Log Home Design Fundamentals: From Concept to Construction Documents

A log home is more than a stylistic choice—it's a specialized building system. Translating design intent into buildable construction documents demands a production-focused mindset, where early decisions on structure and materials are carried through with absolute discipline. This alignment protects margins, ensures predictability, and prevents costly field fixes.

Why Log Home Design Is a Specialized System

For teams accustomed to conventional wood framing, log home design requires a fundamental shift in thinking. This isn't about applying a rustic aesthetic; it's about treating the log itself as the primary building module from day one. Each log serves as both structure and finished surface, demanding tighter integration between architectural concept, structural logic, and documentation than typical residential projects.

This disciplined approach is what drives operational consistency and margin protection. An avoidable RFI, a field modification, or a coordination error chips away at profitability. Success depends on recognizing that a log home is a manufactured system, not a site-built approximation of one. The market's growth, projected to reach $13.91 billion by 2030, is increasingly driven by systems that reward this kind of upfront planning. You can learn more about the market growth from recent industry analysis.

Bridging the Gap Between Concept and Constructability

The most common point of failure in log home projects is a disconnect between conceptual design and the physical realities of log dimensions. This gap creates entirely preventable problems that threaten budgets and timelines.

Common production challenges include:

- Dimensional Conflicts: Conceptual elevations that ignore specific log diameters and course heights, leading to drawings that simply don't stack.

- Settling Oversights: Window and door openings detailed without accommodating the inevitable vertical settling of log walls, causing binding and long-term structural issues.

- System Disconnects: Roof and floor systems designed in a vacuum, guaranteeing coordination clashes and a flood of RFIs from the field.

These aren't minor hiccups. They are direct threats to profitability that stem from a lack of system-level thinking early in the design process.

Adopting a Production-Oriented Mindset

Success hinges on treating the process less like a traditional architectural project and more like a manufacturing workflow. This means establishing decision checkpoints where the log system, its size, and joinery method are defined early and then carried through every phase with precision.

When design, coordination, and documentation are in sync, you shift from reactive problem-solving to proactive, predictable delivery. This is the core of a mature production process.

Making Critical System and Material Decisions Upfront

Successful log home projects are forged in the conceptual phase. Every decision—from log species to profile—sets off a chain reaction that directly impacts constructability, coordination, and your bottom line. This isn't just design; it's production planning.

Think of each log as a fixed building module. Its height, length, and joinery dictate the rules for the entire structure. When these rules are set early and respected, the project flows. When they're ignored, you're setting the stage for costly field corrections and RFIs.

Defining the Core Building Module First

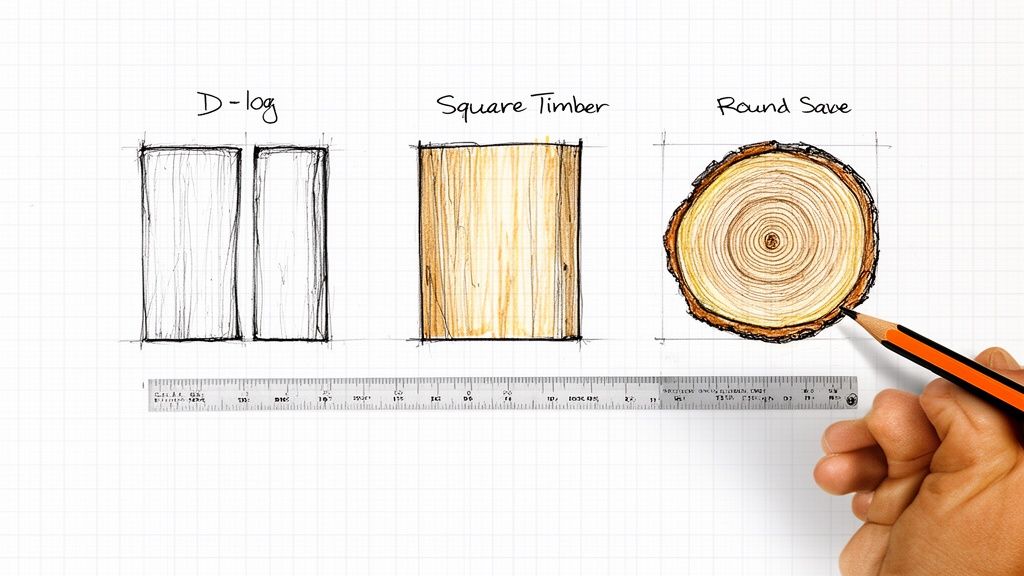

The first decision checkpoint is committing to a specific log system. This choice is the cornerstone of your entire log home design, influencing everything that follows. An eight-inch round log behaves differently from a ten-inch squared timber, and the design must reflect that reality from day one.

