How Builders Evaluate Your Construction drawings (And What Makes Them Lose Trust)

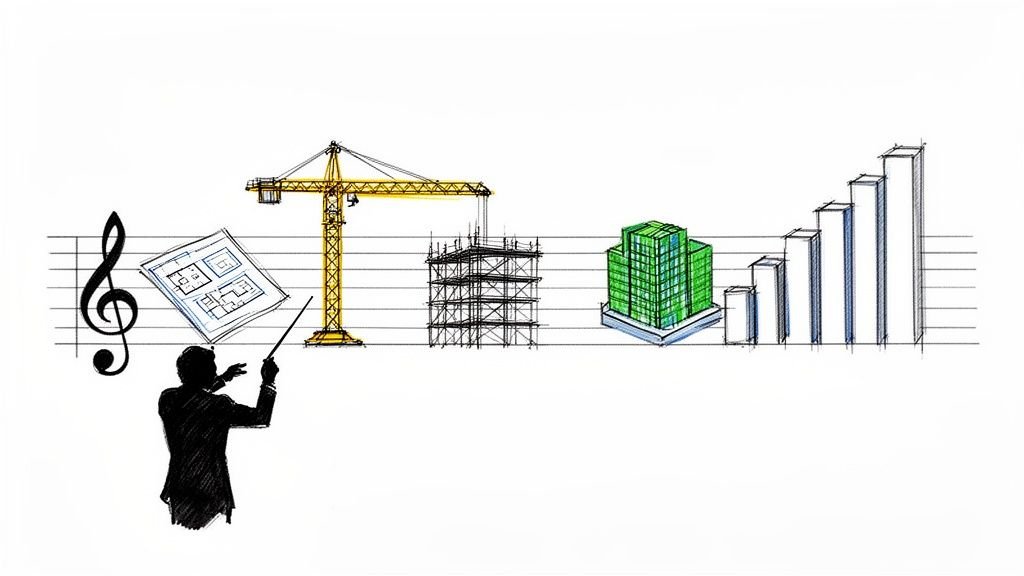

Long before a single shovel hits the dirt, your building construction drawings have already told a story. To a builder, that drawing set isn't just a stack of instructions; it's a direct reflection of your firm’s competence and respect for their time.

A clean, well-coordinated set signals predictability and protects their margins. A sloppy one? That’s a crystal ball predicting a future filled with RFIs, change orders, and schedule delays. The kind of friction that kills profitability for everyone.

Your Drawings Are Your First Handshake with a Builder

Think of your drawing set as the first handshake with the construction team. It’s a moment that either builds immediate trust or plants a seed of doubt that’s hard to remove.

Builders are masters at spotting shoddy documentation because their profit margins depend on it. They aren’t looking for aspirational design sketches; they need a clear, constructible, and predictable roadmap. Anything less is a liability that creates friction and delays.

When a builder unrolls your drawings, they are immediately assessing risk. Every ambiguity, every missing dimension, and every conflicting note translates directly into a potential Request for Information (RFI), a schedule delay, or a change order. These aren't just minor annoyances—they systematically erode project predictability and strain the architect-builder relationship.

The Three Signals of a Trustworthy Drawing Set

A builder’s confidence is won or lost based on three immediate quality signals they look for in your building construction drawings:

- Clarity: Is the information easy to find and understand? Are callouts consistent, line weights logical, and annotations unambiguous? Or is it a confusing mess that requires a decoder ring?

- Completeness: Are all the necessary dimensions on the page? Are correct details provided for tricky junctions? Does the set feel comprehensive, or are there obvious gaps that will force them to guess and submit an RFI?

- Coordination: Do the architectural, structural, and MEP plans actually align? A beam on the structural drawings clashing with a duct on the mechanical plan is a massive red flag. It screams that no one ran a quality check.

A well-executed drawing set is the ultimate form of risk management. It tells a builder that you’ve done your homework, respected their process, and invested in the systems needed to deliver a project without drama.

Mastering these elements is about more than just good drafting; it’s about protecting project margins through production maturity. By focusing on template discipline—from robust BIM workflows to rigorous QA checkpoints—you transform your deliverables from a source of conflict into the foundation of a strong partnership.

The goal is simple: deliver a set of drawings that lets the builder focus on building, not on interpreting your intent. This is how you become the firm every great builder wants to work with.

