Clash Detection in BIM: From Software Feature to Production Governance

True clash detection BIM isn’t about running a test in Navisworks; it’s about production governance. It’s the critical quality assurance process that protects your margins, your schedule, and your reputation for reliable delivery.

For architects, builders, and design-build teams, this mindset shift is what separates a reactive, fire-fighting scramble from a predictable, well-managed construction process. The real value isn’t found in a software feature—it’s built through upstream discipline in your BIM workflow.

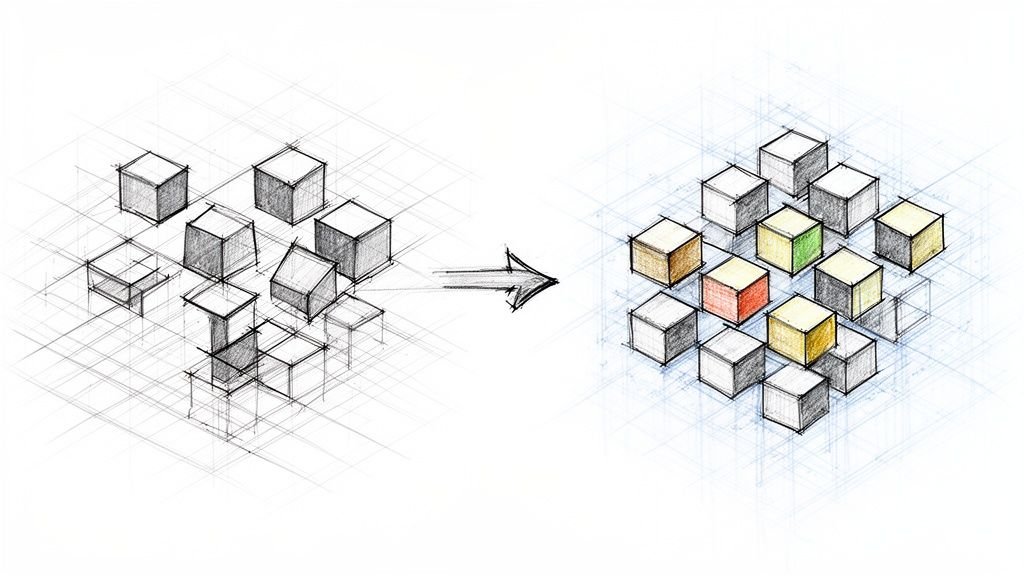

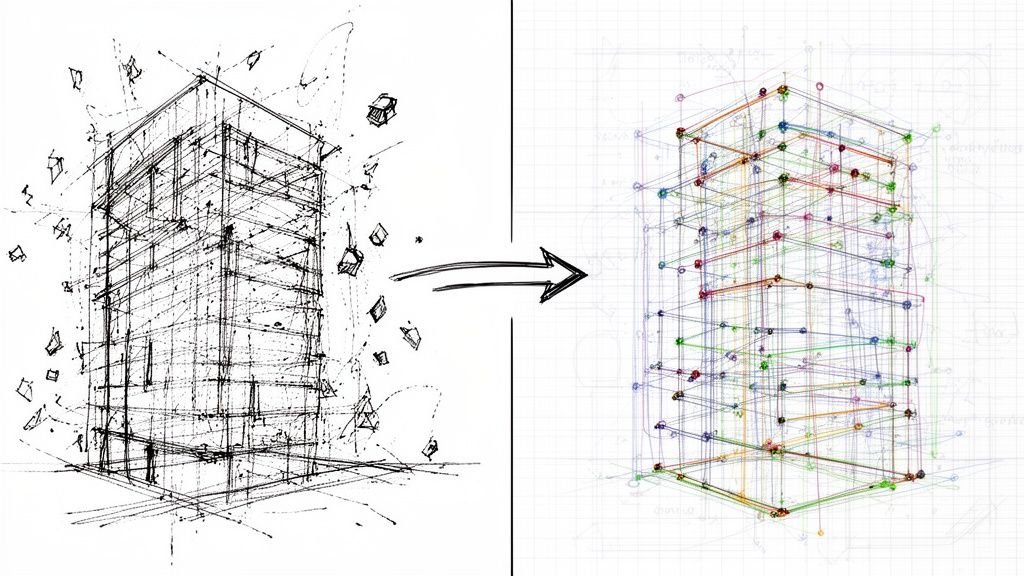

Moving Beyond Software to a System of Governance

Too many teams get stuck in a frustrating loop. They run weekly clash tests, generate overwhelming reports filled with irrelevant conflicts, and then spend hours in unproductive coordination meetings. This is reactive clash detection. It treats the symptom, not the cause.

