Beyond the Clipboard: The Commercial Building Inspection Checklist That Protects Your Margins

A commercial building inspection is often seen as a final, stressful hurdle. For high-performing architecture, engineering, and construction firms, however, it’s simply a verification of a well-executed QA process. A generic safety checklist misses this entirely. The real objective isn't just to pass; it's to eliminate the friction, RFIs, and costly delays that erode margins. This is achieved when the inspection framework is integrated into the entire project lifecycle, starting with template discipline and rigorous BIM workflows.

The most common inspection failures don't originate from on-site errors but from preventable disconnects: inconsistencies between drawings and field conditions, ambiguous equipment tags, or last-minute changes that weren’t coordinated. These are fundamentally documentation and production maturity problems.

This guide reframes the commercial building inspection checklist as a tool for production management. We connect each critical inspection category—from structural to MEP and life safety—back to the clarity of your drawings, models, and specifications. The goal is to show how disciplined documentation and a mature construction inspection workflow lead to predictable outcomes and protect profitability. The core lesson is simple: the best inspections start long before an inspector arrives.

1. Structural Inspection: The Foundation of Confidence

A structural inspection is a critical checkpoint, but it's not about finding cracks. It's a rigorous verification that the as-built reality aligns perfectly with the structural engineer's design intent. This process validates the building's load paths and connection details, forming the literal foundation of the project's integrity.

Confidence during an inspection is a direct result of documentation clarity. When an inspector can easily trace load paths from the roof to the foundation and verify that connection details match the approved plans, the process is smooth. Discrepancies between the drawings and field conditions are what trigger costly reviews and stop-work orders.

Bridging the Gap Between Design and Reality

The most common friction point during a structural inspection is the deviation between 2D plans and the actual built environment. To mitigate this risk, leading AEC firms integrate reality capture into their commercial building QA processes.

We’ve seen commercial inspections move faster when teams start with accurate as-builts and coordinated BIM models instead of outdated plans.

By leveraging a Scan-to-BIM workflow, you create a dimensionally accurate digital twin of the structure at critical milestones. This allows for a direct comparison against the design model, catching deviations in column placement or slab elevations long before an inspector steps on site. To understand how this technology transforms traditional workflows, explore the fundamentals of creating a BIM model from a laser scan.

Actionable Tips for a Seamless Structural Inspection

- Overlay Reality Capture Data: Before the formal inspection, overlay Scan-to-BIM point cloud data onto your structural model. This pre-emptive check flags deviations, allowing you to address issues proactively.

- Maintain a Photographic Log: Document key structural milestones with high-resolution, dated photographs, especially rebar placement before a concrete pour and steel connection welding.

- Annotate Connection Details: Ensure all structural connection details are clearly annotated and easily accessible in the document package provided to the inspector.

- Visualize Clearances in BIM: Use your BIM model to confirm required clearances around major structural elements are maintained, preventing clashes with MEP systems that could be flagged later.

