From Factory to Foundation: The Complete Prefabrication Workflow Explained

From Factory to Foundation: The Complete Prefabrication Workflow Explained

Prefabrication is transforming construction by shifting much of the work from on-site assembly to controlled factory production. This approach saves time, reduces costs, and improves quality. Here’s a quick breakdown:

- What It Is: Building components are manufactured in factories and assembled on-site.

- Key Tools: Digital design technologies like BIM and CAD ensure precision and efficiency.

- Benefits:

- Faster project timelines by overlapping site prep and manufacturing.

- Consistent quality through factory-controlled environments.

- Reduced material waste and better resource management.

- Challenges: Coordination errors, supply chain delays, and local code compliance can disrupt workflows.

- Solutions: BIM tools like clash detection, point cloud modeling, and detailed 3D designs help streamline processes.

Prefabrication is reshaping construction by combining advanced technology with streamlined workflows, ensuring projects are completed faster, with fewer errors, and at lower costs.

BIM in Modular Design and Construction: Benefits and Challenges

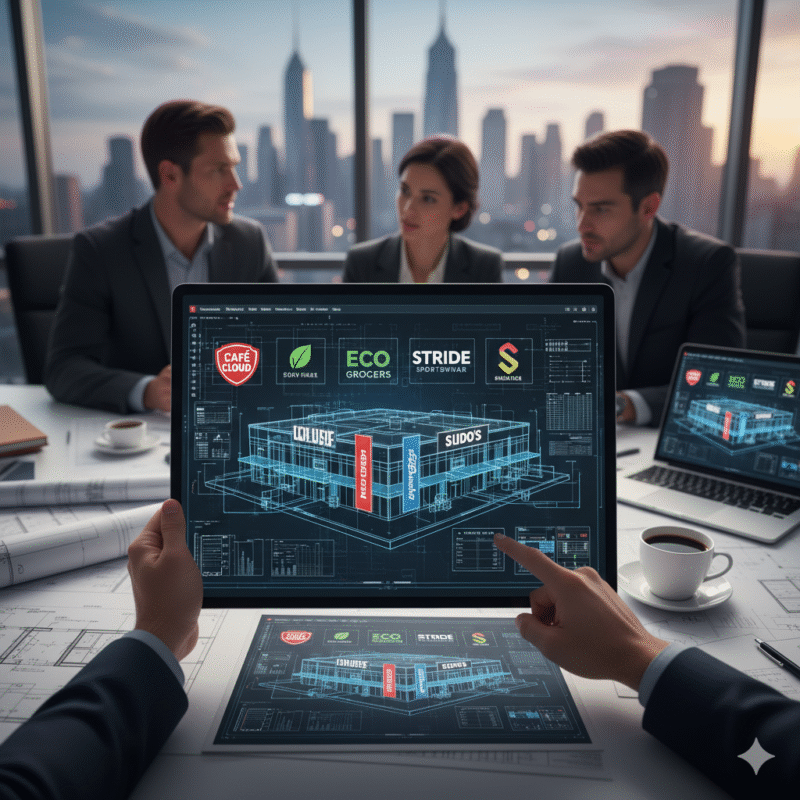

Digital Design Tools: BIM and CAD for Prefabrication

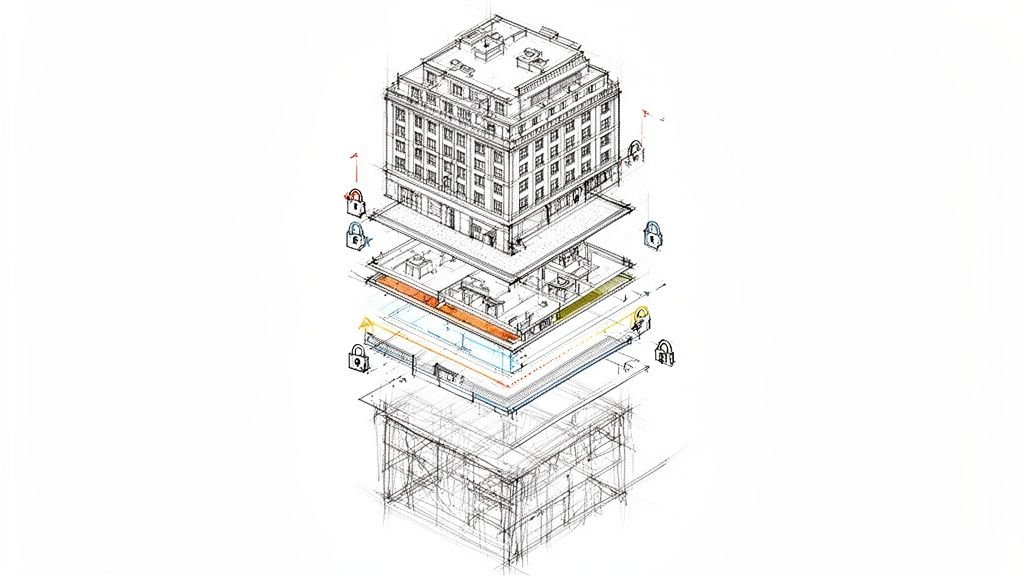

Prefabrication thrives on digital accuracy. Without precise digital models, even the most advanced factory equipment can’t produce components that fit together perfectly on-site. Building Information Modeling (BIM) and Computer-Aided Design (CAD) serve as the foundation of the prefabrication process. These tools not only ensure accuracy in design but also enable streamlined automated production.

