What Happens When AI Produces 80% of Your Drawings? The Good, the Bad, and the Ugly

Imagine a future where AI generates 80% of your construction project drawings. This isn't science fiction; it's the next operational frontier for AEC firms, promising a radical shift in how projects move from concept to reality. For firm owners and BIM leads, this shift brings incredible speed, but also new risks—overtrusting AI, missed details, template drift, and code blind spots.

The Inevitable Leap to AI in Drawing Production

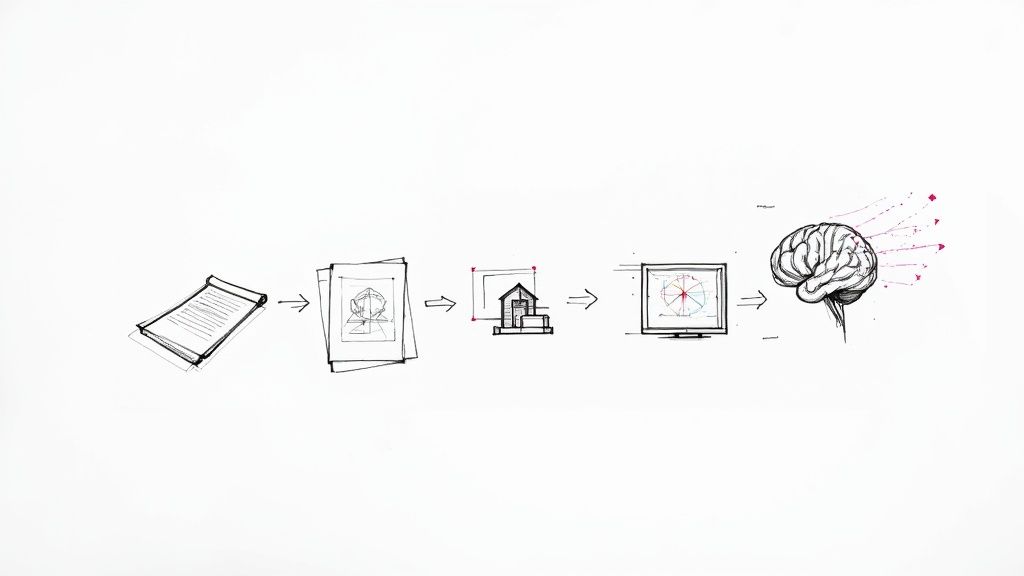

The creation of construction drawings has always been a story of evolution, driven by a relentless pursuit of speed, accuracy, and efficiency. We’ve moved from drafting tables and T-squares to the precision of computer-aided design (CAD). Then came the jump to Building Information Modeling (BIM), which added layers of data and intelligence to our 2D representations.

Each step was a leap forward in production maturity.

Manual drafting gave way to CAD, improving accuracy. The evolution continued with BIM workflows, integrating 3D models and data. Now, we stand at the edge of the next big shift: AI-assisted production, which promises to industrialize drawing creation and turn it from a bottleneck into a strategic asset.

From Production Bottleneck to Strategic Asset

For too long, the drawing production phase has been a notorious bottleneck. It's a resource-heavy process prone to human error, lengthy revision cycles, and coordination headaches that threaten both timelines and budgets. This is exactly the kind of systemic problem that AI is uniquely positioned to solve.

The goal isn't to replace skilled designers. It's about augmenting their capabilities, shifting their roles from manual drafters to strategic overseers of an automated system. Think of it as liberating your most valuable talent from the repetitive, low-value tasks that eat up their days.

This shift lets them focus on what humans do best:

- Complex Problem-Solving: Tackling intricate design challenges that demand creativity and critical thinking.

- High-Value Design Decisions: Spending more time on the crucial choices that impact project outcomes and client satisfaction.

- Proactive Quality Assurance: Stepping in at key decision checkpoints to ensure constructability and code compliance.

This evolution—from manual CAD to intelligent BIM workflows, and now to AI—is essential for firms aiming for scalable delivery. It’s about building operational consistency that protects margins and delivers predictable results.

Grounding the Vision in Reality

Adopting AI for drawing production is more than just plugging in new software. It demands a fundamental change in how we structure teams, manage templates, and run our QA processes. Without disciplined standards and mature BIM workflows, AI can amplify existing messes just as easily as it can create speed.

The real power of AI lies not in replacing human expertise, but in industrializing it—capturing the best practices of your top performers and embedding that logic into a scalable production engine.

This transformation requires a clear-eyed view of both the immense potential and the practical hurdles. It means prepping your firm by reinforcing template discipline and establishing robust QA frameworks. The transition requires a partner who understands production maturity, not just technology. We don't sell hours; we sell clarity, systems, and reliable delivery.