2. Electrical Systems Inspection: Powering Safety and Compliance

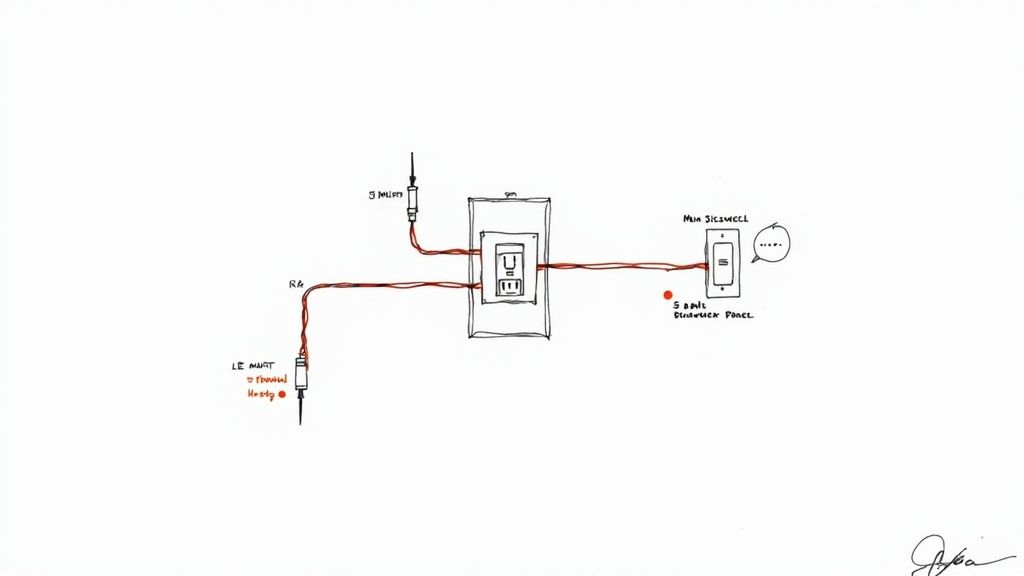

An electrical systems inspection is a fundamental component of any commercial building inspection checklist, verifying that all components from the service entrance to the final outlet are safe, code-compliant, and capable of handling their designed loads. This is not just about flipping switches; it's a deep dive into the building's electrical backbone to identify potential fire and shock hazards, ensuring the system aligns with National Electrical Code (NEC) standards and the engineer's specifications.

A smooth inspection hinges on clear, accurate documentation. When panel schedules, one-line diagrams, and as-built locations of key components are precise, it builds confidence. In contrast, poorly labeled panels or discrepancies between plans and the installed system can lead to immediate red flags and operational delays.

Mitigating Risks Before the Walkthrough

One of the most significant challenges in an electrical inspection is verifying unseen infrastructure and identifying overloaded components before they fail. Modern diagnostic tools and disciplined documentation practices are essential for pre-empting issues that could halt operations or compromise safety.

We’ve seen a dramatic reduction in electrical-related RFIs when teams use thermal imaging to validate panel loads and verify as-built conduit runs against the BIM model ahead of the formal inspection.

This proactive approach moves beyond a simple visual check. It involves a technical audit that confirms panel schedules are accurate, all GFCI and AFCI devices are functional, and the system shows no signs of thermal stress. Such diligence is critical in scenarios like retrofitting an older building for modern, high-density server use or planning for new EV charging station installations.

Actionable Tips for a Flawless Electrical Inspection

- Use Thermal Imaging: Conduct a thermographic survey of all distribution panels and switchgear to detect hot spots indicative of overloaded circuits or loose connections. Address these findings before the inspector arrives.

- Verify and Document Panel Schedules: Ensure every panelboard has a clear, accurate, and up-to-date circuit directory. This is one of the first items an inspector will check, and accuracy is non-negotiable.

- Test All Safety Devices: Systematically test every Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) outlet and breaker to confirm they are functioning correctly according to UL standards.

- Check Voltage and Phase Balance: Use a multimeter to verify proper voltage levels and ensure loads are balanced across all phases. Imbalances can lead to equipment damage and energy inefficiency.

3. HVAC Systems Inspection: Ensuring Operational Health

An HVAC systems inspection is a fundamental part of any commercial building inspection checklist, verifying that the building's climate control systems perform as designed. This process moves beyond a simple temperature check; it’s a detailed assessment of equipment health, ductwork integrity, control systems, and energy efficiency. It ensures the as-installed mechanical systems align with the engineer's specifications for occupant comfort, indoor air quality, and operational cost control.

Confidence during an HVAC inspection hinges on clear documentation and demonstrable performance. When an inspector can easily verify equipment model numbers, confirm maintenance logs, and witness correct thermostat responses, the process is efficient. Discrepancies between the design documents and the installed reality, such as unsealed ductwork or incorrect VAV box programming, can lead to failed inspections and costly rework.

