Revit Families: Build or Buy?

Revit Families: Build or Buy?

When working with Revit families, you face a key decision: use pre-built manufacturer families or create custom ones. Each option impacts your workflow, project accuracy, and long-term outcomes differently. Here’s the breakdown:

- Manufacturer Families: Ready-made, include technical specs, and save time. But they can be over-detailed, inconsistent, and less flexible for unique needs.

- Custom Families: Tailored to project requirements, offer full control, and align with US standards. However, they require more time, expertise, and upfront investment.

Quick Overview

- Manufacturer Families: Best for speed and standardization.

- Custom Families: Ideal for precision and project-specific demands.

For US-based projects, factors like imperial units, building codes, and energy goals make this decision even more critical. Your choice depends on balancing immediate needs with long-term project goals.

Introduction to Revit Families

What Are Revit Families?

Revit families are parametric elements that combine 3D geometry with detailed information about building components like windows, doors, HVAC systems, and furniture. Unlike static CAD blocks, Revit families can adjust based on different parameters while keeping their core properties and relationships intact.

"A family is simply a collection or group of elements with a common set of properties called parameters, along with a related graphic representation." – Autodesk

These families play a key role in tasks like precise quantity takeoffs, cost estimation, clash detection, and project coordination throughout the design and construction process. A well-structured family often includes parameters such as model numbers, manufacturer details, materials, product codes, performance data, and even electrical and mechanical connections.

For construction projects in the U.S., Revit families offer clear benefits over traditional documentation methods:

| Feature | PDF Catalog | Generic CAD Block (.DWG) | Revit Family |

|---|---|---|---|

| 3D Geometry Support | ❌ | ✅ | ✅ |

| Parametric Behavior | ❌ | ❌ | ✅ |

| Intelligent Connectors | ❌ | ❌ | ✅ |

| Schedulable in BIM | ❌ | ❌ | ✅ |

| Metadata Embedded | ❌ | ❌ | ✅ |

| Coordination-Ready | ❌ | ❌ | ✅ |

| Visual + Technical Accuracy | ⚠️ Basic visuals | ⚠️ Limited | ✅ |

| Reusability Across Projects | ❌ | ⚠️ Manual reuse | ✅ |

| FM and COBie Compatibility | ❌ | ❌ | ✅ |

This comparison highlights the advantages of Revit families, setting the foundation for a closer look at their different types.

Types of Revit Families

Revit organizes families into three main categories, each tailored for specific roles in the modeling process.

System Families are the built-in elements that form the backbone of any Revit project. These include walls, floors, roofs, ceilings, and stairs. While system families can’t be loaded or unloaded, you can create various types within each family to meet specific project needs.

