Beyond the Basics: 10 Building Information Modeling Benefits That Protect Margins and Tame Chaos

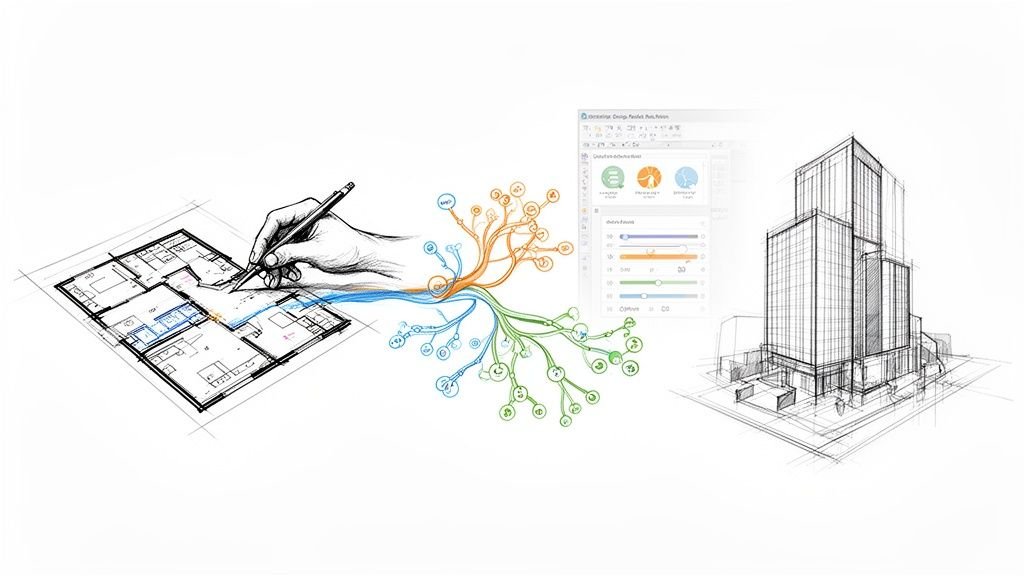

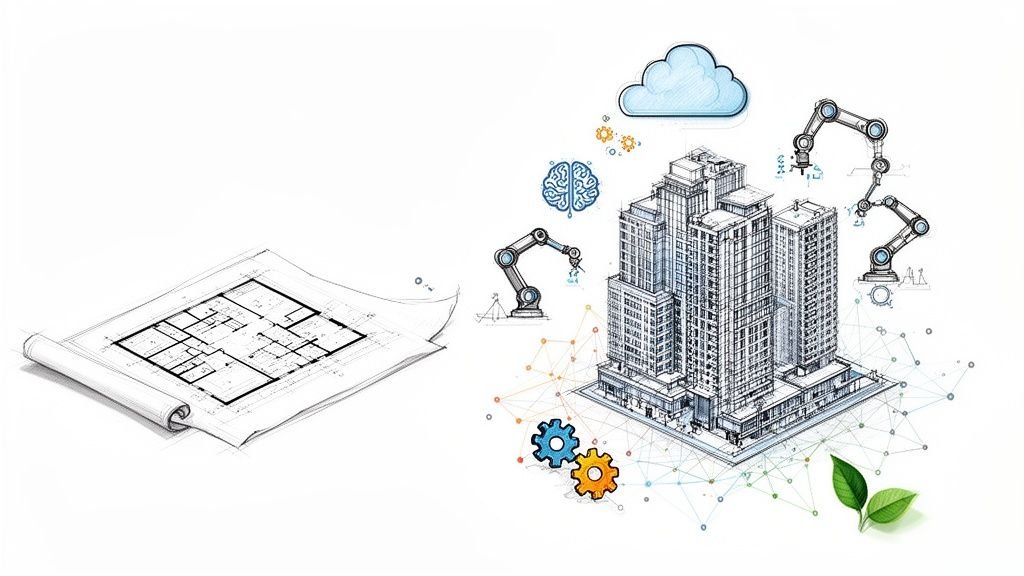

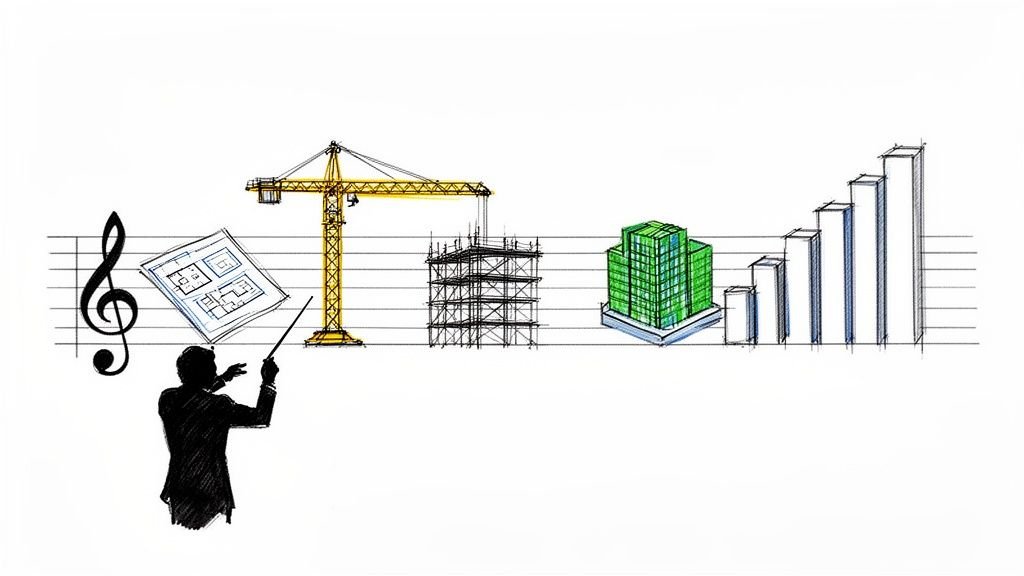

If you’re reading this, you know BIM exists. You’ve seen the 3D models and heard the high-level promises of “better coordination.” But the real building information modeling benefits aren’t found in flashy renderings; they are measured in protected margins, fewer RFIs, and calmer project teams. The difference between a firm fighting its models and one scaling with them comes down to a simple shift: BIM isn’t a software skill—it’s the operating system for modern, predictable delivery.

Mature BIM adoption moves beyond basic visualization to create a production system where standards, templates, and QA checkpoints drive every decision. This approach transforms a model from a picture into the single source of truth for everything from permitting to fabrication. It’s the framework that enables firms to achieve tangible BIM productivity outcomes, moving past chaotic, one-off projects toward scalable, repeatable success. When BIM is treated as a production system, it ensures design-to-permit continuity, tightens fabrication cycles, and creates a clear path for every stakeholder.

In this list, we'll skip the obvious and focus on the practical, business-driven BIM advantages in construction that emerge when it becomes the backbone of your workflow. We will explore ten core benefits that matter most to architects, builders, and pre-construction leaders focused on operational consistency and profitability.

1. De-Risk Permitting with Model-Driven Sheet Logic

One of the most powerful and often underestimated building information modeling benefits is the ability to transform the permitting process from a high-risk bottleneck into a predictable checkpoint. In a mature BIM environment, the model isn't a visualization tool; it's the single source of truth that drives all documentation.

How Model-Driven Logic Works

This approach hinges on template discipline where drawing sheets are not manually drafted but are live, direct views of the vetted 3D model. Plans, sections, elevations, and schedules are all generated and coordinated through a centralized system. If a wall moves or a window changes, that revision automatically populates across every relevant sheet.

This eliminates the frantic, error-prone process of manual cross-checking that plagues traditional 2D workflows. The consistency inherent in a model-driven process gives plan reviewers confidence that what they see on one sheet is accurately reflected on all others, significantly reducing comments and revision cycles.