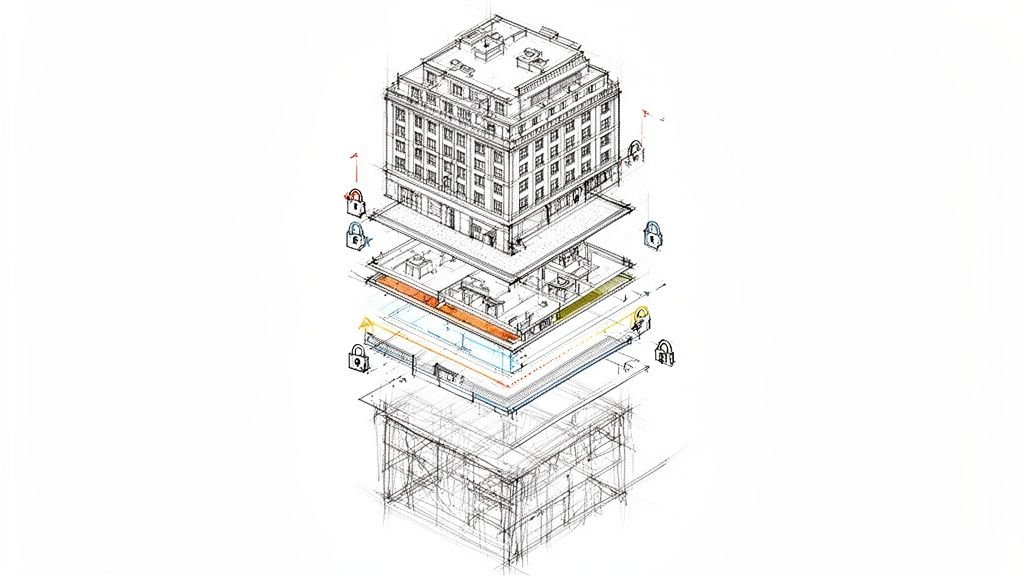

The Anatomy of a High-Confidence Drawing Set

What separates a set of building construction drawings that gets a builder excited from one that has them seeing red flags before they even finish their coffee? It’s not about flashy renderings. It’s about a disciplined, holistic approach to the documents themselves.

Builders don't see a drawing set as a stack of individual sheets. They see a single, interconnected system that has to work perfectly, because any hiccup costs them time and money. When they flip through your set, they're looking for a clear, logical story.

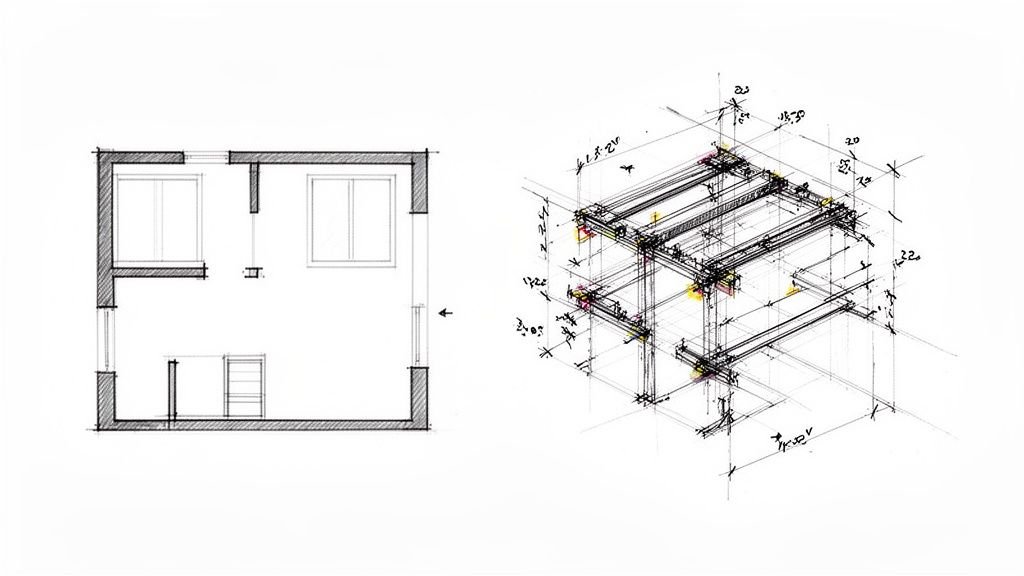

Architectural Plans: The Strategic Road Map

The architectural plans are ground zero. This is the first place a builder looks for clarity, complete dimensions, and consistent callouts. They’re checking for a rational grid system that holds true from the basement to the roof. They’re looking for clean, unambiguous dimensions that actually add up.

A builder’s confidence starts to crater when they spot floating dimensions, inconsistent callouts between a plan and a detail, or notes that were obviously copied and pasted from a completely different project. These aren’t just typos; they’re tell-tale signs of a sloppy QA process. A builder needs a reliable road map, not one full of dead ends and conflicting street signs.

This really drives the point home: trust isn't a single checkmark. It's the result of consistently nailing clarity, completeness, and coordination in your documents.

Structural Drawings: The Uncompromising Skeleton

If the architectural plans are the map, the structural drawings are the laws of physics that govern the whole thing. They are non-negotiable.

Builders look for an immediate, obvious marriage between the architectural vision and the structural reality. Are the column locations on the A-sheets identical to the structural grid? They trace load paths from the roof all the way down to the foundation, and they expect to see a clear, unbroken chain of command.