This single selection dictates the project's dimensional logic:

- Wall Heights: The log diameter determines the exact height of each course. Elevations must be designed to align with these fixed increments.

- Structural Grid: The log's length and joinery define corner conditions, wall lengths, and the overall structural layout.

- Opening Placement: Window and door headers must land on a log course. You can't just nudge a rough opening up a few inches like in conventional framing.

Delaying this decision forces designers to work with assumptions that rarely align with the final log package, creating rework that eats into the budget. Getting this right is a core part of any effective residential BIM workflow.

Establishing a Disciplined Grid and Datum Strategy

Once the log module is locked in, the next step is establishing a rigid grid and datum system. This is your most effective tool for maintaining dimensional control across all drawings. It becomes the project’s single source of truth for all horizontal and vertical placement.

A simple but unchangeable grid and datum strategy ensures architectural plans, structural engineering, and the final log house architectural drawings are all speaking the same language. This discipline prevents the common scenario where floor plans don't align with elevations or sections, a primary source of RFIs.

A log home design without a strictly enforced grid system is just a collection of suggestions. It leaves critical coordination to chance, and in log construction, chance is an expensive variable.

This control system is essential for preventing coordination breakdowns. If a structural engineer works from a slightly different grid, their roof trusses may not align with the log gable walls—a classic RFI that a disciplined datum strategy completely avoids.

The Cause and Effect of Early Decisions

Every choice has a direct, measurable consequence. Different log profiles demand different detailing, and late changes create significant rework.

| Log Profile Selection | Impact on Documentation | Consequence of Late Changes |

|---|---|---|

| D-Log | Requires clear detailing of the flat interior for partition walls and cabinetry. | Interior wall layouts might conflict with log intersections, forcing field adjustments. |

| Square Timber | Demands precise corner joinery details (e.g., dovetail vs. butt-and-pass) on the CDs. | Changing the joinery late in the game forces a complete redesign of wall elevations and lengths. |

| Round Log | Interior and exterior corner projections must be accurately modeled and documented. | Miscalculated projections can violate setback requirements or interfere with exterior features. |

Successful log home construction documents are the product of early, definitive system choices. By treating the initial design phase as production planning, you build the operational consistency needed to deliver these projects predictably. For more on this, explore best practices for LOD planning.

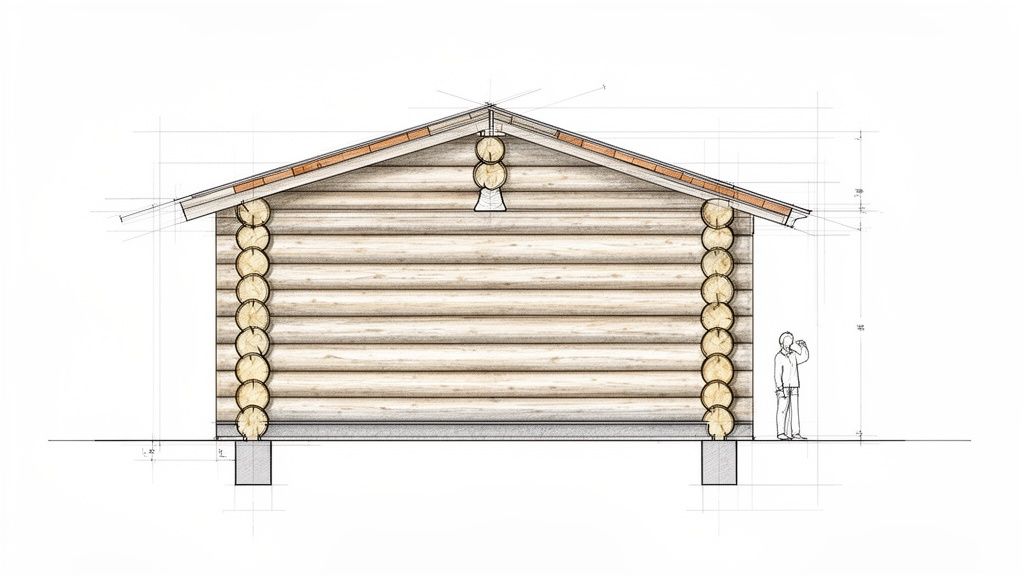

Mastering Wall Coordination and Log Settling

A log home is not a static object. It's a structure that settles under its own weight. This vertical movement is the single most critical factor to manage in a log home design. Getting it wrong guarantees performance failures and costly callbacks.