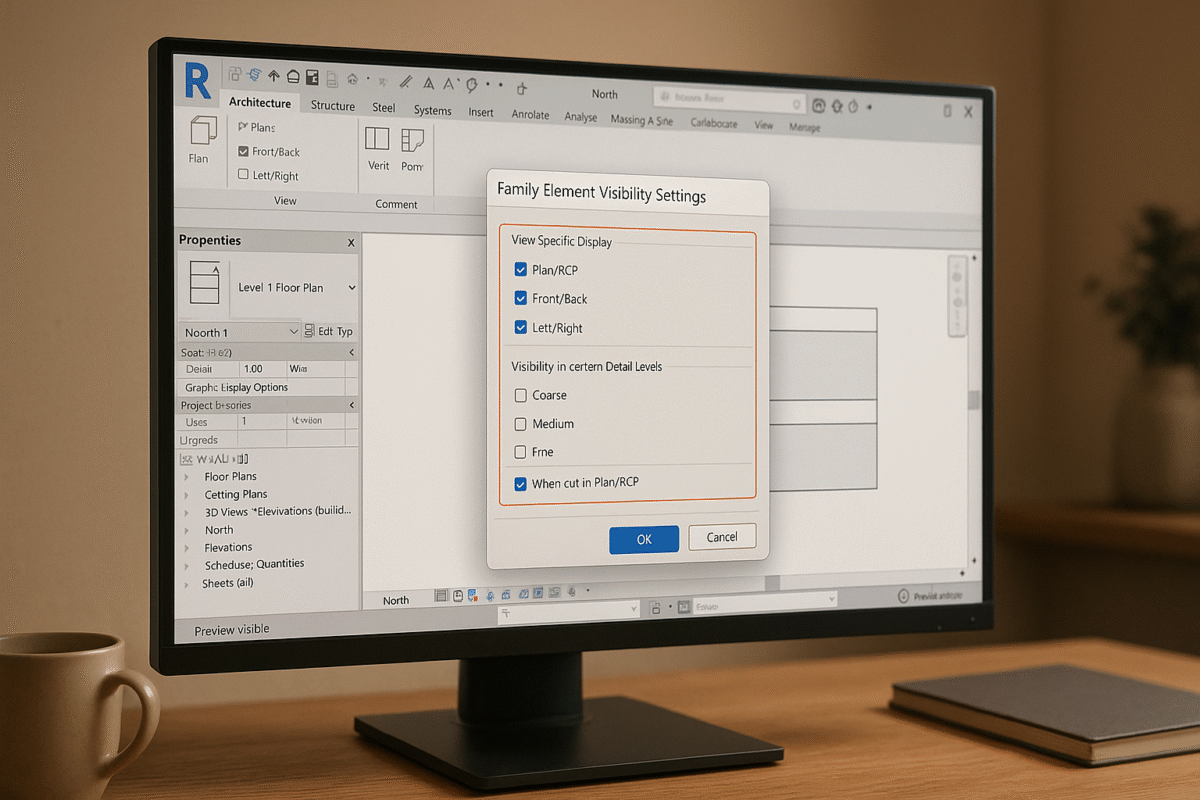

Loadable Families are the most flexible and widely used. Created outside the project using Revit’s Family Editor, they include components like doors, windows, furniture, lighting fixtures, and mechanical equipment. These families are stored as separate .rfa files, making them easy to share across projects and teams.

In-Place Families are custom elements created directly within a project. These are ideal for unique, project-specific components but are less transferable and can impact file performance.

"In Revit, a family is a collection of elements that share the same properties, behaviors, and physical similarities."

Each of these family types allows for multiple variations, such as different sizes, materials, or configurations. This ensures consistency and organization across a project’s components.

US Project Requirements

Construction projects in the U.S. come with specific requirements that influence how Revit families are created and used. One major factor is the use of imperial measurement units – feet, inches, and fractional dimensions that align with American building codes.

Revit handles these units by storing all lengths as decimal feet and converting them in real-time for display. Autodesk provides both metric and imperial content and templates to accommodate regional needs.

"Revit stores all lengths as decimal feet and converts on the fly so the only unit conversion going on is in the UI. You can type 1” into a length parameter and it will instantly present it as metric if that is what the unit is defaulting to." – BarrieSharp, Contributor