Mature firms see it differently. For them, clash detection is the final quality check for a highly disciplined modeling process.

The shift is from finding problems to preventing them. Instead of drowning in hundreds of clashes spit out by bloated or inconsistent models, a proactive system ensures that by the time you run a test, most major conflicts have already been designed out. The focus moves upstream, where it belongs.

The Friction Point: Inconsistent Modeling

The real friction in any BIM coordination effort comes from inconsistent inputs. Trades model differently, naming conventions are ignored, and the specified Level of Development (LOD) varies from one discipline to the next.

This lack of standardization is what creates the downstream mess. A governance-led approach solves this by establishing the rules of engagement before a single element is modeled.

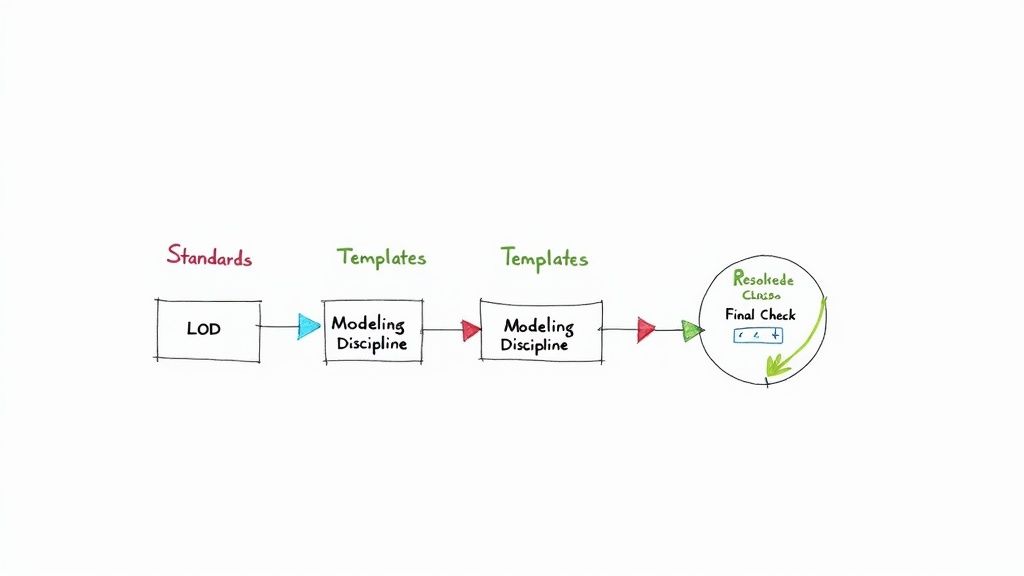

This system prioritizes a few key things:

- Clean Modeling Standards: Mandating how families are built, used, and categorized.

- Consistent LOD: Ensuring all trade partners model to the same required level of detail at each project stage.

- Rigorous Template Discipline: Using standardized project templates that enforce worksets, view templates, and parameters from day one.

- Structured Coordination Cycles: Implementing a predictable rhythm for model exchange and review.

We’ve seen teams reduce coordination cycles dramatically when their clash workflow is tied directly to standards, not just software. This proactive discipline is the core of effective production, and our detailed guides on BIM and 3D modeling dig into how to build these foundational habits.

The table below contrasts the two mindsets. It shows the difference between simply reacting to problems and proactively preventing them.

Shifting from Reactive to Proactive Clash Detection

| Attribute | Reactive Approach (Common Practice) | Proactive Approach (Mature Workflow) |

|---|---|---|

| Mindset | "Software will find our mistakes." | "Our process will prevent mistakes." |

| Timing | Late-stage, weekly clash reports. | Early and continuous, integrated into modeling. |

| Focus | Generating massive clash reports. | Enforcing modeling standards and discipline. |

| Meetings | Long, unproductive, and overwhelming. | Short, focused, and centered on exceptions. |

| Outcome | Constant fire-fighting and rework. | Predictable delivery and fewer RFIs. |

| Responsibility | The BIM Coordinator owns the problem. | The entire project team owns the quality. |

Moving from the left column to the right is the goal. It requires a fundamental shift in how the team approaches modeling and coordination.

