Design-Build for Schools: Accelerated Delivery for Educational Projects

School design projects operate on a schedule that doesn't bend. The academic calendar is absolute, and that first-day-of-school deadline is immovable. For architects, builders, and school districts, this reality makes accelerated delivery a necessity, not an option. But speed without a system is just a faster way to get to chaos.

Design-build for schools isn't a shortcut; it's a risk-managed acceleration strategy. It only succeeds when systems, coordination, and BIM maturity are in place to manage the unique constraints of educational projects: fixed academic calendars, summer-only construction windows, and intense stakeholder scrutiny.

Why School Projects Have Zero Margin For Error

School projects run on a clock that simply doesn't budge. Unlike a commercial build, the deadline isn’t a target—it’s locked in by the academic year. When the bell rings, students and teachers must walk into a finished, safe, and fully operational building.

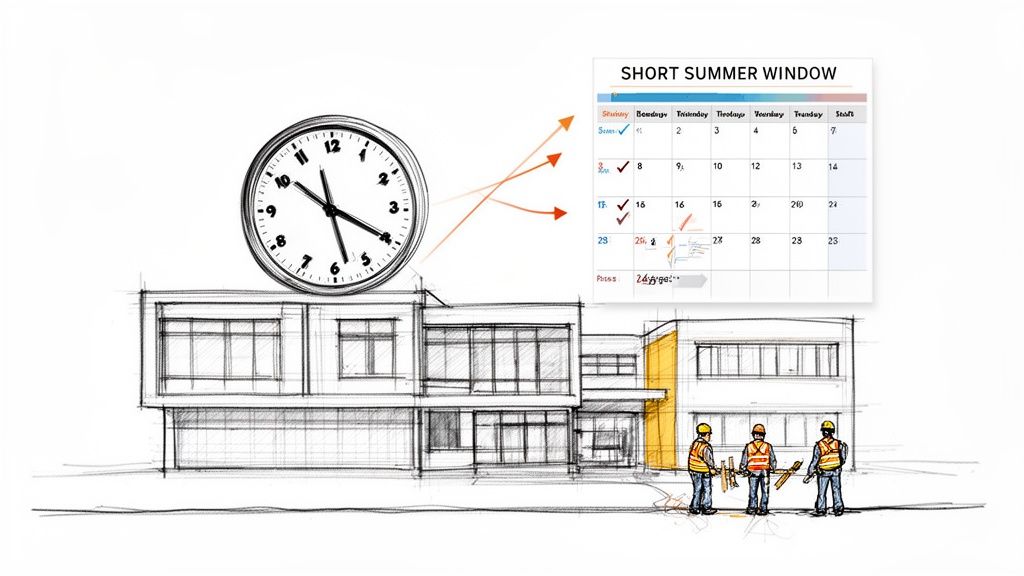

This reality puts intense pressure on design-build teams. The entire project timeline is reverse-engineered from that fixed opening date, which leaves zero margin for error. A single two-week delay in the spring can blow the entire summer construction window, potentially pushing an opening back a full year and disrupting thousands of students.

The Unforgiving Calendar

The biggest constraint in any educational design-build project is time. The critical deadlines are set by forces outside the construction team's control.

- Summer Construction Windows: Most heavy construction must happen during the short 8-10 week summer break to minimize disruption and ensure student safety.

- Funding Deadlines: Public projects are often tied to bond measures or grants with strict spending deadlines. Delays can put essential funding at risk.

- Phased Occupancy: If a project is phased on an active campus, every milestone must align perfectly with semester breaks and exam periods.

We’ve seen school projects meet immovable opening dates when design-build teams aligned BIM, coordination, and decision-making early. This isn't about rushing; it’s about using a disciplined approach as a risk management strategy.

