and agree to the plan, accountability skyrockets.

Integrate BEP Reviews at Key Milestones

To keep the BEP relevant, build review checkpoints directly into the project schedule. These are quick, focused, 15-minute huddles at critical project handoffs.

Schedule quick reviews at milestones like:

- Schematic to Design Development: Is the LOD plan holding up? Are model responsibilities clear?

- DD to Construction Docs: As detail ramps up, do naming standards need a tweak? Is the coordination workflow keeping pace?

- CDs to Pre-Construction: How will the BEP be handed off to trade partners for permitting prep?

A 15-minute review before each phase is far cheaper than a week of rework. This simple discipline shifts the mindset from static documentation to active project governance, safeguarding your margins at every step.

This proactive approach ensures the BEP in construction remains a practical tool, not an outdated artifact.

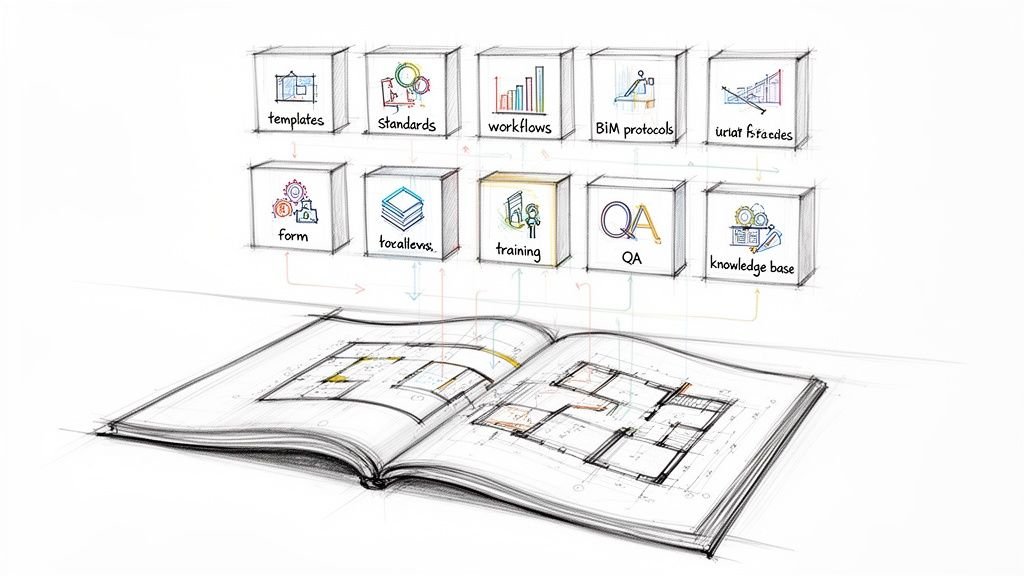

The Power of Template Discipline

For firms juggling multiple projects, template discipline makes scalable delivery pods possible. Mature organizations develop a robust internal BEP template that codifies their best practices from CAD-to-BIM evolution. This becomes the starting point for every new BIM project setup.

But a template is just that—a starting point. The real discipline is customizing it for each project's unique goals. While academic frameworks like Penn State University's widely respected BIM Project Execution Planning Guide offer an excellent foundation, real-world application means adapting those standards to your operational reality. This blend of standardization and flexibility is a hallmark of production maturity.

Common BEP Failures and How to Prevent Them

A BIM Execution Plan can quickly become useless if it’s not built on real-world discipline. We've all seen its rules get ignored once a project hits peak complexity. This erosion of standards is a direct attack on your margins, leading to rework, delays, and a flood of preventable RFIs.

Seasoned firms see these failure points as predictable problems with straightforward solutions. A BEP’s value comes from active enforcement, not just passive agreement.

The Unenforced Standard

This is the classic failure. The BEP outlines a file naming convention, but within weeks, one trade partner reverts to their old habits, and the "single source of truth" is a mess.

Prevention Tactic: You need a "keeper of the BEP." This is usually the BIM Manager. Their job is to own the plan, conduct quick audits, and gently—but firmly—correct anyone who deviates. It’s not about being a police officer; it's about being a project guide.

The Copy-Paste Problem

Grabbing a BEP from a previous project and doing a quick find-and-replace is a recipe for disaster. A BEP for a hospital has different goals and deliverables than one for a residential complex. A generic BEP provides a false sense of security.

Prevention Tactic: Treat your internal BEP template as a starting point. Insist on a project-specific BEP kickoff to review and customize it. This forces everyone to think critically about what success looks like for this project. Understanding common stakeholder issues in BIM projects is crucial here.

A BEP isn't a legal document to be filed away. It's an operational agreement that governs daily production. If it's not being referenced in coordination meetings, it’s already failed.

LOD Ambiguity

This one is subtle but destructive. A BEP might state "LOD 300 for CDs," but fails to define what that means for each discipline. This leads to trades either over-modeling (wasting hours) or under-modeling (creating coordination gaps).

Prevention Tactic: Get granular. Use a responsibility matrix in your BEP that explicitly defines LOD requirements by discipline and by key model element for each project milestone. For example: "Structural steel beams to LOD 350 at 90% CD milestone, including all plates and connections."