Key Insight: When your permit set is a direct, filtered reflection of a coordinated model, you aren't just submitting drawings; you're submitting a verifiable, internally consistent project database.

Actionable Implementation

To leverage this, firms must invest in developing and enforcing robust BIM standards and templates. This involves:

- Standardized View Templates: Define specific settings for how drawings are displayed to ensure consistency.

- Automated Sheet Setup: Use project templates to automatically generate sheets with the correct title blocks and views.

- Rigorous QA Processes: Conduct regular model audits to ensure data integrity before generating permit documents.

We’ve seen firms shorten pre-con timelines when they master this workflow. The predictability it creates not only accelerates approvals but also protects project margins by preventing costly delays and rework. For any firm focused on scalable delivery, treating the permit set as a direct output of the model is a non-negotiable step toward operational maturity.

2. Enhanced Collaboration and Communication

Beyond mere 3D visualization, one of the most transformative building information modeling benefits is its function as a central nervous system for project communication. BIM creates a unified digital environment where architects, engineers, contractors, and owners access and contribute to a single, shared model. This dismantles the communication silos that plague traditional, document-centric workflows.

How Model-Driven Logic Works

This centralized approach ensures all stakeholders are working from the same real-time information. When an engineer updates a structural element or a builder identifies a constructability issue, the change is logged and visible within the model for all disciplines to see. This direct, model-based communication dramatically reduces the misunderstandings and costly rework that arise from outdated drawing sets and fragmented email chains.

Mature BIM workflows prevent the friction caused by late changes from trades and coordination headaches. The shared model becomes the primary platform for resolving conflicts before they reach the field, saving time and resources.

Key Insight: A centralized BIM model transforms communication from a series of disjointed conversations into a structured, transparent, and fully documented dialogue tied directly to project data.

Actionable Implementation

To turn a model into a true collaboration hub, project leaders must establish clear protocols. This involves:

- Defining a BIM Execution Plan (BEP): Create a clear document outlining roles, responsibilities, and communication workflows for all stakeholders.