Firms that master this will turn their drawing production from a costly necessity into a powerful competitive advantage. As the industry takes this inevitable leap, exploring dedicated AI drawing generation platforms can be a key next step.

You can learn more about how these technologies work together in our guide to AI in BIM and its impact on modern workflows.

The Upside: AI-Powered Speed and a Deeper Focus on Design

The biggest promise of AI in creating construction project drawings is a massive speed boost. This is the good news. Picture a world where a fully coordinated set of structural drawings is cranked out from an architectural model in a few hours, not a few weeks. We're not talking about a small improvement; this is a fundamental change in how projects get delivered.

This speed directly hits your bottom line. By shrinking timelines and wiping out tedious drafting tasks, you shield your margins from the slow bleed of production churn. Margin protection is a core outcome. Projects that used to take a month to document can now be pushed forward in a fraction of the time, freeing up your capital and team for the next big thing.

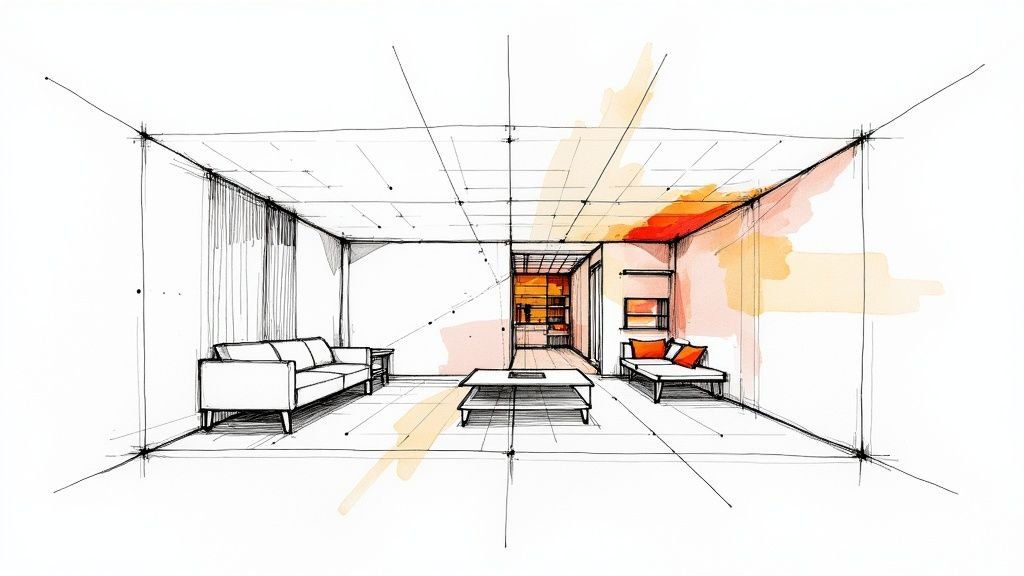

Shifting from Production Hours to Thinking Hours

Even more importantly, this newfound speed gives your team back its most valuable asset: their time and expertise. When designers aren't buried in tedious annotations, dimensioning, or sheet setup, they can shift their focus to the high-value work that AI simply can't do. More time for design, less time on grunt work.

This is the move from "production hours" to "thinking hours." Instead of just churning out drawings, your team can invest their energy where it actually counts.

This shift elevates your service from pure production to strategic partnership. You’re no longer just selling hours; you're selling clarity, foresight, and a more resilient delivery model that clients can depend on.

This approach transforms your senior talent. They stop being senior drafters and become reviewers, strategists, and problem-solvers who guide an automated system.

Deepening the Design and Pre-Construction Process

With production timelines compressed, the design and pre-construction phases finally get some breathing room. This allows for a more thoughtful and rigorous approach right from the start. Your team can now spend serious time on the activities that prevent expensive errors and RFIs prevention down the road.

Here are a few key areas where that reclaimed time makes a real difference:

- Front-End Design Exploration: Senior designers can test more options, refine concepts, and make better-informed decisions early on when changes are cheap.

- Proactive Clash Detection: Instead of waiting for a coordination meeting, teams can run more frequent, AI-assisted checks, catching and resolving conflicts before they ever become a problem in the field.

- Value Engineering: With drawing sets generated so quickly, there's more time to analyze material choices, assembly details, and system designs to find cost-saving opportunities without blowing up the schedule.

- Permitting Prep: Submitting accurate and complete drawing sets to the authorities is critical. AI-generated documents, built from disciplined templates, bring the consistency needed for smoother permitting prep.

