How Rainscreen Fabrication Fails: It’s Not the Shop, It’s the Model

A rainscreen model can look perfect in Navisworks yet quietly set the fabrication team up for failure. We’ve all seen the results: misaligned panels, field-drilled holes, and re-fabrication costs that vaporize project margins.

This isn’t a shop-floor problem. The errors were locked in months earlier, deep inside the BIM model, through seemingly minor decisions about Level of Development (LOD). For complex rainscreen systems, fabrication accuracy is decided long before shop drawings begin.

Why Fabrication Accuracy Is Decided Upstream

The root of most rainscreen fabrication errors is a fundamental misunderstanding of Level of Development (LOD). Teams often treat LOD as a simple modeling preference—a box to check for a design review. But for high-tolerance enclosure systems, this view is a direct threat to predictability.

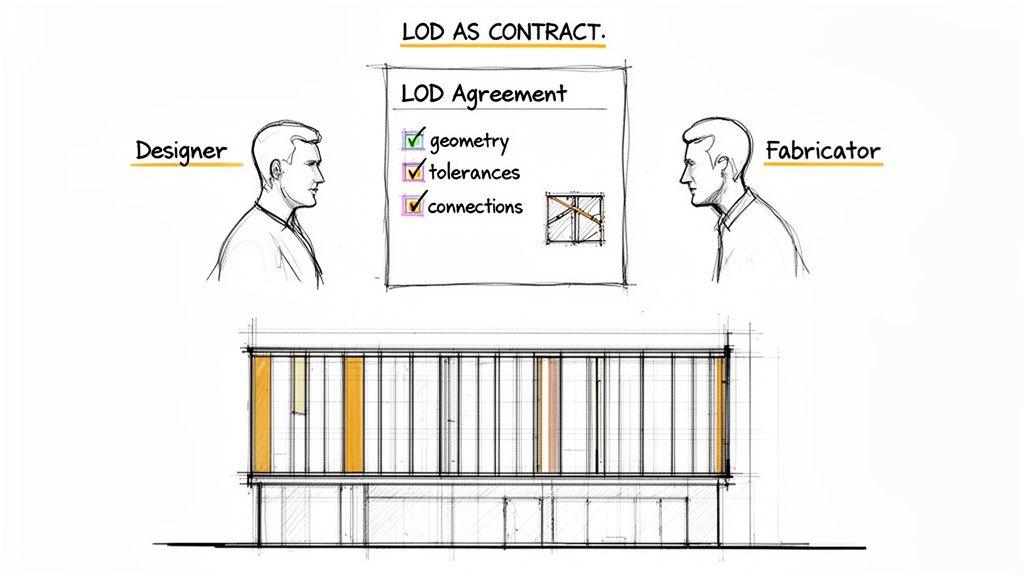

LOD isn’t a measure of detail; it’s a contract for reliability. A model that looks visually complete for a client presentation often lacks the specific, fabrication-critical information that rainscreen systems demand.

When this contract is vague, fabricators are forced to reinterpret design intent. Those assumptions translate directly into physical errors during assembly, leading to painful and predictable consequences:

- Panel Mismatches: Geometry modeled at a generic LOD 300 might show panel outlines, but it lacks the specific return depths and edge conditions needed for CNC fabrication.

- Misaligned Sub-Framing: Support rails drawn as simple lines—instead of precisely located, clash-detectable elements—lead to mounting points that don’t line up with the actual structure.

- Incorrect Tolerances: The model fails to account for thermal expansion or construction variance, resulting in panels that are too tight or have sloppy, inconsistent gaps.

- Systemic Misalignment: Inconsistent datum references between the structural, backup wall, and façade models are a guarantee for misalignment across the entire building envelope.

In rainscreen systems, fabrication accuracy isn't decided during shop drawing review. It’s decided by how intentionally LOD is defined and modeled from the start, turning the BIM model from a representation into a precise production mandate.

These failures ultimately compromise the building envelope, preventing it from preventing water from compromising wall integrity. This isn't just a technical problem; it's an erosion of project profitability that proves small modeling decisions have massive fabrication consequences.

