Digital Twins: A Practical Introduction for Architects and Builders

The term digital twin is everywhere, but it's often buried in marketing noise and futuristic hype. Let's cut through that. A digital twin is a virtual model of a physical asset—like a building—that is dynamically linked to its real-world counterpart. It's not just a static 3D model; it's a living system that evolves with the building, bridging the gap between the as-designed plan and the as-is operational reality.

What Is a Digital Twin in AEC?

Forget the buzzwords about "buildings that think." At its core, a digital twin in AEC is the logical outcome of well-executed BIM and disciplined data management. It's a system that connects models, data, and real-world feedback over time to help owners and operators make smarter decisions.

Think of it this way: a BIM model is the detailed blueprint, frozen at a specific point in the project lifecycle, like "Issued for Construction." An as-built model is the final, corrected blueprint showing exactly what was constructed.

A digital twin is the live operations dashboard. It takes that accurate as-built model and connects it to the building's central nervous system—sensors, meters, and management systems. That live connection is what makes it a twin.

This system is built on three simple components:

- The Physical Asset: The actual building or infrastructure.

- The Virtual Model: The high-fidelity digital representation, which must start as a reliable as-built model.

- The Data Connection: The continuous flow of information between the physical and virtual worlds.

To clarify the distinction, here’s a quick comparison.

BIM vs Digital Twin: A Quick Comparison

| Characteristic | BIM Model (including As-Built) | Digital Twin |

|---|---|---|

| Purpose | Design, planning, and construction coordination. | Real-time monitoring, operational analysis, and maintenance planning. |

| Data Source | Primarily manual inputs during design and as-built verification. | Live data from IoT sensors, drones, and building management systems. |

| Nature | Static; represents a specific point in time (e.g., "as-designed" or "as-built"). | Dynamic; continuously updated to reflect the current state of the physical asset. |

| Lifecycle Stage | Primarily used during pre-construction and construction. | Used throughout the entire operational lifecycle of the asset. |

The table shows the evolution: a digital twin takes a static model and makes it a dynamic operational tool.

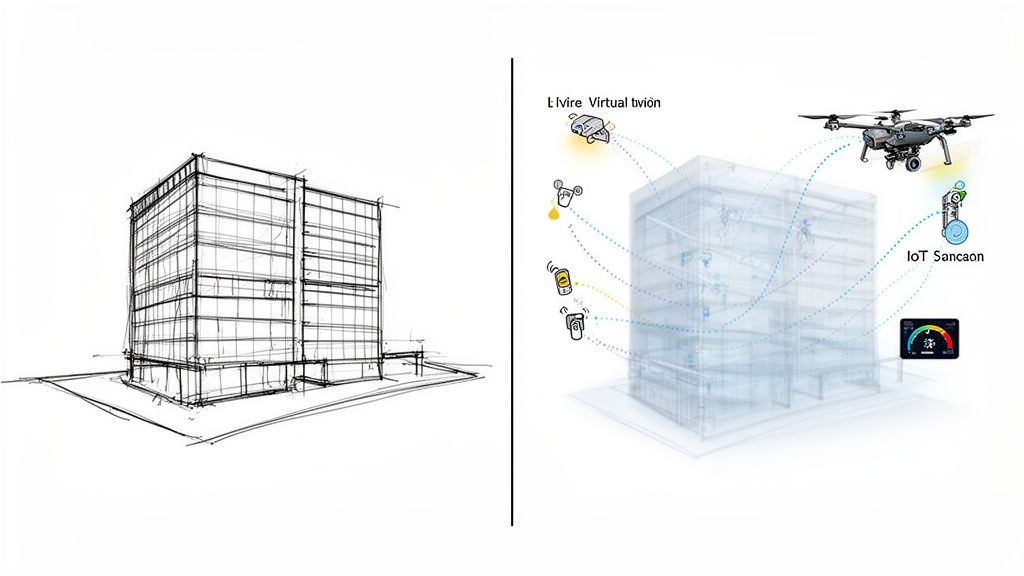

The Power Of a Living Connection

That data connection is the key. It's fed by IoT sensors tracking temperature and occupancy, drone scans verifying conditions, and building management systems monitoring energy use. This constant stream of data in motion turns the model from a static database into an active, operational tool.