Speed Without Structure Leads to Rework

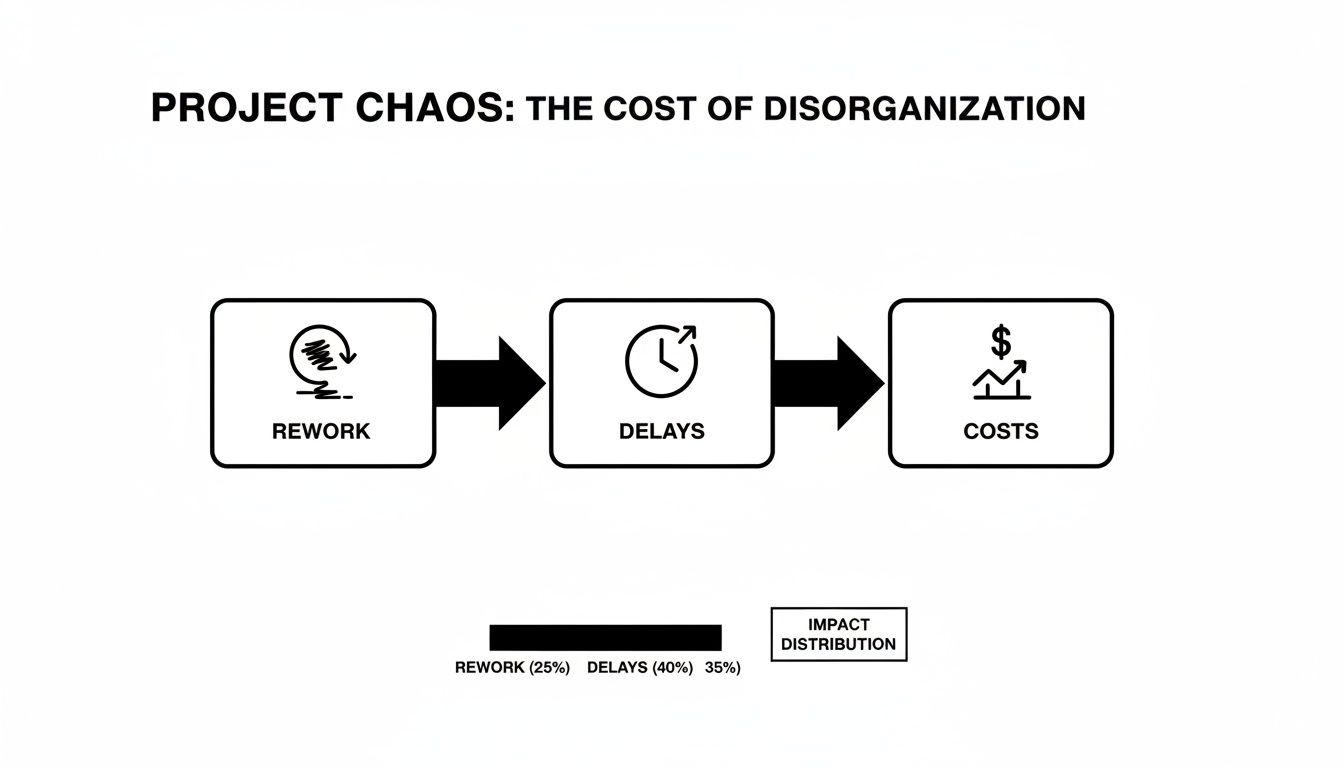

Attempting to fast-track a school project without a solid framework is a high-stakes gamble. Under intense scrutiny from parents, school boards, and the community, every misstep gets magnified. The pressure to "move faster" tempts teams to skip critical QA processes or make rushed decisions, leading to a domino effect of rework, RFIs, and compromised quality.

A well-run school design project replaces contingency with clarity. When systems for collaboration, BIM maturity, and decision checkpoints are established upfront, speed becomes a predictable outcome of operational consistency, not a source of risk.

This is why successful design-build for schools depends on production maturity. It’s about engineering collaboration through shared models and disciplined workflows from the start. This structured approach prevents the late-stage clashes between design and construction that erode margins and destroy predictability.

Where Accelerated School Projects Typically Go Wrong

Many teams adopt design-build expecting an automatic speed boost, only to find themselves buried in rework, budget overruns, and RFIs. The promise of an accelerated timeline evaporates when the right systems aren't in place to support it.

Speed without structure isn't acceleration; it's a faster path to failure. We’ve all seen schedules torched when coordination is an afterthought instead of a day-one priority. The problem isn’t the delivery method—it’s the lack of a disciplined operational system to guide it.

The Collision of Late Decisions and Early Construction

In a well-run educational design-build project, design and construction overlap intentionally. When mismanaged, it’s a collision course. A late design decision—like shifting a classroom wall—sends shockwaves through procurement and fabrication. Suddenly, crews on-site have to stop work or, worse, tear out what they’ve already built.

This is a classic sign of poor production maturity. The common pain points include:

- Undefined Decision Checkpoints: Key decisions aren't locked in at agreed milestones, letting scope drift long after foundations are poured.