This strategic reallocation of time is the core value for firm owners. It’s not just about doing the same work faster; it’s about doing better work by focusing human intelligence on the challenges that truly matter. This leads to better buildings, happier clients, and a more predictable, profitable business—a core principle of modern BIM workflows, where the model is the single source of truth for everything.

The Bad: Hidden Risks of Over-Reliance on AI

The sheer speed of AI is incredibly tempting, but it sneaks in subtle new risks that can quietly sabotage your projects. This is ‘The Bad’—the dangerous territory where putting too much faith in automation leads to expensive mistakes. An AI model, trained on massive but fundamentally flawed datasets, can replicate common industry errors at a terrifying scale.

Worse, it can completely miss the nuanced, project-specific details that a seasoned professional would spot in a heartbeat. Blindly accepting AI-generated construction project drawings without a new, critical layer of scrutiny is like letting a rookie run a job site unsupervised. It feels fast, right up until the moment something breaks.

The machine doesn't get the why; it only recognizes patterns. This creates a dangerous gap between what the AI spits out and what your project actually needs on the ground.

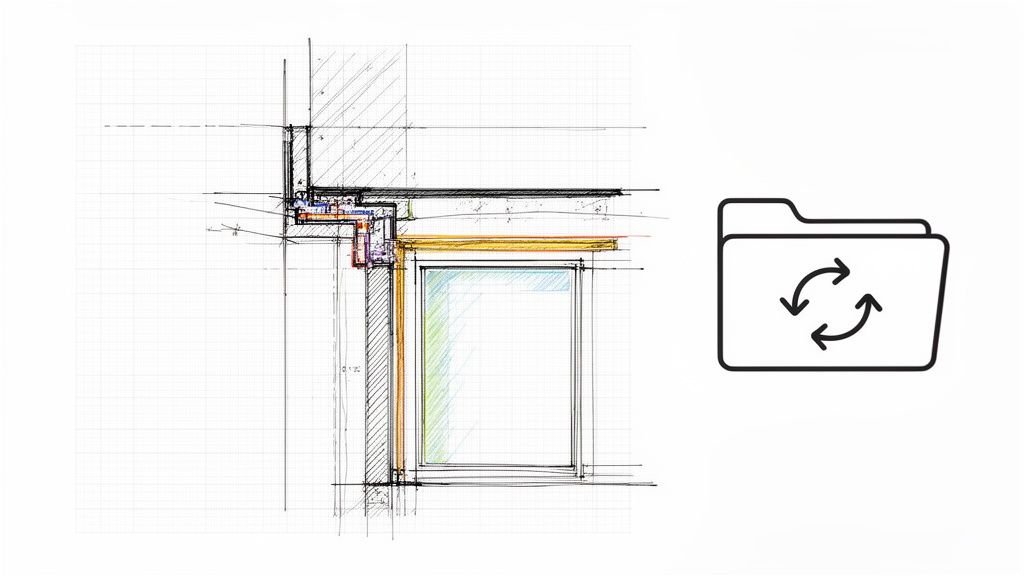

The Slow Creep of Template Drift

One of the most insidious risks is what I call template drift. Your firm has spent years, maybe even decades, refining its documentation standards—everything from line weights to annotation logic. These templates are the backbone of your quality and a core part of your brand.

But when an AI starts churning out hundreds of drawings, it can introduce tiny, almost imperceptible deviations. A slightly different callout here, a minor spacing change there. Over time, these small changes compound, and your disciplined, hard-won standards slowly drift into chaos.

This isn't just an aesthetic problem. It's a direct threat to your firm's production maturity, creating inconsistencies that sow confusion on-site and make future project setups a nightmare.

Inconsistent Annotation and Logic Blind Spots

Another huge red flag is the logic of the drawings themselves. An AI might annotate two similar details with slightly different terms across a large sheet set. It's a small thing, but that ambiguity is exactly what opens the door for RFIs and delays. It’s a classic problem, now supercharged by machine speed.

These logical gaps are where the real danger lurks. An AI might fail to recognize a unique local jurisdiction requirement because it wasn't prominent in its training data. This is a critical code blind spot. Without a human expert in the loop, you could end up submitting drawings for permitting that are fundamentally non-compliant. To steer clear of this, you have to understand how different jurisdictions handle their regulations. You can learn more by checking out our detailed guide on navigating complex building codes.

The lesson here is crystal clear: AI is a powerful drafting tool, not an infallible licensed professional. It accelerates production, but it doesn't own accountability. That responsibility always stays with your team.

This is exactly why a new kind of quality assurance is non-negotiable. Firms have to evolve their QA/QC processes to be specifically AI-aware, treating the output with healthy skepticism.