The real value of a digital twin isn't just having a model; it's the ability to query that model with real-world operational data to predict outcomes, optimize performance, and prevent problems before they happen.

This is where digital twins deliver tangible returns, especially in facility management. Teams can use a twin to locate assets, simulate the impact of an HVAC shutdown, or plan maintenance with pinpoint accuracy. You can see more examples in our guide to BIM for facility management.

A digital twin is not a starting point—it is the outcome of disciplined BIM, data, and delivery practices.

Why Disciplined BIM Is Your True Starting Point

A valuable digital twin isn’t something you buy. It’s something you earn through disciplined information management. Before you can achieve a functional, reliable twin, you need a rock-solid BIM foundation. It’s the unavoidable first step.

Too many firms hear the hype around digital twins in AEC and want to skip straight to the finish line. But without clean, well-structured models based on consistent naming and defined LOD, you’re just building a digital replica of chaos. The "garbage in, garbage out" rule applies with punishing force. An unreliable twin built on messy data is worse than no twin at all—it leads to bad decisions and destroys trust.

This is where production maturity and template discipline become the bedrock of your strategy.

The Non-Negotiable BIM Prerequisites

A high-fidelity digital twin starts with mastering BIM fundamentals. This has less to do with new software and more to do with enforcing process discipline across every project phase.

This foundation is built on key elements:

- Consistent Naming Conventions: Every asset, from an HVAC unit to a light fixture, must be named systematically. This ensures that data from the model is clean, searchable, and usable for operations.

- Defined Levels of Development (LOD): Be crystal clear about the level of detail required at each project stage. This prevents both under-modeling (missing critical information) and over-modeling (wasting time on useless detail).

- Robust Template Discipline: Project templates are the constitution for your models. Starting with standardized templates guarantees consistency and prevents data fragmentation.

This commitment to QA processes is a direct line to protecting your margins. Every inconsistency fixed early on prevents a costly RFI or change order later. Explore the core benefits of Building Information Modeling in our detailed guide.

A digital twin strategy that doesn't begin with a rigorous BIM execution plan is destined for failure. Process must always precede technology.

From As-Built to Operational Twin

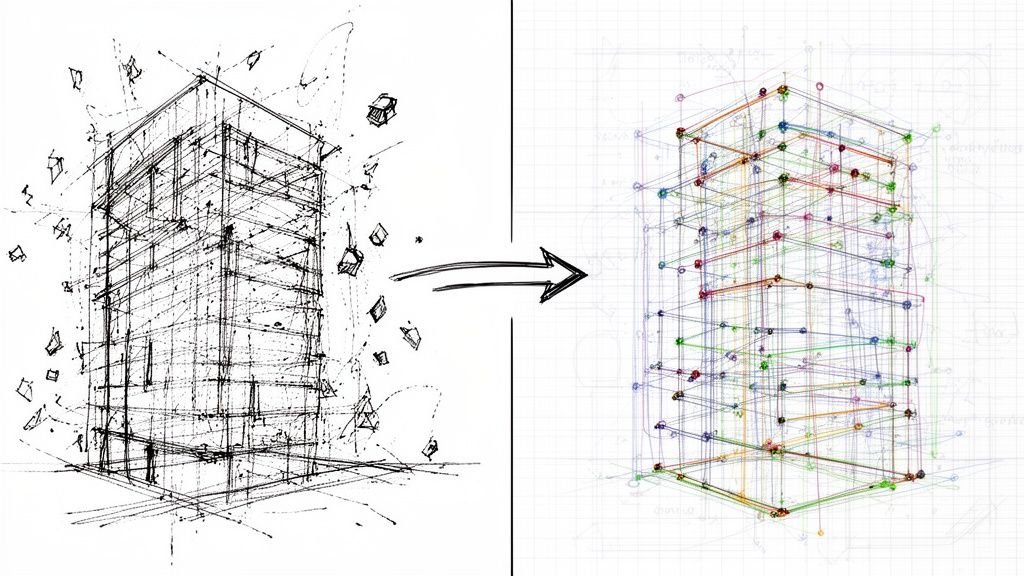

The journey from a design model to a living digital twin is full of critical handoffs. One of the most common failure points is the transition from construction to operations. This is where a meticulously documented as-built model becomes essential.