You can’t fight gravity. Ignoring the physics of a settling log home leads to bound windows, jammed doors, and buckled interior walls. These aren't minor punch-list items; they are fundamental structural failures that demolish client trust and project margins. The goal is not to prevent settling but to control it with intentional detailing from the start.

Detailing Openings for Inevitable Movement

Every window and door opening needs a system that allows the logs above to settle without crushing the unit below. This is non-negotiable and must be crystal clear in your log home construction documents. The solution is a combination of splines and slip joints.

This system includes key components:

- Keyways or Splines: Grooves are cut into the log ends at the rough opening to accept a floating spline. The window or door unit is fastened to this spline—not directly to the logs—allowing the wall to slide vertically.

- Settling Space: A calculated gap is left above the unit, hidden by trim, to give the wall room to settle. The required space depends on the log's moisture content, species, and wall height.

- Slip Joints in Trim: Head trim is fastened to the log wall above the opening, allowing it to slide down over the side casings as the wall settles.

Omitting these details creates immense pressure on window and door frames, resulting in cracked glass and failed seals—the calling card of an amateur design.

Coordinating Interior and Non-Structural Walls

A common and expensive mistake is rigidly attaching conventional interior walls to the log structure. As exterior log walls settle, a fixed interior wall acts like a post, either taking a load it wasn't designed for or causing the floor system above to heave.

Every connection between a log wall and a non-log component must be engineered to float. This isn't a suggestion; it's a fundamental rule of log construction.

Interior partition walls require their own slip joints where they meet ceilings or intersect with log walls, often using a top plate that isn't fastened directly to the ceiling joists. Showing these connections clearly in your log house architectural drawings prevents RFIs and ensures the crew builds them correctly. A thorough constructability review can catch these issues before they become field problems.

Managing Roof Systems and Staircases

The principle of accommodating movement extends to every other system touching the log walls. You can't just nail roof trusses, rafters, or floor joists to the log structure and call it a day. Early decisions have a ripple effect that impacts everything from the CD set to the final build quality.

How Log Home Design Decisions Impact Constructability

| Early Design Decision | Impact on Construction Documents | Consequence of Poor Planning |

|---|---|---|

| Roof Trusses resting on log gable end walls. | Requires detailed drawings of slotted brackets or hardware allowing vertical movement. | The ridge will sag as parallel log walls settle, pushing the trusses upward. |

| Staircase fixed to the floor below and a log structure above. | Must show a "floating" design, with slip joints at the top connection point detailed clearly. | The staircase will bind or lift as the walls settle, becoming unusable or unsafe. |

| Porch Roof tied into a settling log wall and supported by non-settling posts. | Calls for detailing adjustable screw jacks at the base of each porch post. | Severe structural stress and distortion will occur as the main house settles but the porch does not. |

These are not minor details to be figured out in the field. They are core engineering decisions that must be resolved during design and communicated with absolute clarity in the construction documents. Success with any log home project comes down to this: anticipate movement and design a coordinated system where every component works together.