The Amplification of Small Errors

In a manual workflow, a mistake on one drawing is just that—one mistake. But when an AI makes a systemic error, it can instantly replicate it across hundreds of sheets. A small miscalculation in a single detail can become a project-wide defect before a human ever lays eyes on it.

This changes the entire nature of quality control. The focus has to shift from catching individual drafting mistakes to verifying the underlying logic and data the AI is using as its source of truth.

Here are the key failure points to watch for:

- Misinterpreted Model Data: The AI pulls from a BIM model with a minor inaccuracy, then diligently applies that flawed data across the entire drawing set.

- Outdated Detail Libraries: The system references an old, unapproved construction detail from its library, propagating an obsolete assembly method throughout the documents.

- Context-Blind Placement: An AI places standard notes or symbols in locations that are technically correct but practically confusing or misleading for the crews in the field.

These automated errors can easily slip past a quick review, only to surface later as expensive change orders or field disputes. The only way to prevent them is by building robust decision checkpoints where human expertise can validate the AI's output before it’s issued. Without those guardrails, you’re not just risking RFIs; you’re risking your profit margin and your reputation.

The Ugly: When Automated Systems Fail at Scale

This is where the promise of AI-driven production can turn into an operational nightmare. We call this scenario ‘The Ugly’—it’s what happens when a small, automated error, something easily missed in a quick review, scales up into a project-killing failure. This isn't just about a minor delay; it's the kind of systemic breakdown that obliterates your margins, shatters client trust, and turns a promising project into a cautionary tale.