LOD as a Contract for Reliability, Not a Modeling Preference

In the world of rainscreen systems, viewing Level of Development (LOD) as just a measure of how detailed a model looks is a critical mistake. It’s time to see LOD for what it is: a binding contract for reliability between the design team, the delivery pod, and the fabricator.

This contract must spell out the exact geometric certainty needed for production, long before anyone thinks about shop drawings.

When that contract is vague, it quietly shoves risk downstream. Fabricators are left to guess at design intent, making expensive assumptions about everything from panel returns to anchor locations. A model that looks complete on screen can be useless for fabrication if the right information isn't locked in. This is the operational gap where margins evaporate and RFIs are born.

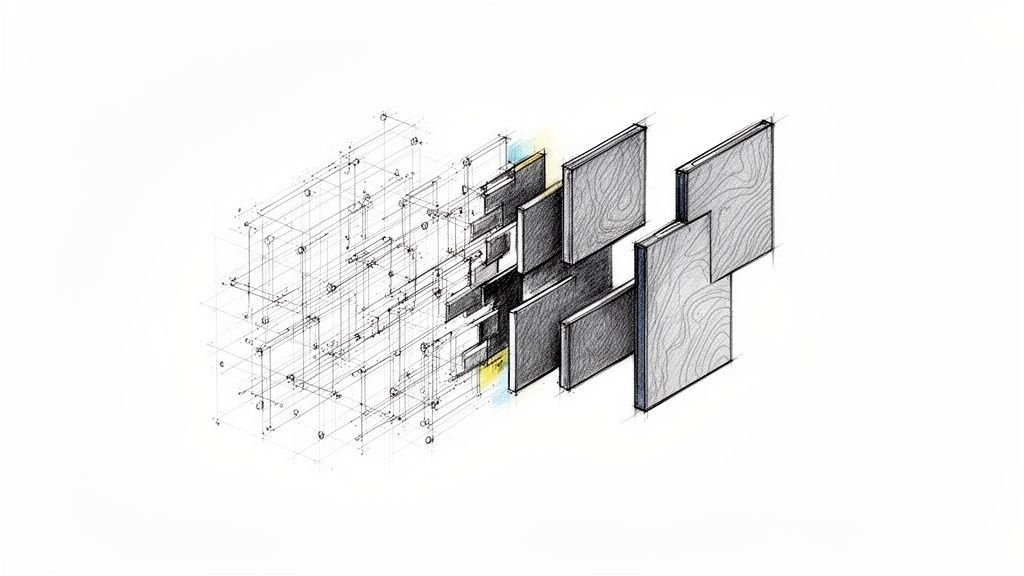

From Vague Geometry to Fabrication Certainty

The gap between a design-intent model and a fabrication-ready model is massive. An LOD 300 model might show a panel's general shape and location. But a fabricator needs LOD 400 logic to drive their CNC machines.

This means the model must define:

- Exact joint tolerances: Not a line showing a joint, but the specific, dimensioned gap for thermal movement.

- Precise return depths: The actual dimension of a panel’s edge return, crucial for rigidity and water management.

- Defined connection points: The modeled locations of clips, rails, and fasteners—not a generic blob representing the support system.

Without this level of detail, the fabricator is essentially re-engineering the system on the fly. A visually "detailed" model missing this fabrication-specific data isn't detailed at all—it's a liability. You can explore these concepts deeper in our guide on BIM Level of Detail.

LOD Decision Impact on Rainscreen Fabrication

| Rainscreen Component | Ambiguous LOD (Common Pitfall) | Fabrication Consequence | Intentional LOD (Best Practice) |

|---|---|---|---|

| Panel Corner | Modeled as a simple mitered corner with no defined return depth. | Fabricator must assume the return size, leading to inconsistent panel rigidity and on-site fit issues. | Corner modeled with a specific, dimensioned return depth (e.g., 25mm), allowing for precise automated folding. |

| Sub-framing Clip | Represented by a generic block or family without defined anchor points. | Clip locations are guessed during shop drawing creation, causing misalignment with the primary structure. | Clip family includes modeled anchor points with clearance zones, enabling pre-drilling and accurate placement. |