Any fuzziness—a missing beam size, a vague connection detail, or a slab thickness that just feels too thin for the span—is a massive warning sign. This part of the set has to be absolute. Any guesswork here introduces an unacceptable level of risk to safety, the budget, and the schedule.

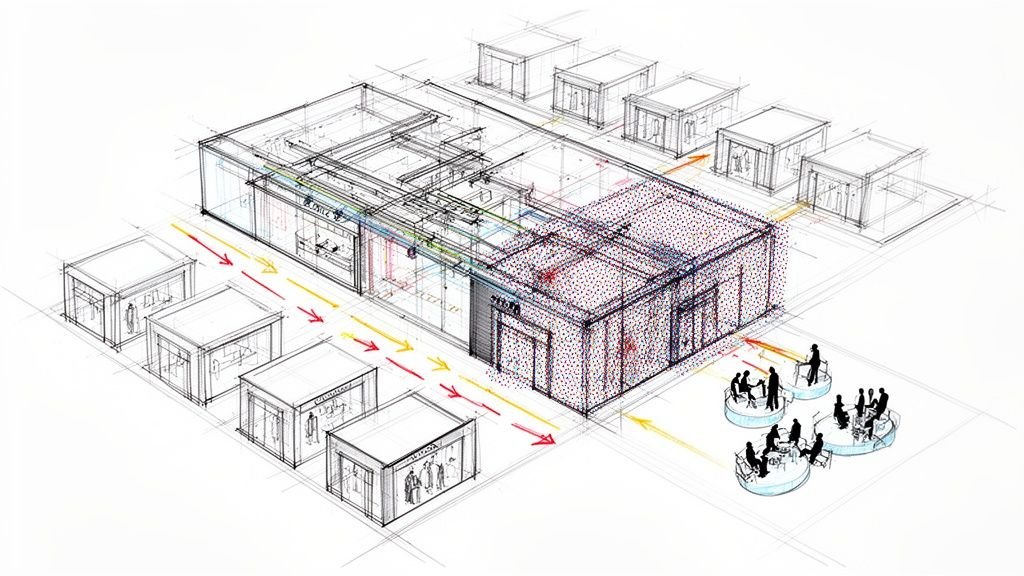

MEP Drawings: The Coordinated Nervous System

Finally, we get to the MEP drawings—the complex systems that bring a building to life. For a builder, this is the ultimate coordination stress test.

The first thing they do is mentally overlay the HVAC layout on the structural framing. Can that massive 24×12 duct really fit under that W-beam without wrecking the ceiling height? They’re looking for clear pathways for plumbing, conduit, and fire sprinkler lines that don't fight with each other or with the structure.

A set of MEP drawings where every discipline is perfectly drawn in isolation but clashes with the others is functionally useless. It’s a guarantee of on-site arguments, costly rework, and a flood of schedule-killing RFIs.

We've put together a quick table summarizing what a savvy builder is really looking for—and what makes them nervous—when they review the core drawing types.

Key Drawing Types and What Builders Scrutinize

| Drawing Type | Builder's Primary Focus | Common Red Flag |

|---|---|---|

| Architectural | Clarity, complete dimensions, and consistency. | Inconsistent callouts or notes between plans and details. |

| Structural | Clear load paths and perfect alignment with architectural plans. | Mismatched column lines or ambiguous connection details. |

| MEP | System coordination. Do ducts, pipes, and conduits fit without clashing? | Major ducts running through structural beams with no clear solution. |

| Details & Sections | Constructible notes and realistic sections. Does the detail provide all info to build it? | Vague material callouts or missing dimensions that force assumptions. |

This table isn't exhaustive, but it hits the high points. A breakdown in any one of these areas tells a builder that the entire production system is weak, putting their margins—and yours—at risk.

A high-confidence drawing set is one where every discipline speaks the same language. The dimensions on the architectural plan must match the structural grid, which must in turn provide a clear and unconflicted path for the MEP systems.

This intense need for detailed, multi-disciplinary coordination isn't new. The practice of creating detailed building construction drawings became standard as projects grew in complexity, requiring a clear separation of plans, elevations, and details to keep everyone on the same page.

Today, a typical commercial project can easily top 100 sheets to satisfy modern building codes and wrangle all the disciplines, from structural to fire protection. You can explore more about the evolution of construction project delivery and what it means for today's market. A single weak link in this chain can have huge consequences.

Red Flags That Immediately Destroy a Builder's Trust

Some mistakes on a set of building construction drawings aren't just errors; they're loud, clear signals of a weak production system. To a builder, these aren't simple oversights—they are direct threats to their schedule, budget, and sanity. They're the red flags that immediately make them question your firm's ability to deliver.

Trust isn't lost in a single dramatic moment. It erodes with every inconsistent dimension, lazy note, and detail that was clearly never thought through. A builder's first pass on a drawing set is a hunt for these signals, because finding them early is a form of self-preservation.