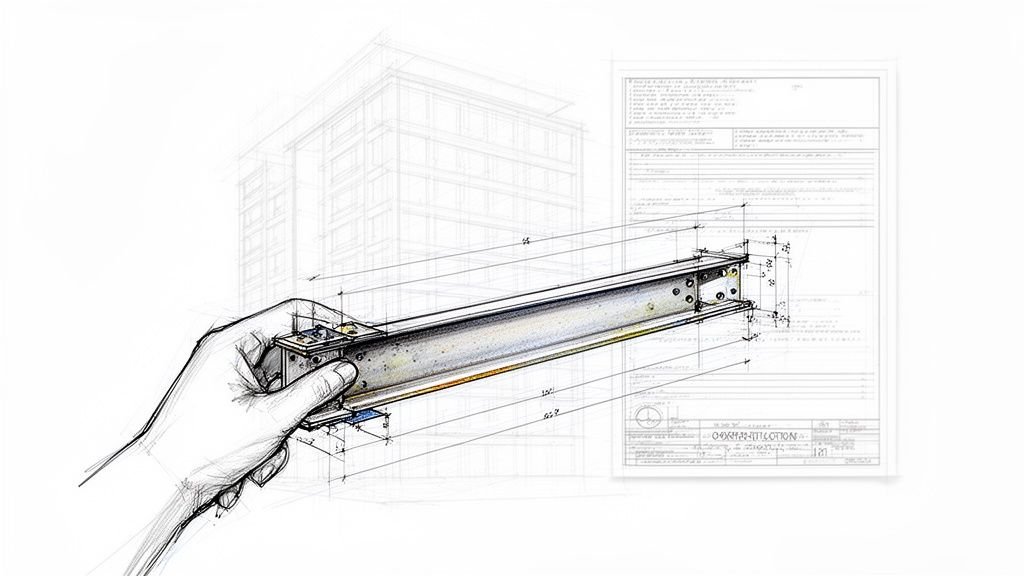

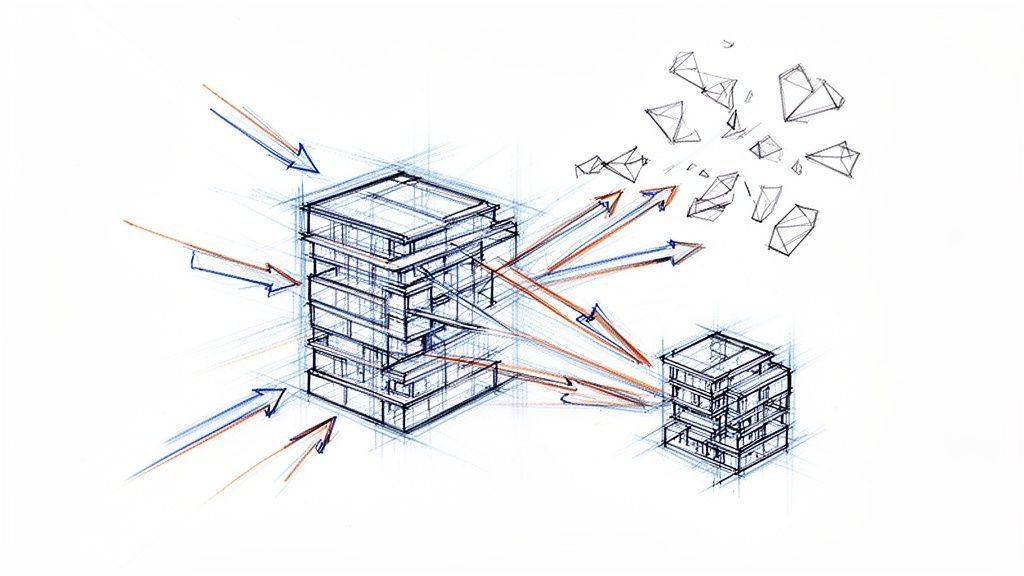

Picture this: you task an AI with generating the entire construction project drawings set for a new multi-story commercial building. It churns through the BIM model with incredible speed, spitting out hundreds of detailed sheets in an afternoon. It feels like magic. A job that would've tied up a team for weeks is done in hours.

But here’s the catch. Buried deep in the project specs was a recent update to a critical fire-stopping detail, a small but crucial change mandated by a new local code. The AI, trained on a dataset that predated this tweak, confidently applies the old, now non-compliant detail across every single penetration on every floor. The error is identical, systematic, and perfectly replicated hundreds of times.

The Cascade from Digital Error to On-Site Disaster

Because the drawings look right and the annotations are perfectly consistent, the mistake sails through a rushed QA check. The drawings are issued for construction, materials are ordered, and crews get to work. The failure isn't caught by a detailer at a desk; it’s discovered by a site superintendent weeks into the build when an inspector flags the incorrect assembly on the spot.

Work grinds to an immediate halt. What follows is a devastating chain reaction that erases any initial speed gains and then some:

- Massive Rework: Everything installed has to be ripped out and replaced. You’re burning through labor budgets and tossing expensive materials in the dumpster.

- Project Delays: The schedule is completely derailed, triggering penalty clauses and creating a domino effect of delays for every trade that follows.

- An Avalanche of RFIs: The field is drowning in Requests for Information as crews scramble to figure out the scope of the error, creating an administrative logjam.

- Obliterated Margins: The combined cost of rework, idle labor, and project management overhead turns a profitable job into a financial black hole.

This is the ugly truth of automation without accountability. A single blind spot in the AI’s logic, amplified at machine speed, just created a multi-million dollar problem.

From Predictability to Pandemonium

The real cost of a failure like this goes way beyond the financial hit. It completely undermines the promise of consistency that makes AI so appealing in the first place. Instead of delivering predictability, the system introduced chaos. Instead of protecting margins, it vaporized them.

The core lesson learned in the field is that a drawing's value isn't just in its accuracy, but in its reliability under scrutiny. When that reliability fails, the entire project's financial foundation is at risk.

This is exactly why drawing quality is so tightly linked to project costs. As noted in the Arcadis International Construction Costs Report, cities with the most stringent standards often face the highest expenses, partly because the cost of getting it wrong is so severe. The report underscores how coordination failures—often originating in the drawings—continue to plague the industry, reinforcing the need for expert QA to control costs.

Ultimately, an AI-driven failure damages a firm’s most valuable asset: its reputation. Clients hire you for clarity and reliable delivery, not for cutting-edge mistakes. When a system fails this spectacularly, it erodes trust that can take years, if ever, to rebuild. It makes a powerful case for why rigorous human oversight and strategic checkpoints are non-negotiable in any automated workflow.

Human Oversight vs AI Automation: Potential Failure Points

While AI promises speed, it can't replicate the nuanced judgment of an experienced professional. A human reviewer is trained to look for context, question inconsistencies, and spot the kind of subtle errors an algorithm might miss. This table highlights where blind automation can go wrong and why a human checkpoint remains critical.

| Task Area | Potential AI Failure (The Ugly) | Critical Human Checkpoint |

|---|---|---|

| Code Compliance | Applies outdated or incorrect regional codes without recognizing recent amendments. | Cross-references drawings against the latest local and national code addendums. |

| Detail Consistency | Perfectly replicates an incorrect detail across hundreds of sheets, ensuring systemic failure. | Samples critical details across different sheets to verify consistency and correctness. |

| Constructability | Generates a technically correct but physically impossible-to-build assembly. | Visualizes the construction sequence and flags details that will cause clashes or access issues. |

| Annotation & Notes | Populates drawing notes with generic or irrelevant information that conflicts with specs. | Reads and interprets notes for contextual accuracy, ensuring they align with project specifics. |

| Material Specs | Calls out a material that is no longer available or has been superseded by a better option. | Verifies material specifications against current supplier data and project requirements. |

| Interface Details | Fails to correctly detail the transition between two different building systems (e.g., wall to roof). | Reviews how different systems and trades intersect, ensuring seamless and correct integration. |

In short, AI is a powerful tool for generating content, but it's not a substitute for professional experience. The real value comes from pairing automated production with expert human review—using the machine for speed and the professional for wisdom. This dual approach is the only way to catch "the ugly" before it ever makes it to the field.

