HVAC Load Calculation: It’s a Decision Tool, Not a Math Problem

An HVAC load calculation isn't just a technical prerequisite for permitting; it's a critical decision-making tool that sets the stage for project predictability and margin protection. In simple terms, it determines the precise heating and cooling capacity a building needs. But its real value isn't the final number—it's the clarity it provides, ensuring the system you design is the system that gets built, without costly surprises.

Why Accurate Load Calculation Is a Strategic Checkpoint

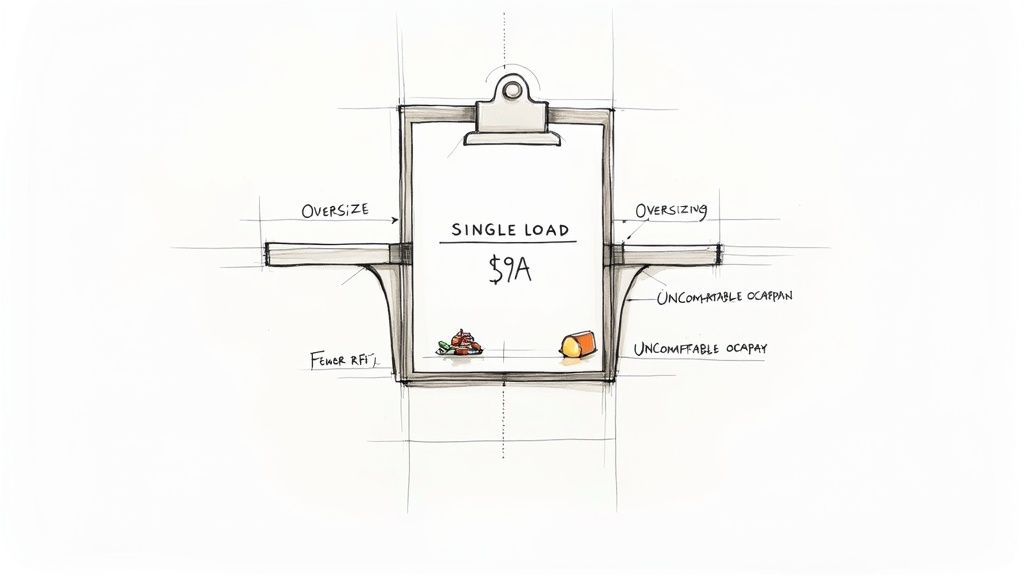

Let's set aside the complex formulas. An HVAC load calculation is one of the most critical decision points in the design lifecycle. When done right, it's your best defense against two of the most common—and costly—mistakes in MEP design:

- Oversizing: This doesn't just inflate initial equipment and installation costs. It leads to short-cycling, an inefficient process that wastes energy, creates uncomfortable humidity swings, and shortens the equipment's lifespan. Margin erosion starts here.

- Undersizing: This is a guaranteed recipe for occupant comfort complaints and reputational damage. It almost always leads to expensive, disruptive post-construction fixes that eat into profitability.

From Guesswork to Precision Engineering

For decades, many HVAC designs were based on rules of thumb, which almost always resulted in oversized, energy-guzzling equipment. The industry has since evolved, driven by the need for efficiency and the power of data-driven software tools.

Modern tools have led to HVAC equipment sizing that can cut energy waste by up to 20-30% compared to older methods. You can find more great insights on the evolution of BIM for load calculations on csemag.com.

This shift from guesswork to data-driven analysis is what enables production maturity. We've seen it time and again: when this step is treated with discipline, it becomes the bedrock of efficient MEP coordination, dramatically cutting down on RFIs and smoothing the path to permitting.

A Foundation for Predictable Delivery

An HVAC load calculation is far more than an engineering task. It's a strategic checkpoint that brings operational consistency to a project. When architects, builders, and MEP coordinators align on accurate load data from the start, a cascade of downstream problems is prevented.