- Lack of Stakeholder Alignment: School boards and facility managers are brought in too late, leading to eleventh-hour changes that derail progress.

- Vague Scope Boundaries: Without clear ownership between the architect, builder, and trades, critical design elements fall through the cracks until they become jobsite emergencies.

These issues turn theoretical efficiency into real-world chaos, eating into margins and destroying schedule predictability. The goal is to make decisions early and protect them fiercely.

Uncoordinated BIM Models Create Bottlenecks

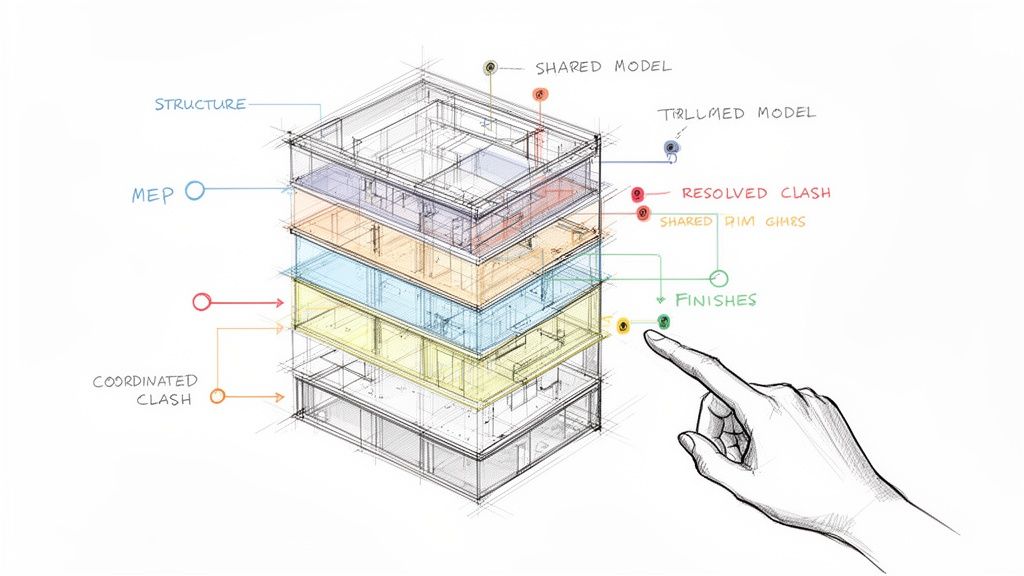

A BIM model should be the project's single source of truth. On failing projects, it’s a single source of confusion. We see it constantly: BIM models are either underdeveloped or siloed, making them useless for fast-track sequencing. When architectural and trade models don't align, clashes that should be caught on a screen become expensive physical problems.

Speed in school construction is a direct result of clarity. When BIM models are mature and coordination is disciplined, teams can build with confidence, replacing costly contingency with engineered certainty.

This lack of BIM for education projects maturity brings progress to a grinding halt. A prefabrication strategy for MEP racks is dead on arrival if the structural and mechanical models don't line up. While design tools from companies like Adobe offer powerful collaboration, the tech is only as good as the workflow behind it.

The failure isn't the software. It’s the lack of a disciplined QA process to ensure the model is buildable before a single piece of steel is ordered. Real acceleration happens when the digital twin is vetted, preventing field changes and keeping the project on its tight schedule.

Engineering Predictability Into Your Design-Build Process

True acceleration in design-build for schools is not accidental. Putting architects and builders in the same room isn’t enough. Real speed is the result of engineered collaboration and extreme discipline from day one. This systematic approach is what separates chaotic projects from those that hit deadlines and budgets with predictable consistency.

The core idea is simple: replace costly contingency with engineered certainty. Instead of scrambling to fix problems on-site, a mature design-build process finds and solves them digitally, long before they can disrupt the schedule. This demands a mindset shift from siloed teams to a shared system of accountability.

This next image shows the all-too-common spiral where a lack of coordination leads to rework, delays, and blown budgets.

This entire cycle is preventable. It requires engineering predictability into the workflow from the start.

Establishing Clear Decision Ownership

The first step toward predictable delivery is making it crystal clear who owns every decision. On educational design-build projects, input from school boards and faculty is vital, but it must be gathered and locked in at specific checkpoints.