This isn’t just another BIM deliverable; it’s the birth certificate of your digital twin. It must accurately reflect every field change, every substituted piece of equipment, and the precise location of all serviceable assets. Getting this right demands rigorous QA processes and clear decision checkpoints to ensure the model reflects ground-truth reality.

Once you have that validated as-built model, you can connect it to live operational data. But to make that leap, you need sound data engineering best practices for scalable systems. This ensures data from sensors and facility management systems is structured, clean, and correctly mapped to the assets in your model.

Perfecting your BIM workflows is the most direct route to a successful digital twin in construction. It transforms the concept from a marketing buzzword into a tangible asset that delivers predictability, protects margins, and establishes operational consistency. It’s not about buying a solution; it’s about building a system of clarity, one well-managed model at a time.

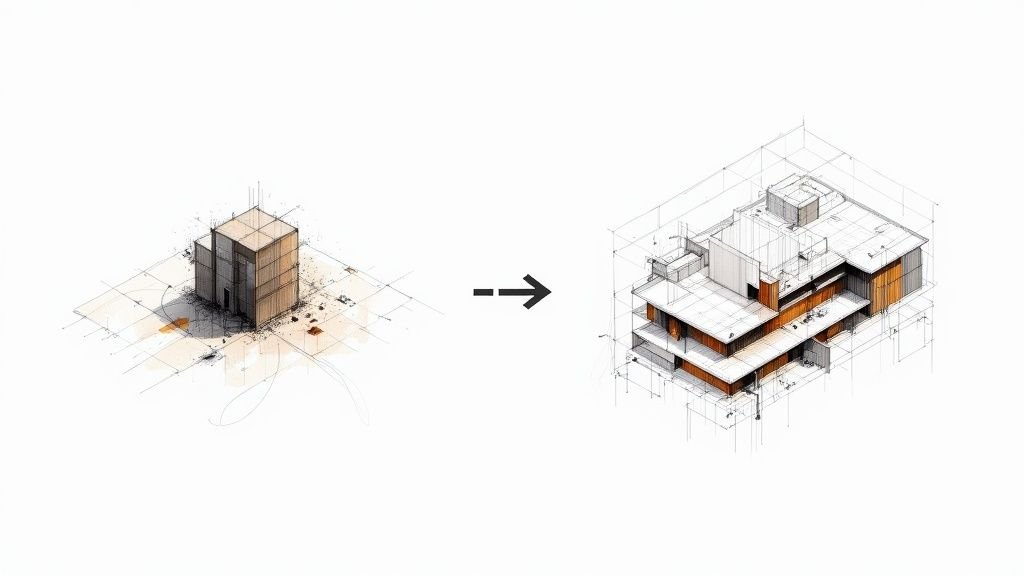

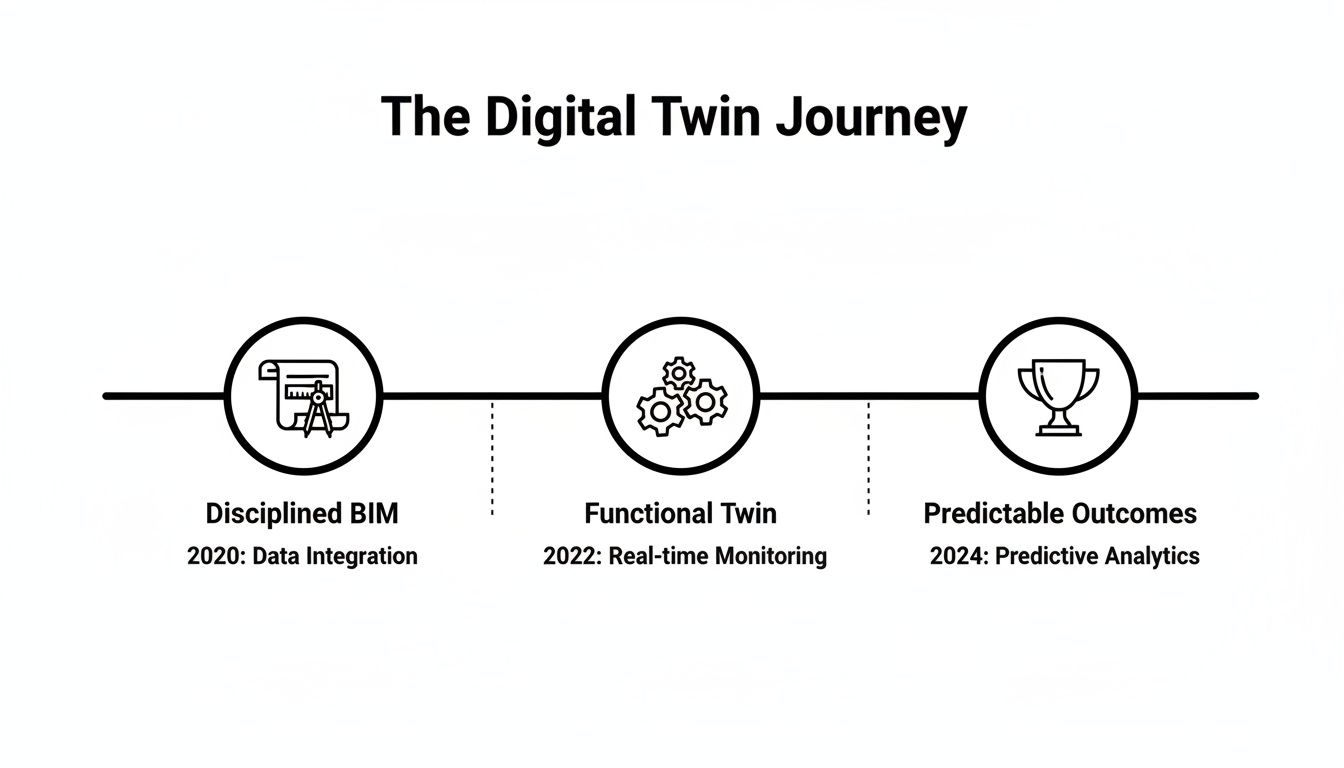

How a Digital Twin Evolves Through the Project Lifecycle

A digital twin isn't a static deliverable handed over at project completion. It's a living system that grows in value and complexity at every stage, evolving from a sophisticated design tool into a powerful operational asset. Its real power is in that journey.

This evolution is where firms with disciplined CAD-to-BIM evolution and solid template management cash in. Each phase builds on the last, layering in data and functionality that protects margins and delivers predictable outcomes.

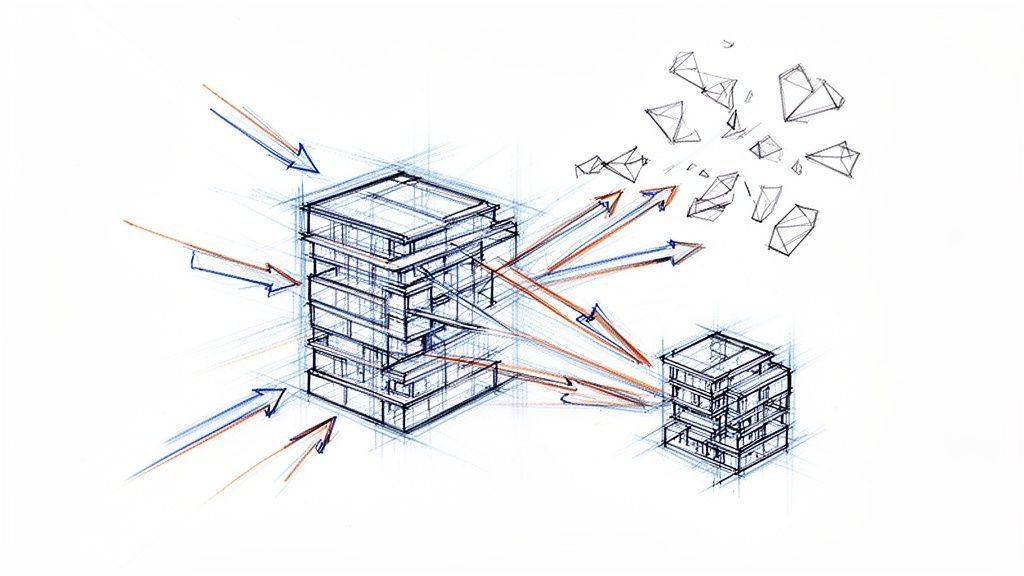

Design Phase: The Simulation Engine

In the beginning, the digital twin acts as a high-fidelity simulation platform. Before the first shovel hits the ground, architects and engineers use this early-stage twin to test and validate critical design decisions. It’s a virtual proving ground.