Bridging the Gap Between Design and Performance

A common point of failure in HVAC inspections is the disconnect between the theoretical performance outlined in the design and the actual operational efficiency on-site. To de-risk this, AEC firms are using detailed BIM models not just for clash detection, but for validating system installation and performance metrics long before the final inspection.

We’ve seen hospital projects pass critical air exchange rate inspections on the first attempt because the team used a coordinated BIM model to verify duct routing and equipment placement against the as-built conditions, ensuring compliance with strict healthcare standards.

By aligning the mechanical BIM model with as-built conditions captured via laser scanning, you can confirm that specified clearances for maintenance are met and that duct runs match the design intent. This digital verification ensures the physical system can deliver the performance calculated during the design phase. A critical precursor to this is an accurate upfront analysis; you can learn more about performing an HVAC load calculation for a commercial building.

Actionable Tips for a Seamless HVAC Inspection

- Document Equipment Data: Maintain a clear, accessible log of all HVAC equipment, including manufacturer, model number, serial number, and warranty information. Link this data directly to the equipment in your BIM model for easy reference.

- Test and Balance (TAB) Report: Ensure a certified TAB report is completed and available for the inspector. This report provides empirical evidence that the system is distributing air according to the design specifications.

- Conduct Pre-Inspection System Cycling: Before the official inspection, run all heating and cooling systems through their full operational cycles. This proactive test helps identify any control logic issues, unusual noises, or performance gaps.

- Verify Ductwork Integrity: Visually inspect all accessible ductwork for proper sealing at joints and connections. Use a blower door test where specified to quantitatively measure duct leakage and prove the system meets energy code requirements.

4. Plumbing Systems Inspection: Ensuring Flow and Function

A plumbing systems inspection is a fundamental part of any commercial building inspection checklist, safeguarding occupant health and operational continuity. This goes beyond looking for drips; it's a comprehensive evaluation of the entire water supply, drainage, and fixture network to ensure it meets design specifications, local codes, and performance standards. A properly functioning plumbing system is critical for sanitation, safety, and preventing costly water-related damage.

Confidence during this inspection hinges on clear, accessible documentation. When an inspector can easily verify pipe materials, fixture schedules, and cleanout locations against the approved plans, the process is streamlined. In contrast, unverified installations or signs of hidden leaks can halt progress, requiring destructive testing and significant remediation efforts.

Bridging the Gap Between Design and Reality

One of the most common challenges in plumbing inspections is verifying the condition of inaccessible or concealed piping, such as drain lines embedded in concrete or hidden behind finished walls. To address this, modern inspection workflows are adopting non-destructive evaluation methods to gain clarity without costly demolition.

We’ve seen projects avoid major setbacks when teams use video camera inspections to proactively assess drain line integrity, identifying potential blockages or pipe degradation that would have been missed by a purely visual check.

This technology allows teams to document the as-built condition of critical infrastructure, providing tangible evidence of compliance and system health. For complex retrofits, this data can be integrated into a BIM model to coordinate new plumbing routes with existing structures, preventing clashes and ensuring precise installation.

Actionable Tips for a Seamless Plumbing Inspection

- Perform Video Pipe Inspections: Use a borescope or pipe camera to inspect main drain and sewer lines for cracks, root intrusion, or blockages before the final inspection. Provide this video documentation to the inspector.

- Test and Document Water Pressure: Measure water pressure at various points in the building, including the lowest and highest fixtures. Ensure readings fall within the optimal range (typically 30-80 PSI) and match design specifications.

- Verify Water Heater Compliance: Check that the temperature setting on commercial water heaters is appropriate for the building’s use (often 120°F-140°F) and that all safety features, like pressure relief valves, are correctly installed and functional.

- Map All Shut-off Valves and Cleanouts: Ensure that all main water shut-off valves and sewer cleanouts are clearly labeled and their locations are accurately marked on as-built drawings, providing crucial information for future maintenance and emergency response.