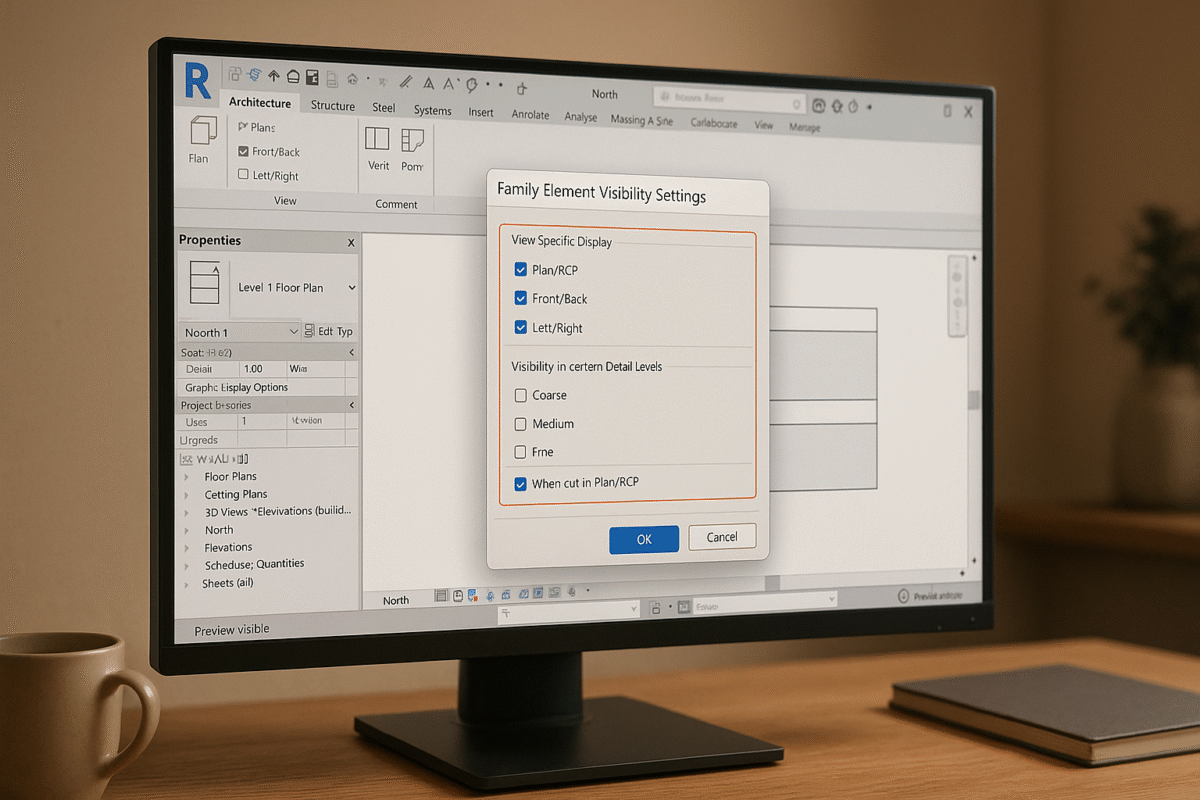

Using BIM and CAD for Prefabrication

Tools like Revit and AutoCAD are at the heart of detailed prefabrication modeling. Unlike traditional 2D drawings, these programs create comprehensive 3D models with exact dimensions, material details, and step-by-step assembly instructions.

By leveraging BIM and CAD, teams can ensure the prefabrication process – from design through manufacturing – operates with greater precision and efficiency.

For instance, Revit allows teams to build parametric models that automatically adjust when changes are made. If an architect alters the thickness of a wall, related components like structural frames or MEP (mechanical, electrical, and plumbing) systems update instantly. This level of synchronization is essential when working with components that require tight tolerances.

AutoCAD, on the other hand, excels in producing detailed shop drawings. These define every measurement, connection, and detail – down to the exact location of bolt holes and weld points. Modern BIM models take it a step further by embedding critical production data, such as material properties, weight, and manufacturing tolerances. This data seamlessly integrates with factory machinery, automating processes like cutting, drilling, and assembly.