| Panel Joint | Shown as a single line, with no specified tolerance or sealant backer rod geometry. | Inaccurate material takeoffs. Panels fabricated too tight, leading to oil-canning or installation failure. | Joint is modeled as a dimensioned gap (e.g., 12mm) with geometry representing the backer rod and sealant profile. |

| Window Interface | Panel edge near the window opening is a simple extrusion, no flashing modeled. | Major RFI storm. Flashing is field-fabricated, increasing labor costs and creating a high-risk point for water intrusion. | Panel edge includes a modeled receiver channel for flashing, with the flashing itself modeled as a separate element. |

Intentional LOD choices turn the model from a visual aid into a direct instruction manual for machines, preventing the rework that erodes profitability.

Why Intentional LOD Planning Protects Margins

High-performance enclosures are no longer a niche market. The global rainscreen cladding market was valued at USD 144.53 billion in 2023 and is projected to hit USD 233.08 billion by 2030. This boom raises the stakes for getting production right the first time.

Intentional LOD in BIM planning is a core risk mitigation strategy. It’s about providing geometric certainty at the right project phase, ensuring what is modeled can be built with precision.

This proactive approach shoves the QA checkpoint upstream. Instead of finding clashes during shop drawing review—or worse, on-site—they are fixed within the model. This protects margins by preventing field fixes, killing re-fabrication costs, and ensuring the final installation matches design intent. It’s how top firms build operational consistency.

Common Failure Points Where Rainscreen LOD Breaks Down

A rainscreen model can look flawless but still set the fabrication team up for failure. This disconnect happens when LOD is treated like a visual checkbox instead of a contract for production accuracy. Fabrication mistakes are the predictable outcome of information gaps left in the model months earlier.

These gaps force fabricators to inherit risks created long before shop drawings began. When a model looks "detailed enough" but isn't detailed in the right way, it guarantees downstream pain. Here are the most common façade LOD decisions that fall apart.

Panel Geometry Lacks Fabrication Logic

The most common breakdown happens when panel geometry is modeled at LOD 300, but fabrication demands the precision of LOD 400. A design-intent model might show a panel as a simple extruded solid. It looks clean and communicates the aesthetic.

But that representation is useless to a CNC press brake. That machine needs to know the exact return depth, bend radius, and material thickness to fold the panel correctly. When this critical geometry is missing, the fabricator must make assumptions that lead to inconsistent panel stiffness and alignment issues. This oversight is a leading cause of panel mismatches.

The core issue is modeling for visual representation instead of for manufacturing. An LOD 300 model shows what a panel is, but an LOD 400 model must define how it gets made.

Support Rails Are Abstracted Instead of Located

Another massive failure point is how the rainscreen sub-framing is represented. In early design, support rails are often modeled as abstract lines. That’s fine for initial coordination, but it becomes a liability if not evolved to a higher LOD before fabrication handoff.

A fabricator needs the rail's precise location relative to a reliable datum, its profile, and exact fastener locations. Abstract lines force the fabricator to re-engineer the support system, increasing the risk of misaligning with the structure or clashing with openings. This unleashes a cascade of RFIs and often results in costly field drilling.

Tolerances Are Implied Instead of Modeled

High-performance envelopes must account for thermal expansion, deflection, and construction variances. The problem is, these tolerances are almost never shown in a design-stage model. Joints are often drawn as a single line, implying a gap with zero dimension.

This creates two significant problems:

- Material Errors: Without a modeled gap, takeoffs for gaskets and sealant are wrong.

- Installation Failure: Panels fabricated to a "perfect" grid with no room for error will inevitably bind, oil-can, or refuse to fit when they meet real-world site conditions.

A fabrication-ready model must define these gaps with dimensional accuracy. A 12mm joint isn't a line; it's a 12mm space. Skipping this step is a recipe for expensive field fixes. Find more examples in our guide to common BIM modeling errors and how to avoid them.