The Outcome: Predictability and Margin Protection

When you nail this, clash detection becomes a simple validation step—not a dreaded, week-long ordeal. In the United States, over 80% of large construction firms now use cloud-based BIM to support real-time collaboration and resolve conflicts faster. This shift ensures the model actually reflects what can be built, leading to fewer RFIs, smoother fabrication, and faster approvals.

Ultimately, it’s about protecting project profitability and your firm's reputation for delivering on time and on budget.

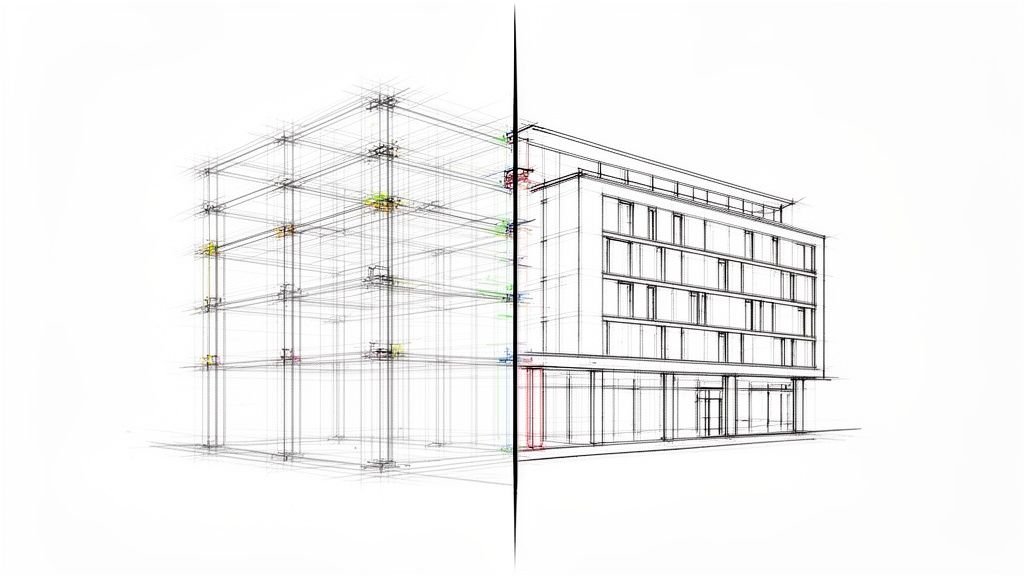

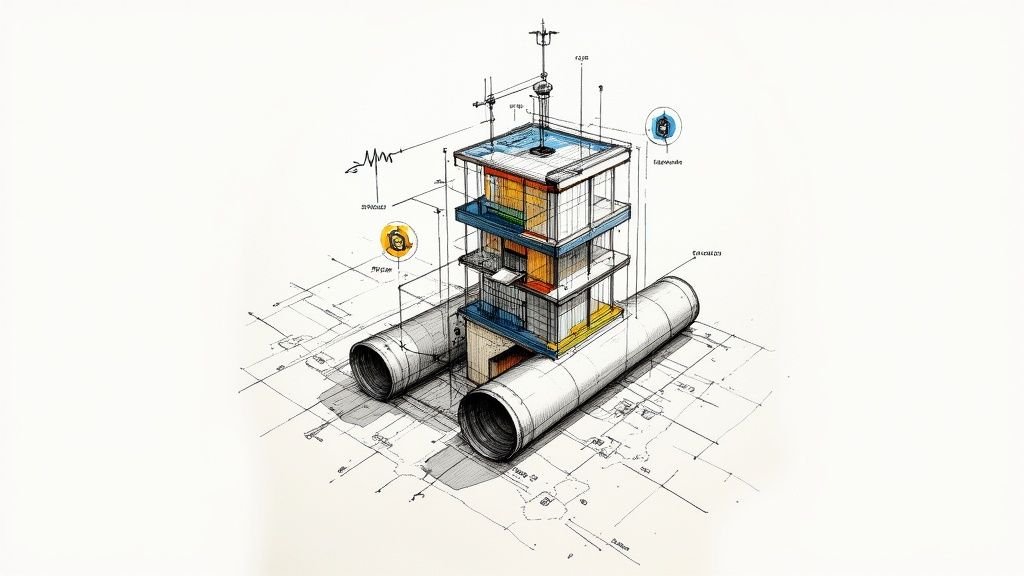

Upstream Discipline: The Foundation of Clean Clash Reports

Effective clash detection has almost nothing to do with powerful software. It’s the direct result of disciplined modeling habits. The vast majority of coordination issues can be prevented long before you run a clash test in Navisworks. Precision upstream creates clarity downstream.