We’re talking about real project pain: HVAC systems being redesigned after CDs because space data was wrong, MEP contractors requesting last-minute changes due to unclear room schedules, or energy models failing review because they were based on outdated drawings.

A disciplined HVAC sizing workflow, grounded in accurate BIM data, transforms a potential project bottleneck into a tool for proactive coordination and RFI prevention. It’s about building predictability into the process from the start.

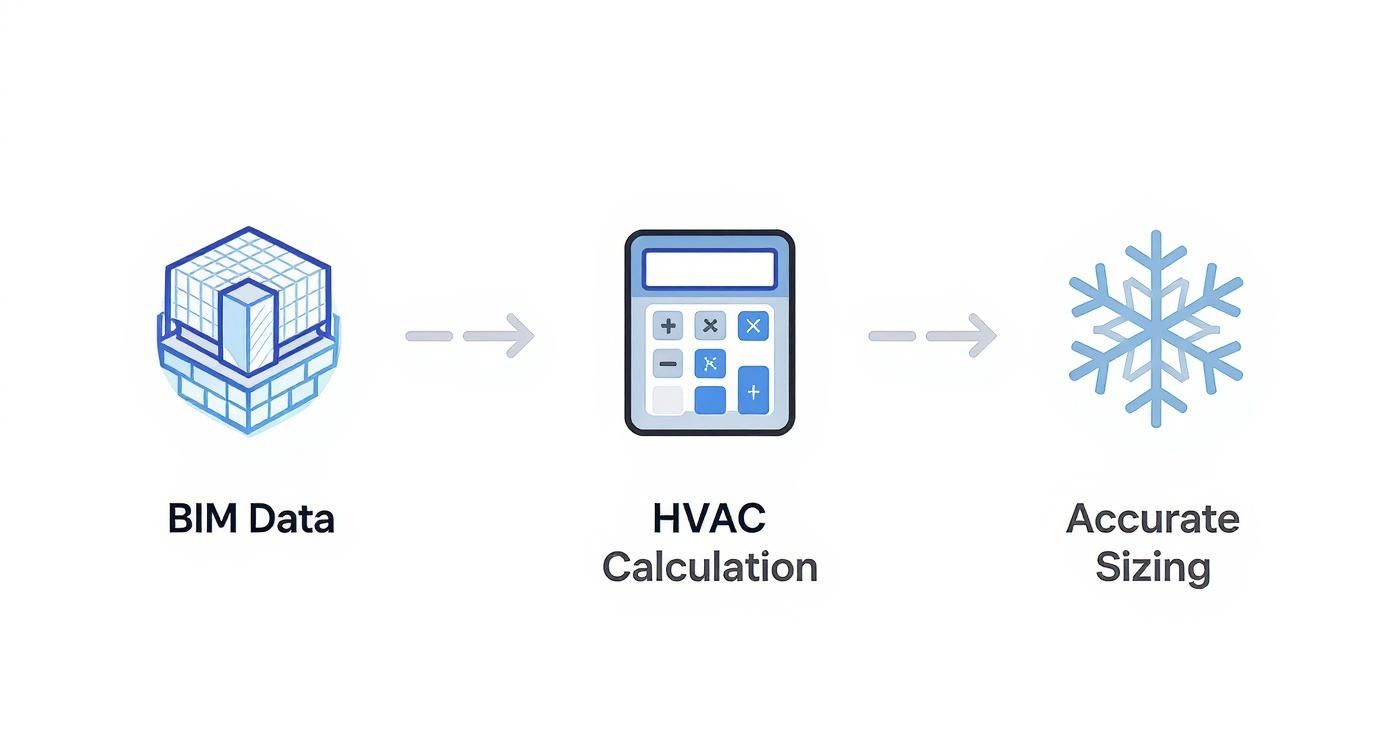

Ultimately, this whole guide hinges on one simple truth: the calculation is only as reliable as the BIM data feeding it. This is where the evolution from CAD-to-BIM proves its worth, turning what was once a static number into dynamic intelligence that informs every subsequent decision.