Datum References Are Inconsistent

Perhaps the most destructive failure is the use of inconsistent datum points. If the structural model, backup wall, and façade model don't share a single set of grid lines and elevations, systemic misalignment is baked into the project. It doesn't matter how accurately an individual rainscreen panel is modeled if its placement is based on an incorrect reference point.

This lack of a common coordinate system forces the fabrication team to "pick a source of truth," leading to compounding errors. The solution is rigorous template discipline and a BIM Execution Plan that locks in a universal project origin. Without it, every dimension on the shop drawings is built on guesswork.

Aligning LOD with Project Phases and Trade Responsibility

The solution is a disciplined, strategic approach to LOD planning. A successful rainscreen model isn't just detailed; its detail is intentionally phased, timed with project milestones, and assigns clear ownership at every decision checkpoint.

This shift is about moving from reactive problem-solving to proactive production planning. This deliberate process creates a single source of truth that cuts down on assumptions, prevents coordination chaos, and protects margins long before shop drawings are on the table.

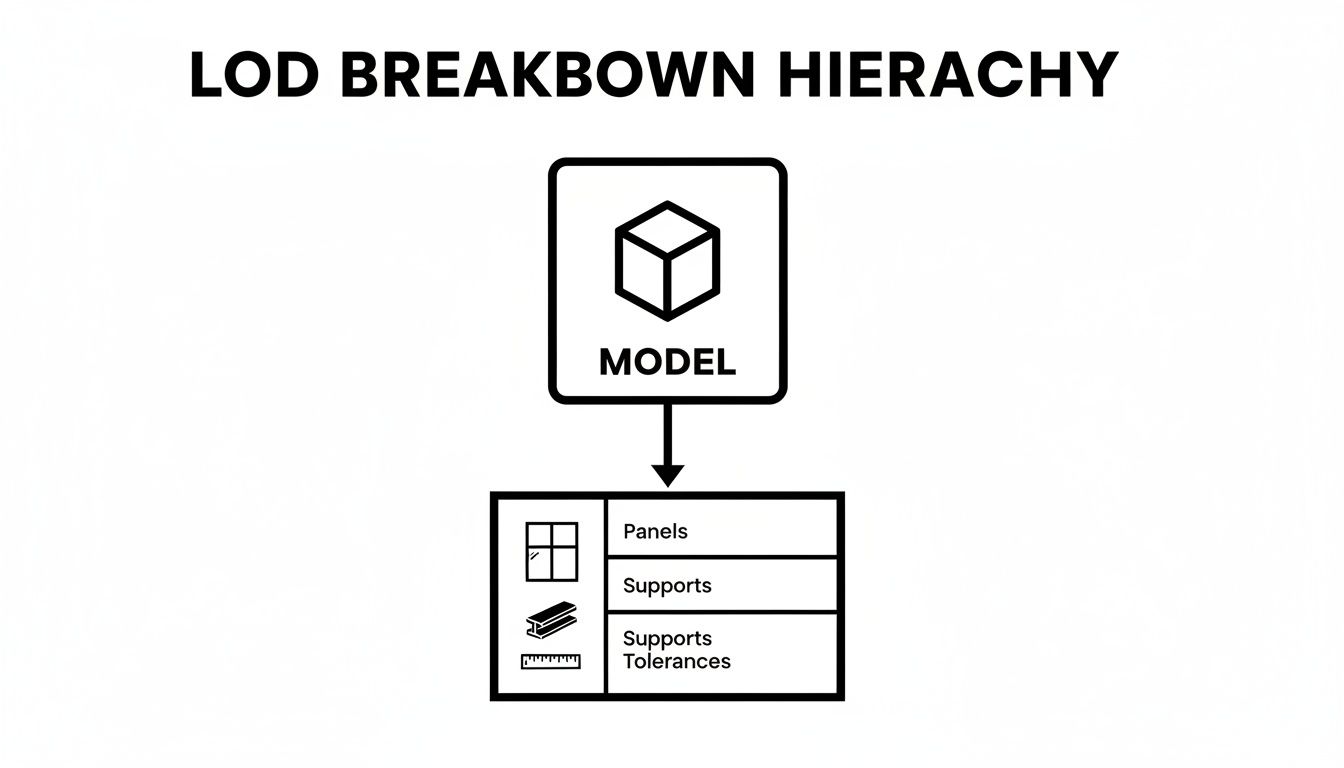

Building an LOD Matrix for the Building Enclosure

The best tool for this is a façade-specific LOD matrix. This isn't a generic BIM deliverable; it’s a project contract that spells out who models what, to what level of detail, and by when. It becomes the single source of truth for the entire enclosure system.