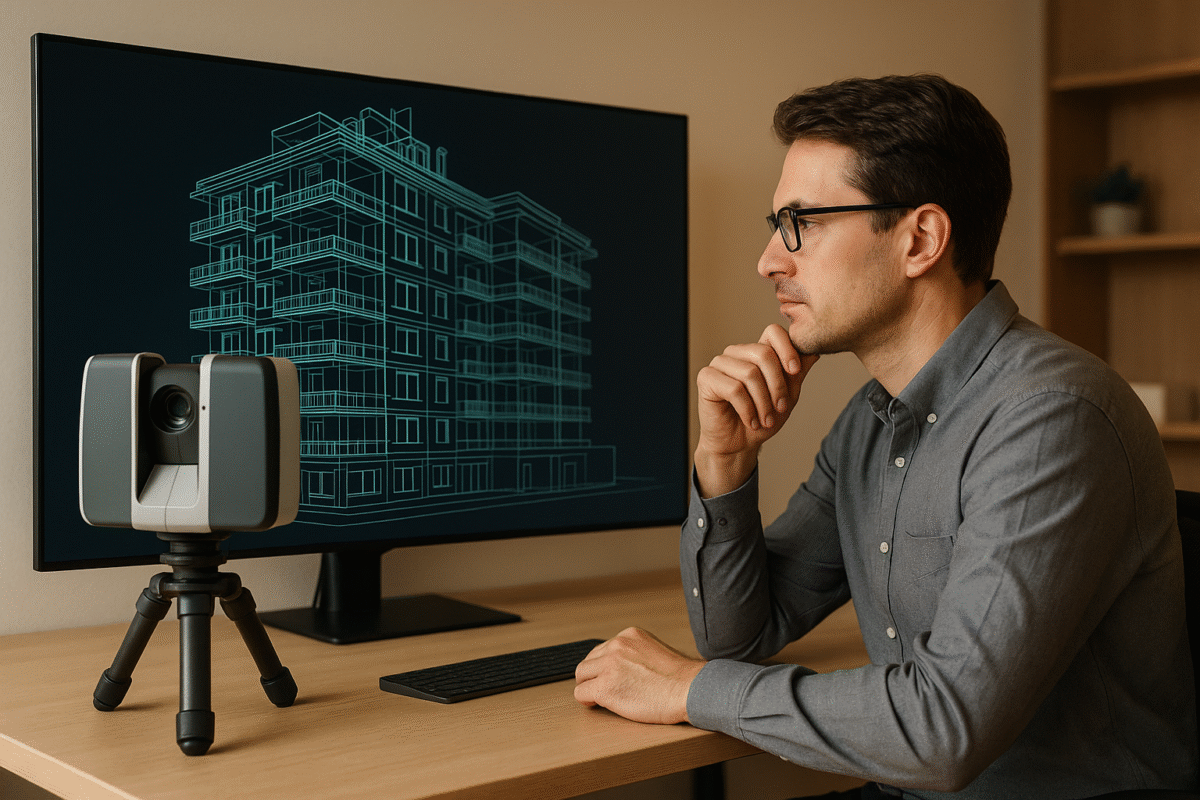

Scan to BIM and Data Integration

Scan to BIM technology bridges the gap between existing site conditions and new prefabricated components. By using laser scanners and photogrammetry, teams capture millions of data points to produce highly accurate point cloud models of existing structures. This approach is especially valuable when prefabricated elements need to align with existing buildings, where traditional measuring techniques might miss crucial details.

For example, BIM Heroes’ Point Cloud to BIM service converts dense point clouds into clean, workable Revit models. These models support precise production planning, reducing the chances of costly on-site adjustments.

The process also includes rigorous data validation. Scanned data is compared to original design plans, and any discrepancies are flagged for resolution before manufacturing begins. By addressing these issues early, teams can ensure prefabricated components fit as intended during installation, avoiding extensive field modifications.

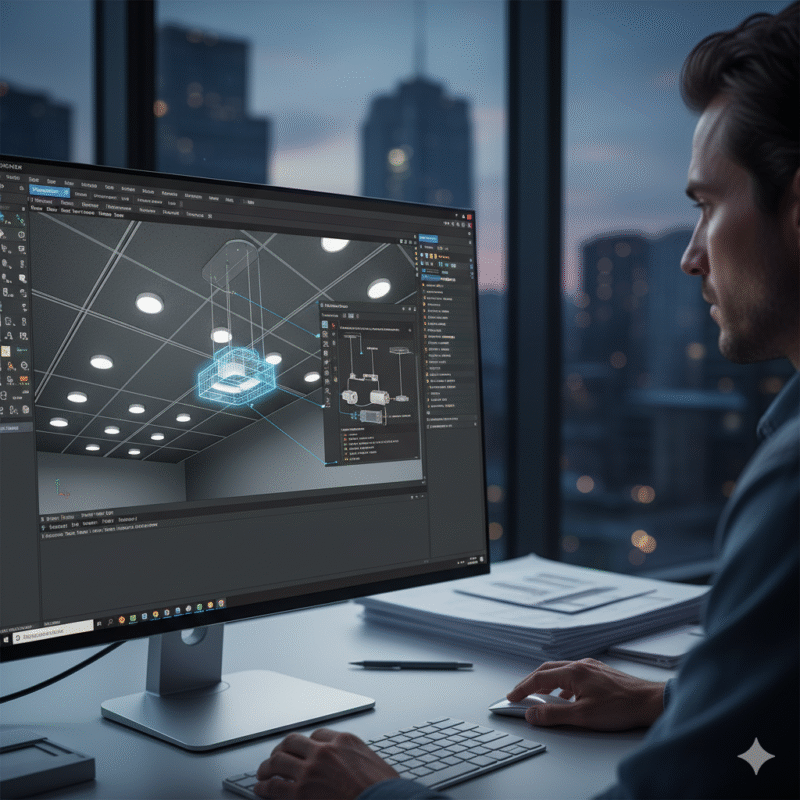

Clash Detection and Quality Control

Clash detection has become a standard practice in construction, especially during the early design and preconstruction phases. In prefabrication, this step is even more critical because components must fit perfectly during assembly. Resolving conflicts early is essential.