How Clean BIM Data Drives Accurate HVAC Sizing

Any experienced HVAC engineer will confirm: a load calculation is the ultimate “garbage in, garbage out” scenario. The reliability of your mechanical load calculation in construction lives or dies by the quality of the architectural model.

This is where a firm’s production maturity shows. The final calculation is only as accurate as the BIM data feeding it.

The Model Is the Source of Truth

Every piece of information we need—from room dimensions and envelope assemblies to U-values and glazing specs—is pulled directly from the model. When that data is incomplete, inconsistent, or just plain wrong, the calculation is fundamentally flawed. This isn’t a theoretical problem; it’s a direct cause of blown budgets and busted schedules.

We've seen projects forced into last-minute ductwork redesigns because the space data was off from day one. On another job, the energy model failed its review because it was based on an outdated architectural file, creating a major setback right before permitting. These aren't just modeling mistakes; they're costly breakdowns in the QA process.

The lesson learned in the field is clear: an HVAC load calculation isn't a math exercise. It's a data-driven decision-making tool, and its reliability is a direct reflection of your firm's commitment to BIM discipline and template discipline.

Treating the architectural model as the single source of truth is the first step toward protecting your margins and delivering consistent, high-quality work.

Key BIM Inputs That Define Accuracy

A solid BIM for HVAC design workflow demands precision across several key data points. Each one has a direct, significant impact on the final load numbers. Assumptions and placeholders introduce risk downstream.

- Accurate Space and Room Data: This means correct room dimensions, volumes, and properly defined space boundaries. We’ve seen load calculation accuracy improve dramatically when architectural BIM models follow consistent naming and space standards.

- Building Envelope Details: Wall assemblies, roof construction, and floor types must be modeled with their correct material layers and thicknesses. This data directly drives the U-values used for calculating heat transfer.

- Glazing and Fenestration Data: Window and door schedules need to be populated with accurate U-values and Solar Heat Gain Coefficients (SHGC). Simply modeling a generic window isn’t good enough.

- Building Orientation: The model's true north orientation must be set correctly. This is a surprisingly common oversight, yet it dramatically affects solar heat gain calculations.

Even data from existing conditions, like information from a 3D scan, must be meticulously processed. Our guide on how to clean point cloud data for accurate models offers practical steps for ensuring this foundational data is reliable.

Impact of BIM Data Quality on HVAC Load Calculation Outputs

| BIM Data Input | High-Quality Input (Correct) | Low-Quality Input (Incorrect/Missing) | Resulting Impact |

|---|---|---|---|

| Space Volume | Accurate room dimensions and ceiling heights are modeled. | Generic or incorrect ceiling heights; undefined plenum spaces. | Oversized or undersized HVAC units, leading to energy waste or comfort issues. |

| Wall U-Values | Wall assemblies are modeled with correct material layers and thicknesses. | Default or generic wall types are used without specific material properties. | Inaccurate heat loss/gain calculations, affecting system sizing and long-term energy costs. |

| Glazing SHGC | Window schedules include precise Solar Heat Gain Coefficient (SHGC) values. | Placeholder SHGC values or default settings are left in the model. | Miscalculation of solar heat gain, potentially causing overheating or unnecessary cooling load. |

| Building Orientation | True North is correctly set in the project coordinates. | Model is oriented to Project North without adjusting for True North. | Skewed solar load calculations for each facade, leading to improper zoning and system selection. |

As you can see, small errors in the model have massive consequences, reinforcing the need for rigorous data management from the start.

From Model Discipline to Predictable Outcomes

Firms that enforce strict template discipline and coordinated BIM workflows see tangible benefits. A disciplined HVAC sizing workflow is less about the engineering software and more about the integrity of the input data.

This process isn't unique to our industry; it aligns with broader data management principles. Ensuring accurate HVAC sizing fundamentally relies on clean input, a concept detailed in these essential data quality best practices. When the model is clean, the process is smooth.