For a rainscreen system, this matrix breaks the assembly down and assigns responsibility for geometric and data accuracy at each phase.

A typical matrix includes columns for:

- Component: e.g., Primary structure, backup wall, insulation, sub-framing, panels.

- Responsible Party: e.g., Structural Engineer, Architect, Façade Consultant, Fabricator.

- Design Development (DD) Phase LOD: What's needed for coordination and pricing?

- Construction Documents (CD) Phase LOD: What's required for permitting and trade handoff?

- Fabrication Phase LOD: The final, manufacturing-ready level of geometric certainty.

This structured planning transforms the model into a reliable production tool. It establishes a clear QA process, ensuring the right information is available at the right time.

From Model to Manufacturing: A Clear Hierarchy

This diagram shows the critical components of a fabrication-ready rainscreen model, from the overall structure down to the tolerances that ensure a perfect fit.

The visualization drives home that fabrication accuracy is built on layers of detail, where each element's precision depends on the one before it.

This structured approach ensures critical decisions about joints, sub-framing, and interface details are made intentionally within the model, not left to chance during a frantic RFI exchange.

This clarity has a direct impact on project predictability. The rising adoption of high-performance envelopes underscores this need. In North America alone, the rainscreen cladding market was valued at USD 40.70 billion in 2023 and is projected to hit USD 76.23 billion by 2032. This growth is fueled by demand for energy-efficient buildings, where a well-executed rainscreen is a cornerstone. Explore more trends in the full Grand View Research report.

The Power of Defined Handoffs

Ultimately, aligning LOD with project phases creates clean, unambiguous handoffs. When the architect delivers a model with a clearly defined LOD for the rainscreen panels and supports, the fabricator gets a reliable starting point.

This prevents the costly process of reverse-engineering design intent. The fabrication team gets a clear mandate, not a model full of assumptions. This is the foundation of scalable delivery pods and operational consistency. It’s how you stop selling hours and start delivering clarity.