Using advanced software, teams can identify conflicts between structural, MEP, and architectural elements within the 3D model – such as a steel beam intersecting ductwork or plumbing lines clashing with electrical conduits. Unlike traditional construction, where these issues might be resolved on-site, prefabrication demands that they be addressed before production begins.

Recent data highlights the importance of early clash detection. A 2023 study revealed that substandard installations occurred in 78% of cases, on-site cutting errors in 65%, and 50% of prefab wall projects faced alignment issues, leading to costly reworks and delays.

Clash detection is an ongoing process, running iteratively throughout the design and coordination phases. It continuously checks for new conflicts as different trades refine their designs. This ensures the creation of clash-free 3D models, minimizing potential issues like misaligned components or grouting problems during construction.

BIM Heroes utilizes advanced clash detection workflows to ensure prefabricated components integrate seamlessly with overall project designs. This meticulous digital coordination helps prevent costly errors and ensures a smooth transition from design to factory production.

The Factory Manufacturing Process

After digital models pass through clash detection and quality control, the next step is turning those virtual designs into real-world components. This shift from digital to physical requires careful coordination between design teams, factory equipment, and quality control systems. Factories provide an ideal environment for this process, with controlled temperatures, secure workspaces, and advanced machinery ensuring precision and consistency. This smooth handoff from digital planning to physical production lays the foundation for accurate manufacturing workflows.

From Digital Model to Factory Production

The BIM model plays a key role in guiding material procurement and preparation. Factory teams extract detailed specifications from the model, such as steel grades, concrete mixes, and finishing requirements, ensuring all materials meet project standards before production begins.

Volumetric prefabrication involves constructing entire room-sized modules in the factory. These fully assembled units arrive on-site complete with flooring, walls, ceilings, and often pre-installed mechanical, electrical, and plumbing (MEP) systems. The digital model dictates every detail, from the framing dimensions to the exact placement of outlets and plumbing fixtures.

Non-volumetric prefabrication, on the other hand, focuses on individual components like wall panels, roof trusses, or structural steel frames. Each piece is manufactured to the precise specifications embedded in the BIM model. CNC machines use this data to cut materials and drill connection points with millimeter accuracy.

Quality control in the factory is rigorous. Dimensional checks ensure components match their digital designs, while material testing confirms they meet strength and durability standards. Visual inspections catch any surface defects or inconsistencies in finishes that might affect final assembly. These controlled processes significantly reduce the variability often seen in traditional construction.

Automation and Data Standards

Prefabrication facilities rely heavily on BIM-driven automation. Machines like CNC cutting tables, robotic welders, and automated assembly lines receive direct instructions from standardized data formats, eliminating errors that can occur when manually interpreting drawings.

Industry Foundation Classes (IFC) act as a universal language, enabling seamless data exchange between design software like Revit and manufacturing equipment, regardless of the machinery’s brand. IFC files carry more than just geometric details – they also include material properties, assembly instructions, and quality standards.

Real-time data exchange protocols further enhance efficiency. When architects update designs, the changes are instantly reflected in factory operations, preventing outdated components from being produced. This integration reduces waste and ensures production always aligns with the latest design.

Manufacturing execution systems track each component throughout production, creating a digital trail linked back to the original BIM model. This traceability becomes invaluable during installation, allowing teams to quickly identify components and access their production history if issues arise.

Manufacturing Workflow Comparison

The layout of a factory has a major impact on production speed, costs, and scalability. Different production strategies highlight how standardizing processes can improve efficiency. Choosing the right approach depends on the specific needs of the project.

| Factor | Linear Production Line | Static Production Stations |

|---|---|---|

| Speed | High throughput for repetitive components | Slower but adaptable for custom elements |

| Scalability | Easy to scale for large projects | Limited by station capacity |

| Initial Cost | Higher setup costs for conveyor systems | Lower initial investment |

| Labor Requirements | Specialized workers for each station | Cross-trained workers handling multiple tasks |

| Quality Control | Consistent quality through standardization | Quality varies based on worker skill |

| Flexibility | Hard to adjust for design changes | Easily adapts to unique components |

| Floor Space | Requires long, continuous workspaces | Compact layout with dedicated areas |

Linear production lines are ideal for producing large quantities of identical components. Items move through a series of stations where specialized tasks like cutting, welding, and finishing are performed. This setup is perfect for projects requiring hundreds of similar wall panels or structural elements.

Static production stations, by contrast, are better suited for custom or complex components. Skilled workers handle each piece from start to finish at fixed stations. This approach works well for unique architectural features or projects with significant design variations that could disrupt linear workflows.

