Quality Check: Why Late QA Destroys Project Margins and Morale

A solid quality check isn’t the final hurdle you clear before the finish line; it’s the continuous process that keeps a project healthy from kickoff to handover. For architecture and engineering firms, treating QA as an eleventh-hour event is a surefire way to kill your margins, wreck your deadlines, and burn out your team.

It’s a system design problem, not a people problem. And it has predictable consequences.

The True Cost Of A Late-Stage Quality Check

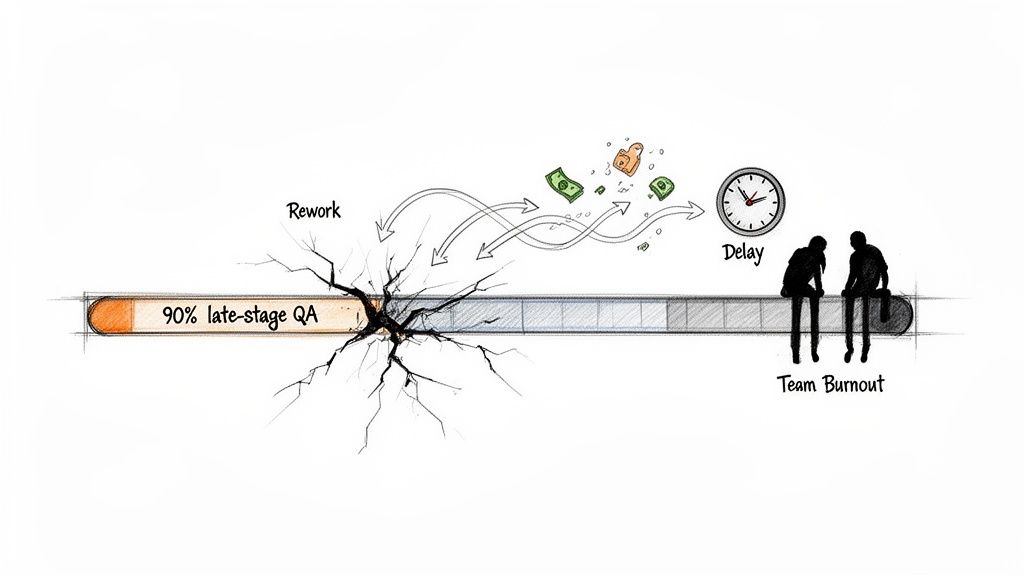

For too many firms, hitting the 90% completion milestone triggers a familiar panic. The project, which seemed to be sailing along smoothly, is suddenly drowning in a sea of redlines. This last-minute scramble isn't a sign of a bad team; it's a symptom of a broken system where the quality check is treated as a final gate, not an ongoing workflow.

This approach—saving all your quality assurance for the very end—doesn’t just find problems. It actively creates them.

When Core Assumptions Unravel Too Late

When QA only kicks in after the model is nearly done, the issues you uncover are rarely minor tweaks. Instead, they often cut right to the project's core. A slip-up in a structural grid, a misunderstood zoning requirement, or a flawed MEP coordination strategy finally comes to light when it's most expensive and disruptive to fix.

What happens next is a waterfall of compromises. Teams can't afford to rebuild from the ground up, so they patch things together with rushed fixes. These solutions often introduce new, subtle clashes and inconsistencies, leading to drawings that might technically “pass” but feel fragile and carry hidden risks into construction. This is a primary source of preventable RFIs.

The Domino Effect on Timelines and Margins

Late-stage QA issues are the silent killers of project predictability. That week you thought you had for permitting prep? It’s now gone, spent fixing a major coordination oversight that surfaced too late. Consultants seeing a fully coordinated model for the first time drop conflicting markups, creating bottlenecks that grind decisions to a halt. The schedule doesn't slip because of one big disaster; it bleeds out from a thousand tiny cuts.

This bleeds directly into your bottom line. Rework isn't just an annoyance; it’s a direct hit to profitability. A mature BIM QA/QC process is the best defense against this margin erosion. Mature firms know that operational consistency is the key to protecting profit.