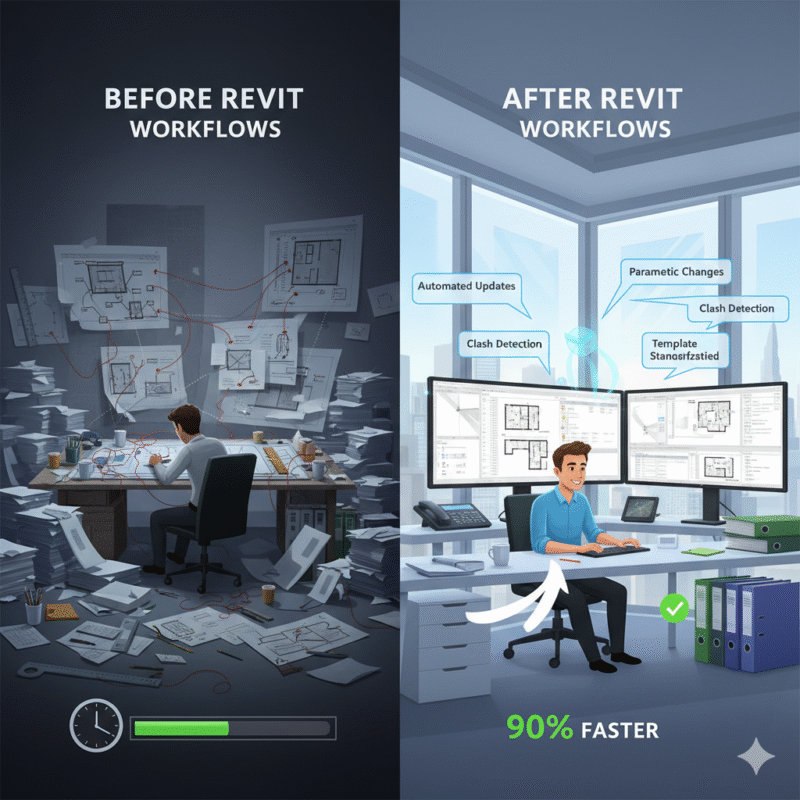

How BIM Drives Production Maturity in Log Home Projects

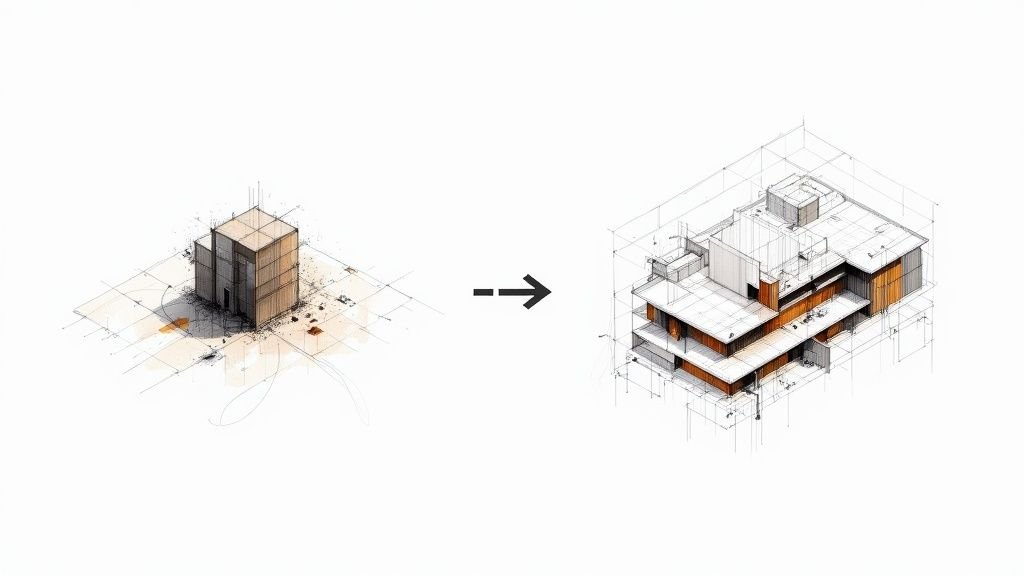

Building Information Modeling (BIM) is the central nervous system for a modern log home project. It’s the digital backbone that ensures every log fits perfectly, from the conceptual model to fabrication drawings. What truly matters is not the software, but the disciplined workflow that a robust BIM for residential construction process enables.

When managed well, the model becomes the single source of truth, locking in the precise location of every log course, joinery detail, and structural connection. This single reference point slashes the coordination errors between architectural, structural, and manufacturing teams that often derail complex projects.

Establishing Template Discipline and QA Processes

Real production maturity begins with a robust, project-specific template pre-loaded with settings, families, and annotation styles tailored for log construction. Template discipline enforces standards from the start, ensuring every team member uses wall types that reflect correct log profiles and tags that pull the right data. It creates a reliable, repeatable baseline.

The other half of the equation is a rigorous internal Quality Assurance (QA) process. Regularly scheduled model audits and clash detection are critical decision checkpoints. These reviews are designed to catch conflicts early—like a plumbing stack running through a solid log girder—before they become costly field fixes and prevent RFIs.