This all begins with a well-defined and rigorously enforced BIM Execution Plan (BEP). Think of it as the constitution for your project. It sets the non-negotiable rules for every stakeholder involved. Without one, you’re just inviting chaos.

These foundational rules are what separate a clean, predictable clash detection BIM process from a messy, reactive fire drill. You’re building a reliable system, not just a 3D model.

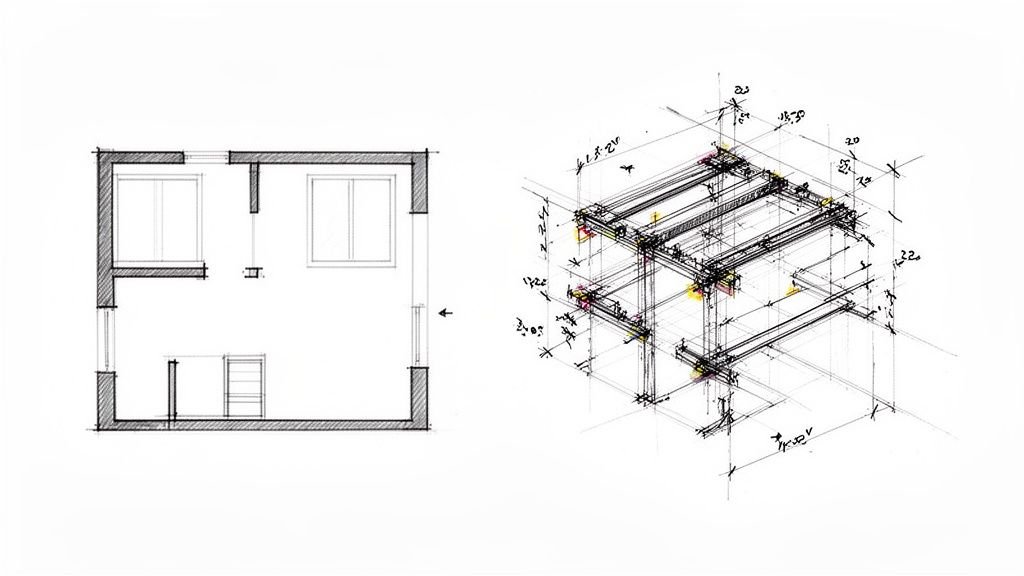

The Non-Negotiables of Clean Modeling

Picture your federated model as an assembly line. If each station uses different parts and follows different instructions, the final product is going to be a disaster. The exact same thing happens in BIM.

To protect project margins and timelines, mature teams enforce strict adherence to a few critical standards:

- Consistent Family and Workset Usage: Every trade must use pre-approved, standardized families with the correct data parameters. This stops generic, unclassified elements from polluting the model.

- Clear Naming Conventions: A pipe labeled "P-101" is useless if the clash test is set to filter for "Plumbing-Main-Line." Standardized naming is essential for creating logical clash tests.

- Defined Level of Development (LOD): The BEP must specify the required LOD for each discipline at each project milestone. This simple rule prevents a hyper-detailed plumbing model from clashing against a schematic-level structural frame, which would generate thousands of irrelevant conflicts.

We’ve seen teams slash their coordination cycles in half just by tying their clash workflow directly to these standards. It’s the difference between targeted problem-solving and drowning in a sea of false positives.

How Upstream Chaos Creates Downstream Noise

Here's a scenario we see all the time: an MEP contractor models an air handling unit using a generic family but forgets to categorize it correctly. When it's time for clash detection, the software can't tell the difference between the AHU and an architectural wall.

The result? Hundreds of false-positive clashes that a BIM Coordinator now has to manually investigate. This derails coordination meetings and burns hours. The root cause wasn't a true design conflict; it was a simple failure of modeling discipline.