We’ve seen school projects succeed because teams created a simple responsibility matrix spelling out who approves what—and when. Once a decision milestone passes, that part of the scope is frozen. This prevents the late-stage changes that cause rework and delay, allowing design to advance on a solid foundation.

A well-structured design-build process isn't about moving faster; it's about removing the friction that slows projects down. Clarity on decision ownership is the lubricant that keeps the system running smoothly.

This framework is essential for managing the complex needs of a modern school, ensuring every choice is deliberate and final. You can learn more about how different frameworks stack up by reading our comprehensive guide to project delivery methods in construction.

Integrating Constructability Into Design

In a typical workflow, constructability reviews happen too late to make a difference. A disciplined design-build process integrates these reviews as a mandatory part of the design phase. This means fabricators and trade partners are at the table from the start, reviewing the BIM model for buildability, spotting clashes, and refining details for efficient assembly.

This proactive QA approach enables strategies that drive accelerated school construction:

- Standardized Details: Using proven, repeatable details across the project reduces design time and removes guesswork for field crews.

- Prefabrication Opportunities: Early collaboration and a mature BIM workflow are required to identify components like MEP racks or exterior wall panels for off-site prefabrication.

- Sequencing Simulation: The team uses the shared model to digitally rehearse the construction sequence, catching logistical bottlenecks before they happen on-site.

The table below illustrates how a systems-driven approach flips the script on the traditional, reactive model. It front-loads critical thinking, creating a clear path to project predictability.

Traditional Vs Disciplined Design-Build Workflow For Schools

| Project Stage | Reactive Design-Build Approach | Disciplined Design-Build Approach |

|---|---|---|

| Schematic Design | Basic massing models, key decisions deferred. | Stakeholder alignment is finalized; program is locked. |

| Design Development | Disciplines work in silos; coordination is an afterthought. | Integrated design sessions with trade partners; constructability is a core focus. |

| Construction Docs | Rushed documentation leads to RFIs and field changes. | Models reach LOD 350 for key trades; procurement packages are released. |

| Procurement | Bidding based on incomplete information creates budget risk. | Fabrication begins from a fully coordinated BIM model. |

| Construction | Constant on-site problem-solving and rework. | Prefabricated components arrive for streamlined assembly. |

| Commissioning | Unforeseen issues delay project turnover. | Smooth handover, as systems were validated digitally. |

By locking in decisions and integrating trade knowledge early, the disciplined approach transforms the project timeline from a series of reactive sprints into a well-orchestrated relay race.

Defining LOD Milestones for Production

Finally, a predictable process depends on clear Level of Development (LOD) milestones. Instead of a vague notion of "design complete," LOD milestones tie model detail directly to construction packages. For example, the model must reach LOD 350 for foundations before that package is released for construction.

This ensures trade partners receive information that is complete enough to begin fabrication and installation immediately, eliminating the ambiguity that fuels RFIs. By aligning the BIM execution plan with the construction schedule, the team ensures every piece of the puzzle is defined before it’s needed, protecting margins and guaranteeing a predictable outcome.

How Mature BIM Workflows Drive Project Acceleration

In successful educational design-build projects, Building Information Modeling (BIM) is more than a 3D modeling tool. It’s the central nervous system for the entire delivery process, enabling teams to responsibly overlap design and construction. Attempting to accelerate a project without this digital backbone leads to rework, RFIs, and compromised quality.

We’ve seen school projects hit immovable opening dates because teams aligned on BIM, coordination, and decision-making from day one. A mature BIM workflow transforms the model from a static picture into a dynamic, data-rich environment where every trade sees how their piece fits into the puzzle. That shared understanding is what drives accelerated school construction.

From Digital Blueprint to Production Engine

The power of BIM for education projects is unlocked when it graduates from a visualization tool to a production management engine. A shared model acts as the single source of truth, letting teams find and fix clashes digitally before they become expensive problems on-site.

This proactive approach is essential for the tight timelines of school construction. A clash between a structural beam and an HVAC duct found during a coordination meeting is a simple fix on a screen. That same clash discovered in the field can halt work for days, derailing a critical summer construction window.

Clarity replaces contingency in a well-run design-build delivery. A mature BIM process provides the operational consistency needed to build faster, not by cutting corners, but by eliminating the guesswork and friction that cause delays.

