Common BIM Modeling Errors and How to Avoid Them

Common BIM Modeling Errors and How to Avoid Them

Building Information Modeling (BIM) errors can lead to costly delays and miscommunication. Here’s how to avoid the most common mistakes:

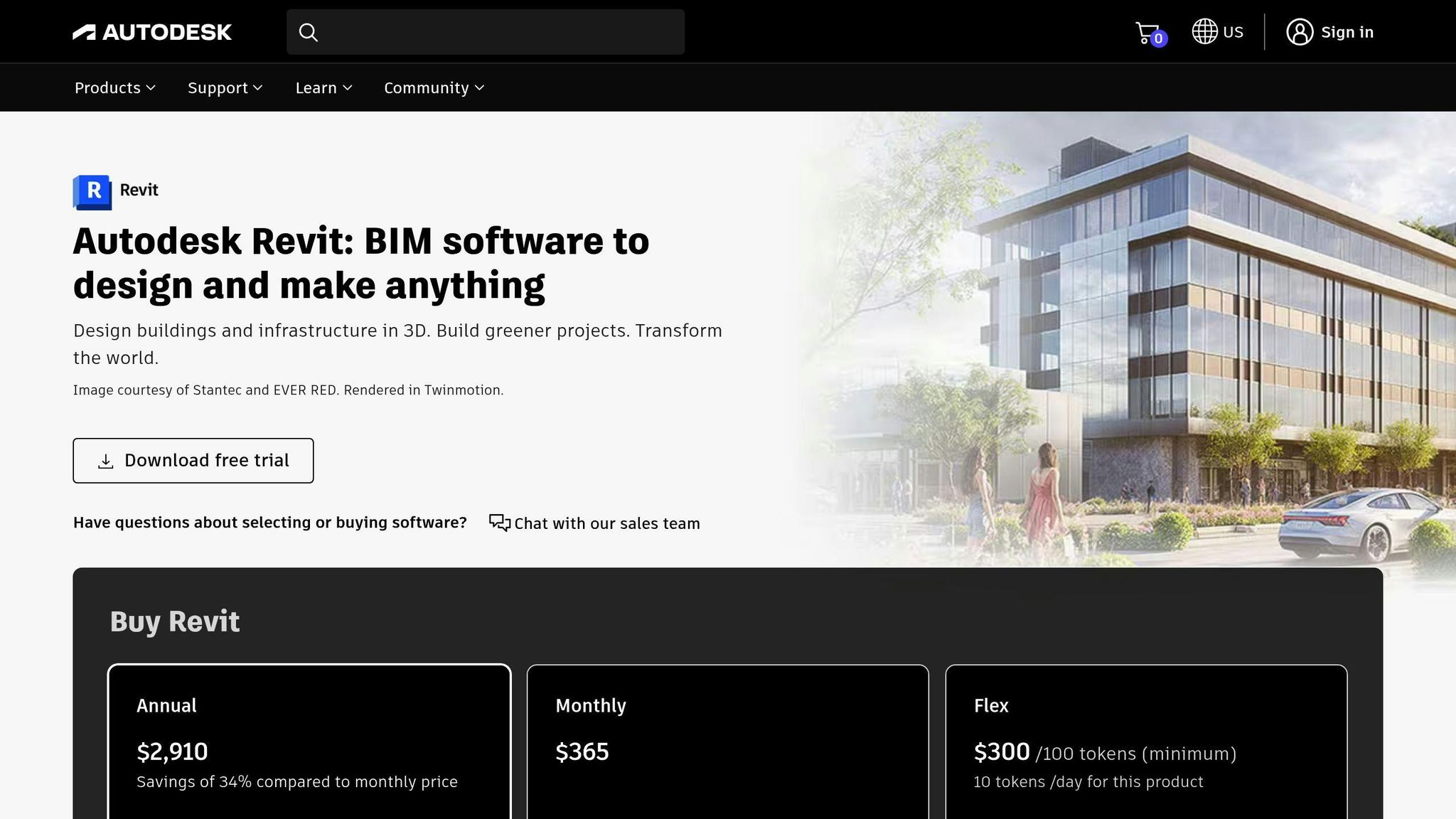

- Element Placement Issues: Misaligned or incorrectly placed components disrupt workflows. Use tools like Revit to ensure accuracy.

- Data Inconsistencies: Incorrect or inconsistent parameters cause confusion. Regularly validate data with Navisworks or Solibri.

- Coordination Problems: Poor communication between teams results in clashes. Tools like Autodesk Construction Cloud improve collaboration.

Quick Solutions:

- Automate daily model checks.

- Use quality control software like Solibri for detailed validation.

- Establish clear workflows with naming conventions and review schedules.

- Hold regular coordination meetings to align teams.

By combining technology, structured processes, and strong communication, you can minimize errors and ensure smoother projects.

Revit and Navisworks Issues Integration with the Autodesk Construction Cloud

Major BIM Modeling Mistakes

Mistakes in BIM, like misaligned elements or inconsistent data, can cause expensive delays and rework. Knowing these common pitfalls can help teams take steps to avoid them.