This proactive approach stops the typical pain points that eat away at profitability. MEP contractors aren't left guessing about room schedules, and the chances of a major redesign after CDs are issued drop significantly.

The result is a more predictable path to permitting, fewer RFIs during construction, and a final product that performs as designed. This is what happens when you move beyond CAD-to-BIM thinking and embrace a fully integrated, data-first mindset.

Building A Disciplined HVAC Sizing Workflow

Let’s move from theory to practice. A mature HVAC sizing workflow is what separates teams that consistently deliver predictable outcomes from those who firefight their way through every project. This isn't a technical manual. It’s a strategic look at the decision checkpoints successful design-build firms use to protect margins and prevent common headaches.

The core principle is non-negotiable: architectural space data must be validated and locked down before MEP engineers begin their calculations. This single discipline prevents a cascade of problems downstream.

As you can see, high-integrity BIM data is the foundation. It directly feeds into a reliable mechanical load calculation, which in turn leads to a right-sized, efficient system.

Establish A Formal QA Process For All BIM Inputs

A disciplined workflow is built on a formal Quality Assurance (QA) process for all BIM data. This isn’t a quick visual check. It’s a structured review designed to validate the model's integrity before it’s handed over for the hvac load calculation.

Treat this QA process as a critical decision gate. This simple step prevents countless problems, like an MEP contractor flagging vague room schedules deep into design development, forcing massive rework.

Your QA checklist should verify:

- Space Naming and Standards: Are all rooms, spaces, and plenums correctly defined and following a consistent naming convention?

- Envelope Integrity: Are all wall, roof, and floor assemblies modeled with their actual material properties and thicknesses? No generic placeholders.

- Glazing Data Accuracy: Are the window and door schedules populated with accurate U-values and SHGC data?

- Correct Project Orientation: Is the model’s True North set correctly to reflect the building’s real-world position?

This checkpoint isn't about slowing things down; it’s about building in predictability and preventing last-minute changes that kill profitability.

Turn Reactive Calculations Into Proactive Design Tools

The old-school approach treats the mechanical load calculation in construction as a final, reactive step. A mature workflow uses it as a proactive design tool. By running preliminary load calculations early, teams can inform critical architectural decisions before they are locked in.

For example, an early calculation might show that a proposed glazing spec will create an excessive cooling load. This insight allows the design team to proactively explore higher-performance glass or exterior shading—long before that decision becomes expensive to change.

This flips the calculation from a validation exercise into a powerful decision-making aid.

A preliminary HVAC load calculation is one of the most effective tools for RFI prevention. It surfaces potential design conflicts and performance issues when they are still easy and inexpensive to solve, protecting both the project schedule and the budget.

This proactive stance directly prevents the pain of redesigning systems after CDs are issued because space data was wrong or an energy model failed review.

Standardize The Process With Scalable Delivery Pods

For firms seeking true operational consistency, the key is to build a standardized, repeatable process. This is where scalable delivery pods—small, focused teams operating from clean BIM templates and a well-defined HVAC sizing workflow—make a huge difference.

This ensures every project gets the same high level of discipline and QA, eliminating inconsistencies that arise when different teams use different methods.

This approach transforms the BIM for HVAC design process from a potential bottleneck into a smooth, predictable system. To keep refining your HVAC sizing workflow, exploring various business process improvement techniques can offer valuable frameworks for optimizing every step. The goal is to create a system where clarity upstream protects performance and profitability downstream.

Integrating Load Data Into Construction Documents

An HVAC load calculation is only as good as its application. The data has to move from a static report back into the BIM environment to drive MEP design, sidestep coordination clashes, and protect your margins.

This process is about creating a single source of truth where architectural, structural, and MEP models are aligned. When you get this right, the system designed in the model is the system that gets built. This level of clarity can shave weeks off permitting and slash RFIs from the field.