- Holding Model-Based Coordination Meetings: Use the live model and clash detection reports as the central agenda, making discussions visual, specific, and decisive.

- Implementing Cloud-Based Platforms: Utilize tools like Autodesk Construction Cloud or Trimble Connect to provide universal, real-time access to the model.

Mastering this collaborative workflow is essential for any firm aiming for scalable delivery and margin protection. It converts the BIM model from a design artifact into an active project management tool. For teams looking to improve their systems, it's wise to evaluate the best collaboration tools for architectural teams that align with their production goals.

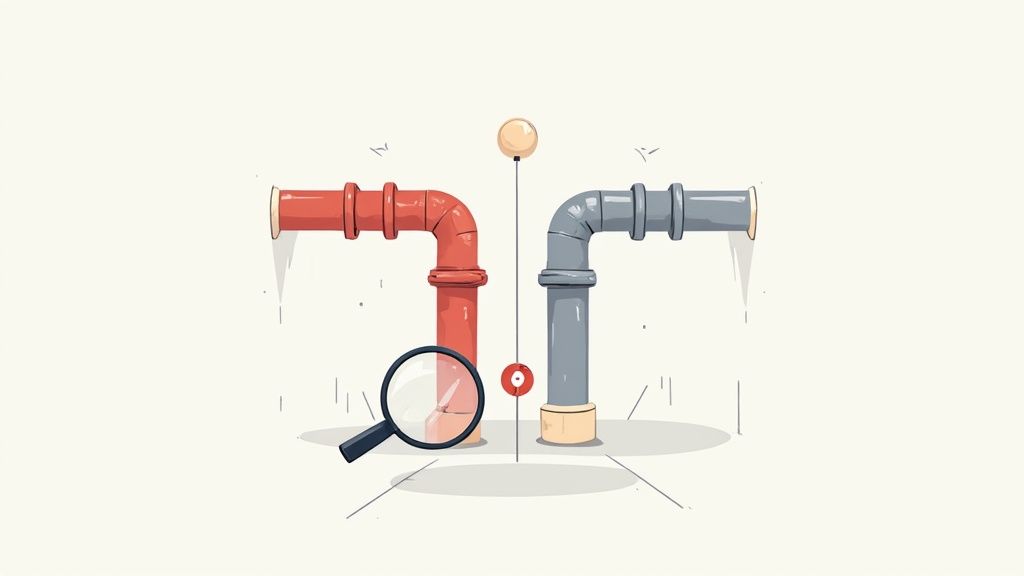

3. Clash Detection and Conflict Resolution

One of the most transformative building information modeling benefits is the ability to shift conflict resolution from the chaotic, expensive construction site to the controlled digital environment. Clash detection proactively identifies spatial conflicts where different building systems (e.g., HVAC, plumbing, structural beams) are modeled to occupy the same space, preventing costly rework and schedule disruptions before a single shovel hits the ground.

How Model-Driven Logic Works

In a coordinated BIM workflow, models from all disciplines—architectural, structural, and MEP—are federated into a single composite model. Specialized software then runs automated checks to find interferences, from hard clashes (two objects in the same space) to clearance clashes (insufficient space for maintenance or code requirements).

This systematic process replaces the unreliable method of overlaying 2D drawings. By catching these issues virtually, project teams can resolve thousands of potential on-site conflicts during pre-construction, which directly reduces RFIs prevention.

Key Insight: Proactive clash detection transforms the model from a design representation into a buildability simulation, allowing you to de-risk the construction phase with unprecedented accuracy.

Actionable Implementation

To turn clash detection into a reliable production system, firms must establish a clear and consistent process. This involves:

- Implementing Early and Often: Begin running clash detection routines as soon as models from different disciplines are available and continue through design development.

- Defining Clash Rules: Establish project-specific rules defining what constitutes a clash and set appropriate tolerance levels for different system interactions.

- Holding Regular Coordination Meetings: Conduct weekly or bi-weekly clash review meetings where stakeholders are assigned specific conflicts to resolve with clear deadlines.

- Assigning Responsibility: Ensure every identified clash is assigned to a specific team member for resolution, tracking its status until it is closed out.

Mastering this workflow is fundamental to protecting project margins and schedules. It directly reduces the number of costly change orders and RFIs, ensuring a smoother path from design to completion.