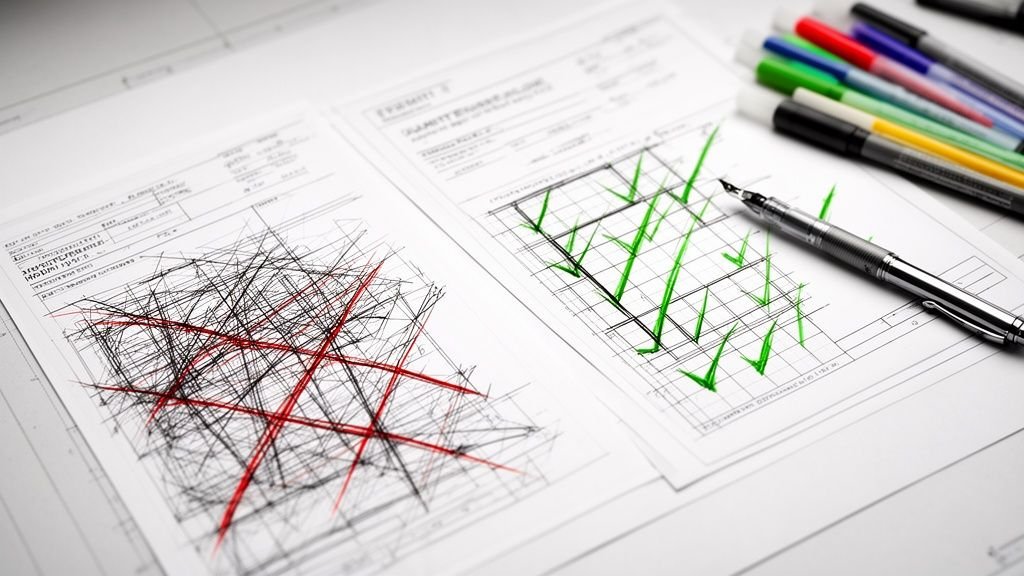

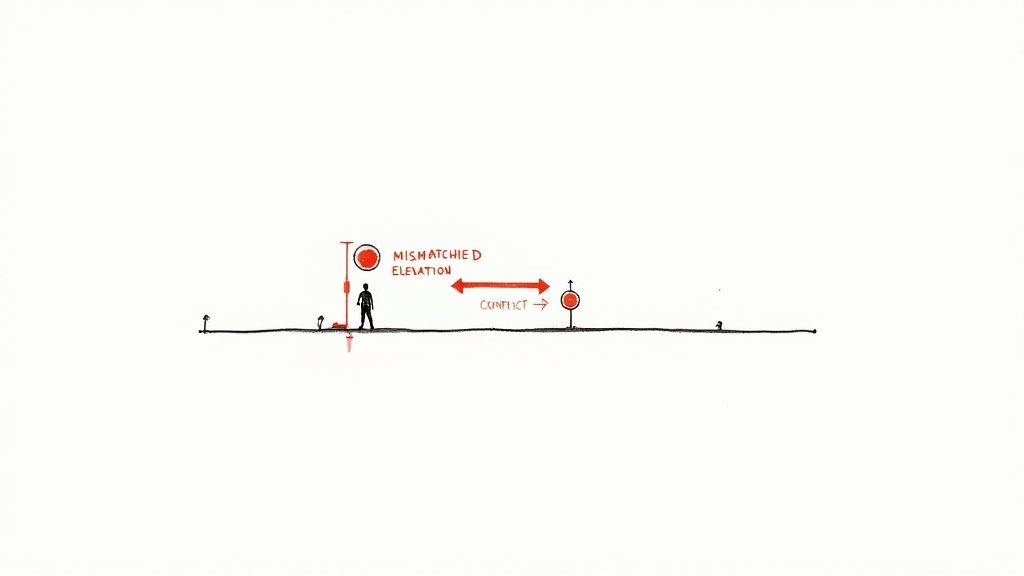

Conflicting Dimensions and Inconsistent Callouts

This is the cardinal sin of sloppy documentation. When the dimension for a wall on the floor plan reads 12'-6" but the elevation shows it as 12'-4", work grinds to a halt. It’s not a minor discrepancy; it’s a full stop that forces a field superintendent to drop everything and write an RFI.

The problem bleeds over into callouts and annotations, too. A window tag might be labeled 'W-01' on the plan but 'WD-A' on the window schedule. A detail callout might point to Sheet A5.1, but the detail actually lives on A5.3. These inconsistencies tell a builder one thing: your QA process is broken. It’s proof that no one performed a final, methodical check to make sure the documents agree with themselves.

This isn't just about typos. It's about operational consistency. A builder needs to trust that the information they're looking at is accurate, no matter where they find it in the set.

Details That Defy Physics and Common Sense

Another massive red flag is the "impossible detail." This is a beautifully drawn section of a wall assembly or a roof junction that looks perfect on paper but is physically impossible to build.

You see it all the time in the field:

- A flashing detail that requires a waterproofer to bend metal in three directions at once.