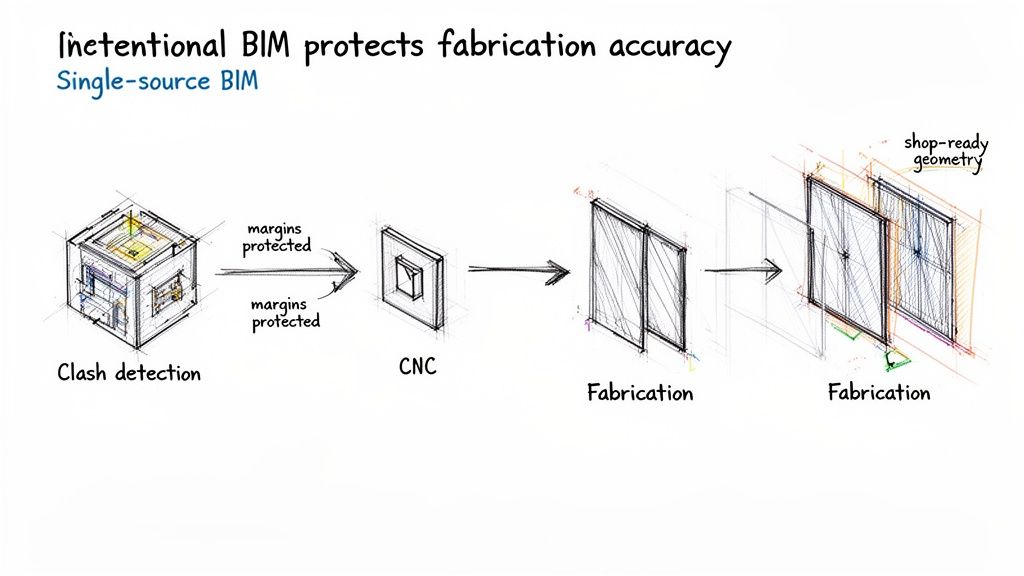

How Intentional BIM Workflows Protect Fabrication Accuracy

A well-defined Level of Development (LOD) plan isn't an academic exercise—it's how you protect margins. When you build a rainscreen model with fabrication in mind, it becomes the single source of truth for manufacturing. This shift moves quality control from a chaotic job site into a controlled digital environment, locking down geometry and killing guesswork.

The fabrication-ready model becomes the central contract where the complex dance between structure, backup wall, and cladding is choreographed. It’s where you win predictability.

From Clash Detection to CNC Handoffs

The payoff for this upstream discipline is immediate. A model built with fabrication-level detail lets you run precise clash detection long before material is ordered. You can see exactly where a sub-framing rail collides with a window opening or where a support clip lacks clearance.

This level of accuracy provides key production advantages:

- Automated Quantity Takeoffs: When every panel, clip, and gasket is modeled correctly, material takeoffs are accurate.

- Smoother CNC Handoffs: A model with fabrication logic can often feed directly into CNC machinery, reducing the time and human error of manual shop drawings.

- Fewer RFIs: Questions about joints and connections are answered inside the model, preventing the RFI storm that hits when fabricators get ambiguous information.

This workflow isn’t just about better modeling; it’s about creating a production system. It’s a deliberate investment in upstream clarity to prevent downstream chaos.

This rigor is becoming the new standard. The global rainscreen cladding market is set to rocket from USD 163.94 billion in 2024 to USD 298.87 billion by 2033. US firms adopting advanced BIM for enclosure systems are aligning with global best practices that put fabrication accuracy first. Dive deeper into market trends in this detailed Straits Research report.

Protecting Margins Through Production Maturity

At the end of the day, an intentional BIM workflow is a direct defense of project profitability. Every field fix and rejected panel is an unrecoverable loss traced back to a gap in the model. Investing in disciplined, fabrication-aware modeling isn't a cost center; it's effective risk management.

By locking down geometry and establishing a single source of truth, you eliminate the main causes of rainscreen fabrication errors. This builds a foundation for scalable, repeatable delivery—the hallmark of a mature production process. You stop selling hours spent fixing problems and start delivering clarity, systems, and reliable outcomes.

Building a Production-Ready Rainscreen Model

We’ve seen it happen: a detailed model leads to disaster on site. The truth is that for rainscreen systems, fabrication accuracy isn’t decided in the shop—it’s locked in by how you define LOD from day one. This isn't about cramming more detail into your model; it's about embedding the right detail at the right time.

Think of your LOD specification as a contract for reliability. Vague contracts breed assumptions, and assumptions lead to mismatched panels and costly rework. By pinpointing failure points early—like generic supports or undefined tolerances—you shift quality control out of job site chaos and into the controlled digital environment.

From Theory to Production Maturity

This process moves a firm from reactive problem-solving to proactive production planning. As you prep your fabrication-ready rainscreen model, you must account for real-world materials, like high-quality aluminium sheet cladding, and ensure the model reflects its properties.

An intentional LOD plan, tied to project phases and trade responsibilities, is what makes the outcome predictable and protects your margins. It’s the foundation of a mature system that prevents RFIs before they start. For teams looking to sharpen their process, understanding how digital models become physical parts is the next step. Our guide on panel fabrication dives deeper into that translation.

Ultimately, this discipline ensures the architect’s design intent survives the journey to reality, delivering operational consistency and building trust with every successful project.

Instead of just modeling what a rainscreen looks like, you model how it gets built. That shift transforms your output and proves you understand production better than most.

For teams ready to build more predictable and profitable façade production systems, our Façade Fabrication Readiness Checklist is a valuable technical resource. It provides a clear framework for implementing a more intentional LOD strategy on your next project.