This is where the connection between upstream habits and downstream efficiency becomes painfully obvious. A clean model, built on a foundation of clear standards, produces a clean clash report. This is especially critical when you're integrating existing conditions, as a quality Scan to BIM process is only useful if the new modeling is precise.

From Digital Model to Actionable Insight

Clash detection has become a core part of modern BIM workflows, flagging conflicts before anyone steps on-site. Today’s tools can automatically scan entire models for issues long before they become costly rework. You can read more about how the future of clash detection is evolving on prototechsolutions.com.

But the intelligence of these tools is only as good as the data they're given. Without upstream discipline, the most advanced software will only highlight the underlying chaos faster. The real goal is operational consistency.

Structuring a Repeatable BIM Clash Detection Process

A mature BIM clash detection process isn’t a one-off task. It's a system—a repeatable, predictable framework that brings order to coordination. This is how you shift from reactive firefighting to proactive governance, turning a flood of clash data into a focused, actionable agenda.

The goal here isn't to learn software tricks. It’s about building a framework that protects your margins and schedule by focusing on what matters.

This entire process is built on one simple truth: not all clashes are created equal. Trying to solve a thousand minor issues at once is a surefire way to burn out your team. Instead, experienced teams break down the problem with a clear order of operations.

Setting Tolerances to Eliminate Noise

The very first step in any practical workflow is defining your tolerance rules. A clash report showing a pipe is 1/8" inside a stud isn't a real-world problem. It’s digital noise that clogs up the coordination process.

By setting a tolerance—telling your software to ignore all clashes under a half-inch, for instance—you immediately eliminate thousands of insignificant items. This simple filter lets your team focus on genuine constructability issues. This must be agreed upon in the BEP.

Defining Coordination Zones for Manageable Segments

Trying to coordinate an entire multi-story building in one shot is a recipe for disaster. A much smarter strategy is to break the project down into manageable coordination zones by floor, wing, or complex areas like mechanical rooms.

This approach pays off in several ways:

- It focuses team energy. Teams can tackle one area at a time, like "Level 3 – West Wing MEP."

- It simplifies problem-solving. Resolving 50 critical clashes in a single mechanical room is far more achievable than staring at a list of 5,000 issues spread across the entire building.

- It aligns with the construction schedule. You can prioritize zones based on when they're needed for construction or permitting.

Creating a Prioritized Clash Test Matrix

Not all building systems carry the same weight. A flexible duct hitting a primary structural girder is a showstopper. A piece of conduit conflicting with a non-load-bearing wall? Not so much. A clash test matrix, defined in the BEP, formalizes this hierarchy.

For example, a typical matrix would prioritize tests like this:

- Priority 1: Major Structural vs. Major MEP Mains (e.g., steel beams vs. large ductwork).

- Priority 2: Major MEP Mains vs. Gravity-Fed Systems (e.g., ductwork vs. sanitary piping).

- Priority 3: All Disciplines vs. Architectural Finishes (e.g., ceiling grids and lighting).

This tiered approach ensures the "big rocks" get moved first. A well-structured matrix provides a clear agenda for every coordination cycle, which is a core part of our approach to BIM coordination strategies.

Here’s a simplified example of what that might look like for a commercial project:

Sample Clash Test Matrix for a Commercial Project

| Test Name | Priority | Selection Set A | Selection Set B | Clash Type | Tolerance |

|---|---|---|---|---|---|

| STR vs. MEP (Hard) | High | Structural Framing | MEP (Duct, Pipe, Conduit) | Hard Clash | 1 inch |

| MEP vs. MEP (Hard) | High | MEP (Duct, Pipe) | MEP (Duct, Pipe) | Hard Clash | 0.5 inches |

| STR vs. ARCH (Ceilings) | Medium | Structural Framing | Architectural Ceilings | Clearance | 2 inches |

| MEP vs. ARCH (Walls) | Medium | MEP (All) | Architectural Walls (Interior) | Hard Clash | 0.25 inches |

| Fire Protection vs. All | High | Fire Protection (Sprinklers) | All Disciplines | Clearance | 6 inches |

By structuring tests this way, you ensure that the report for the "STR vs. MEP" test only contains high-priority structural conflicts, making it easier for the right people to review and resolve.

One of the biggest friction points we see is the "unassigned clash." A report is useless if no one is responsible for fixing the issues. This is where a structured process brings much-needed clarity.