5. Fire Protection Systems Inspection: Validating Life-Safety

A fire protection systems inspection is a non-negotiable component of any commercial building inspection checklist, verifying that all life-safety systems function exactly as designed and meet strict code requirements. This goes far beyond counting fire extinguishers; it's a systematic validation of detection, suppression, and egress systems, from sprinkler head placement to fire alarm control panel (FACP) programming. It ensures that in an emergency, the building's automated and passive systems perform reliably to protect occupants and assets.

Confidence during this inspection is built on meticulous documentation and verifiable system performance. When an inspector from the Authority Having Jurisdiction (AHJ) can easily cross-reference as-built drawings with installed components and review clear testing logs, the approval process is streamlined. Any inconsistencies between the design, installation, and documentation can result in significant delays and mandatory, costly remediation.

Aligning Design Intent with Life-Safety Code

The primary challenge in fire protection inspections is ensuring that the installed systems precisely match the approved life-safety plans and adhere to all relevant NFPA standards. Discrepancies often arise from field modifications made to accommodate other trades, which can compromise system integrity. To prevent this, proactive QA using digital tools is essential for maintaining compliance.

We’ve seen final inspections get fast-tracked when facility managers provide complete, organized testing and maintenance logs alongside BIM models that accurately map every sprinkler head, detector, and emergency light.

By coordinating the fire protection system within the master BIM model, you can run clash detection against MEP and structural elements, ensuring required clearances are maintained and no device is obstructed. This digital verification process identifies potential code violations before they are built, preventing issues that would otherwise be flagged by a fire marshal on site.

Actionable Tips for a Flawless Fire Protection Inspection

- Maintain Comprehensive Logs: Keep detailed and up-to-date inspection, testing, and maintenance (ITM) logs for all systems, including sprinklers, alarms, and extinguishers. This documentation is the first thing an inspector will ask for.

- Conduct Professional Flow Tests: Schedule annual flow tests for sprinkler systems conducted by a certified professional to verify water pressure and flow rates meet design specifications.

- Verify Egress Pathways: Regularly walk all evacuation routes to ensure they are free of obstructions, well-lit, and clearly marked with functional exit signage and emergency lighting.

- Document As-Built Conditions: Capture the final locations of all fire protection devices, such as smoke detectors, sprinkler heads, and pull stations. Annotate these locations in your as-built drawings or BIM model for precise documentation.

6. Accessibility (ADA) Inspection: Ensuring Equitable Access

An accessibility inspection is a critical part of the commercial building inspection checklist, ensuring the facility meets all requirements of the Americans with Disabilities Act (ADA) and local codes. This is not a matter of opinion; it’s a detailed audit of clearances, slopes, signage, and hardware to guarantee equitable access for all individuals.

Confidence during this inspection depends on precision. When an inspector can measure compliant door clearances, ramp slopes, and restroom layouts that perfectly match the drawings, the process is efficient. Small deviations that seem minor on site—a grab bar an inch too high or a door closer with too much tension—can lead to failed inspections, rework, and potential legal exposure. These are often symptoms of poor template discipline or a breakdown in the CAD-to-BIM workflow.

From Design Detail to As-Built Certainty

The most common failure point in accessibility inspections is the disconnect between the design details in the drawings and the final as-built conditions. A contractor might shift a wall by a few inches to accommodate plumbing, inadvertently creating a non-compliant restroom stall.

We’ve seen projects sail through ADA inspections because the architectural team embedded accessibility checkpoints directly into their BIM model. This allows for automated QA checks on door swings, fixture clearances, and accessible routes long before construction begins.

By treating ADA requirements as non-negotiable data points within your BIM model, you can run automated checks that flag non-compliant conditions during the design phase. This proactive QA process prevents the kinds of on-site errors that lead to costly and frustrating rework at the finish line. For more on this, you can explore the essentials of navigating building codes and regulations.