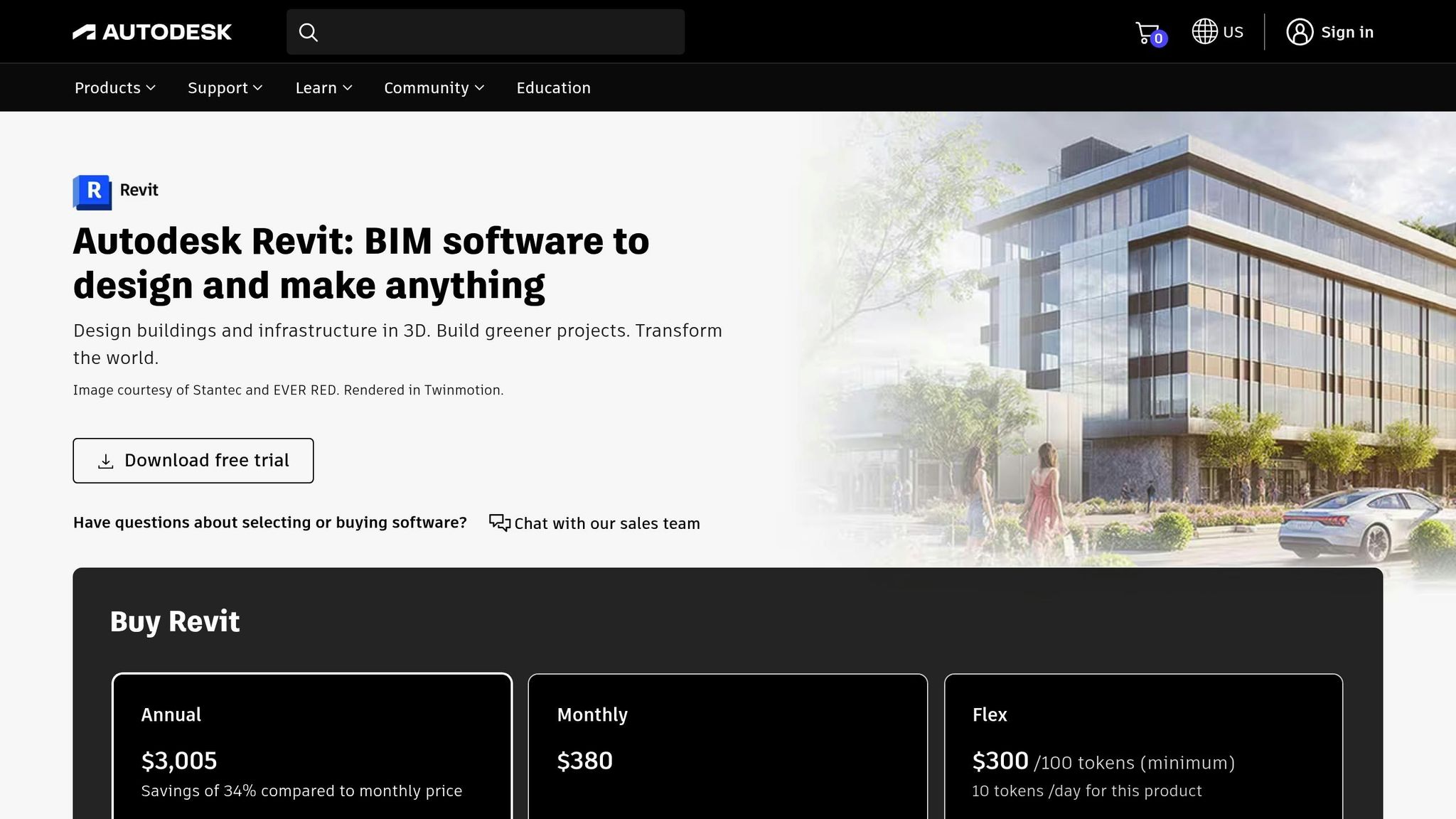

Autodesk Revit holds a 36.47% market share in the BIM and architectural design software category, with the U.S. leading as the largest customer base, accounting for 9,160 users.

For U.S.-based projects, compliance with building codes, energy efficiency standards, and specific performance criteria is critical. Families designed with imperial units ensure that dimensions, connection details, and performance data align with American construction practices.

However, working in mixed-unit environments can be tricky. Metric-created families, when used in imperial projects, undergo mathematical conversions that may result in nonstandard dimensions. For instance, a 100 mm measurement converts to 3.937 inches instead of the standard 4 inches commonly used in U.S. construction.

"It doesn’t really matter because Revit will convert them accordingly. The only thing to be careful with is standard dimension. Revit will convert mathematically." – dhurtubise, Certifiable AUGI Addict

To avoid these issues, U.S. projects benefit from using imperial-based templates and families specifically tailored for American construction standards.

Manufacturer Families: Pros and Cons

Manufacturer Revit families are pre-built digital components provided by product manufacturers. These families often include product specifications, performance data, and manufacturer details, making them a convenient option for streamlining workflows. However, they come with their own set of challenges that can impact performance and flexibility. This balance between efficiency and control is a key consideration in Revit family creation.

Benefits of Manufacturer Families

Easier Product Specification

A significant majority – over 75% of AEC professionals – prefer products available in Revit format, as it simplifies product selection and reduces time spent on research. When a product can be seamlessly added to a BIM model, it becomes the easiest choice during design development. This demand has motivated manufacturers to create extensive Revit family libraries.

Access to Technical Data and Visibility

Manufacturer families provide engineers with direct access to critical information, such as performance data, electrical connections, maintenance details, and product codes, all within the BIM environment. Key parameters like model numbers, material specs, and voltage requirements are often embedded, ensuring more accurate quantity takeoffs and cost estimates.

Better Project Coordination

With precise dimensions and connection points, manufacturer families help detect clashes early in the design process. They also support facility management by embedding reliable data. Manufacturers can even create and approve custom components for specific projects ahead of time, reducing waste and keeping costs in check.

Improved Scheduling and Documentation

These families integrate seamlessly with Revit’s scheduling tools, allowing teams to generate equipment lists, specification schedules, and procurement documents directly from the model. This reduces manual data entry and minimizes errors in project documentation.

While these advantages can significantly enhance workflows, there are notable challenges to consider.