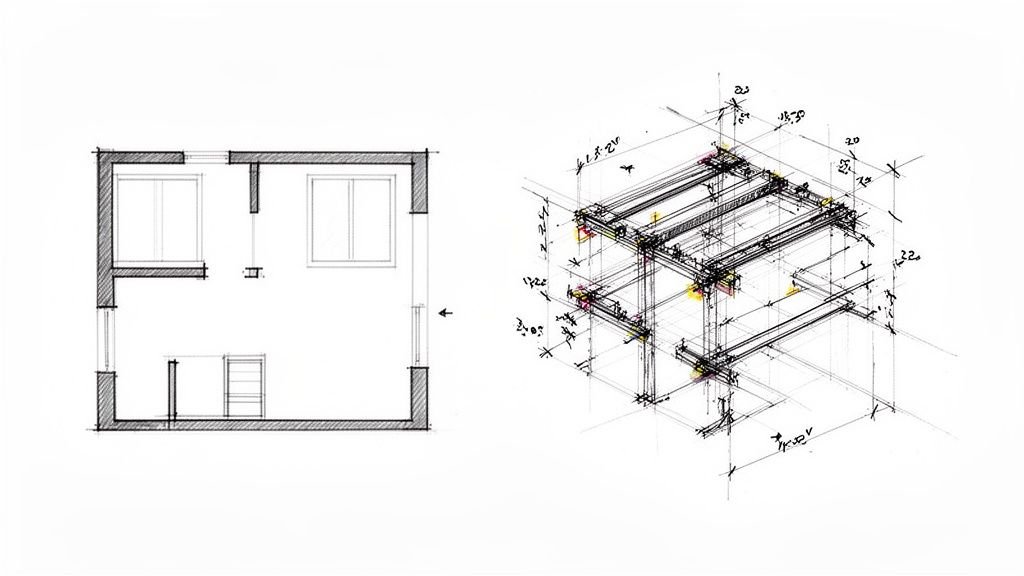

Modeling with the Right Level of Development

A common mistake is over-modeling too early. Getting bogged down in every dowel and chamfer during initial design creates a heavy, clunky model. The key is to align the Level of Development (LOD) with the project phase.

- Conceptual Design (LOD 100-200): Model log walls as simple masses to define the building’s form, volume, and structural grid. Focus on course heights and major dimensions.

- Design Development (LOD 300): Refine the model to include accurate log profiles, specific joinery types, and precise locations for openings and settling spaces.

- Construction Documents (LOD 350): The model is now detailed enough to generate clear log home construction documents, including log schedules, detailed wall elevations, and critical connection details.

This phased approach keeps the model efficient while ensuring the right information is available at each decision point, preventing downstream rework.