We’ve seen projects stabilize instantly when QA shifted from a final event to a continuous workflow. Predictability isn't about working harder; it's about finding problems when they are small, cheap, and easy to solve.

The Hidden Toll on Team Morale

Forget the money and schedules for a second—there's a human cost. When a team pours months of work into a project only to get hit with an avalanche of redlines right before a deadline, it’s demoralizing. Designers get stuck fixing the same types of errors repeatedly, and BIM managers turn into permanent firefighters, constantly putting out last-minute emergencies.

This burnout is a direct result of a system design failure. It pits team members against each other, creates a culture of blame, and destroys the collaborative spirit that high-quality quality control in construction documentation depends on. Production maturity isn't about celebrating who’s best at putting out fires. It’s about building systems that prevent them from starting in the first place.

How Late QA Destroys Project Predictability

A late-stage quality check isn’t a safety net; it’s a trap. It provides a false sense of security while quietly setting the stage for chaos. The real damage from late-stage QA issues isn’t just finding errors; it’s about the brand-new, far more tangled problems you create when those errors are finally uncovered with a deadline looming. This is where predictability goes to die.

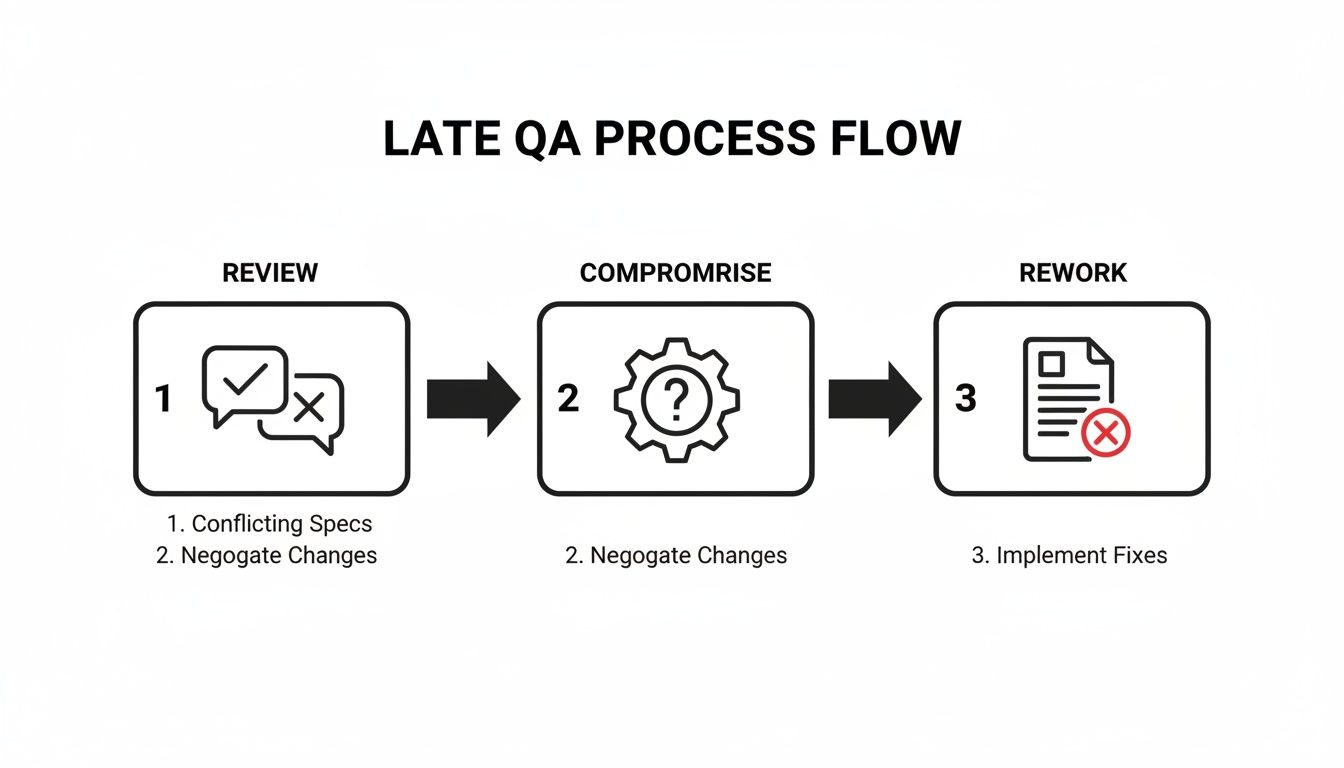

It's a scene every production lead recognizes. The model gets submitted for review, and what comes back isn’t a clean, consolidated list of issues. It’s a storm of conflicting markups.