For example, you can run energy models to optimize HVAC efficiency or simulate structural loads under extreme weather. This front-loaded analysis is a powerful way to prevent costly RFIs and prepare for permitting by heading off issues early.

Construction Phase: The Progress Monitor

Once construction kicks off, the digital twin becomes a real-time progress monitor. The virtual model gets a dose of reality from the job site, creating a single source of truth that keeps delivery pods aligned.

This phase is about feeding real-world data streams into the model:

- Laser Scans: Regular point cloud updates from a Scan to BIM process are overlaid on the design model to verify accuracy and catch deviations early.

- Drone Photography: Aerial imagery provides a clear visual record of progress, perfect for tracking site logistics and installation milestones.

- Field Reports: Daily logs and inspection results can be linked directly to their corresponding elements in the model, adding crucial context.

This constant feedback loop is what makes a digital twin in construction so valuable. It shifts teams from reactive problem-solving to proactive quality control, protecting both the schedule and the budget.

Operations Phase: The Living Asset

The biggest long-term payoff comes during the operations and maintenance (O&M) phase. Here, the as-built model—validated through rigorous as-built documentation—becomes the foundation for a living operational tool.

By integrating with Building Management Systems (BMS) and IoT sensors, the twin gives facility managers an unprecedented look into asset performance. This data-rich environment supports key operational goals:

- Predictive Maintenance: Instead of reacting to a broken HVAC unit, sensors report performance data back to the twin, allowing teams to predict failures before they happen.

- Asset Tracking: Locate a critical piece of equipment for service by querying the model, not searching the facility.

- Space Management: Occupancy sensors provide real-time data on how spaces are actually used, helping owners optimize layouts and reduce energy waste.

This timeline shows how the journey progresses from a strong BIM foundation to a functional system that delivers tangible results.

Getting to predictable outcomes is a deliberate, step-by-step process that starts with disciplined BIM practices.

The ultimate goal is to create an operational asset that continues to deliver value long after the construction team has left the site. It’s a system built for clarity and reliable delivery, not just a one-off model.

The market is catching on. The U.S. digital twin growth research highlights a market expected to grow significantly. For AEC firms, this translates to tangible benefits like reducing rework and improving project timelines through better data management.

This lifecycle perspective makes it clear that a digital twin isn't a fantasy. It's the logical result of well-executed BIM, rigorous data management, and a commitment to quality from the first sketch to daily operations.