- A structural connection where bolts are shown so close to a flange that no wrench could ever fit to tighten them.

- Insulation layers compressed into a space far too small, rendering their R-value useless.

These drawings reveal a profound disconnect from the reality of construction. They signal that the designer has never considered the actual sequence of work or the physical limitations of materials and tools. For a builder, this means they are the ones who will have to invent a solution on-site—often at a premium cost and with serious schedule implications.

A drawing that can't be built is worse than no drawing at all. It creates a false sense of security in the office that quickly turns into a real-world liability on the job site.

Generic Notes and Ghost Details

Nothing screams "we didn't care enough to check" louder than generic, copied-and-pasted notes that are irrelevant to the current project. A note specifying a wood stud size for a building framed in cold-formed metal is a classic giveaway. It shows a lack of template discipline and a reliance on old files without proper review.

These errors and omissions aren't just minor annoyances; they're a quantifiable drain on a project's financial health. In fact, documentation issues like incomplete drawings and clashes between disciplines are estimated to account for 5–12% of total project cost overruns and can add 6–12 weeks to the schedule on typical commercial projects. You can find out more about how these issues impact market trends by reviewing recent industry analyses. Each sloppy drawing is a direct hit to the bottom line.

These red flags—inconsistency, impracticality, and irrelevance—are what turn a builder’s initial optimism into wary skepticism. Avoiding them isn’t about achieving perfection; it's about demonstrating a commitment to production maturity and a respect for the people who have to bring your vision to life.