The structural engineer’s feedback contradicts the MEP consultant’s needs, while the architect’s design intent clashes with both. This isn't just a coordination failure—it's a timing failure.

When these fundamental disagreements surface just weeks before a deadline, teams don't have the luxury of finding the right solution. They're forced to scramble for the fastest one. This pressure cooker leads to compromised decisions where the goal shifts from creating a robust design to just making the redlines go away. The result is fragile construction documentation—drawings that are technically "complete" but are riddled with patched-over issues just waiting to blow up into costly RFIs on site.

The Anatomy of a Last-Minute Fire Drill

That final-hour scramble isn't a reflection of your team's skill; it's a direct symptom of a broken process. When a BIM QA/QC process is absent until the final hour, you're guaranteeing a collision of unresolved assumptions from every discipline.

Here’s what that fire drill actually looks like:

- Exploding Redlines: That small modeling error that would have taken five minutes to fix at the 30% stage has now rippled through the entire model. Fixing it now means hours, sometimes days, of complex rework.

- Design Compromises: Instead of solving a coordination problem holistically, designers are forced into making localized, patchwork fixes that can weaken the overall design integrity.

- Cascading Consultant Delays: One significant change request from a single consultant can trigger a domino effect, forcing other disciplines to redo their work and completely derailing the project timeline.

This is the operational quicksand that swallows timelines and profit margins whole. Every hour spent in this reactive, fire-drill mode is an hour stolen from proactive, value-adding work like preparing for permits or ensuring construction readiness.

From Model Clashes to Confidence Clashes

But the most insidious damage from late QA isn't geometric—it’s the slow erosion of confidence. When teams are repeatedly forced to rush and patch their work, the model itself starts to feel untrustworthy.

BIM managers get buried in last-minute checks, trying to validate work that was built on a shaky foundation. Designers get frustrated fixing the same types of issues over and over because the root cause was never addressed early on.

This is where a mature approach to QA in architecture projects changes everything. Instead of holding their breath for one big, final review, high-performing firms embed quality checks at every key milestone. They run regular model audits against their established BIM standards, use automated scripts to keep everyone on template, and conduct focused, role-specific reviews.

By building a proactive system, they can confidently knock down issues long before they become project-derailing bombs. A structured BIM clash detection workflow provides the foundation for this proactive approach, turning what is often a late-stage headache into a continuous improvement tool.

The constant stress and firefighting near a deadline are not signs of a dedicated team; they are the predictable consequences of a poorly timed quality check. True operational consistency comes from a mature process, not heroic last-minute efforts.

Ultimately, pushing your quality check to the end of the line doesn't just risk finding problems—it guarantees you’ll create new ones. It undermines RFI prevention, generates unreliable documents, and turns the most critical phase of a project into a chaotic, margin-destroying scramble. Quality has to be built in, not inspected in at the end.

Building Quality Into Your BIM Workflow

Shifting from a reactive to a proactive quality check isn’t just about moving deadlines around; it’s a complete overhaul of your production philosophy. Instead of bracing for one chaotic, final review, experienced firms build quality directly into their process from day one. This transforms QA from a bottleneck into a system that delivers stability and predictability.

This doesn’t happen by chance. It’s the result of a deliberate system designed to find and fix issues when they are small, simple, and cheap to solve.

Implementing Milestone-Based Checkpoints

A continuous BIM QA/QC process isn't about checking everything constantly. It's about setting up smart, milestone-based reviews that align with critical project phases. These decision checkpoints get the right eyes on the right details at exactly the right time, stopping small errors from snowballing into major rework.