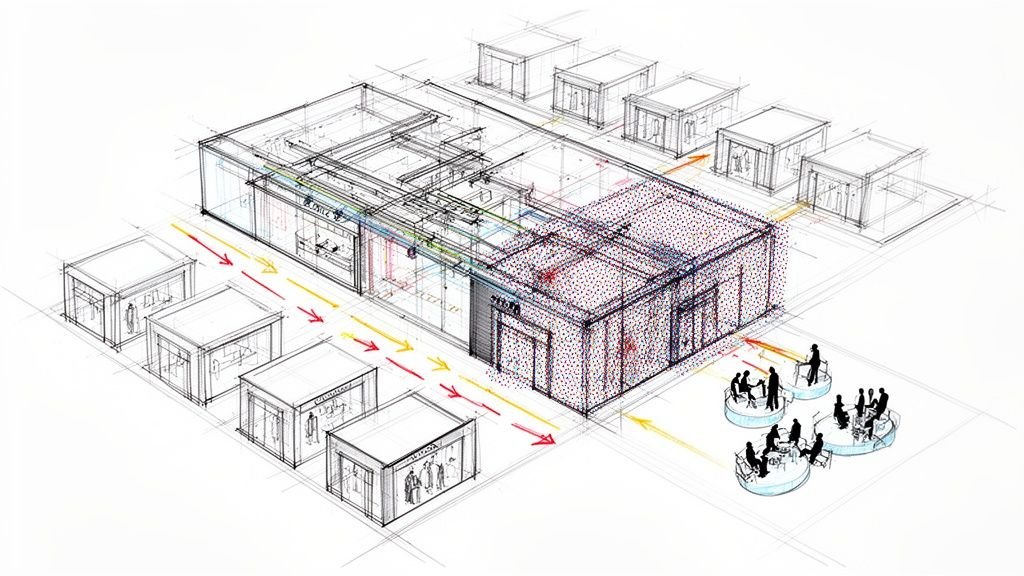

4. Improved Project Schedule Management

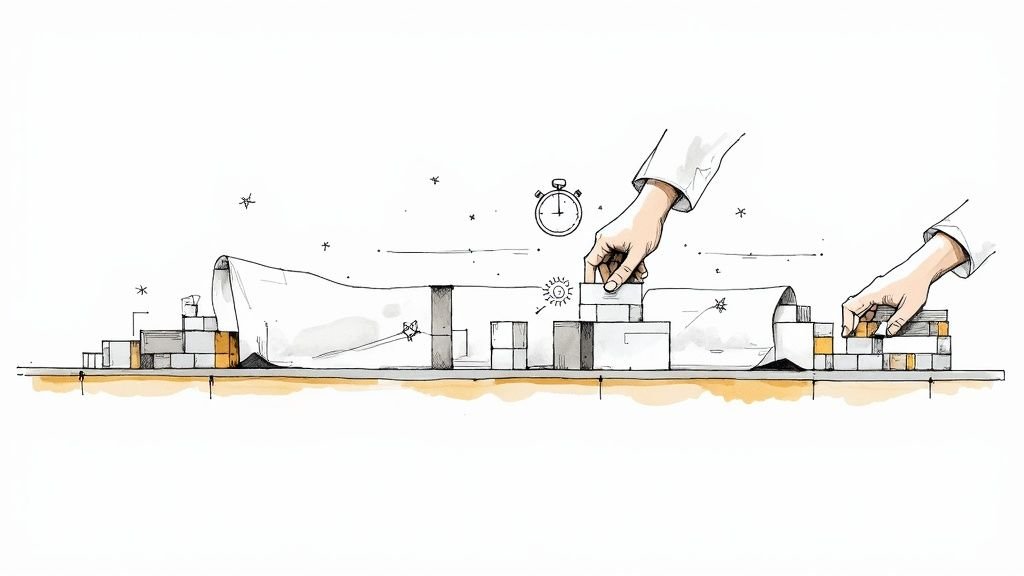

Another of the most significant building information modeling benefits is the ability to integrate project timelines directly with the 3D model, creating what is known as 4D BIM. This moves scheduling from an abstract Gantt chart into a dynamic, visual simulation of the construction sequence. The model becomes a tool to watch the project come together digitally before work begins on site.

How Model-Driven Logic Works

In a 4D environment, every modeled element—from foundations and steel to MEP systems—is linked to a specific task in the project schedule. As you move through the timeline, you can see the building assemble itself in the correct sequence. This visual verification instantly exposes logical flaws and trade stacking issues that are nearly impossible to spot on a traditional schedule.

This proactive approach allows project managers to optimize the construction path and identify opportunities to compress timelines. The ability to simulate different sequences helps teams find the most efficient path forward, reducing on-site delays and schedule pressure.

Key Insight: A 4D model transforms the project schedule from a static document into a dynamic simulation, enabling teams to rehearse the entire construction process virtually to de-risk on-site execution.

Actionable Implementation

To leverage 4D scheduling, teams must connect their model data with scheduling software. This requires:

- Linking BIM Elements to a WBS: Connect model components to corresponding items in the Work Breakdown Structure and construction schedule.

- Simulating Construction Sequences: Run multiple simulations to test different phasing strategies and identify the optimal path for logistics and trade coordination.

- Using 4D for Stakeholder Communication: Use the visual timeline in meetings to clearly communicate the construction plan and validate key milestones.

In mature BIM environments, 4D is a core part of the production workflow. For any construction or design-build firm focused on predictable delivery, integrating the schedule with the model is a crucial step toward mastering project flow and protecting delivery dates.