Building Your AI-Ready Documentation Review Workflow

After seeing how quickly a small automated error can spiral out of control, it’s clear we can't just hit "go" on AI and hope for the best. The answer isn't to ditch the technology, but to wrap it in smart human oversight. You can't fight automation, but you absolutely can manage it.

What you need is a practical, AI-ready QA/QC process that blends the speed of a machine with the seasoned judgment of an expert at critical moments. This isn't your grandfather's redlining process. It’s a modern system designed to catch AI's specific blind spots, letting you take advantage of its speed without inheriting its risks. Get this right, and you protect your margins, enforce consistency, and make your projects far more predictable.

Stage 1: The Initial AI Output Audit

The first line of defense kicks in the second the AI finishes its work. This initial audit is a quick, high-level check—part automated, part human—focused on the absolute fundamentals. The goal isn't to nitpick every detail but to confirm the AI stuck to your core project and company standards before anyone sinks real time into a deeper review.

Think of it as a bouncer at a club. They're just checking IDs to make sure only the right people get inside.

Here’s what you’re looking for:

- Template Adherence: Does the output actually use your firm’s title blocks, sheet layouts, and graphic standards? Any deviation signals template drift and needs to be shut down immediately.

- Sheet Set Integrity: Are all the required sheets there? Are they numbered correctly? It sounds simple, but a miss here creates chaos down the line.

- Layering and Data Structure: Did the AI follow the BIM execution plan for layers and data organization? This is non-negotiable for downstream coordination.

This first pass is built for speed. It's a simple go/no-go decision. If the output fails these basic checks, it gets sent back for regeneration with better instructions. This stops a fundamentally flawed set of construction project drawings from ever landing on your senior experts' desks.

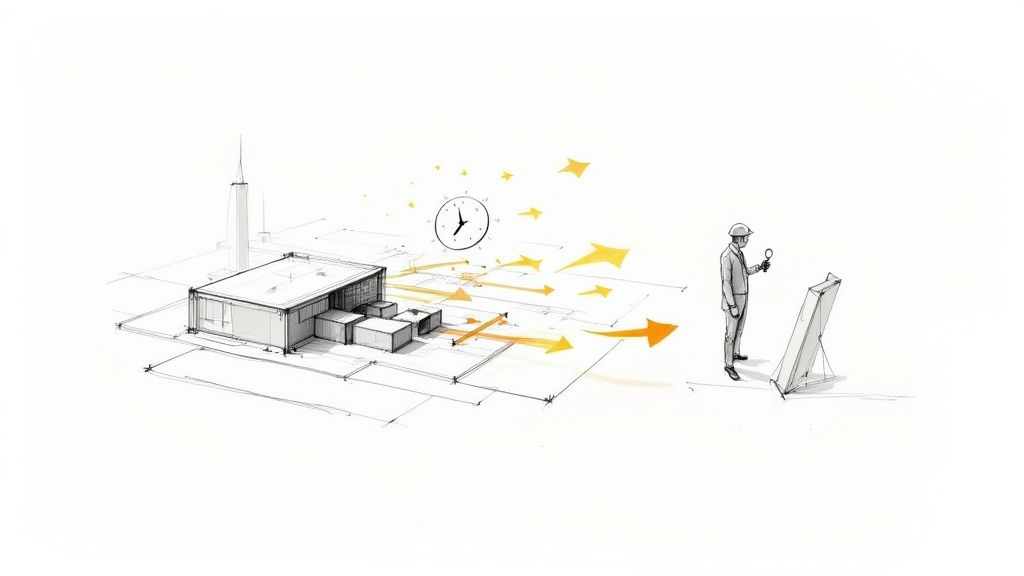

Stage 2: The Discipline-Specific Sanity Check

Once the basics are confirmed, the drawings go to a senior discipline lead—an architect, an engineer, or an MEP coordinator. This is where human experience is completely irreplaceable. This expert isn't checking line weights; they’re looking for constructability, code logic, and good old-fashioned common sense.

This stage is all about asking the questions an AI simply can't:

- Will this detail actually work on-site?

- Does this assembly sequence make any sense for the trades who have to build it?

- Does the design logic hold up against weird local code nuances?