The choice between these methods depends on the project’s scale and complexity. Large-scale residential developments benefit from the efficiency of linear production, while custom commercial projects often require the flexibility of static stations. Many factories combine both approaches, using linear systems for standard components and static setups for specialized tasks.

sbb-itb-0af4724

Transportation and On-Site Assembly

Once components are manufactured, the next step is getting them from the factory to the construction site. This stage demands careful planning to preserve the quality achieved during production while managing the logistical challenges of transportation and assembly.

Transportation and Handling

Transporting components is no small feat. If not handled properly, the integrity of these parts can be compromised. That’s why transportation planning often begins during the design phase. Tools like BIM models help evaluate component dimensions and ensure site access, factoring in road and bridge clearances.

In the U.S., oversized loads require route planning and special permits to navigate regulatory restrictions. Large modules may need routes that avoid low bridges, narrow roads, or other obstacles.

To protect components during transit, packaging strategies are tailored based on the material and distance. For instance, steel components might be treated with protective coatings and securely fastened, while precast concrete panels are cushioned and covered to prevent damage and moisture exposure.

Modern technology, like GPS tracking and sensors, plays a key role in monitoring transit conditions. These tools help maintain sensitive materials within ideal temperature and humidity ranges throughout the journey.

Once on-site, specialized lifting equipment ensures components are handled and delivered safely. With transportation complete, attention shifts to the assembly process.

On-Site Assembly Process

After safely arriving at the site, components are assembled with precision. Preparation begins with foundational work and utility setup, aligning with a just-in-time delivery system to ensure components are installed in the correct order.

Assembly typically follows a logical sequence: structural elements go up first, followed by the building envelope, and then MEP (mechanical, electrical, and plumbing) systems. BIM models guide the placement of every piece, ensuring accuracy.

The method of connecting components depends on how they were prefabricated. Some modules are joined with mechanical fasteners and sealed joints for quick assembly, while others might require welding, bolting, or more specialized techniques that take additional time and expertise.

To protect sensitive areas during construction, temporary enclosures are often used. Throughout the process, quality control is maintained through regular inspections and digital tools that verify alignment and placement. Dimensional surveys ensure the final structure matches design specifications.

Testing and Defect Management

Once assembly is complete, testing ensures everything meets the required standards. Structural, building envelope, and MEP systems are all evaluated using non-destructive methods to confirm performance and safety.

For building envelopes, tests like blower door and water spray evaluations check for air and water infiltration, while thermal imaging identifies insulation gaps. MEP systems undergo standard commissioning tests, such as pressure checks for plumbing and HVAC systems and electrical tests to confirm grounding and circuit continuity.

If defects are found during testing, they are documented in tracking systems to ensure quick resolution. Issues can range from minor cosmetic flaws to more serious structural concerns. Depending on the severity, fixes may occur on-site or require rework or replacement of components.

Smart building systems also provide ongoing performance monitoring, tracking factors like energy use, structural movement, and environmental conditions to ensure long-term reliability and efficiency.

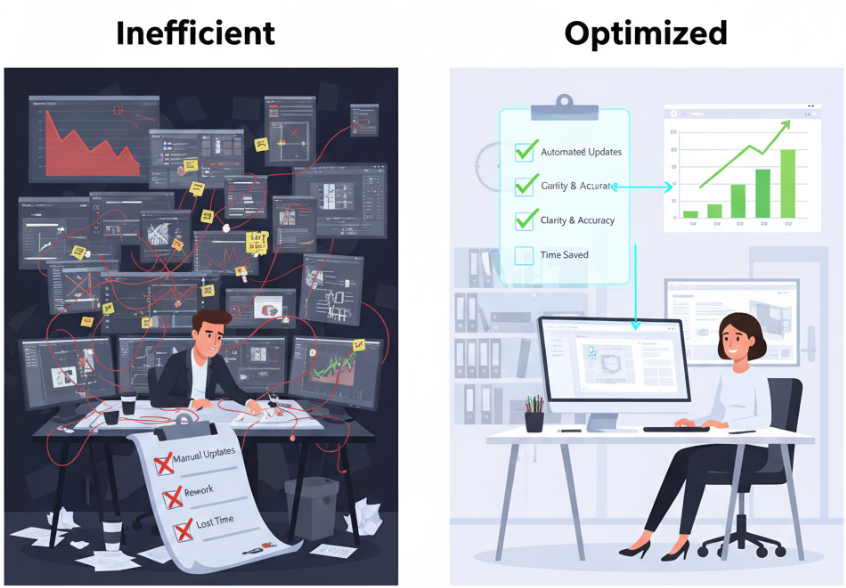

Solving Prefabrication Challenges with BIM Heroes

Prefabrication projects, even with advanced planning and cutting-edge technology, often encounter obstacles that can disrupt timelines and inflate costs. Addressing these challenges effectively can mean the difference between a smooth project and one riddled with setbacks. Prefabrication, while efficient, comes with its own set of hurdles that require precise, well-thought-out solutions.