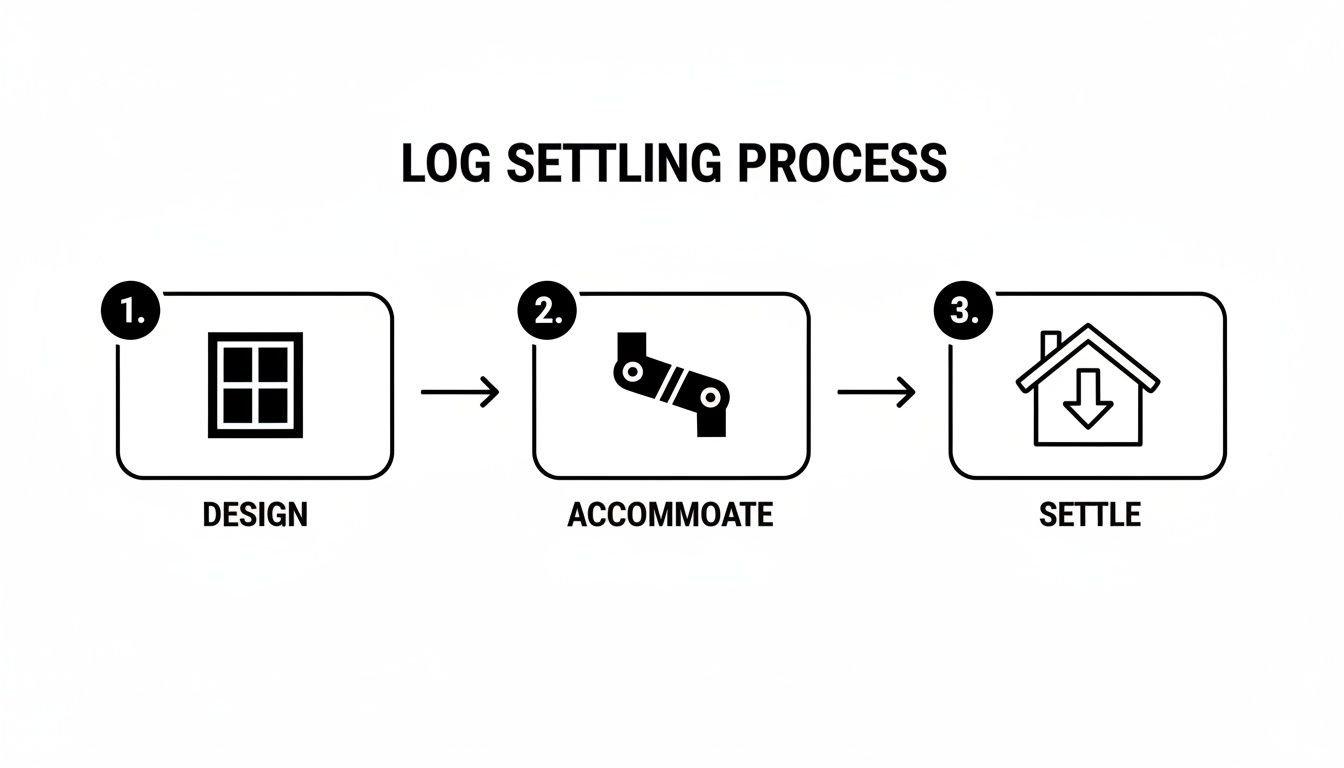

This process flow visualizes how to design for and accommodate the natural settling of log walls.

The key insight: settling isn't a problem you solve in the field. It’s a known behavior systematically managed within the BIM environment from the very first line drawn.

From Digital Model to Buildable Reality

BIM is a production management system that embeds manufacturing logic directly into the design process. This digital-to-field workflow is where you protect margin. Professional 3D architectural rendering services can further enhance the precision and communication of these designs, contributing to a more mature production pipeline.

The model becomes the direct source for creating clear log house architectural drawings and often the CNC fabrication files that cut the logs. This tight integration ensures what was designed is exactly what gets built, eliminating the interpretive guesswork that leads to RFIs. A well-run BIM workflow delivers the operational consistency needed to scale. For similar workflows, see our guide on wood framing construction.

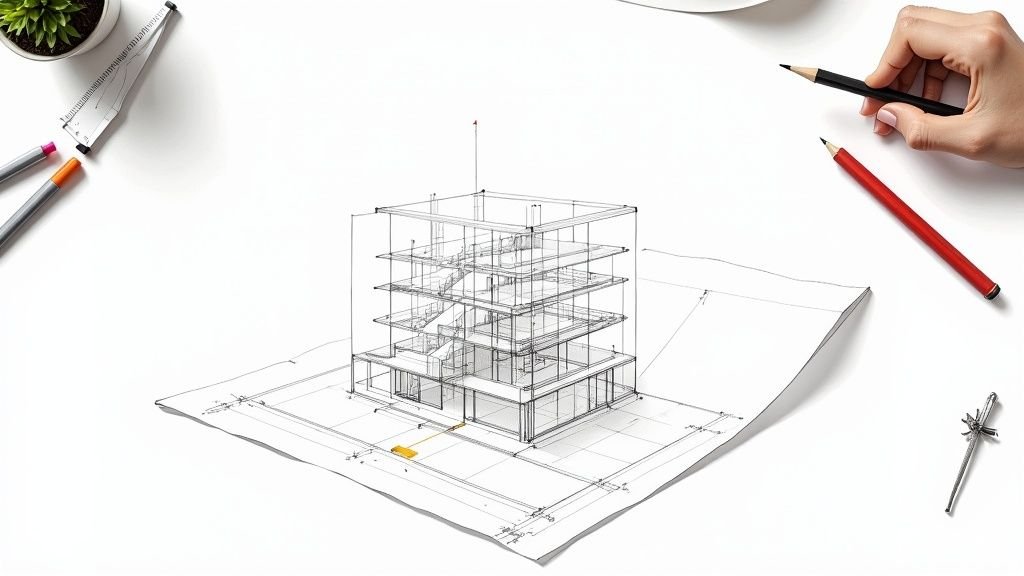

Developing Buildable Construction Documents That Leave No Guesswork

The transition from a coordinated BIM model to construction documents is where project margins are made or broken. For a log home, you're creating a step-by-step assembly manual. Vague plans are an invitation for expensive RFIs, while a high-quality set of log house architectural drawings is your best tool for protecting the bottom line.