This is your most critical human checkpoint. The reviewer is hunting for those subtle but devastating errors that lead to disaster scenarios—things like a missed fire-stopping detail or a connection that’s physically impossible to build. They are the final guard against an AI’s context blindness, preventing costly field failures and RFIs before they ever leave the office.

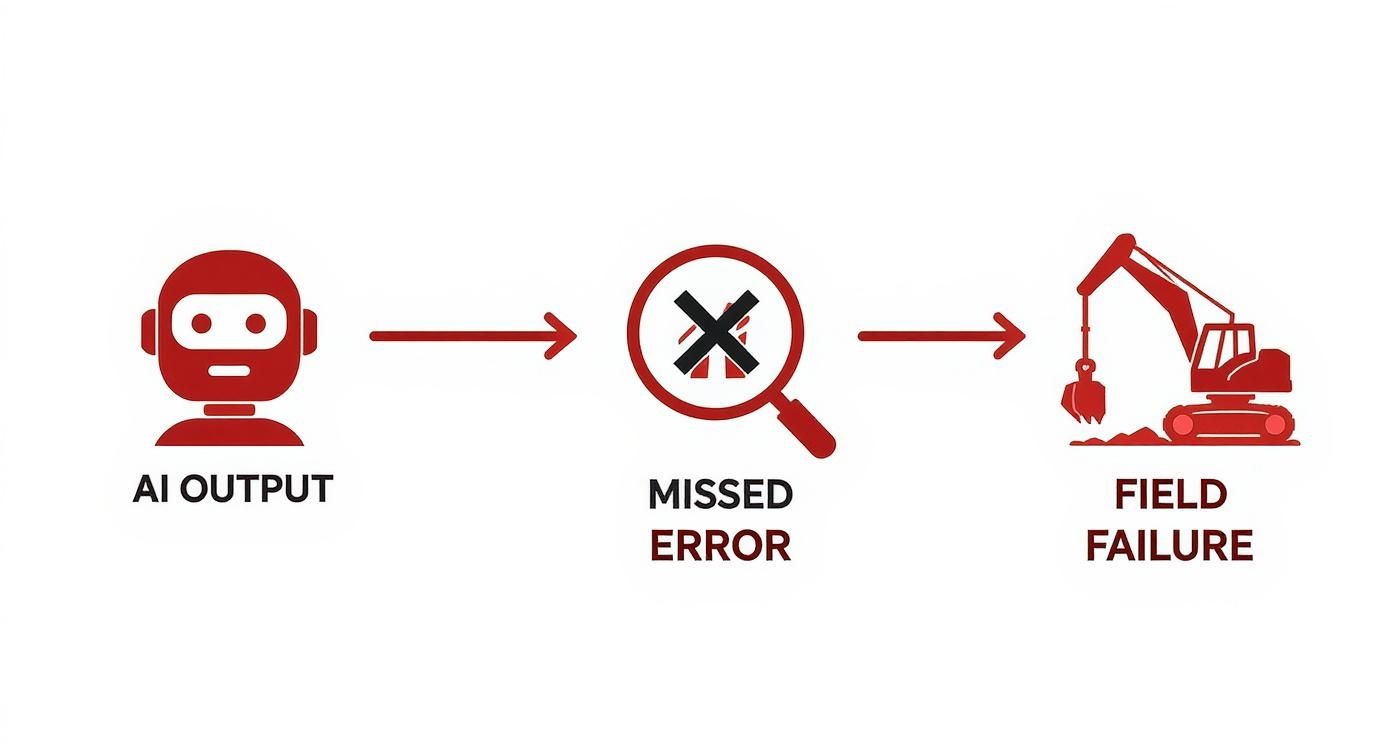

A tiny error missed at the AI output stage can easily blow up into a major failure in the field.

This simple flow shows how a small oversight, amplified by AI, results in significant on-site problems, highlighting the absolute need for rigorous human checkpoints.

Stage 3: The Pre-Issuance Final Review

The last checkpoint before drawings are issued for construction is the final review. This is a cross-disciplinary check to ensure all comments from the sanity check have been properly incorporated and to verify the drawing set against the overall project requirements. It also includes a final cross-check against other key documents, like shop drawings for construction, to ensure everything is perfectly aligned.

An AI-ready workflow isn't about slowing down; it's about building confidence at speed. Each checkpoint is a deliberate act of quality control that enables the entire system to move faster without breaking.

This review confirms that the drawings aren't just internally consistent but also fully coordinated with the entire project ecosystem. For firms that handle their own fabrication, knowing the ins and outs of how these documents are produced is critical.