Wrong Element Placement

Placing elements incorrectly is a major issue in BIM modeling. This can include misaligned parts, wrong scaling, or incorrect spatial placement. Research by Mojtaba Valinejadshoubi highlights how geometric errors can disrupt construction workflows, leading to delays, higher costs, and wasted materials.

While these errors affect the physical layout, they also highlight another issue: inaccurate data entry.

Data Entry Errors

Accurate data is key to maintaining a reliable BIM model. Mistakes often happen when incorrect parameters are entered or when information is inconsistent across components. These errors can lead to miscommunication and poor coordination among teams.

Using tools like Revit and Navisworks can help catch and fix these mistakes early. Regularly checking data against project guidelines is another way to ensure everything stays on track.

Cross-Team Conflicts

BIM projects often involve multiple teams, and this can lead to coordination problems. Common issues include:

- Lack of Communication: Teams working separately without enough interaction

- Different Standards: Departments using varied modeling practices

- Version Control Problems: Overlapping or untracked changes by team members

Collaborative tools like Autodesk Construction Cloud help address these challenges by offering real-time updates and shared workspaces. Better coordination means fewer mistakes and smoother project execution.

sbb-itb-0af4724

Error Prevention Methods

Fixing common BIM errors requires a mix of technology, clear processes, and effective communication.

Quality Control Software

Using BIM quality control tools helps catch errors early in the process. For instance, Solibri is great for model validation, especially with IFC files, as it combines models from different disciplines to perform detailed checks. Similarly, ACC’s clash detection tools focus on resolving coordination problems, helping to reduce mistakes across various teams.

Standard Work Processes

Following consistent modeling practices is key to avoiding errors. Clear and well-documented workflows keep teams on the same page. A solid BIM workflow often includes:

| Process Stage | Key Requirements |

|---|---|

| Pre-modeling | Templates, naming conventions, shared parameters |

| Active modeling | Element placement rules, data entry standards |

| Review cycle | Clash detection schedule, coordination meetings |

BIMcollab helps teams stick to these requirements by centralizing them for easy access and application.

While software plays a big role, having dependable workflows is just as important in reducing mistakes.

Team Communication Tools

Good communication is essential to avoid conflicts between disciplines. Tools like Autodesk Construction Cloud keep teams aligned and help resolve conflicts fast. Real-time collaboration ensures everyone works with the latest model version, avoiding version control issues.

Newforma Konekt is another tool that focuses on resolving critical clashes, especially between structural and MEP systems, making it easier to prioritize and address key problems.

Quality Control Steps

Ensuring BIM model accuracy involves a structured approach to quality control, catching errors early and building team skills.

Model Check Schedule

A well-planned review schedule, combining both automated and manual checks, helps identify issues promptly. Tools like Solibri can automate daily scans, focusing on geometric precision and consistent data.

| Review Type | Frequency | Key Focus Areas |

|---|---|---|

| Automated Scans | Daily | Element placement, data consistency |

| Team Reviews | Weekly | Cross-discipline coordination |

| Milestone Checks | Project phases | Complete model validation |

These regular reviews also address coordination challenges, ensuring all teams work with the latest, accurate models.

Staff Training Plans

Continual training boosts technical skills and quality control knowledge.

| Training Component | Target Skills | Implementation |

|---|---|---|

| Software Mastery | Revit, Navisworks | Monthly workshops |

| Industry Standards | AEC protocols | Quarterly updates |

| Quality Tools | Solibri, BIMcollab | Hands-on sessions |

Training should emphasize software expertise, adherence to industry standards, and effective use of quality tools. BIMcollab is helpful for tracking progress and maintaining consistent modeling practices.

With a skilled team in place, clear modeling guidelines further enhance accuracy and coordination.

Modeling Rules

Clear modeling guidelines minimize errors and improve project results. Focus areas include:

Element Placement Standards

- Define parameters for component positioning

- Specify level-of-detail expectations

- Set naming conventions for consistency

Data Entry Protocols

- Use pre-defined templates

- Specify required parameters

- Apply validation checks to ensure accuracy

Coordination Requirements

- Outline handoff procedures

- Set clash detection tolerances

- Plan regular coordination meetings

Conclusion

Key Takeaways

Creating accurate BIM models demands a structured approach to avoid errors and maintain quality. A well-defined BIM Execution Plan is essential, outlining workflows, standards, and validation steps clearly. Here’s how you can improve your BIM modeling process:

Practical Next Steps

Evaluate your current tools and workflows to see how they measure up to the strategies shared here. To improve accuracy in your BIM modeling, focus on these actions:

- Automate daily model checks to catch issues early.

- Hold regular coordination meetings across teams to reduce clashes.

- Use quality control tools like Solibri for systematic issue detection.

Collaboration and communication among team members are critical for successful BIM projects. Set up shared digital platforms to streamline coordination between stakeholders. Tools like BIMcollab can help maintain consistent modeling practices throughout the project lifecycle.

Start small by prioritizing the most crucial areas of your projects and gradually implement these strategies. If needed, consult BIM professionals for help with establishing workflows and training programs tailored to your needs.