Actionable Tips for a Seamless Accessibility Inspection

- Embed ADA Standards in BIM Templates: Create and enforce BIM templates with built-in clearance zones for doors, fixtures, and accessible routes to standardize compliance across all projects.

- Verify Hardware and Signage Specifications: Double-check that all specified hardware (e.g., lever-style door handles, compliant door closers) and signage (e.g., Braille, mounting height) are installed correctly per the approved submittals.

- Conduct a Pre-Inspection Walkthrough: Use a tape measure and digital level to perform your own detailed accessibility audit before the official inspection. Document everything with photos.

- Document All Accessible Routes: Ensure the path of travel from parking, public sidewalks, and building entrances is fully compliant, including curb ramps, walkway slopes, and entryway thresholds.

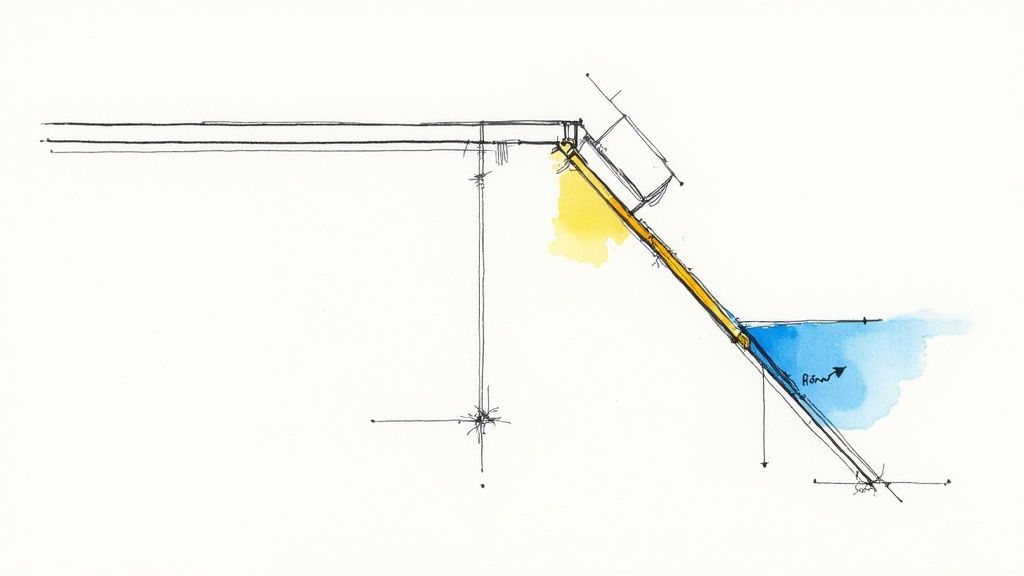

7. Building Envelope Inspection: The Primary Protective Barrier

A building envelope inspection is a fundamental component of the commercial building inspection checklist, serving as the first line of defense against water intrusion and thermal loss. This evaluation goes beyond simply looking for visible wear; it's a comprehensive assessment of the roof membrane, wall assemblies, windows, flashing, and all penetrations. A properly executed inspection validates the integrity of the building’s primary protective barrier.

Inspectors look for evidence of ponding water, compromised seams, unsecured flashing, and improperly sealed penetrations from HVAC units or vents. Inconsistencies between drawings and field conditions can raise red flags, leading to more invasive testing. This is where clarity in design details and disciplined QA processes pay off.

From Visual Checks to Verifiable Data

The most significant challenge in envelope inspections is accurately assessing large areas and documenting gradual degradation. To move beyond subjective visual checks, firms are using drone technology and thermal imaging to capture high-resolution data that pinpoints moisture intrusion beneath a roof membrane or thermal bridging in a wall assembly long before it becomes a visible failure.