Translating Calculations Into Clear Model Data

The jump from calculation to documentation is a critical checkpoint. It’s not enough to have the right BTUs; you must translate that information into clear, standardized data embedded directly within your BIM for HVAC design. This avoids the classic RFI about an undersized plenum or equipment that won’t fit.

This means embedding key outputs directly in the model:

- Equipment Schedules: Populate mechanical equipment families with the calculated capacity, airflow (CFM), and electrical load data. This ensures schedules are always in sync with the model.

- Airflow Requirements: Tag every space or zone with its required supply, return, and exhaust airflow values. This gives ductwork designers instant clarity.

- Zoning Diagrams: Use color schemes and annotations on floor plans to clearly define thermal zones, making system logic easy to understand.

The industry has moved from older methods to the more precise Heat Balance (HB) method, now considered the gold standard for reliable data in modern designs. For a deeper dive, you can explore the history of load calculation methods on elitesoft.com.

Protecting Design Intent Through Documentation

Clear documentation is your best defense against design intent being lost in translation. When load data is properly integrated, it becomes the backbone for all subsequent mechanical design, preventing mid-project redesigns.

We’ve seen projects where the specified VAV box couldn't deliver the required airflow because the CFM values from the load report were never updated in the model tags. The result was a costly, avoidable change order.

Think of your construction documents as the final QA checkpoint for your HVAC load calculation. If the data isn't clearly represented in your schedules, tags, and diagrams, it might as well not exist.

This level of detail is also what makes accurate and constructible shop drawings possible. When the CD set is clear and data-rich, it gives the MEP contractor everything they need to produce high-quality fabrication models with minimal RFIs. Our own guide on shop drawings for construction explains how this upstream clarity directly impacts downstream success.

Creating A Single Source Of Truth For MEP Coordination

Ultimately, weaving the mechanical load calculation in construction documents is about establishing and protecting a single source of truth. When architects, engineers, and contractors all work from the same coordinated model—informed by the same accurate load data—project delivery becomes far more predictable.

This alignment prevents common headaches, like a duct conflicting with a structural beam that was never coordinated. By embedding load data and using it to drive the 3D design, these issues are caught during design, not construction. This operational consistency is what separates mature production teams from the rest.

Common Pitfalls That Can Wreck Your Load Calculations

Even with the best software, a sloppy process can quietly sabotage your HVAC load calculation. Think of this as a field guide to the mistakes that lead to flawed results and eat into your margins. Spotting these early protects your budget and ensures the system works.

The most precise calculation is worthless if it's built on bad information. This is about having a QA process that flags systemic issues before they turn into expensive field problems.

Relying on Outdated Architectural Models

This is the most common and damaging pitfall. The mechanical load calculation in construction is a direct reflection of the architectural model. If the model is wrong, the calculation is wrong.

We’ve seen projects where a lighting spec was updated late in the game, but that new heat gain never made it into the final numbers. The result? An undersized cooling system and an unhappy client.

Your model of record has to be the current model. A disciplined HVAC sizing workflow has clear checkpoints to ensure the MEP team is always working from the latest architectural version. Failing to keep things in sync is a primary source of common BIM modeling errors and how to avoid them.

Making Broad Assumptions About Internal Loads

Internal loads—heat from people, lights, and equipment—are not the place for guesswork. Plugging in generic, rule-of-thumb values instead of specific data is a recipe for disaster.

For instance, a standard office space has a completely different load profile than a packed data closet. Each needs its own assessment:

- Occupancy: Are we talking about a fixed-seating auditorium or a flexible workspace?

- Lighting: What’s the actual lighting power density (watts per square foot) from the specified fixtures?

- Equipment: What specific gear will be running in each space? A few laptops are one thing; a room full of servers is another.

When architectural BIM models use consistent naming and space standards, assigning the right internal load data becomes dramatically easier and more accurate.