Drawbacks of Manufacturer Families

Over-Modeling Slows Performance

One common issue is excessive geometric detail in many manufacturer families, which can lead to larger file sizes and slower Revit performance. This over-modeling can create inefficiencies, especially for project teams working on complex models.

Inconsistent Standards

Another challenge is the lack of uniformity among manufacturer families. Different manufacturers often use varying parameter names, units, or categorization systems, complicating the creation of unified schedules or bulk operations. Quality issues, such as inconsistent naming, missing geometry in plan views, or unconstrained parameters, require extra effort to standardize and organize.

Brand-Specific Limitations

Manufacturer families can be too brand-specific for early design phases when generic components are needed before selecting a specific manufacturer. Misassigned categories or connector inconsistencies can also create compatibility problems, making it essential to verify parameters against the current design to avoid errors.

Reduced Flexibility for Customization

While manufacturer families work well for standard products, they often lack the adaptability required for unique project needs or custom designs. Issues like poor flexing behavior, excessive parameters, or overly complex file structures – especially from less experienced creators – can disrupt workflows and limit their usability. Coordinating similar devices with varying shared parameters can further complicate the process.

Custom-Built Families: Pros and Cons

Custom-built Revit families involve creating components from the ground up to meet specific project needs. While this method requires a greater investment of time and expertise initially, it provides unmatched control, especially for US-based projects with unique demands. For professionals tackling complex designs, this approach offers tailored solutions that align perfectly with specialized requirements.

Advantages of Custom-Built Families

Full Control Over Design and Precision

Custom Revit families give architects and designers complete authority over every detail of a component’s behavior and appearance. This means they can precisely visualize designs, reduce errors, and ensure both structural integrity and aesthetic appeal. Unlike pre-made manufacturer families, which come with fixed parameters, custom families allow for the creation of unique architectural elements or specialized systems that aren’t otherwise available.

Flexibility for Project-Specific Needs

These families can be adjusted to meet evolving project demands. Whether it’s functional requirements or technical specifications, custom families ensure a perfect fit throughout the project’s lifecycle.

Improved Performance and Efficient File Handling

By controlling the level of detail, geometric complexity, and parameter structure, custom-built families can be optimized for better performance. This is especially important for large-scale projects with numerous components, where lightweight and efficient families are crucial.

Alignment with US Standards

Custom families can be designed to meet US building codes and integrate energy-efficient components seamlessly. They also support compliance with green building certifications like LEED, which is widely recognized in North America.

Better Collaboration and Standardization

Using standardized custom components enhances teamwork and coordination among project stakeholders. These families help maintain model accuracy and streamline collaboration.

While the benefits are clear, opting for custom-built families does come with its challenges.

Drawbacks of Custom-Built Families

Time-Intensive and Expertise-Driven

Creating custom Revit families requires a significant investment of time and a deep understanding of Revit’s parametric modeling tools. This process demands advanced skills, making it difficult for every team member to contribute effectively without specialized training. As a result, bottlenecks in workflows may arise.

Higher Initial Costs

The upfront costs of custom families can be steep, especially for smaller firms. Skilled labor and the learning curve associated with creating and modifying these families add to the expense, potentially straining resources.

Ongoing Maintenance

Unlike manufacturer families, which are regularly updated by their creators, custom families require internal upkeep. Teams must dedicate time to fixing bugs, adding features, and ensuring compatibility across projects. Managing version control as families evolve adds another layer of complexity.

Challenges in Creation and Management

Developing custom families can be tricky, particularly when dealing with parametric families across multiple projects. Striking the right balance between detail and performance is essential – overly detailed families can slow down project files. Common technical issues include applying correct geometric constraints, maintaining relationships between elements, and ensuring flexibility in parameter variations.

Manual Input of Product Data

Unlike manufacturer families that come pre-loaded with product specifications and technical details, custom families require manual input of this information. This involves researching and entering accurate data, such as performance specs and procurement details, which can be time-consuming. This trade-off highlights the ongoing challenge of balancing efficiency with control when selecting Revit families.

sbb-itb-0af4724

Efficiency vs. Control: Side-by-Side Comparison

When weighing efficiency against control, the decision often hinges on the specific needs of a project. Opting between manufacturer and custom families is essentially a trade-off between speed and precision. Manufacturer families shine in scenarios where rapid deployment is crucial – they allow teams to populate models quickly with industry-standard components. This makes them ideal for routine projects with tight schedules. On the other hand, custom-built families, while requiring more time and expertise, offer unparalleled control over design specifics.