Think of it as a series of gates, not a final wall. Each checkpoint validates the work before the team moves on.

- 30% Design Development: The focus here is on the fundamentals. Is the model adhering to core BIM standards? Are the primary structural grids, levels, and massing aligned with the design intent? Catching a grid error here is a five-minute fix. Finding it at 90% can derail the entire project.

- 60% Construction Documentation: As the model gets more detailed, so do the checks. This is the perfect time for initial clash detection runs between major systems—structural, MEP, and architectural. The goal isn’t to be clash-free yet, but to flag systemic coordination problems before all the details are locked in.

- 90% Final Coordination: This final major check is all about fine-tuning. We're talking detailed drawing reviews, annotation consistency, and ensuring every consultant model is fully integrated. Because the big issues were handled weeks ago, this review becomes a validation exercise, not a frantic fire drill.

This tiered approach builds momentum and confidence. It dismantles the high-stakes, all-or-nothing pressure of a single, late-stage quality check and replaces it with a predictable rhythm of review and refinement.

The Foundation of Template Discipline

Milestone checks work, but only if they’re built on a solid foundation of standardization. Without strict template discipline and clear BIM standards, every project is a fresh start, forcing your teams to reinvent the wheel every single time.

Quality has to be built in, not inspected in at the end. A disciplined template is the scaffolding that allows teams to build quality consistently and at scale.

This isn't about stifling creativity; it's about giving your team a reliable starting point. A well-built project template enforces naming conventions, standardizes line weights, and comes pre-loaded with the correct families and view settings. It eliminates low-level guesswork, freeing up your designers and technicians to focus on actual problem-solving. This is the bedrock of creating scalable delivery pods that churn out high-quality work, project after project. You can dive deeper into this foundational strength by exploring production systems.

From Manual Inspection to Proactive Audits

The industry is finally moving past the old model of just reacting to fixes. The digital shift in construction is turning quality assurance on its head, moving from manual inspections to proactive, data-driven QA that slashes errors. Today, platforms can centralize real-time data, making sure everyone from the architect to the contractor is on the same page from concept to handover. You can learn more about these critical construction quality trends for 2025.

The old way of doing things—waiting until the last minute—creates a vicious cycle.

This graphic perfectly illustrates the negative feedback loop of late-stage QA. Waiting until the end forces teams into a corner, where they have to make compromises and deal with expensive rework, which destroys both profit margins and team morale.

This shift toward proactive auditing is where technology becomes a game-changer. Instead of just relying on human review, leading firms are using automated model health checks and scripts to constantly monitor whether standards are being met. These tools can flag things like incorrect family usage, deviations from naming conventions, or model performance issues long before a person would spot them. This systematic approach is a core part of any effective project management strategy in the AEC world.

Embedding these systems—milestone checks, disciplined templates, and automated audits—fundamentally changes the nature of your quality control in construction documentation. You stop chasing errors and start preventing them. The result is a production environment defined by clarity, consistency, and predictable success.

Late-Stage QA Versus Continuous QA: A Project Lifecycle Comparison

| Project Stage | Impact of Late-Stage QA | Outcome of Continuous QA |

|---|---|---|

| Conceptual Design | Standards are ignored; focus is solely on design, creating future rework. | BIM Execution Plan is established; foundational model is clean and compliant. |

| Design Development | Errors in core geometry (grids, levels) go unnoticed and are built upon. | Regular milestone checks catch fundamental errors when they are easy to fix. |

| Construction Docs | The first major review becomes a chaotic "clash-and-burn" session. | Coordination issues are resolved progressively, making final checks a formality. |

| Pre-Construction | The team scrambles to fix hundreds of clashes and drawing errors under pressure. | The model is reliable and validated; focus shifts to procurement and logistics. |

| Handover | Final documentation is inconsistent, and the as-built model is unreliable. | A high-quality, data-rich model is delivered, providing value for facility management. |

Ultimately, integrating quality checks from the start isn’t just a "best practice"—it's a business imperative. It turns your BIM process from a potential liability into a strategic asset that protects your bottom line and your reputation.