By mandating disciplined BIM workflows and clear LOD milestones, teams ensure design information is truly production-ready when released. This level of detail is the critical ingredient for downstream activities like prefabrication.

Unlocking Standardization and Prefabrication

Hitting tight summer construction windows often depends on off-site construction. A mature school design workflow is the key that unlocks this potential. A detailed, coordinated BIM model is the non-negotiable prerequisite for identifying opportunities for standardization and prefabrication.

This systematic approach delivers major advantages for accelerated delivery:

- Standardized Details: The model allows teams to reuse proven design details for elements like classroom layouts, speeding up both design and installation.

- Prefabrication: Components like multi-trade MEP racks or exterior wall panels can be built in a factory while site work happens, dramatically compressing the project schedule.

- Reduced On-Site Congestion: With major assemblies built off-site, fewer trades compete for space, improving safety and efficiency during the final push.

Advanced technology is pushing the boundaries of school design. Tools like LiDAR for capturing precise 3D data and VR/AR for stakeholder visualization are becoming common. Districts effectively using BIM have reported a 25% reduction in change orders, showing how technology-driven precision directly protects the bottom line.

This shift toward prefabrication is only possible with a solid digital foundation. Our guide on BIM and 3D modeling dives deep into building that foundation correctly. A mature BIM process provides the certainty needed to manufacture building components with confidence, ensuring they fit perfectly on site. This is how speed becomes a predictable outcome of a disciplined system.

Integrating Future-Ready Designs Without Delay

Hitting an accelerated deadline is one thing; delivering a facility with lasting value is another. A disciplined design-build framework makes it possible to weave forward-thinking school design concepts into a project without disrupting the schedule. It proves that production efficiency and thoughtful educational design aren’t at odds—they enable each other.

The goal is to build facilities that support evolving teaching methods for decades. That means creating dynamic, adaptable learning environments. When your systems, BIM workflows, and decision checkpoints are locked in, the team can focus on what truly matters: creating spaces that help students thrive.

Building Flexible and Adaptable Learning Hubs

Modern educational spaces must be flexible. Rigid, single-purpose rooms are being replaced by multi-functional hubs that adapt to different teaching styles. A mature design-build process makes integrating these complex spaces manageable.

Using a shared BIM model, teams coordinate the structural, MEP, and architectural needs for features like operable walls or integrated tech from the beginning. This prevents the late-game surprises that trigger rework and delays.

Key elements of a future-ready design often include:

- Career and Technical Education (CTE) Hubs: These specialized labs are coordination-heavy, demanding careful planning for equipment, power, and ventilation. Early collaboration ensures these needs are met without derailing the schedule.

- Flexible Classrooms: Movable furniture, modular walls, and accessible tech infrastructure let educators reconfigure their space to support everything from individual work to group projects.

- Collaborative Zones: Open areas, breakout nooks, and commons are essential for project-based learning outside the traditional classroom.

Prioritizing Wellness and Universal Design

A great school design centers on the well-being of its occupants. This means embracing principles of universal design for learning (UDL) to create inclusive environments that work for every student, regardless of their learning style or physical ability.

UDL spaces are a growing focus in educational design. As districts consolidate, they are pushing for consistent, welcoming classroom experiences across their portfolio. Performance Services highlights the rise of multi-functional hubs like “learning stairs”—tiered staircases that double as collaborative seating—as a prime example. By integrating flexible furniture and interactive systems, you create an environment where students feel at home in any building. You can explore more K-12 design trends on Spaces4Learning.

A disciplined process doesn't stifle creativity; it provides the structure to execute ambitious design concepts reliably. When constructability is baked into the design from day one, innovation becomes a manageable part of the plan, not a source of risk.

By front-loading coordination for daylighting, acoustic performance, and clear circulation paths, teams ensure student wellness is a foundational part of the project. This proactive approach allows for seamless integration of features that support mental and physical health.

Ultimately, a systems-driven approach to design-build for schools makes it possible to deliver on the promise of accelerated school construction while creating inspiring, future-ready learning environments.

Incorporating Modern Safety And Security Seamlessly

In modern school design, safety and security are non-negotiable. They are the foundation of the project, not a feature to be added at the end. On an accelerated delivery schedule, treating these critical systems as an afterthought is a recipe for disaster. Attempting to bolt on security infrastructure late in the game will derail the schedule, force expensive rework, and compromise the design's integrity.