We’ve seen facility managers prevent catastrophic failures by using thermal drone scans to identify saturated insulation. This data-driven approach allows for surgical repairs instead of a full, and often unnecessary, roof replacement.

By integrating this data into a BIM model, you can create a detailed, time-stamped record of the envelope's condition. This digital log allows for precise tracking of repairs and informs capital expenditure planning with verifiable data. This approach aligns with guidance from organizations like the National Roofing Contractors Association (NRCA) on proactive maintenance.

Actionable Tips for a Thorough Envelope Inspection

- Schedule Bi-Annual Inspections: Conduct detailed inspections in the spring and fall to identify damage from winter ice or summer heat before it escalates.

- Leverage Drone Inspections: For large or high-sloped roofs, use drones equipped with high-resolution and thermal cameras to safely inspect every square foot and identify subsurface moisture.

- Document All Penetrations: Create a detailed photographic and written log of every penetration (vents, skylights, drains). Note the condition of the sealant and flashing at each point, as these are common failure points.

- Verify Sealant and Flashing Details: Confirm that all window, door, and material transition joints are sealed according to the architect's specifications and manufacturer’s instructions.

8. Interior Systems and Finishes Inspection

An inspection of interior systems and finishes is a critical final step in the commercial building inspection checklist, but it's more than a simple punch list. It’s a verification that all interior components meet the design specifications, installation standards, and durability requirements for commercial use. This includes everything from wall assemblies and flooring to ceiling systems and millwork.

A smooth handover depends on documented quality. When an inspector or owner’s representative sees consistent finishes, properly installed hardware, and clean detailing, it builds confidence in the overall quality of the project. Conversely, misaligned grid ceilings, poorly fitted doors, or damaged finishes can signal a lack of QA discipline, leading to a lengthy and contentious close-out process.

Connecting Documentation to Craftsmanship

The most common friction point during an interiors inspection is the discrepancy between the level of detail shown in the construction documents and the final executed work. Vague specifications or uncoordinated details often lead to installer interpretation, resulting in inconsistencies that get flagged during the final walkthrough.

We consistently see faster project close-outs when the BIM model includes detailed interior elevations and material specifications. This leaves no room for ambiguity and gives the field team a clear benchmark for quality.

By embedding finish schedules, material data, and installation details directly into your BIM model, you create a single source of truth for the entire team. This level of documentation maturity minimizes RFIs, prevents rework, and ensures the final product aligns perfectly with the design intent. It’s the hallmark of a firm with a mature production system.

Actionable Tips for a Flawless Interiors Inspection

- Verify Material Submittals: Before the final inspection, confirm that all installed materials (e.g., flooring, paint, ceiling tiles) match the approved submittals and product data sheets.

- Check for Uniformity and Alignment: Systematically inspect finishes for consistency in color, texture, and alignment. Look for visual defects like uneven paint, gaps in flooring, or misaligned ceiling grids.

- Test All Operable Components: Open and close every door, window, and cabinet to ensure proper operation, latching, and clearance. Check that all hardware is secure and functions as specified.

- Document with a Digital Punch List: Use a mobile application to create a digital punch list during your pre-inspection walkthrough. Attach photos, assign responsibility, and track resolution in real-time.

9. Final Documentation and As-Built Verification

A thorough inspection of final documentation is a crucial, though often overlooked, item on any commercial building inspection checklist. This step is not just about organizing files; it's an audit that verifies a building’s operational integrity. It confirms that permits, as-built drawings, O&M manuals, and warranties are present, accurate, and aligned with the final built conditions. This creates a reliable asset for facility managers and owners.

Confidence in a building's handover is built on a foundation of verifiable records. When an inspector or facility manager can easily trace a system from the as-built drawing to the physical equipment tag and corresponding O&M manual, the process instills trust. Missing certifications or outdated as-built drawings create significant risks and operational inefficiencies down the line.