Establishing Clear Clash Ownership

Once you’ve identified and prioritized the clashes, the next step is assigning ownership. This is often where coordination meetings fall apart. A mature workflow solves this by establishing clear rules of engagement before arguments start.

Ownership is typically assigned based on a simple principle: which element is easier or more logical to move? A flexible conduit is almost always easier to re-route than a concrete shear wall. These rules are decided in coordination meetings, and the resolution is formally assigned to the responsible trade partner with a clear deadline.

This accountability is what makes the whole system work. Without it, the same clashes appear week after week, pushing problems into the field where they become expensive change orders. A repeatable Navisworks clash detection process isn’t just about finding problems; it’s about creating a system that ensures they actually get solved.

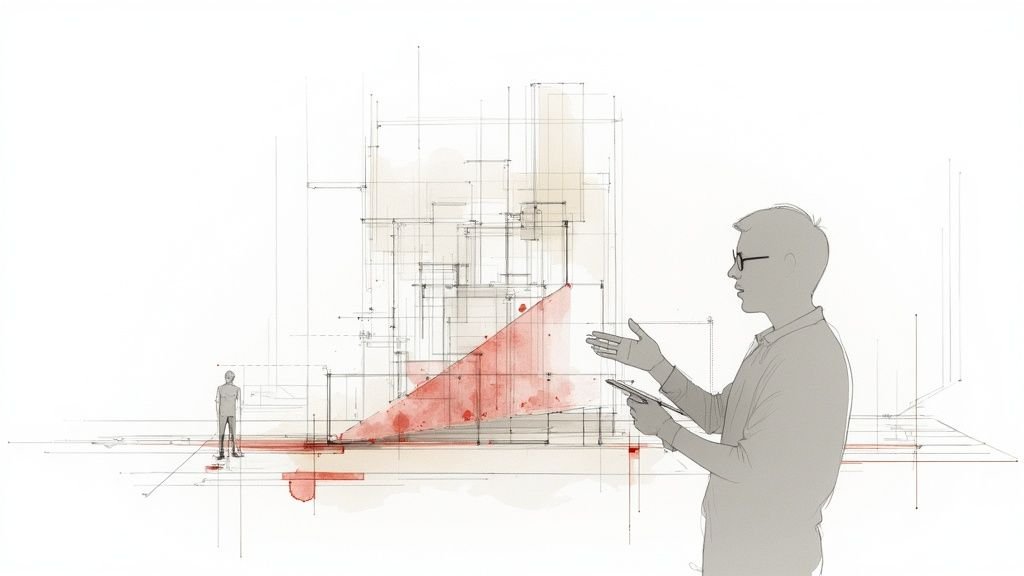

Making BIM Coordination Meetings Productive Decision Checkpoints

A well-structured clash report is more than just a list of problems—it’s the agenda for a decision-making meeting. Too often, coordination meetings devolve into endless discussions with no clear outcomes. The most productive teams transform these sessions from simple reviews into critical decision checkpoints that actively prevent RFIs and protect the schedule.

The meeting's purpose isn't to find problems; the clash test already did that. Its purpose is to solve problems, assign responsibility, and document every resolution.

Mature BIM coordination hinges on this principle. The goal is to walk out of the meeting with a clear, actionable plan that moves the project forward, not a longer list of questions.

Setting the Agenda for Action

An effective meeting starts long before anyone walks into the room. A clean, prioritized clash report, focused only on high-priority issues within a specific coordination zone, becomes the agenda.

The most successful meetings are built on a few core disciplines:

- Time-Boxing: Give each clash a specific time slot. If you can't reach a resolution, it gets escalated or assigned for someone to solve offline. The meeting keeps moving.

- Live Model Navigation: Don't just stare at static screenshots. Pull up the federated model live. This lets the team see the conflict from all angles and test potential solutions in real-time.

- Solution-Oriented Dialogue: The conversation should always drive toward a solution. The question isn't "Whose fault is this?" It's, "What is the most efficient way to resolve this for the good of the project?"

A productive coordination meeting is a series of decisions, not a long conversation. Every item on the agenda should end with a clear action assigned to a specific person with a firm deadline.

Defining Roles for Clear Accountability

Chaos in coordination meetings often comes from fuzzy roles. Mature teams define these roles in their BEP to make sure every meeting has structure.