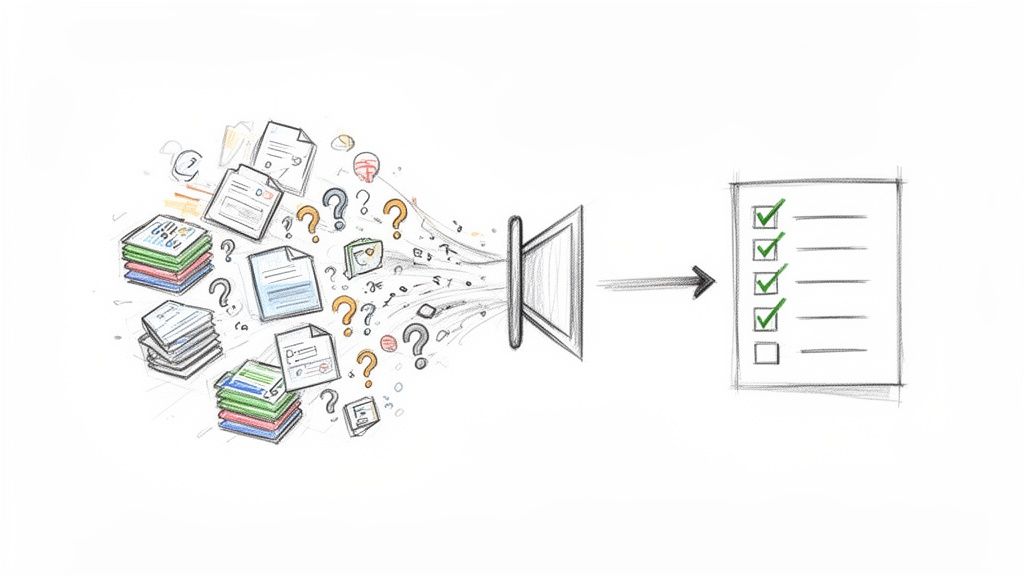

Moving From Data Chaos To Decision Clarity

A proper quality check in a modern BIM workflow goes far beyond spotting clashes. While geometry is important, the real measure of a mature process is the integrity of the data inside the model. When your QA system is weak, it doesn't just produce messy drawings; it creates unreliable information that quietly sabotages every decision down the line, from permitting to construction.

This is the fundamental shift from seeing a model as a 3D picture to understanding it as a structured, intelligent database. A solid BIM QA/QC process isn’t just about making sure pipes don't hit beams. It's about ensuring the information embedded within every single element is accurate, consistent, and trustworthy.

Why Unchecked Data Erodes Predictability

Inconsistent or incomplete model data is a massive hidden cost that chips away at project certainty. When a door family is missing fire rating data, or a beam lacks the correct material properties, the model becomes a liability. Schedules, cost estimates, and energy analyses built on that shaky foundation are unreliable at best and dangerously misleading at worst. This is where a seemingly sound project can quietly fall apart.

The goal of a quality check isn't just to create a clean model. It's to create a single source of truth that every stakeholder—from the project manager to the fabricator—can rely on without hesitation.

Getting from disorganized data to clear, actionable insights means you have to tackle the root of the problem. If you want to see the broader business impact, it's worth understanding how to solve data quality issues that cost your business money.

From Data Validation To Smoother Decisions

When you build data validation directly into your QA process, those critical decision-making meetings become far more productive. Instead of spending an hour debating which set of information is correct, teams can focus on making informed choices based on data they can actually trust.

This takes a systematic approach to data integrity:

- Parameter Checks: Automate audits to make sure all required data fields—like fire ratings, material codes, or manufacturer info—are filled out correctly according to your firm's BIM standards.

- Classification Validation: Verify that every model element has the right classification (e.g., OmniClass, UniFormat). This is absolutely critical for accurate quantity takeoffs and facility management handovers.

- Data Consistency Audits: Run checks to find and flag inconsistencies, like a component having different names in different views or schedules.

These checks are non-negotiable for maintaining the integrity of open-format deliverables. For teams working with openBIM, using specific IFC validation tools for BIM projects is essential to ensure data is correctly structured and interoperable.