The complexity of this choice grows when factoring in long-term project goals. Manufacturer families may deliver immediate efficiency, but their adaptability can fall short as designs evolve. Custom families, though more demanding upfront, provide the flexibility to fine-tune parameters throughout the project’s lifecycle. This balance between short-term gains and long-term adaptability is a critical consideration for many teams.

Comparison Table

| Factor | Manufacturer Families | Custom-Built Families |

|---|---|---|

| Creation Time | Pre-built and ready for immediate use | Require additional time and expertise for development |

| Flexibility | Built to standard specifications with limited customization | Tailored to specific project needs with full control over parameters |

| Team Collaboration | Easily integrated by teams with diverse skill levels | May require specialized training and closer collaboration |

| Long-term Value | Provide quick efficiencies but may limit adaptability as design needs change | Offer scalable, reusable solutions that evolve with project requirements |

This side-by-side comparison highlights the practical effects on project workflows. For large-scale efforts, the advantages of custom families often become more apparent. Not only can they enhance model performance, but they also ensure that only the necessary level of detail is included in construction documentation, reducing unnecessary complexity.

From a cost perspective, custom families require a higher initial investment. However, they often pay off in the long run by improving design flexibility and minimizing coordination issues down the line.

While manufacturer families are well-suited for teams needing quick, industry-standard solutions, custom families – despite their upfront demands – provide a scalable and adaptable foundation for long-term project success.

"While more time consuming, I find it usually best for companies to invest in creating their own Revit libraries of customize parametric families. Data is relevant and with full control over the origin, features and family size." – Geoffrey Jennings

In the U.S., where sustainable design is increasingly prioritized, the choice of Revit families can also influence energy efficiency goals. Buildings account for about 40% of the nation’s total energy consumption and greenhouse gas emissions. Striking the right balance between efficiency and long-term adaptability is not just a project decision – it’s a step toward meeting broader energy and environmental targets.

BIM Heroes Solutions for Revit Family Creation

BIM Heroes bridges the gap between efficiency and precision, offering solutions that cater to both immediate project demands and long-term design adaptability. Their specialized services simplify the decision between building in-house resources and outsourcing by delivering Revit family creation services that combine the ease of pre-made solutions with the accuracy of custom designs.

Maintaining an in-house BIM team can be expensive, but outsourcing BIM management provides an affordable alternative. It offers access to expert-level support at a cost comparable to hiring a single full-time employee. This makes it a practical choice for tailored Revit family creation and streamlined BIM consulting.

Revit Family Creation and BIM Consulting

BIM Heroes focuses on creating parametric families designed to meet the specific needs of US construction projects. Their team, which includes architects, engineers, and BIM specialists, ensures that every family adheres to local codes and technical standards. Quality control is a top priority, ensuring all deliverables align with industry expectations.

Beyond creating individual families, BIM Heroes also provides BIM consulting services. This includes developing standards for consistent naming conventions, parameter structures, and family hierarchies. Their approach includes key practices like:

- Standardizing naming conventions

- Incorporating reference planes and shared parameters

- Nesting families for better organization

- Optimizing geometry for performance

- Thoroughly testing designs to ensure reliability

Flexible Pricing for Every Project

BIM Heroes complements their technical expertise with pricing options tailored to different project requirements:

- Dedicated Team: Ideal for ongoing family creation or handling multiple projects, with a minimum 6-month contract commitment.

- Fixed Price: Best for projects with clearly defined scopes and deliverables, providing predictable costs.

- Hourly: Offers maximum flexibility for projects with evolving needs during design development.

Outsourcing BIM services also brings scalability and quicker turnaround times, thanks to ready-to-go teams that can handle tasks in parallel. For US firms struggling with a shortage of specialized BIM professionals, outsourcing helps address recruitment and retention challenges.

Conclusion: Making the Right Choice

Deciding between pre-designed manufacturer families and custom-built options comes down to finding the right balance between efficiency and control. Your choice should align with your project’s specific needs, budget, and timeline. For straightforward projects with tight schedules, manufacturer families often provide a quick and practical solution. On the other hand, custom families are better suited for unique designs that require greater precision and flexibility – especially when time and budget allow.

"Think beyond the initial design."

Families aren’t just about the design or construction phase; they play a crucial role throughout the building’s lifecycle. To ensure long-term value, it’s essential that families are compatible with COBie or IFC parameters. The decision you make today will influence the entire lifecycle of the building.

"Strategize your approach."