This is about clearly communicating tolerances, assembly sequences, and the unique behavior of a log structure to the crew on the ground. Every ambiguity left in the drawings will be solved on-site—usually at a premium.

The Anatomy of a High-Clarity CD Set

Standard residential drawings are insufficient for a log home. Your construction documents must speak the language of the building system, addressing the specific manufacturing and assembly logic required.

Key documents that eliminate guesswork include:

- Log Wall Elevations: Functioning as assembly diagrams that map out every log course, identify components with piece marks, and dimension all openings relative to log heights.

- Corner Detail Drawings: Explicit, large-scale drawings showing exactly how joinery (e.g., dovetail, butt-and-pass) comes together, including seals, gaskets, and fasteners.

- Settling Space Specifications: Clearly dimensioned settling space details for every window, door, and vertical post—not just a generic note.

This clarity directly prevents the common errors that become change orders, ensuring the final build matches the design intent.

Communicating Tolerances and Connections

For any custom home, but especially a log home, comprehensive construction documents are the secret to a smooth build. It's worth digging into understanding construction documents to see how a great set functions as an instructional guide.

Your log home construction documents must establish the non-negotiable rules for the build, with explicit notes and diagrams for tolerances and the sequence of critical connections.

A great set of log home plans doesn't just show what to build; it clearly explains how and in what order to assemble components, especially where different systems interact.

This level of detailed instruction is closer to manufacturing documentation. For a deeper look, check our resources on how shop drawings for construction deliver that critical, piece-by-piece assembly information.

The Financial Impact of Thorough Documentation

The upfront effort to create a bulletproof set of construction documents pays for itself by preventing costly delays and rework. It's also central to sustainable building, a market projected to hit $10.47 billion by 2035. Log homes can reduce carbon footprints by 30% compared to conventional builds, an efficiency best captured through precise, waste-reducing construction guided by clear plans.

The goal is to shift problem-solving from the expensive field environment back to the controlled, digital design environment. A well-documented project creates predictability, protects the schedule, and demonstrates a level of professionalism that clients and contractors value.

Bringing It All Home: Predictability and Protected Margins

Ultimately, the success of a log home project comes down to outcomes: project predictability, operational consistency, and protected margins. A disciplined, systems-based approach stops being a theoretical best practice and starts impacting your firm’s bottom line.

The entire workflow, from critical system decisions to leveraging BIM for residential construction for tight coordination, is designed to eliminate expensive guesswork. It transforms a potentially chaotic process into a scalable, reliable delivery model. This is how you build a reputation for delivering excellence on time and on budget.

From Production Discipline to Profitability

Each step we've covered is a checkpoint designed to prevent value from leaking out of the project. A disciplined grid strategy shuts down coordination errors. Smart settling details eliminate costly callbacks. And clear log home construction documents stop RFIs in their tracks.

This isn't just about better building; it's about building a better business. The firms that thrive in this niche don't just sell beautiful designs—they sell clarity, reliability, and a predictable process.

The key is a mental shift from a purely architectural exercise to a production-oriented workflow. It’s a framework that guarantees the design intent established in the conceptual phase is the exact reality built in the field. Operational consistency becomes your firm’s most valuable asset.

Building a Scalable Delivery Model

When your team has a repeatable framework for executing a log home design, you stop reinventing the wheel. You build deep internal expertise and create a system that new team members can adopt quickly. This creates a scalable delivery pod that can handle more volume without sacrificing quality.

The result is a business that runs on proactive planning, not reactive firefighting. It's a model that protects your time, resources, and reputation. You gain the ability to forecast schedules and costs with greater accuracy, giving your team and your clients the peace of mind they deserve.

At BIM Heroes, we believe a well-defined process is the key to unlocking profitability on complex residential projects. To help your team put these principles into practice, we’ve created a Log Home Documentation Checklist. It is a technical resource, not a sales pitch, designed to bring more clarity and consistency to your workflow. Download it here.