Ignoring Thermal Bridging and Infiltration

A building’s envelope is only as strong as its weakest link. Thermal bridging happens wherever structural elements, like concrete slab edges or steel studs, punch through the insulation layer, creating superhighways for heat transfer. Ignoring them can lead to a major underestimation of your true loads.

Likewise, air infiltration—uncontrolled air leakage through tiny gaps and cracks—can be a massive energy hog. While modern BIM for HVAC design software can model these factors, the outputs are only as good as the architectural details you provide.

These aren't trivial rounding errors. Studies on residential HVAC sizing have shown that bad input data is a leading cause of massive operational inefficiencies. One study found that about 17% of homes ran their cooling equipment at full blast far too often, a classic sign of an undersized system caused by incomplete data. You can read the full research about HVAC sizing inaccuracies to see just how deep this problem goes.

The lesson learned in the field is that a load calculation is a composite of dozens of critical details. A single overlooked assumption can compromise the entire result, leading to comfort issues, wasted energy, and preventable change orders.

Achieving Predictability One Calculation At A Time

This brings us back to the core message: a high-integrity HVAC load calculation is the direct result of a high-integrity design process.

For mature production teams, it's never about the math—it's always about the system that produces the inputs. The path to a smoother project isn't a secret formula; it’s a commitment to getting the fundamentals right, every single time.

By treating BIM data with discipline and establishing clear decision checkpoints, teams create the operational consistency and predictability that clients value most. The focus shifts from just running a mechanical load calculation in construction to building a repeatable, defensible workflow.

This disciplined approach ensures the final system performs as intended, protecting both budgets and reputations. It’s the difference between reactive problem-solving and proactive, system-driven delivery.

The reliability of your HVAC system is decided long before equipment is ordered. It's determined by the quality of the BIM data and the rigor of the workflow that validates it, protecting performance downstream.

If you’re ready to put these principles into practice, our BIM-Ready Space Data Checklist can help you establish the foundational data integrity your projects need. It’s a simple framework for ensuring your architectural models are set up for success.

Download the BIM-Ready Space Data Checklist

Questions We Hear All the Time About HVAC Load Calcs in BIM

Here are a few common questions we get about running HVAC load calculations within a modern, BIM-first workflow. Getting this right is key to protecting your project's accuracy and budget.

How Does BIM Actually Make Load Calculations More Accurate?

BIM’s biggest advantage is that it replaces assumptions with hard data. Instead of someone manually entering room dimensions or U-values, a BIM for HVAC design workflow pulls that information straight from the architectural model.

This direct link means the calculation is based on the actual design, including specific material properties, true orientation for solar gain, and exact space volumes. When the model is the single source of truth, the risk of a simple data entry error throwing everything off drops dramatically.

Can We Run Load Calculations Before the Model is Totally Finalized?

Yes, and you absolutely should. Running a preliminary mechanical load calculation in construction documents during schematic design isn't just a good idea—it's a sign of a mature, proactive process.

This early analysis is a powerful decision-making tool. It gives architects and engineers a chance to see how different glazing specs or insulation levels will impact the mechanical system. Catching these things early prevents expensive, time-consuming redesigns later on.

What's the Single Biggest Mistake Teams Make in This Workflow?

The most common—and costly—mistake is treating the architectural model as a static background file instead of a live source of data. We constantly see teams that don’t have a clear checkpoint to confirm their MEP engineers are working from the most current model.

When the lighting spec changes, the window schedule is updated, or the occupancy data is revised in the architectural model, the load calculation must be updated too. A disconnected HVAC sizing workflow that misses these updates will inevitably lead to an incorrectly sized system.

This single process failure—a lack of good version control—is a huge source of coordination headaches, budget overruns, and buildings that just don't perform as intended. Consistency is everything.

At BIM Heroes, we help firms build the disciplined workflows needed for reliable project delivery. If your team is struggling with coordination and consistency, we provide the systems and production support to bring clarity to your process. Learn more at https://www.bimheroes.com.