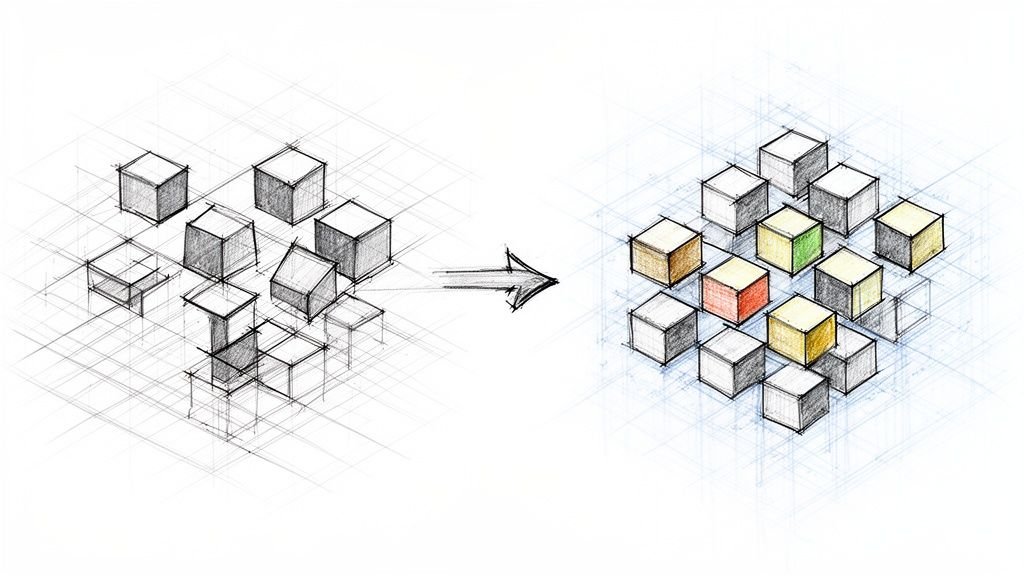

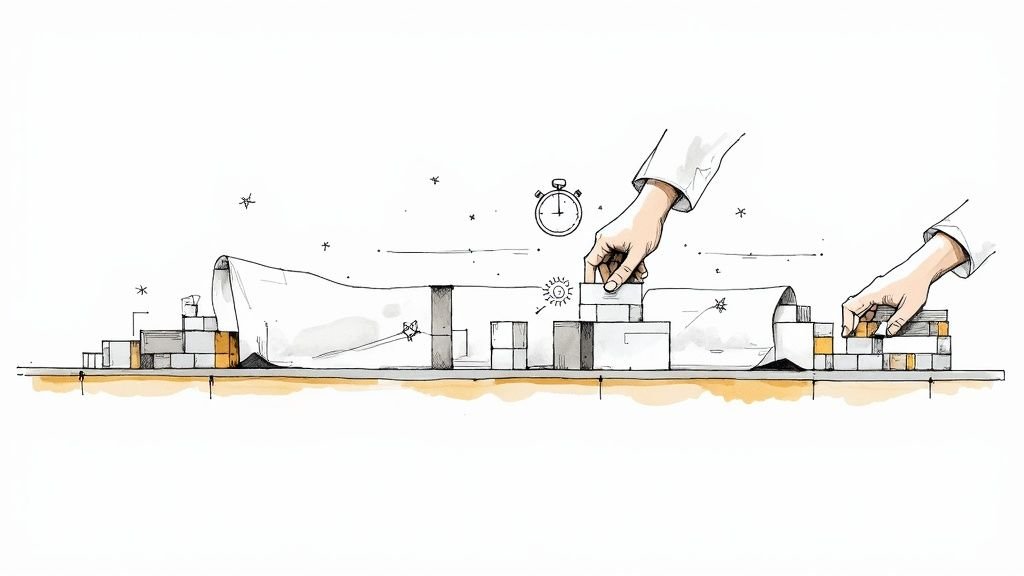

Building a Reliable System from CAD Chaos to BIM Clarity

Those red flags—inconsistent dimensions, impossible details, and coordination failures—aren't just minor mistakes. They're symptoms of a broken production process. Consistently producing top-tier building construction drawings isn't about luck or pulling all-nighters. It's the direct result of a reliable, well-oiled system.

For decades, the industry ran on 2D CAD. It was a powerful tool, but it created silos. The architectural plan was its own little island, completely separate from the structural and MEP layouts. Keeping everything in sync was a monumental task of manual cross-checking, leaving the door wide open for human error. This is "CAD chaos"—where your drawing set is a fragile patchwork of lines instead of a unified, trustworthy guide.

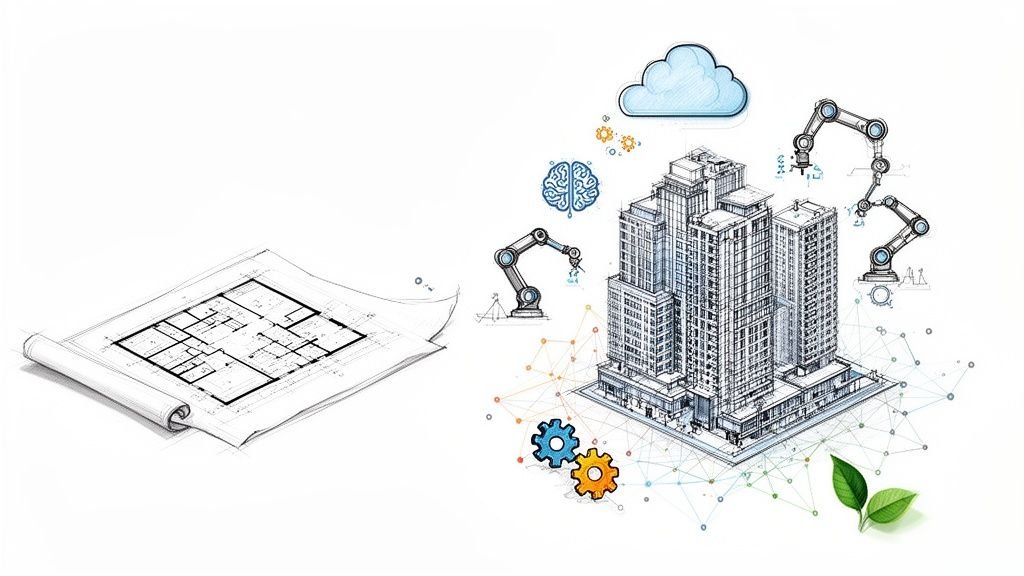

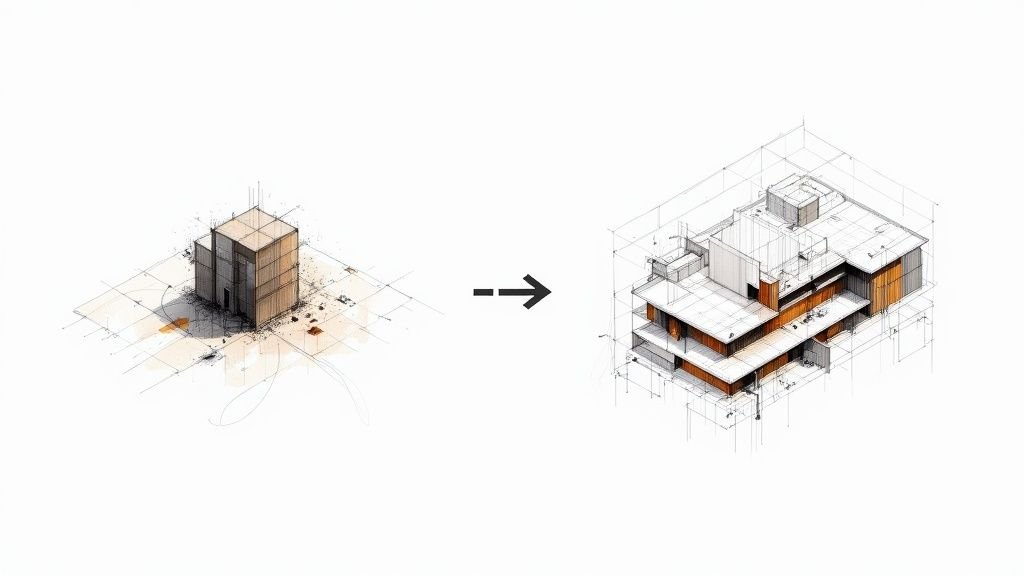

From Disconnected Lines to an Integrated Model

The evolution from CAD to Building Information Modeling (BIM) is our path out of that chaos. A mature BIM workflow isn’t just about making a pretty 3D model; it's about building a single source of truth for the entire project. In a BIM environment, a wall isn't just two parallel lines. It's an intelligent object with its own data—materials, dimensions, fire ratings—and it understands its relationship to every other component in the building.