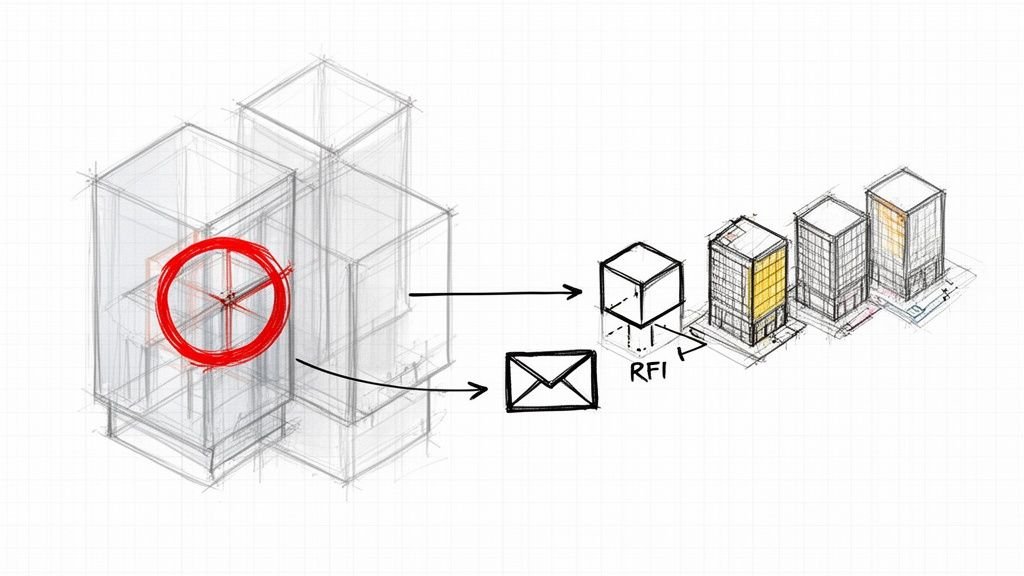

Common Prefabrication Challenges

One of the biggest issues in prefabrication is coordination errors. When architectural, structural, and MEP teams work in silos, conflicts often go unnoticed. For instance, a misaligned conduit can render a prefabricated panel unusable, leading to expensive rework and delays.

Supply chain delays are another common problem. A delay in materials can throw off production schedules, disrupt on-site assembly, and create a domino effect of setbacks for other trades waiting to begin their work.

Local building codes add another layer of complexity. These codes vary widely across states and municipalities, and prefabricated components must comply with local standards. For example, what passes inspection in Texas might fall short of California’s seismic requirements or Florida’s hurricane-resistant standards. Navigating these differences demands expertise and detailed documentation.

Site constraints can also cause headaches. A prefabricated module that looks perfect in a digital model might face real-world challenges like narrow site access or overhead power lines, making installation difficult or even impossible.

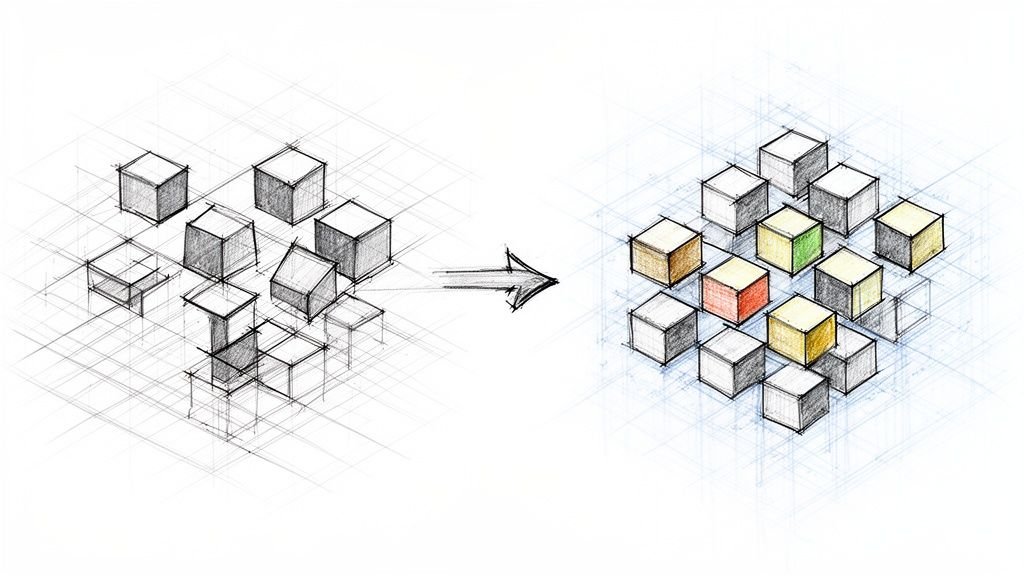

Finally, data management becomes a daunting task as projects grow. With multiple software platforms, file formats, and team members involved, information silos and version control issues can arise. Outdated drawings might reach the factory floor, or critical design updates might not make it to all stakeholders, leading to costly mistakes.

These challenges require focused solutions, and that’s where BIM Heroes steps in with their expertise.