The True Outcome: Margin Protection

Ultimately, a data-centric quality check process is about protecting your margins and delivering predictable results. Clean, reliable data prevents the costly rework that comes from ordering the wrong materials. It streamlines consultant coordination by providing a clear, unambiguous source of truth. It can even speed up permitting by ensuring your documentation is backed by verifiable data.

This isn't an academic exercise; it's a practical requirement for any firm looking to scale. When your data is clean from the start, you spend less time fixing preventable errors and more time delivering real value. This is how high-performing firms turn their BIM models from simple geometric representations into powerful, reliable project databases.

Your Framework For A Proactive Quality Check System

Shifting to a proactive quality check isn’t an overnight fix. It’s a deliberate move toward operational maturity, one that builds quality directly into your culture, tools, and daily workflows. This isn’t about adding more meetings or bureaucracy. It’s about creating a system where doing things the right way is also the easiest way.

The core principle is simple: quality isn't a final inspection—it's a continuous state. The goal is to move QA upstream, finding and fixing issues when they're small, manageable, and cheap to resolve. We’ve seen firms transform their delivery predictability by building their system on three key pillars: Clarity, Consistency, and Accountability.

Establish Clarity with a Strong Foundation

Predictable outcomes start with clear expectations. Before anyone creates a single model element, your team needs a unified understanding of what "quality" means for the project. This is where your foundational documents become mission-critical.

Your BIM Execution Plan (BEP) is the constitution for your project. It must clearly define standards, roles, and responsibilities. Learn more about creating a robust BIM Execution Plan that provides this essential clarity. Without a well-defined BEP, your quality check process is just a series of subjective opinions, leading to endless debates and inconsistent results.

Build Consistency Through Process and Templates

Once you have clarity, the next step is building a system that ensures those standards are applied consistently. This is where process discipline and smart template usage become your greatest assets. A mature BIM QA/QC process relies on repeatable workflows, not on individual heroics.

To build this operational muscle:

- Implement Milestone-Based Reviews: Formalize checks at key project stages (like 30%, 60%, and 90%). Each review should have a specific focus, from foundational model integrity at 30% to detailed coordination at 90%.

- Standardize Checklists: Create role-specific checklists for designers, project managers, and BIM leads. This ensures everyone knows what they are responsible for reviewing and prevents critical items from slipping through the cracks.

- Leverage Template Discipline: Your project templates are your first line of defense. A well-constructed template with pre-loaded standards, view settings, and families eliminates countless low-level errors before they can even happen.

This structure turns your quality check from a chaotic, last-minute scramble into a predictable and manageable workflow. It provides the rhythm that scalable delivery pods need to produce reliable work, time and time again.

Quality has to be built in, not inspected in at the end. The right framework doesn't just find problems—it prevents them from ever occurring.

Foster Accountability with Clear Roles

A system is only as good as the people who run it. The final pillar of a proactive framework is creating clear accountability. Every team member has to understand their specific role in maintaining quality throughout the project lifecycle.

This isn’t about creating a blame game; it's about empowerment. When designers are responsible for running self-checks before submitting work and project managers are accountable for validating milestone deliverables, everyone has ownership. This distributed responsibility lightens the load on BIM managers, freeing them from being the sole quality police and allowing them to focus on higher-level system improvements. To build a robust and continuously evolving system, it's helpful to understand various approaches to quality improvement initiatives that can foster this culture of shared ownership.

This framework—Clarity, Consistency, and Accountability—is the engine of a mature production system. It turns the abstract goal of "high quality" into a tangible, repeatable process. By embedding quality control in construction documentation from the very start, you protect your margins, stabilize your timelines, and build a reputation for reliable delivery.

Ready to build a more predictable production system? Instead of starting from scratch, consider using a proven framework. We've developed a milestone-based QA checklist that helps teams embed quality checks from kickoff to handover.

Download our Progressive QA Framework to get a practical resource for building a more stable and profitable production workflow.

Explore our Architectural & BIM Production Services to see how we can help you build quality into your workflow from day one.