When you move that wall, the change ripples through the entire model automatically. Every plan, section, elevation, and schedule updates instantly. This is a game-changer. It automates one of the most error-prone parts of documentation: coordination. Think of it as the difference between manually updating a dozen spreadsheets versus changing a single cell that updates everything else.

A disciplined BIM workflow is the engine of predictability. It replaces manual cross-checking with automated consistency, freeing up your team to focus on constructibility and design intent rather than chasing down annotation errors.

The Pillars of a Mature BIM Workflow

Here’s the thing: just owning BIM software like Revit doesn't guarantee quality. Real production maturity comes from the systems you build around the technology. These are the decision checkpoints that turn a 3D model into a reliable drawing factory:

- Rigorous Template Discipline: Every project must start from a robust, pre-configured template. This locks in consistency for everything—line weights, annotation styles, sheet organization—from day one.

- Strict Modeling Standards: Everyone on the team has to model elements the same way. Period. This means having clear rules for wall assemblies, family creation, and data input so the model stays clean and predictable.

- Shared Parameter Files: Using shared parameters ensures that critical data, like material finishes or fire ratings, is identical across all schedules, tags, and families. No more contradictions.

As teams transition from 2D habits, mastering the new way of thinking is critical. For instance, understanding the logic behind creating architectural elements like curtain walls in Revit is fundamental to leveraging the model's full power. If you're making that move, our CAD to BIM conversion checklist can help guide your process.

This move to a model-based workflow isn't just theoretical; it delivers real, measurable results. Studies comparing BIM-enabled drawing sets to traditional 2D ones show a 30–60% drop in clash detection issues during construction. That directly translates to less rework, saving anywhere from 5–15% on total construction costs.

By investing in a mature production system, you’re tackling the root cause of the problems builders hate most. You stop delivering chaos and start delivering clarity, ensuring your building construction drawings are a tool for progress, not a source of friction.

Implementing a Builder-Focused QA Checklist

A standard drawing review won't prevent the friction that inevitably pops up on the job site. Most internal QA processes get stuck on design intent and code compliance, but they completely miss the practical, on-the-ground issues that drive builders crazy. What you really need is a quality assurance process that anticipates their questions before they even have to ask.

This isn't about adding another layer of bureaucracy; it's a strategic move. It protects your reputation, project margins, and your client's budget. The goal is to shift your team's mindset from a purely design-centric review to a production-minded, builder-focused QA process. It’s all about catching the problems that matter most in the field long before the drawings ever leave your office.

Moving Beyond a Simple Peer Review

A simple peer review, where one architect quickly glances over another's work, is a decent first step, but it’s nowhere near enough. A truly builder-focused QA system is a multi-stage framework with clear decision checkpoints. It's about creating a production system that consistently delivers drawings that are clear and, above all, buildable—not just a one-off check.

This process needs to be baked into your project milestones from the beginning. It can't be something you rush at the last minute right before a permitting prep deadline.

Critical QA Decision Checkpoints

A robust QA process for your building construction drawings should have at least three distinct stages, each with a very specific goal.

-

Internal Consistency Review: This is your first line of defense. A dedicated team member—someone who isn't the project architect—does a methodical scrub of the entire drawing set. They aren’t second-guessing the design; they are hunting for contradictions. Do the dimensions on the floor plans actually match the elevations? Are all the detail callouts pointing to the right place? Is the window schedule in perfect sync with the window tags on every single sheet?

-

Cross-Disciplinary Clash Detection: This is where a mature BIM workflow really shines. Before a single drawing is issued, you should be running automated clash detection between the architectural, structural, and MEP models. This isn't just about finding where a duct smacks into a beam. It’s about identifying tight spots, potential maintenance access issues, and sequencing problems that old-school 2D drawings would never reveal.

-

Dedicated Constructibility Review: This is the most crucial—and most often skipped—step. The sole purpose of this review is to "mentally build" the project from the drawings. It requires asking the kind of practical, field-level questions that go way beyond what the drawings explicitly show.

The goal of a constructibility review is to shift your mindset from "Does this drawing accurately represent the design?" to "Can a crew with standard tools actually build this detail as drawn?" It’s a subtle but powerful change in perspective.

How to Conduct a Constructibility Review

During this final QA checkpoint, your team needs to ask some brutally honest questions about the key details and assemblies.