5. Prefabrication and Modular Construction Optimization

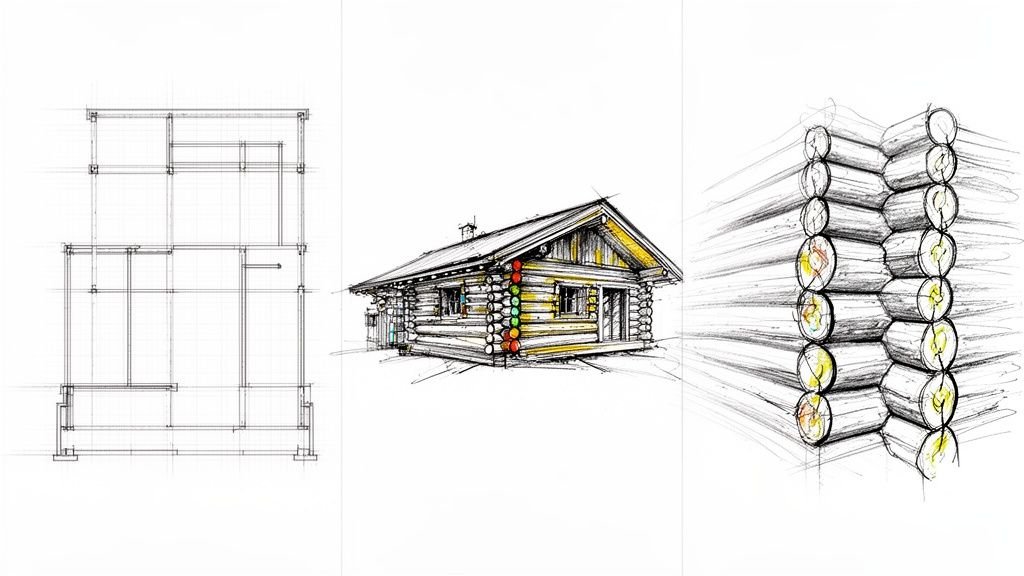

One of the most impactful building information modeling benefits is its ability to radically improve the precision and efficiency of off-site manufacturing. By moving from concept to fabrication within a single, data-rich environment, BIM provides the digital certainty needed for prefabrication and modular construction to thrive. It connects design intent directly to the factory floor.

How Model-Driven Logic Works

In a BIM-driven prefabrication workflow, the model is far more than a design tool; it becomes the direct source for manufacturing instructions. Every component, from structural steel frames to MEP racks, is modeled with fabrication-level detail, including precise dimensions, material specifications, and connection points.

This level of detail allows manufacturers to extract data directly from the model to automate cutting, assembly, and quality control. It eliminates the ambiguity of 2D shop drawings and ensures every component is produced within tight tolerances. When these elements arrive on-site, they fit together with predictable accuracy, dramatically accelerating construction schedules.

Key Insight: When the fabrication line is fed directly from a coordinated BIM model, you aren't just building faster; you're operating a just-in-time manufacturing process that reduces waste and de-risks the entire project timeline.

Actionable Implementation

To capitalize on this benefit, project teams must integrate manufacturing partners into the BIM process early. This collaborative approach ensures the model meets fabrication requirements from the outset.

- Establish Tolerances Early: Define and document all connection tolerances and interface points within the model to prevent clashes during on-site assembly.

- Create Component Libraries: Develop standardized, reusable BIM families for common prefabricated elements to ensure consistency.

- Generate Automated Fabrication Drawings: Leverage BIM software to produce shop drawings and cutting lists directly from the approved model.

For organizations looking to leverage modern construction methods, treating the BIM model as the central manufacturing database is the key to unlocking new levels of productivity. Learn more about the steps involved in a comprehensive prefabrication workflow on bimheroes.com.