One effective method is to use generic families during the early design stages and switch to manufacturer-specific families later for detailed design and procurement. This hybrid approach can help you achieve both efficiency and accuracy.

Start by identifying the products that will have the most significant impact on your project and defining the critical data you need. It’s also important to select families that are lightweight, optimized, meet LOD requirements, are rich in data, and use consistent naming conventions.

For projects in the United States, compliance with local codes and standards is not just important – it’s mandatory. Be sure to account for the required level of detail, the need for parametric flexibility, and the accuracy of quantity takeoffs. These considerations will ensure your choice aligns with both immediate project demands and long-term goals.

FAQs

Should I use manufacturer families or create custom-built Revit families for my project?

When choosing between manufacturer families and custom-built Revit families, it all comes down to the specific demands of your project.

Manufacturer families are pre-designed, complete with accurate product data, and ready to use. They’re a time-saver and help maintain consistency, but they might not always fit perfectly with the unique needs of your design.

Custom-built families, on the other hand, give you complete flexibility. You can tailor every parameter to match your exact specifications, which is especially handy for intricate designs or when uniformity is a priority. The trade-off? They take more time to create and require a certain level of expertise.

Ultimately, it’s about striking the right balance between speed and customization, depending on your project’s timeline, resources, and design objectives.

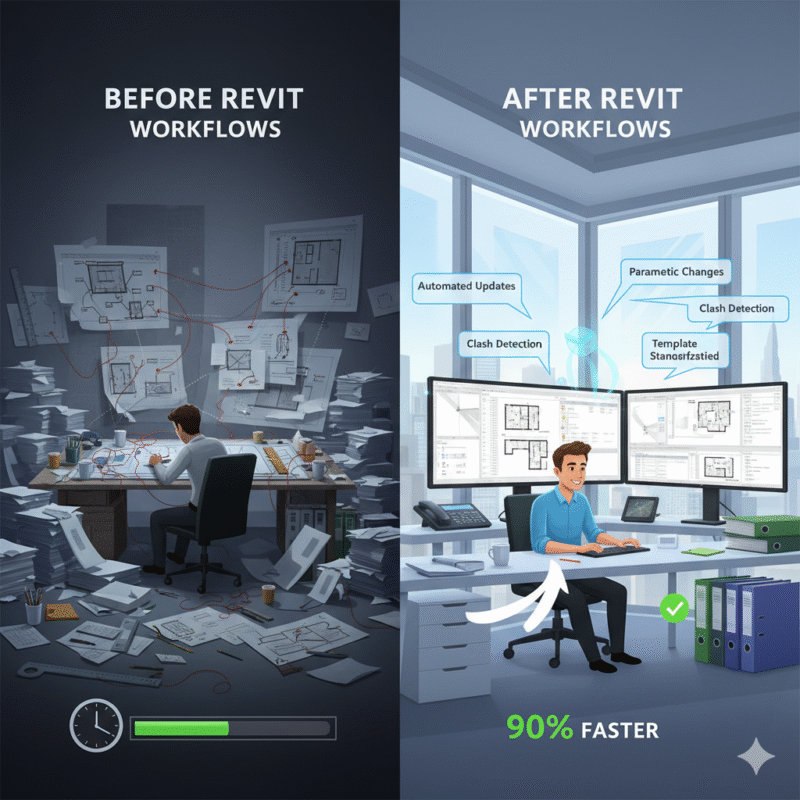

How do Revit families make project coordination and workflows more efficient compared to traditional documentation?

Revit families enhance project coordination and streamline workflows by providing detailed, data-rich components that fit seamlessly into your design. Unlike older documentation methods, these families help maintain consistency across all elements, reducing errors and potential clashes.

They also make updates quicker and improve collaboration across different disciplines. This results in more precise designs, less rework, and a more efficient project delivery process.

What challenges can arise from using manufacturer-created Revit families, and how might they affect my project’s performance?

Manufacturer-created Revit families often come with their own set of challenges that can impact your project’s performance and workflow. Since these families are typically designed to cover a broad range of applications, they can be overly detailed or unnecessarily complex. This added complexity can lead to larger file sizes, slower workflows, and even stability problems in bigger projects.

On top of that, some manufacturer families might not be properly optimized or could include errors like incorrect dimensions or too many nested components. These issues can throw off design accuracy and make your work less efficient. To keep your projects running smoothly, it’s a smart move to thoroughly review or adjust manufacturer families before bringing them into your workflows.