Key roles include:

- The BIM Coordinator (Facilitator): Runs the meeting, navigates the model, and keeps the conversation on track. They are the neutral guide, not the sole problem-solver.

- Trade Representatives (Problem-Solvers): Each key discipline must have someone in the room empowered to make decisions about their scope.

- Project Manager/Superintendent (Decision-Maker): For high-impact clashes, the PM has the final say, ensuring the fix aligns with overall project goals.

To get the most out of the session itself, you can find strategies for achieving during meeting excellence in the Meeting Masters Playbook. The principles of good facilitation apply directly to BIM coordination.

Creating an Audit Trail for Resolutions

The single most important output of a coordination meeting is a documented record of every decision. A resolution isn't real until it's recorded, assigned, and tracked.

This is where connected platforms like Autodesk Construction Cloud are invaluable. Instead of tracking actions in a separate spreadsheet, you document resolutions directly within the coordination platform.

This creates a permanent, auditable trail. When a clash is marked "Resolved," the system records who made the call, what the agreed-upon action is, and the deadline. This simple act of disciplined documentation transforms the clash detection BIM process. It ensures accountability, stops the same issues from reappearing, and provides a clear history of how the design evolved.

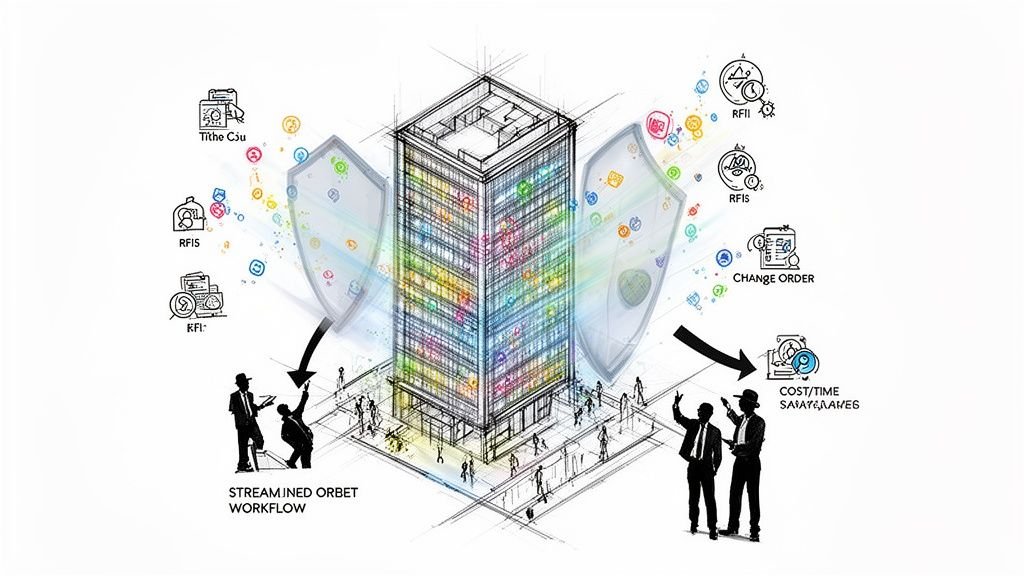

Measuring the ROI of a Mature Clash Detection Workflow

A disciplined clash detection BIM process does more than just clean up a model—it directly protects your firm’s profitability. The real return isn't just about catching a few costly mistakes. It’s about creating operational consistency, which leads to predictable project outcomes.

When your clash detection process is systematic, you build a data-driven case for its value, proving it’s a driver of profitability, not just another overhead cost.

From Vague Benefits to Hard Metrics

The impact of a well-run coordination process shows up clearly in the project data. Instead of making vague promises, you can point to specific key performance indicators (KPIs) that prove the system is working:

- Reduction in Coordination-Related RFIs: A drop in RFIs asking for clarification on routing or clearances is a direct sign your coordination is hitting the mark.

- Fewer Design-Conflict Change Orders: Tracking change orders specifically caused by system clashes puts a clear dollar value on the problems your process is preventing.

- Smoother Fabrication Sequences: When fabricators can trust the model, they can build components off-site with confidence, speeding up the schedule.

- Faster Permitting and Approvals: A well-coordinated model demonstrates a higher level of design maturity, which often translates to quicker review cycles.