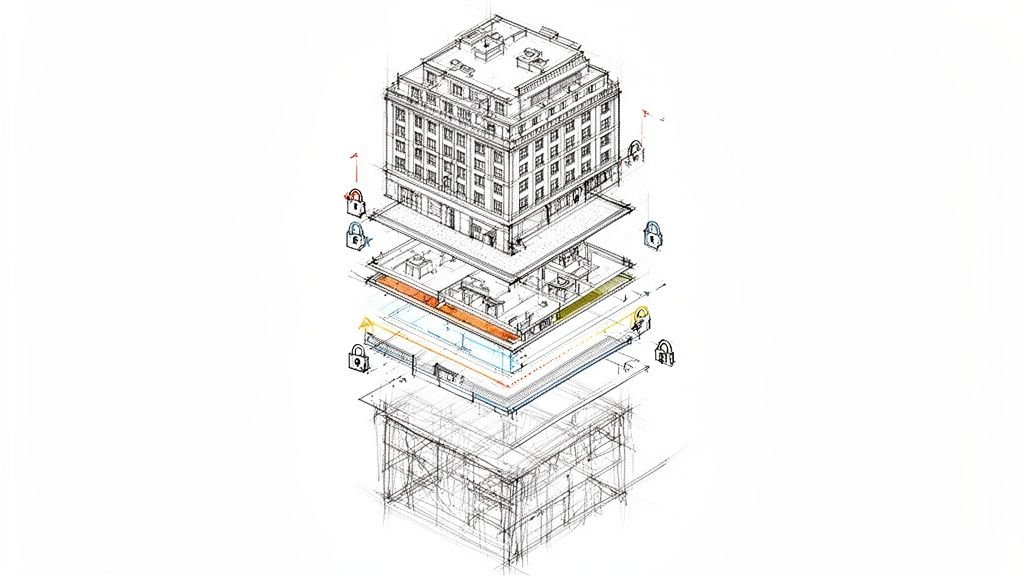

6. Facility Management and Lifecycle Value

One of the most profound building information modeling benefits is the extension of the model’s value far beyond project closeout. Instead of static as-built drawings, the BIM model becomes a dynamic database for the building's entire operational lifecycle. This transforms the handover process from a data dump into the creation of a true digital twin.

How Model-Driven Logic Works

In this approach, the model is enriched during design and construction with data critical for ongoing operations. Assets like HVAC units and pumps are populated with manufacturer details, installation dates, and maintenance schedules. Facility managers can then query the model to locate an asset, access its service history, and schedule preventative maintenance.

This eliminates digging through old manuals or disorganized files. When a building's operational data is tied directly to its spatial representation, facility teams can make faster, more informed decisions, optimizing energy use and streamlining repairs.

Key Insight: A well-structured as-built BIM isn't just a record of what was built; it's a living operational manual that provides asset intelligence for the next 30-50 years of the building's life.

Actionable Implementation

To deliver a model with genuine lifecycle value, project teams must plan for it from the outset. This involves:

- Defining Asset Data Requirements: Collaborate with the owner and facility management team early to establish clear standards for what data needs to be captured for each asset category (COBie is a common standard).

- Integrating FM Data During Construction: Implement workflows to ensure that as-installed information, serial numbers, and commissioning data are accurately logged in the model before handover.

- Connecting BIM to CMMS: Plan for integration between the BIM model and the owner's Computerized Maintenance Management System (CMMS) to enable a seamless flow of operational data.

We’ve seen organizations drastically reduce operational expenditures by leveraging BIM for asset management. The ability to predict maintenance needs delivers a tangible return on investment that continues for decades, solidifying the long-term value of a mature BIM production system.

7. Risk Assessment and Safety Planning

A key building information modeling benefit is its ability to proactively manage and mitigate job site risk before work begins. BIM transforms safety planning from a reactive, checklist-driven exercise into a dynamic strategy. By visualizing complex construction sequences and site logistics in a 4D environment (3D model + time), teams can identify and address potential hazards with clarity.

How Model-Driven Logic Works

In this workflow, the model becomes a virtual proving ground for safety protocols. Teams can simulate high-risk activities, like crane lifts or complex scaffolding, to identify clash points, blind spots, and inadequate clearance zones. This allows for the development of precise, visually-documented safety plans that are easy for field crews to understand.

This data-driven approach moves beyond generic safety guidelines to site-specific hazard analysis. For instance, teams can leverage BIM to meticulously plan crane placement and swing paths, ensuring operations remain clear of power lines and public access.

Key Insight: When your safety plan is derived from a coordinated site logistics model, you aren't just creating a document; you're building a verifiable, sequence-aware safety protocol that anticipates risks before they materialize.

Actionable Implementation

To turn your model into a powerful safety tool, focus on integrating safety planning into your BIM process early. This involves:

- Creating Detailed Site Logistics Models: Model temporary structures, material laydown areas, and heavy equipment paths to visualize the entire construction ecosystem.

- Involving Safety Professionals Early: Bring safety managers into BIM coordination meetings to provide expert input during the design phase.

- Using VR/AR for Immersive Training: Leverage virtual and augmented reality to walk field teams through complex tasks in a safe, simulated environment.

By making the model the centerpiece of safety planning, firms can reduce incidents and protect project timelines from safety-related delays. To better understand how robust data analysis contributes to informed choices, exploring how AI-powered analytics transforms business-decision-making can provide valuable context.

8. Accurate Quantity Takeoffs and Material Procurement

Another impactful building information modeling benefit is generating precise material quantities directly from the model, transforming procurement from an estimate into a data-driven process. In a mature BIM ecosystem, every modeled element contains the data for an accurate bill of materials, eliminating the guesswork that leads to budget overruns.

How Model-Driven Logic Works

This approach relies on the model being the "single source of truth" where elements like walls and doors are not just shapes but data-rich objects. Automated schedules and material takeoff reports can be generated instantly. When a design change occurs, takeoff schedules update automatically, ensuring procurement teams are always working with current information.