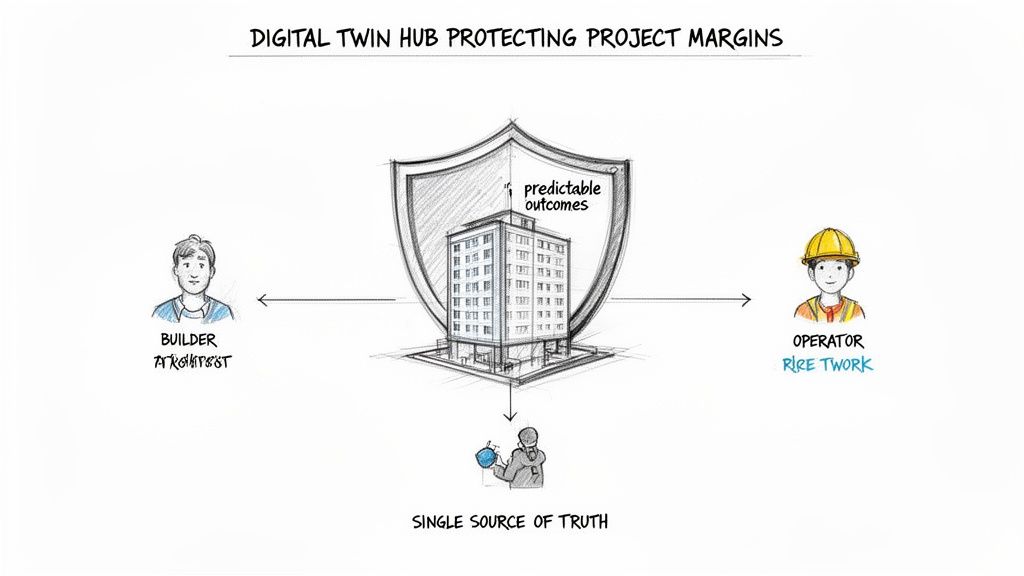

Protecting Margins with Predictable Project Outcomes

What real business problems does a digital twin solve? For architects and builders, its true value is in margin protection, predictability, and operational consistency. When you build a digital twin on a solid BIM foundation, you're not just creating a model; you're turning data into a defensive asset against risk.

This isn't about selling hours. It's about delivering a system for reliable results that moves the conversation from reactive firefighting to proactive quality assurance. That’s the operational clarity that protects your profit.

From Rework Prevention to Performance Validation

For builders, the payoff is immediate. A digital twin, fed by as-built data from laser scanning, acts as a clash detection powerhouse, visualizing conflicts between design intent and on-site conditions. Catching a mechanical duct interfering with structural steel in the virtual model saves a fortune in rework and keeps the schedule from derailing.

Architects can use a digital twin to validate design performance long before handover. By syncing real-world sensor data, they can simulate a building's lifecycle. An architectural firm can test wind loads on a high-rise twin, reducing physical prototyping costs and shrinking design cycles. This is the new standard for design validation.

A Single Source of Truth to Eliminate Friction

Perhaps the biggest impact on your margin is the digital twin's role as the undisputed single source of truth. When everyone—from architects and engineers to subcontractors and facility managers—works from the same live, data-rich model, communication friction evaporates. The twin becomes the central hub for every decision checkpoint.

Miscommunication and ambiguity are silent killers of profit. A digital twin silences that noise by providing a shared, objective view of reality.

This centralized clarity leads to a dramatic drop in RFIs that bleed project margins. When a subcontractor can pull up the twin to see exactly how their installation fits with others, questions are answered before they become formal requests. This access to verified information prevents delays, sidesteps disputes, and keeps the project moving predictably. This is exactly how to reduce construction costs—by eliminating waste at its source.

Ultimately, a digital twin transforms your deliverables from static documents into a dynamic asset. For your clients, it’s an invaluable operational tool. For your firm, it's a scalable system for delivering projects with the consistency and predictability that builds trust and protects your bottom line.

Setting Realistic Expectations for Digital Twins

The hype around the digital twin has created a fog of myths, leading firms down a path of costly mistakes. To get real value, you must cut through the aspirational promises and ground the conversation in today’s reality.

The most damaging misconception is that a digital twin is an automatic, self-managing system that springs to life at project completion. The reality is that a digital twin isn't something you just switch on; it’s the result of serious, ongoing effort in data integration, validation, and management.

It requires dedicated resources to ensure the data flowing from sensors is clean, accurate, and correctly mapped to the virtual model. Without rigorous data governance, the twin becomes unreliable and useless for making decisions.

Not Every Project Needs a Full-Scale Twin

Another common pitfall is assuming every project needs a comprehensive, real-time digital twin. The level of investment must match the operational goals of the asset.

A complex hospital with critical systems will see immense value from a dynamic twin for predictive maintenance. A simple warehouse, however, might only need a well-documented as-built model linked to an asset database.

The question isn't "Do we need a digital twin?" but rather "What specific operational problems are we trying to solve, and what level of data connectivity is required?"

This approach helps you avoid chasing a futuristic ideal and instead focus on an achievable, value-driven implementation. For most firms, this means starting small—with asset tracking or energy monitoring—and scaling the twin’s capabilities over time as the ROI becomes clear.

A Tool for Teams, Not a Replacement

Finally, a digital twin does not replace facility managers or operations teams. It’s a tool that empowers them to make better, more informed decisions. It provides the data to move from a reactive maintenance schedule to a predictive one, or to analyze space utilization with real data instead of guesswork.

A digital twin in construction augments human expertise, not replaces it. It provides clarity and insight, but skilled professionals are the ones who turn that insight into action. By understanding these limitations, you can build a practical strategy that focuses on achievable outcomes and delivers measurable value.

Are You Ready for a Digital Twin?