The ultimate ROI is predictability. When you can reliably forecast your coordination timeline, you can price your work more accurately, protect your margins, and build a reputation for consistent, on-time delivery.

Quantifying the Impact on Project Costs

The financial upside of a mature BIM clash detection process is significant. Evidence shows that catching conflicts early can reduce rework costs by up to 30% while keeping projects on schedule. It's no surprise that on major projects, between 80–90% of contractors now use clash detection—a clear signal of its proven value.

This process is about eliminating the high-cost conflicts that derail schedules. Every major clash you resolve in the digital model represents thousands of dollars saved in field labor, material waste, and schedule delays.

These savings add up, making proactive coordination one of the most effective financial strategies for a modern firm. As we cover in our guide on how to reduce construction costs, proactive digital coordination is fundamental to project profitability.

An Action Plan for a Disciplined Clash Workflow

Mature firms protect their margins by turning clash detection into a repeatable system. This isn't about setting fuzzy goals; it's about building a practical, step-by-step framework for your BIM clash detection process.

True production maturity comes from systemizing your approach. The aim is to make disciplined coordination a default part of every project.

Audit Your Current Modeling Standards

Before you can improve, you need an honest look at where you stand. Crack open your project templates and a few recent models.

- Are your naming conventions actually being used consistently?

- Do your families have the data needed for accurate filtering?

- Is your required Level of Development (LOD) clearly defined and followed?

This audit will shine a light on the upstream mistakes that create downstream noise in your clash reports.

Define Your Clash Matrix and Tolerances

Stop running massive, unfiltered clash tests. Formalize your approach by creating a standard clash matrix in your BEP.

This document should spell out your priority-based tests (like running Structure vs. MEP Mains first) and define acceptable tolerances to filter out the noise. Setting a half-inch tolerance might clear thousands of irrelevant clashes at once.

Standardize Your Coordination Meeting Agenda

A productive coordination meeting is a decision checkpoint, not an open-ended discussion. Standardize your agenda to force a focus on resolution. Every meeting should follow a strict format: review high-priority clashes, use the live model to explore solutions, assign clear ownership for each fix, and document the decision with a hard deadline.

A well-run meeting doesn't just talk about problems; it produces a clear, documented action plan. This transforms your clash detection BIM process from a simple review into a powerful engine for project progress.

Ready to build a more predictable workflow? Our BIM Coordination Checklist offers a practical framework to help you implement these systems and establish clarity within your own team. Download it to get started.

Frequently Asked Questions About Clash Detection

Here are a few common, practical questions we hear from architects, builders, and contractors about implementing and optimizing a BIM clash detection process.

How Do You Handle Thousands of Minor Clashes?

The key is disciplined filtering and prioritization. A mature workflow uses tolerance settings in tools like Navisworks to automatically ignore insignificant clashes—say, anything under a half-inch. More importantly, you must structure your clash tests strategically. Start with the big stuff: major structural systems versus main MEP runs. Then, break the project down into manageable coordination zones.

This lets your team focus on the 50 critical issues in one area rather than drowning in thousands of minor ones project-wide. The goal isn’t a zero-clash report; it’s zero unresolved critical clashes before construction.

What Is the Biggest Mistake Teams Make?

The most common mistake is treating clash detection as a reactive, once-a-week task run by a single person. When teams rely on that weekly report to catch problems, they're already behind.

Effective clash detection BIM is a continuous, team-wide process rooted in discipline. The real focus should be on clean, coordinated model authoring from day one. When every trade follows the modeling standards, the final clash test becomes a simple verification step, not a problem-finding tool.

Who Is Responsible for Resolving a Clash?

This should never be a guessing game. Your BIM Execution Plan (BEP) needs to define ownership clearly.

Typically, the clash is assigned to the trade whose component is easier or more logical to move. For example, it’s much simpler to re-route a flexible duct around a primary steel beam than the other way around. The BIM Coordinator facilitates the conversation, but the project manager often makes the final call based on cost and schedule impacts.

Once a decision is made, the resolution is formally assigned to the responsible modeler with a non-negotiable deadline.

Building a predictable, disciplined clash detection workflow protects your margins and your schedule. At BIM Heroes, we help firms establish the systems and production maturity needed for reliable project delivery.

Explore our BIM Consulting services to learn more.