This data-centric workflow prevents costly errors like over-ordering (material waste) or under-ordering (project delays). This capability helps reduce material waste and optimize supply chain logistics.

Key Insight: A well-structured model doesn't just represent the building; it contains a live inventory of every component required, enabling just-in-time procurement and minimizing financial risk.

Actionable Implementation

To turn your model into a reliable procurement engine, your team must focus on data integrity from day one. This requires:

- Enforcing Data-Rich Families: Ensure all model components contain complete, accurate material specifications and manufacturer data.

- Creating Standardized Takeoff Schedules: Develop and use pre-configured schedule templates that automatically extract and organize the specific data needed for procurement.

- Integrating with Procurement Systems: Link BIM data directly to procurement software to automate purchase orders and coordinate with suppliers.

Mastering this workflow provides unparalleled cost certainty early in the project lifecycle. It allows for more competitive bidding and a streamlined supply chain, protecting project margins by ensuring you buy exactly what you need when you need it.

9. Stakeholder Engagement and Client Satisfaction

Beyond internal production efficiency, one of the most significant building information modeling benefits is its power to transform client communication. BIM moves design discussions beyond abstract 2D drawings into immersive, easily understood virtual experiences. This clarity helps clients and investors grasp design intent, leading to faster decisions.

How Model-Driven Logic Works

Instead of relying on floor plans alone, stakeholders can experience a project through virtual walk-throughs and VR simulations. These are direct outputs from the central BIM model. When a design element changes, the visualizations can be updated in near real-time, ensuring everyone is reviewing the most current iteration.

This direct link builds trust and minimizes misunderstandings. For example, a hospital can use a VR simulation to allow clinical staff to "walk" through a proposed operating room layout, providing critical operational feedback long before construction begins.

Key Insight: When you present the model itself through immersive tools, you are not just showing a picture; you are inviting stakeholders into a dynamic, data-rich environment where they can make informed decisions with confidence.

Actionable Implementation

To turn your model into a powerful engagement tool, your team must prioritize visualization as part of the core workflow. This involves:

- Integrating Visualization Plugins: Use tools like Enscape or Twinmotion that link directly to your BIM software for real-time rendering.

- Establish a Feedback Loop: Create a structured process for capturing client notes during virtual reviews and integrating changes back into the model.

- Set Clear Expectations: Be transparent about the level of detail and accuracy in early-stage visualizations versus final construction documents.

Firms that master this approach see a dramatic reduction in late-stage change orders and an increase in overall client satisfaction. By making the project tangible from day one, you de-risk the design process and build stronger, more collaborative partnerships.

10. Regulatory Compliance and Code Checking Automation

Beyond clash detection, one of the most transformative building information modeling benefits is the power to automate regulatory compliance. This capability shifts compliance verification from a manual, after-the-fact review into an integrated, real-time process. In a mature BIM ecosystem, the model becomes a dynamic tool for validating design decisions against complex legal requirements.

How Model-Driven Logic Works

This approach embeds code-based rules and parameters directly into the BIM environment. Specialized software can then audit the model against these rulesets, automatically flagging non-compliant conditions such as incorrect stair riser heights or ADA accessibility violations. Instead of a project architect manually redlining drawings, the system generates a clear report of issues linked directly to the model elements.

This automated verification process catches errors at the earliest design stages when they are cheapest to fix. For firms looking to evolve from CAD-to-BIM, understanding the importance of going digital is a foundational step. The transition from 2D lines to intelligent 3D objects is what makes automated compliance possible.

Key Insight: When your model contains the necessary data, automated code checking turns regulatory compliance from a reactive, high-risk review into a proactive, data-driven quality control process.

Actionable Implementation

To leverage automated compliance, firms must enrich their models with the right data and establish clear protocols. This involves:

- Defining Rule Sets Early: Work with stakeholders to define the specific codes and standards (e.g., IBC, ADA) that will be checked.

- Enriching Model Elements: Ensure that model components contain the necessary parameters and data for the rules engine to analyze.

- Integrating Regular Audits: Schedule automated compliance checks at key project milestones (e.g., Schematic Design, Design Development) to catch issues before they escalate.

- Documenting Compliance: Use the audit reports to create a verifiable record of compliance, which can accelerate approvals from authorities.

In mature BIM environments, automated checks significantly reduce permit review times by submitting a pre-validated design. You can dive deeper into the frameworks that make this possible by exploring some of the top BIM compliance standards.