BEP Pitfall Prevention Checklist

Use this checklist to keep your BEP a valuable asset.

| Common Pitfall | Symptom (How You Know It's Happening) | Prevention Tactic |

|---|---|---|

| Unenforced Standards | Inconsistent file names in the CDE; late model handoffs. | Designate a "BEP Keeper" (BIM Manager) for regular, brief audits. |

| The Copy-Paste BEP | Stakeholders complain the plan doesn't address their needs. | Hold a mandatory, project-specific BEP kickoff to customize your template. |

| LOD Ambiguity | Models are over- or under-detailed, creating rework. | Create a detailed responsibility matrix defining LOD by element, discipline, and milestone. |

| "Set It and Forget It" | The BEP is never mentioned after kickoff. | Make the BEP a standing agenda item in weekly meetings. Ask: "Are we following the plan?" |

| Lack of Buy-In | Team members ignore BEP rules. | Involve key stakeholders from all major disciplines in the BEP creation process. |

By anticipating these common pitfalls, your team can transform its BIM project setup from a reactive process into a proactive system for predictable, profitable delivery.

Aligning Your BEP with Global Standards Like ISO 19650

As your firm bids on larger, more complex projects, aligning your BIM Execution Plan with global standards like ISO 19650 becomes non-negotiable. Think of them less as red tape and more as a shared blueprint for predictable data exchange.

Essentially, ISO 19650 acts as a universal language for project data. It provides a structured way to define, produce, and hand off information, which dramatically cuts down on miscommunication.

Translating Standards into Practical Workflows

The real magic happens when you translate the core principles of ISO 19650 into your team's day-to-day BIM standards and workflows. It’s about embedding its operational logic into how you work.

Key concepts that will shape your BEP include:

- Information Requirements: The client clearly states what information they need, why, and when. This forces critical clarity right from the BIM project setup phase.

- Defined Roles: The standard brings sharp clarity to information management responsibilities, which aligns perfectly with a strong BEP.

- Common Data Environment (CDE) Workflow: The standard mandates a strict process for how information moves through the CDE—the antidote to version control chaos.

Adopting principles from established standards doesn’t mean you have to scrap your entire process. It’s about leveling it up. You’re mapping your proven internal workflows to a globally recognized structure, making your delivery teams scalable.

Building a Scalable BEP Template

The smartest way to put these standards into practice is to build their logic directly into your firm’s internal BEP template. When your template is structured to align with ISO 19650, you create a consistent foundation for every project.

This alignment demonstrates a level of production maturity that gives clients immense confidence. It transforms your BEP in construction from a simple project document into a strategic tool. You can learn more about the top BIM compliance standards for 2025 to see how they all fit together.

Your Next Step Toward Predictable Project Delivery

A BIM Execution Plan is more than a box to check. It's the governance system for your entire project. It’s what turns chaos into a predictable, high-quality delivery process.

A weak, copy-paste BEP invites rework, RFIs, and shrinking margins. A strong, living BEP is your firm's best defense against those risks. The time you invest upfront in a solid BIM project setup pays for itself over and over again. It’s the difference between last-minute panic and a smooth workflow.

The core lesson is simple: BEPs aren’t documents you create. They are operational agreements you live by. This shift in mindset separates firms that struggle with BIM from those that master it.

From Plan to Practice

Mature firms understand this level of discipline in BIM standards and workflows doesn’t just happen. This commitment is what makes scalable delivery possible, protects your bottom line, and builds a reputation for reliability.

We’ve seen firsthand how a well-crafted BEP can stabilize production. These aren't theories; they're lessons learned in the field that swap ambiguity for accountability.

To help you put these ideas into action, we’ve put together a BEP Starter Checklist. It’s a simple framework to make sure you cover the critical components of a plan that actually works.

Download Our Free BEP Starter Checklist Here

Got Questions About BEPs? We’ve Got Answers.

Even with the best plan, questions pop up. Here are some quick, no-nonsense answers to the most common queries about BIM Execution Plans.

Who’s Actually in Charge of Creating the BEP?

The project's lead BIM Manager or Coordinator typically drafts it, but the creation process must be a team sport. Key players from architecture, engineering, and construction need to have their say to ensure the plan is practical. Without shared ownership, you’ll never get true buy-in.

When Should We Create the BEP?

As early as humanly possible, ideally in the pre-design phase. Creating it early establishes the "rules of the road" and is the best way to prevent the BIM project setup inconsistencies that lead to painful rework.

Are BEPs Just for Massive Projects?

Absolutely not. That’s a common misconception. While non-negotiable for a complex project, a simplified BEP brings incredible clarity to any job. The goal is operational consistency, which protects your margins regardless of project size.

We’ve seen teams accelerate pre-con dramatically when the BEP is treated as a living operational playbook, not a static PDF. This holds true for a small commercial fit-out just as much as it does for a new hospital wing.

How Does a BEP Connect to ISO 19650?

Think of it this way: ISO 19650 is the international playbook for managing information. The BEP is how you run those plays on your specific project. A BEP aligned with ISO 19650 principles takes the standard’s high-level guidelines and turns them into actionable BIM standards and workflows. For deeper resources, check out organizations like the National Institute of Building Sciences.

Can't I Just Download a Template and Call It a Day?

Using a template is a smart starting point. But you should never just copy and paste. Every project has unique goals, deliverables, and team dynamics. The most effective BIM Execution Plan always starts with a solid template but is then carefully tailored to fit the project's real-world needs. A generic BEP is a giveaway of a low-maturity process.

At BIM Heroes, we don’t sell hours; we sell clarity, systems, and reliable delivery. We help firms move beyond checkbox BEPs to build robust governance systems that drive predictable project outcomes. If you're ready to bring this level of clarity to your projects, we’re here to help.