- Sequencing: What's the exact order of operations here? Does the flashing go on before or after the weather barrier? If we install this window now, can we still get to the fasteners for the adjacent panel later?

- Tolerances: Do the specified materials actually have enough room for expansion and contraction? Is there enough tolerance in this opening for the specified storefront system, or is it going to be a nightmare to install?

- Tool Access: Can a worker physically fit their body and their tools—a drill, a wrench, a caulking gun—into this space to do the work properly?

- Material Handling: How is this massive beam going to get lifted into place? Is there enough clearance for the crane, or is this going to require a specialized lift that blows the budget?

This kind of thinking is what prevents those "impossible details" that completely destroy a builder's trust in your firm. Implementing these checks systematically is the key. A comprehensive 3D BIM modeling checklist for construction projects can give you a great foundation for ensuring your models are clean and ready for this level of scrutiny.

Beyond the digital model, having a robust construction quality control checklist on site is essential for translating those great drawings into a successful project. Adopting a builder-focused QA process isn't just a good idea—it's a non-negotiable step to protect your firm’s reputation and deliver drawings that builders can execute with confidence, not questions.

Your relationship with a builder doesn't start at the first site meeting. It starts the moment they unroll your building construction drawings.

Those documents are more than just technical instructions; they’re a direct reflection of your firm's production maturity and respect for the realities of the job site. The difference between a smooth, profitable project and one plagued by friction often comes down to the quality of that first deliverable.

Ultimately, earning a builder’s trust isn't about flawless design—it’s about the flawless execution of your documentation. When you prioritize clarity, complete dimensions, and constructibility, you signal that you are a reliable partner, not just a design firm. You show them you understand that operational consistency and predictability are what protect everyone's bottom line.

This takes a deliberate shift in focus. It means moving beyond fragmented CAD workflows and embracing disciplined, model-based production systems. It means implementing a rigorous, builder-focused QA process that mentally "builds" every detail before it ever reaches the field, heading off RFIs prevention and costly delays before they start.

The goal is to deliver a drawing set that allows a builder to do what they do best: build. When your drawings answer questions instead of creating them, you become the architect that every great builder wants on their team.

This approach transforms your firm's reputation. It leads to smoother projects, fewer conflicts, and better outcomes for everyone involved. It’s the clearest path to becoming the preferred partner for the best builders in the business.

Ready to implement a QA process that builders will thank you for? Our Builder-Focused QA Checklist provides an actionable framework to help you catch critical issues before they become problems on-site.

Frequently Asked Questions

Even with the best intentions, some questions pop up again and again when architects try to create better building construction drawings for builders. Here are some straight answers to the most common ones, focusing on practical steps to build trust and cut down on job-site friction.

What Is the Biggest Mistake Architects Make on Construction Drawings?

Hands down, the single biggest and most frustrating mistake is inconsistent or incomplete dimensioning. When dimensions on a plan don’t add up, are missing from critical spots, or flatly contradict the dimensions on an elevation, it grinds everything to a halt.

That stoppage immediately triggers an RFI. But it's more than just a delay; it's a bright, flashing sign that the drawing set wasn't thoroughly checked. This one oversight can erode trust from day one, while a disciplined, consistent approach to dimensioning is the fastest way to earn a builder’s respect.

How Do I Conduct a Constructibility Review Without Field Experience?

You don't need to be a master carpenter to spot big constructibility problems. The real key is to mentally walk through how key details get assembled and ask simple, sequence-based questions.

- "Can a person and their tools actually fit in here to fasten this?"

- "What's the exact installation order for this flashing and the weather barrier?"

- "If we install this component first, will it block access for the next one?"

For more tangled assemblies, fire up your BIM software and build a quick 3D model. It can instantly reveal clearance issues or connections that are physically impossible to build. The goal is to shift your mindset from just drawing a design to actively thinking through the physical act of building it. That proactive thinking is your best defense against major on-site headaches.

Owning BIM software is not the same as having a disciplined BIM workflow. The model is a tool; the production system you build around it is what dictates the quality of your output.

We Use BIM but Still Get Too Many RFIs. Why?

This is a really common frustration, and it almost always points to a gap between owning the technology and having a mature process. The issue isn't the software—it's the workflow.

Often, the culprits are teams using generic or placeholder elements too far into the design process, poor management of shared coordinates between disciplines, or just kicking sheets out of a "dirty" model without proper cleanup. A solid BIM process demands strict modeling standards, regular automated clash detection, and a dedicated QA step to ensure the 2D sheets pulled from the model are clean, clear, and correctly annotated.

A reliable BIM workflow is your best defense against the endless RFI cycle, turning your drawings into a source of clarity, not confusion.

At BIM Heroes, we specialize in building the disciplined production systems that deliver clear, constructible drawings every single time. We help firms move from CAD chaos to BIM clarity, protecting your margins and strengthening builder relationships.

Learn more about our architectural production and BIM consulting services