10-Point BIM Benefits Comparison

| Feature | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Cost Reduction and Budget Control | Moderate–High; needs costing protocols and parametric models | High — BIM software, training, experienced estimators | Lower costs, reduced waste (10–30%); better budget control ⭐⭐⭐⭐ | Large projects, cost-sensitive programs, lifecycle analysis | Accurate takeoffs, early overrun detection, fewer change orders |

| Enhanced Collaboration and Communication | Moderate; requires firm-wide BIM standards and adoption | Medium — cloud platforms, access control, team training | Fewer coordination errors; faster decisions 📊⭐⭐⭐ | Multi-discipline teams, distributed stakeholders, large design teams | Centralized model, real-time updates, audit trail |

| Clash Detection and Conflict Resolution | Low–Moderate to implement; requires detailed models and workflows | Medium — clash-detection tools, MEP modeling expertise | Reduces rework (up to 40%); fewer on-site conflicts 📊⭐⭐⭐⭐ | MEP-intensive projects, hospitals, complex infrastructure | Automated clash reports, severity classification, virtual resolution |

| Improved Project Schedule Management | Moderate; requires 4D linking and frequent updates | Medium — scheduling integration, planning personnel | Shorter schedules (10–20%); improved resource allocation 📊⭐⭐⭐ | Complex sequencing, tight timelines, infrastructure works | 4D visualization, critical-path in 3D, logistics planning |

| Prefabrication and Modular Construction Optimization | High; needs tight tolerances and manufacturer coordination | High — prefabrication facilities, precise modeling, logistics | Faster on-site assembly (20–50%); higher quality 📊⭐⭐⭐⭐ | Modular housing, repetitive units, offsite manufacturing | Automated fabrication drawings, JIT delivery, quality control |

| Facility Management and Lifecycle Value | Moderate; requires structured handover and data standards | Medium — FM systems, ongoing data management | Lower O&M costs (10–30%); improved asset lifespan 📊⭐⭐⭐⭐ | Large facilities, long-term asset management, airports | Centralized asset data, maintenance schedules, CMMS integration |

| Risk Assessment and Safety Planning | Moderate; complex scenarios require detailed modeling | Medium — safety specialists, VR/AR training tools | Fewer incidents (20–35% reduction); better preparedness 📊⭐⭐⭐ | High-risk sites, crane lifts, high-rise construction | Hazard visualization, training simulations, site logistics planning |

| Accurate Quantity Takeoffs and Material Procurement | Low–Moderate; accuracy depends on model completeness | Medium — standardized families, procurement links | Reduced material waste (10–20%); fewer ordering errors 📊⭐⭐⭐ | Projects with tight procurement, large material orders | Automated takeoffs, JIT scheduling, supplier coordination |

| Stakeholder Engagement and Client Satisfaction | Low–Moderate; requires visualization workflows | Medium — rendering/VR tools and skilled visualizers | Fewer change orders (15–25%); higher client approval ⭐⭐⭐⭐📊 | Client-facing projects, pre-sales, complex design decisions | VR walkthroughs, clear design communication, marketing assets |

| Regulatory Compliance and Code Checking Automation | Moderate; needs jurisdiction-specific rule sets and updates | Medium — code-check tools, rule maintenance | Faster permitting; fewer redesigns 📊⭐⭐⭐ | Projects with strict regulatory review, public-sector work | Automated compliance checks, accessibility/fire/energy analysis |

From Chaos to Clarity: Making BIM Your Operating System

The true power of Building Information Modeling isn’t a single feature. Its value is unlocked when BIM becomes the central nervous system of your production process—an integrated system that brings order, predictability, and control to every stage of a project.

The journey from a CAD-centric workflow to a mature BIM environment is a transition from reactive firefighting to proactive, system-driven delivery. The benefits detailed here, from Cost Reduction to automated Regulatory Compliance, are interconnected outcomes of a well-orchestrated production machine. When your firm commits to BIM as an operating system, you stop modeling buildings and start modeling your entire delivery process for maximum efficiency and margin protection.

Beyond the Model: A Production Mindset

The most significant building information modeling benefits are realized when the technology is supported by a robust operational framework. This is the critical distinction between firms that use BIM and firms that leverage it for scalable delivery.

- Standards and Templates as Guardrails: In mature BIM environments, project setup is not ad-hoc. Standardized templates, disciplined sheet logic, and consistent data structures ensure every project starts from a place of clarity, reducing inconsistencies and downstream errors.

- QA Cycles and Decision Checkpoints: Proactive quality assurance isn't about finding mistakes; it's about preventing them. Integrating structured QA cycles and clear decision checkpoints into your workflow transforms the model into a reliable single source of truth, minimizing RFIs and costly rework.

- From Coordination to Collaboration: The move from basic clash detection to true collaborative BIM workflows is profound. It’s the difference between a report full of problems and a process that solves them before they impact the schedule or budget, streamlining handoffs between disciplines.

Ultimately, adopting BIM as your operating system is about trading chaos for clarity. It’s about building a delivery engine that protects your profit margins, empowers your teams with predictable processes, and consistently delivers high-quality outcomes. This isn’t an aspirational fantasy; it’s a tangible business advantage that top-performing BIM for architects and builders are achieving today.

Ready to assess your firm's production maturity? We developed a BIM Maturity Checklist to help you identify specific gaps in your workflow and create an actionable plan for achieving predictable, profitable delivery. Download it for free and take the first step toward transforming your BIM processes from a tool into a true operational advantage.