Successful school projects treat safety and security as an integrated part of a disciplined, systems-driven process. The goal is to coordinate everything—from access control wiring to the placement of touch-free fixtures—long before breaking ground. This proactive approach weaves safety into the building's DNA.

Using BIM For Proactive Security Coordination

A mature BIM workflow is your greatest asset here. By creating a detailed digital twin, teams can map out the entire security infrastructure before construction begins. It allows architects, engineers, and security consultants to collaborate in a shared model, catching potential conflicts on a screen instead of on the job site.

This digital coordination is essential for managing the layers of modern school security:

- Access Control Systems: BIM enables precise placement of card readers and door hardware, ensuring they integrate cleanly with the architecture and don't clash with MEP systems.

- Surveillance Infrastructure: The model can be used to plan camera locations, simulate fields of view, and map cabling pathways to avoid other trades.

- Emergency Systems: Fire alarms, public address systems, and lockdown protocols can be fully modeled and coordinated, ensuring all components work together flawlessly.

Integrating Health and Hygiene Systems

Since 2020, health and safety have taken on new meaning in school design. North American school systems are fast-tracking safety and security upgrades, with hygiene becoming a dominant theme. Touch-free plumbing like sensor-activated lavatories are now standard in 75% of new builds. These systems aren't just for convenience—they can slash germ transmission by up to 40%.

Proactive integration is the difference between a secure facility and a delayed project. By managing safety requirements through a disciplined BIM workflow, teams can eliminate surprises and protect the schedule.

This early coordination is also critical when incorporating advanced solutions, like the deployment of intelligent security systems in critical infrastructures. These complex systems demand meticulous planning, something a mature BIM process handles perfectly.

This level of upfront planning ensures all safety and hygiene components are integral parts of the building, not last-minute additions. For any team working on an accelerated school construction timeline, this disciplined approach is non-negotiable. Explore more on managing these requirements in our guide on navigating building codes and regulations. It's how you deliver a secure, future-ready school on an immovable schedule.

A Framework For Predictable Project Delivery

Successful design-build for schools isn't about rushing decisions. It’s the direct result of a disciplined, systems-driven framework that engineers collaboration from day one.

When school opening dates are non-negotiable, speed without structure is a faster path to rework, RFIs, and compromised quality.

The concept is simple but powerful: replace contingency with clarity. Instead of reacting to problems on-site, a mature delivery process identifies and solves them digitally, long before they can impact the schedule or budget. This isn't a shortcut; it's a risk-managed acceleration strategy built on production maturity.

The Foundation of Predictable Delivery

We've seen educational design-build projects hit their deadlines when teams align on three pillars: early decision-making, mature BIM workflows, and integrated constructability. Each element builds on the last, creating a system that delivers consistency and protects margins.

This framework shifts the project dynamic. It moves critical thinking and coordination to the front end, ensuring that by the time construction begins, every team member is working from a shared, vetted source of truth.

- Early Certainty: Lock in key design decisions at defined checkpoints to prevent scope creep and late-stage changes.

- BIM Discipline: Use a shared, coordinated model as the project's central nervous system, driving everything from clash detection to prefabrication.

- Engineered Collaboration: Weave trade partner expertise into the design process through mandatory constructability reviews to guarantee the design is buildable.

From Aspiration to Execution

This systematic approach turns the promise of accelerated school construction into a reliable reality. It’s not about having the latest software; it's about having the discipline to use it effectively. When BIM models are tied to clear LOD milestones and QA processes are non-negotiable, teams can responsibly overlap design and construction.

True acceleration in school design is an outcome of operational excellence. It happens when BIM, coordination, and decision-making are so tightly integrated that clarity replaces contingency, allowing teams to build with confidence and predictability.

This is how leading firms deliver complex educational facilities on tight schedules. They don’t leave collaboration to chance; they engineer it through scalable delivery pods, template discipline, and a shared commitment to preventing problems before they start.

The projects that succeed are the ones where architects, builders, and school districts agree that speed is a byproduct of structure. This mindset is the ultimate key to delivering safe, inspiring, and future-ready learning environments on time and on budget.

At BIM Heroes, we believe predictable project delivery comes from robust systems, not just hard work. If your team is preparing for an accelerated educational project, our expertise in production maturity and disciplined BIM workflows can provide the clarity you need.

Download our complimentary Design-Build Readiness Checklist for Educational Projects to assess your team's systems and ensure you're set up for success from day one.