BIM Heroes’ Solutions for Better Prefabrication

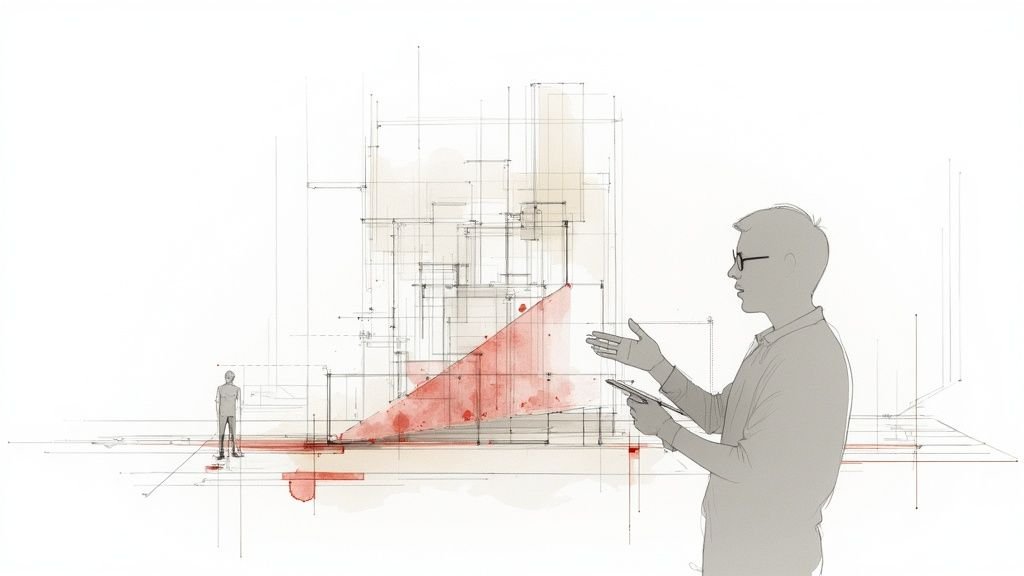

Precision is key when moving from digital design to manufacturing, and BIM Heroes provides tools and expertise to tackle these challenges head-on. Their detailed 2D CAD and 3D modeling services ensure accuracy from the outset. These models account for manufacturing tolerances, assembly sequences, and specific site requirements, minimizing costly errors further down the line.

To prevent on-site conflicts, BIM Heroes uses advanced clash detection and point cloud-to-BIM conversion, allowing designs to adapt seamlessly to real-world conditions.

Their team’s knowledge of regulations ensures designs meet local building codes across different regions without disrupting workflows.

BIM consulting services offer hands-on guidance throughout the prefabrication process. From choosing the right software to streamlining workflows, their consultants bring the insights gained from hundreds of projects. This practical experience helps teams avoid common pitfalls and optimize their processes.

With Revit and BIM family creation, BIM Heroes ensures that every prefabricated component is accurately represented in the digital model. These custom families include details like connection points, material properties, and assembly requirements, supporting precise quantity takeoffs and manufacturing instructions.

These services integrate seamlessly into prefabrication workflows, ensuring everything runs smoothly from start to finish.

Service Plan Comparison

To address these challenges, BIM Heroes offers flexible service plans tailored to meet different project needs:

| Plan | Best For | Key Benefits | Commitment |

|---|---|---|---|

| Dedicated Team | Large-scale projects, ongoing prefabrication programs | Full-time BIM experts embedded in your team, consistent quality, deep project familiarity | Minimum 6-month contract |

| Fixed Price | Well-defined projects with a clear scope | Predictable costs, agreed deliverables, great for budget-conscious planning | Detailed scope required |

| Hourly | Exploratory projects, evolving requirements, or consultations | Pay-as-you-go flexibility, ideal for changing needs | No minimum commitment |

The Dedicated Team model is ideal for organizations managing multiple prefabrication projects or large-scale developments. With BIM experts integrated into your team, you eliminate the learning curve for each new project, ensuring consistency and efficiency.

The Fixed Price plan works well for projects with stable requirements and a clearly defined scope. It offers cost predictability and transparency, making budgeting for prefabrication services easier. Success here depends on thorough upfront planning.

For teams testing the waters with prefabrication or dealing with shifting project demands, the Hourly model offers unmatched flexibility. This option allows you to scale support as needed without locking into long-term commitments – perfect for the early stages of prefabrication adoption.

No matter the plan, all clients gain access to BIM Heroes’ full suite of BIM and CAD tools. This ensures compatibility with your existing workflows, regardless of the software platform you use.

Conclusion: Prefabrication Success Factors

Prefabrication represents a major shift in how construction projects are planned and executed. From creating precise digital models to manufacturing components in a controlled factory setting and assembling them on-site, the process relies on a well-coordinated workflow. Every phase demands accuracy, teamwork, and specialized knowledge to ensure everything comes together seamlessly.