Bridging the Gap Between Construction and Operations

The most common friction point during project close-out is the disconnect between fragmented construction records and the operational needs of the facility team. To mitigate this risk, forward-thinking firms are leveraging technology to create clean, accurate, and integrated handover packages.

We’ve seen facility managers transform their capital planning by starting with a complete, digitized record of maintenance history and as-built conditions, which prevents redundant spending and identifies critical system needs.

Digitizing and organizing handover data, including warranty information and equipment serial numbers, creates a reliable single source of truth. This database becomes indispensable for planning capital improvements and managing ongoing maintenance. To see how modern technology helps create this foundational record, you can learn more about maximizing as-built documentation with mobile mapping for CAD and BIM.

Actionable Tips for a Seamless Documentation Handover

- Create a Digital Handover Package: Scan and digitize all close-out documents, including final permits, as-built drawings, and O&M manuals. Organize them in a secure, searchable system.

- Verify As-Built Accuracy: Before handover, spot-check the as-built drawings against the actual field conditions, paying close attention to the locations of valves, cleanouts, and control panels.

- Index Records for Easy Retrieval: Tag documents with metadata like dates, system types (e.g., HVAC, Electrical), and equipment model numbers to allow for quick, searchable access.

- Compile a Complete Warranty Binder: Create a comprehensive digital and physical binder with all manufacturer warranties, contractor contact information, and service agreements.

Integrate Your Checklist, Solidify Your Process

This exhaustive checklist is more than a series of tasks; it's a blueprint for operational maturity. An effective commercial building inspection checklist isn't a document you pull out at the end. It’s the culmination of a disciplined, system-driven production process that begins on day one. It serves as the final validation that your BIM workflows, QA checkpoints, and documentation standards are performing as intended.

When your firm treats inspections as an internal benchmark for clarity rather than an external hurdle, the dynamic shifts. You move from a reactive stance—fixing what’s flagged—to a proactive one where quality is embedded into every deliverable. This is the difference between firms that struggle with rework and those that deliver projects with predictable excellence and protected margins. The confidence your team has on site is a direct reflection of the clarity engineered into your models and documents.

Key Takeaways for a System-Driven Approach

To transform your inspection process from a bottleneck into a competitive advantage, focus on these foundational principles:

- Documentation is the Foundation: The strength of your inspection lies in the quality of your documentation. Inconsistencies between drawings, models, and as-built conditions are the primary source of failed inspections and RFIs.

- Integrate Technology Early: Leverage tools like laser scanning and disciplined BIM modeling from the start. This creates a single source of truth, minimizing the discrepancies that derail schedules.

- Proactive QA, Not Reactive Fixes: Your checklist should inform your internal QA process. By auditing against inspection criteria throughout the project, you catch red flags long before an inspector arrives.

- Prioritization is Strategic: Not all inspection items carry the same weight. Categorize checklist items by priority—critical life-safety, major system functionality, minor cosmetics—to allocate resources effectively. For teams looking to refine this process, it can be beneficial to see how experts structure their assessments. To benchmark your internal standards, consider engaging comprehensive commercial building inspection services.

From Checklist to System

The goal is to embed these principles into your firm’s DNA. Start by mapping each checklist category—structural, MEP, envelope—back to specific checkpoints in your project lifecycle. Your structural inspection items should align with QA reviews during schematic design, design development, and construction documentation phases.

Viewing your commercial inspection requirements not as a final exam but as a continuous feedback loop builds a system that improves with every project. This approach doesn't just get you through an inspection; it builds a foundation for scalable delivery and solidifies your firm's reputation for quality. The best inspections start long before the inspector arrives—clarity in your documentation creates confidence on site.

Ready to bridge the gap between your BIM production and field-ready results? At BIM Heroes, we provide dedicated production teams that specialize in creating the clear, coordinated, and inspection-ready documentation your projects demand. Learn how our systematic approach can enhance your QA process and ensure smoother project closeouts at BIM Heroes.