How do you know if your firm is truly ready to build a digital twin? The answer isn't about buying new software. It's about taking an honest look at your data maturity and process discipline.

A digital twin is the result of operational consistency, not a magic wand that creates it.

Before investing in advanced tools, you have to get your foundations right. Technology follows process, not the other way around. If your core information management is a mess, a digital twin will only amplify the chaos.

Key Readiness Indicators

A firm prepared for a digital twin in AEC can confidently say "yes" to these questions:

- Do you have a robust BIM Execution Plan (BEP)? A well-defined BEP that’s enforced on every project is non-negotiable. It guarantees consistency in your modeling standards and data structure.

- Is your as-built documentation process reliable? Your ability to capture accurate, field-verified as-builts is critical. Without a trustworthy record of what was actually built, any digital twin is flawed from day one. Our approach to Scan to BIM shows how this works in practice.

- Do you adhere to information management standards? A commitment to standards like ISO 19650 signals a mature approach to data governance. It provides the common language needed for a complex, interconnected system like a digital twin.

These aren't just checklist items. They're the bedrock of reliable project delivery.

A digital twin strategy built on a shaky foundation of inconsistent data and undisciplined processes is like building a skyscraper on sand. It’s not a question of if it will fail, but when.

The Business Case for Discipline

Getting these fundamentals right delivers immediate returns. For instance, according to recent digital twin market insights, firms that embrace digital transformation often report significant improvements in project timelines and cost management.

Mastering your data through disciplined as-built documentation and strong BIM fundamentals is the most important first step. If you're looking to assess where your firm stands, we’ve developed a simple framework to help.

Download our Digital Twin Readiness Checklist to evaluate your current processes and identify the foundational strengths you can build on.

Got Questions About Digital Twins?

As the buzz around digital twins grows, practical questions arise. For architects, builders, and project leaders figuring out where this technology fits, it's easy to get lost in jargon. Let's clear up common questions.

BIM vs. Digital Twin: What's the Real Difference?

It’s a common mix-up. People see a hyper-detailed as-built BIM model and think, "That's a digital twin." But they serve fundamentally different roles.

Here’s a simple way to think about it:

An as-built BIM model is like a perfect photograph. It’s a static, incredibly accurate 3D snapshot of the finished building at handover. It answers the question, “What was built?”

A digital twin is a live video feed. It starts with that same precise as-built model but then connects it to the building's nervous system—live data streams from sensors and management systems. It answers the question, “What is happening right now?”

The game-changer is that live, two-way connection. The as-built model is the blueprint; the digital twin is the living operational brain built upon it.

Does Every New Building Need a Digital Twin?

No. The decision to invest in a digital twin in construction or operations must be driven by the building's complexity and the owner's long-term goals. A digital twin is a commitment to data infrastructure and management, and it needs a clear return on investment.

For complex facilities like hospitals, data centers, or advanced manufacturing plants, a digital twin is a no-brainer. The value in predictive maintenance, energy optimization, and space management is immense.

For a simpler building, a solid as-built BIM model combined with standard facility management software is often more than enough. Match the technology to the real-world operational value it will create.

Smart digital twin strategies aren’t about chasing tech. They’re about solving specific business problems, like cutting maintenance costs or slashing energy bills.

What's the First Step My Firm Should Take?

The most important first step has nothing to do with buying new software. It’s all about getting your information management house in order.

A digital twin is only as good as the data it’s built on. Before considering platforms or sensors, master your internal BIM and data processes.

- Standardize Your BIM Execution Plans (BEPs): Enforce them on every project to ensure your data is clean and structured from day one.

- Get Serious About QA/QC: Your quality assurance process for models can't be an afterthought. It must be rigorous, catching mistakes before they get baked into the final record.

- Perfect Your As-Built Workflow: You need a bulletproof, repeatable process for creating and verifying your as-built documentation. It has to be accurate, every time.

Nailing these fundamentals gives you a trustworthy foundation to build on. This production discipline is the real starting point for any successful digital twin initiative.

At BIM Heroes, we believe technology should follow process, not the other way around. We partner with firms to build the disciplined BIM and data foundations needed for predictable project outcomes. We don’t sell hours; we sell clarity, systems, and reliable delivery.

Explore our services at https://www.bimheroes.com to see how we build system-driven success.