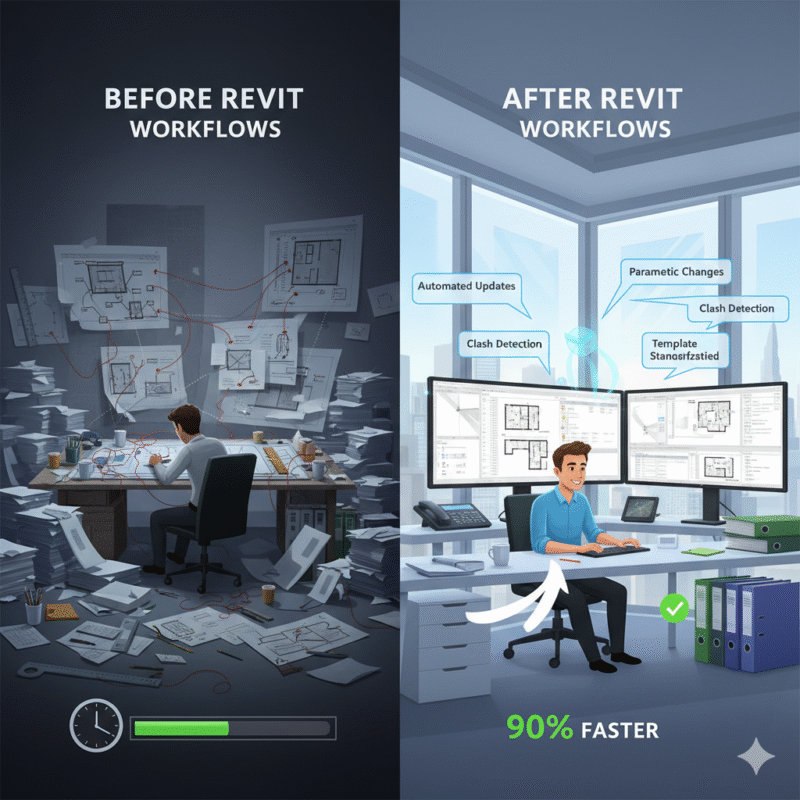

Optimizing Prefabrication Workflows

The success of prefabrication hinges on strong digital integration at every stage. Tools like Revit and AutoCAD provide the backbone for design, but their real power lies in how teams use them to manage data, adapt to design changes, and maintain strict quality control.

Accurate digital models with tight tolerances and pre-planned assembly sequences minimize waste, reduce the need for rework, and ensure components fit perfectly during installation. With proper planning, projects that traditionally took months can now be completed in a fraction of the time.

Specialized expertise also plays a crucial role in refining workflows. Instead of developing in-house BIM capabilities from the ground up, many companies turn to experts who can handle complex tasks like clash detection, advanced modeling, and compliance with regulations. This allows teams to focus on their strengths while ensuring the prefabrication process remains efficient.

Precise digital documentation bridges the gap between the digital and physical stages of construction. When models account for site-specific factors like crane access and installation logistics, on-site assembly becomes more predictable and efficient. Partnering with experts further enhances these benefits, ensuring a smooth transition from design to installation.

Partnering with BIM Heroes for Better Results

BIM Heroes takes digital integration to the next level by offering specialized expertise tailored to the unique demands of prefabrication. Their services cover every phase, ensuring accuracy and efficiency from initial design to final assembly.

With flexible service plans, BIM Heroes adapts to different project sizes and budgets. Whether you need a dedicated team for a large-scale project or occasional consulting for specific challenges, their scalable approach allows you to access expert BIM services without the overhead of maintaining full-time specialists.

Their expertise also ensures compliance with changing building codes and manufacturing standards across various locations. This is particularly valuable for prefabricated projects that must meet different regional requirements.

FAQs

How do BIM and CAD tools improve the prefabrication process in construction?

BIM and CAD tools play a pivotal role in refining the prefabrication process. By offering highly detailed 3D modeling, they help minimize design mistakes and ensure components are manufactured with precision in factory settings. These tools also integrate design and production workflows effortlessly, allowing tasks like fabrication and assembly planning to happen simultaneously. This approach not only saves time but also helps avoid project delays.

Another major advantage is the way these tools enhance collaboration. They create a shared digital workspace for architects, contractors, and manufacturers, ensuring that prefabricated components are accurately designed to fit together seamlessly on-site. This speeds up construction, reduces material waste, and keeps projects running smoothly. By improving efficiency and accuracy, BIM and CAD tools contribute to cutting costs and promoting more resource-conscious building practices.

What are the biggest challenges in the prefabrication process, and how can they be resolved?

Prefabrication comes with its own set of hurdles, particularly when it comes to transportation logistics. Site access restrictions and the need for specialized equipment can make delivery and installation tricky. On top of that, technical issues – like ensuring all components fit together perfectly, managing schedules, and dealing with any damage during transit – can add to the complexity.

However, these obstacles can be addressed by using integrated digital workflows and tools like BIM software. These technologies make collaboration easier, provide real-time tracking, and simplify project management. With the help of these tools, construction teams can cut down on delays, reduce mistakes, and keep the prefabrication process running more smoothly.

What’s the difference between linear production lines and static production stations in prefabrication, and how do they affect efficiency and cost?

The decision between linear production lines and static production stations significantly impacts the efficiency and expenses of prefabrication projects. Linear production lines are best suited for large-scale manufacturing that involves repetitive tasks. They simplify workflows and reduce costs by enabling continuous, high-volume output, making them an excellent choice for projects with standardized designs.

In contrast, static production stations offer more adaptability, which is ideal for custom or smaller-scale projects. This method allows for highly tailored solutions but often leads to higher costs and longer production times. In essence, linear production lines excel in boosting efficiency for large-scale operations, while static stations are better equipped to handle unique and specialized designs.