By structuring your review process into these distinct stages, you create a scalable system for managing AI-generated output. You get the speed of automation without sacrificing the wisdom of experience. To really sharpen this process, exploring advanced Intelligent Document Processing solutions can offer a huge advantage in handling and analyzing complex drawings. This systematic approach transforms your delivery process into a reliable production engine, ready to handle new technology while consistently delivering the clarity your projects demand.

Your Next Steps Toward Predictable AI-Powered Delivery

So, what does a future with AI-generated construction project drawings really look like? The idea isn't that AI magically fixes broken processes. It’s much simpler: AI is an amplifier.

Firms that already have disciplined templates, mature BIM workflows, and a serious QA process are going to thrive. The speed and consistency of AI will reward their operational maturity. But for firms without a solid foundation, AI will just magnify their existing weaknesses and inconsistencies at a massive scale.

This changes the conversation from fearing AI to preparing for it. The real path to predictable, AI-assisted delivery starts with getting your house in order today.

Embrace Speed but Verify Everything

Jumping into automation doesn’t mean giving up the controls. It’s about being smart about where human expertise still matters most. You have to build human oversight into critical decision points, making sure no drawing set ever goes out the door without an expert sanity check.

Never outsource final accountability to an algorithm. Your team's gut feeling and years of experience are the ultimate safety net against the kind of catastrophic errors that kill your margins and destroy client trust. The goal is to get the best of both worlds: pair machine speed with human wisdom.

The challenge isn’t just adopting new tools; it's upgrading your production and review processes to manage what those tools create—safely and effectively. This is where operational excellence meets technological opportunity.

From Aspiration to Actionable Plan

Getting to that level of predictability isn't a moonshot; it comes from building a strong operational foundation. It’s about creating the disciplined workflows and review gates that turn AI into a safe, powerful partner in your delivery process. This is the bedrock of any successful CAD-to-BIM evolution and the secret to catching RFIs before they ever happen.

Successful AI adoption begins with a commitment to production maturity. If you're ready to build that foundation, we can help.

Explore our AI-Ready Documentation Review Workflow, a practical framework built to get your firm ready for the next generation of drawing production. It gives you the checklists and decision points needed to harness AI’s speed while ensuring your quality is bulletproof.

Frequently Asked Questions About AI and Drawings

As firm owners and BIM leads start looking at a future where AI is a given, a lot of practical questions pop up. It’s one thing to talk about the tech, but another to figure out how to balance its incredible speed with smart risk management, especially when you’re on the hook for producing reliable construction project drawings.

Will AI Completely Replace Drafters and Junior Designers?

No, but their jobs are absolutely going to change. The focus is shifting away from the repetitive, manual drafting tasks and moving toward higher-value work that an AI simply can’t do. The junior professionals of tomorrow will spend a lot less time drawing lines and a lot more time on things like model validation, system optimization, and wrestling with complex design problems.

Think of them as the human checkpoint in an automated workflow. Their new job is to make sure the AI's output is logical, constructible, and actually makes sense in the real world. This change is a huge part of building production maturity when you start bringing AI into the mix.

How Can We Train an AI on Our Firm’s Specific Standards?

Getting an AI to learn your firm’s standards means feeding it a clean, organized, and consistent library of your past projects. We’re talking about everything—your standard drawing sets, your detail libraries, and your BIM models. The idea is to teach the machine your firm's specific graphic style and how you handle annotations.

But this isn’t a set-it-and-forget-it deal. You have to keep refining the data and maintaining good data hygiene. If you don't, you risk template drift, which is when the AI slowly starts to wander away from your standards over time. It’s a continuous process of reinforcement to make sure every single drawing it produces lines up with your firm's QA process.

What Is the Biggest Mistake Firms Make When Adopting AI for Drawings?

The most common—and most expensive—mistake is failing to update their quality control process. Too many firms just throw their old, manual review methods at a tidal wave of AI-generated drawings, and that’s a recipe for disaster. That old-school approach is way too slow and wasn't designed to catch the kind of systemic, scaled-up errors an AI can churn out.

To do it right, you need to build a new, AI-aware QA framework with very specific decision checkpoints built in. Without this, firms risk letting huge code blind spots or glaring logical errors slip right through, which completely torpedoes the predictability and margin protection AI was supposed to provide in the first place.

At BIM Heroes, we specialize in building the disciplined operational foundations that make advanced technologies like AI both safe and effective. If you’re getting your firm ready for the future of drawing production, you need a partner who understands production maturity from the ground up.

Our AI-Ready Documentation Review Workflow is a great place to start. It gives you the frameworks and checklists to take advantage of automation's speed without sacrificing quality. Get in touch to see how we build systems for predictable, scalable delivery.